Material

The furnace firebox is made of structural steel grades Steel 10 and Steel 20. The thermal conductivity of these steels is two and a half times higher than the thermal conductivity of stainless steels used in the manufacture of furnaces by other manufacturers.

The most thermally loaded parts of the firebox have a combined metal thickness of up to 14 mm . Inside the reinforced firebox there are specialized replaceable plates and a cast iron grate. These elements can be changed as needed, which will extend the service life of coal-fired stoves up to 10 years!

Fire door and grate made of cast iron.

We understand the features of Zhara brand sauna stoves

There is probably no person who does not know about the benefits of a Russian bathhouse, where you can steam with a broom and gain health. In the bathhouse you not only bathe, but also remove harmful compounds, toxins and salts from the body. In general, a properly equipped sauna with a comfortable and efficient stove will help improve your health, even lose extra pounds. An important factor when building a bathhouse is the firebox. It occupies a central place in the bathhouse; it determines whether it is hot or not.

In the bathhouse, the body is cleansed, and the human nervous system is stabilized. We live in times of progress, when we have to do everything quickly in order to be on time everywhere. Such a busy pace of life affects your overall health. The savior is the bathhouse. How nice it is to sit in a steam room, tapping your sides with a birch broom. In a few hours, your problems will subside.

Quite recently, to equip a bathhouse, you had to look for and invite a stove maker . Today there are no problems with this, since you can simply buy a boiler to heat the room. Today there are many types of fireboxes available from different manufacturers. Customers leave good reviews about Zhara boilers. These fireboxes have a number of advantages, which will be discussed below.

The main activity of the Zhara company is the production of metal sauna boilers. The main office of the company is located in Togliatti. The company is thriving and increasing production rates every year. Modern equipment installed at the enterprise makes it possible to produce heat-resistant boilers for baths. The company produces stoves of different types and models:

- small oven;

- standard type;

- exclusive;

- manufactured according to customer drawings.

Depending on the model, they can run on both wood and gas . A medium-sized stove can heat a room that is about 32 m³. Boilers have different firebox thicknesses. It ranges from 6 to 8 millimeters. All products have different sizes, so they are easily suitable for baths of any size. The Zhara-Extra models are considered the most affordable and popular. These products have only good reviews, they weigh little, and the walls are thin. This design makes it possible to mount the boiler on a concrete foundation. Such fireboxes are designed for a room with a volume of no more than 8 m³.

Guarantee

The manufacturer provides a guarantee for the integrity of welds for 20 years on “ZHARA on coal” sauna stoves with a firebox roof thickness of 8 mm. (subject to the operating rules set out in the Operating Manual and subject to private use).

The manufacturer provides a 1-year warranty.

Service life of a stove with a firebox roof thickness of 8 mm. - 10 years.

For commercial use of the oven, the manufacturer provides a 6-month warranty.

Heater stove Zhara-Malyutka 500 on coal. Dobrostal Photos

Gas stoves for saunas Heat

These units are produced for heating rooms of different sizes, can be made with different wall thicknesses of the combustion chamber, differ in weight, type of GGU (gas burner device) and cost. Appearance and drawing of the stove in the photo.

Sauna stove "Heat" running on gas

MalyutkaGaz is the smallest representative of this series of sauna stoves. It is designed for heating steam rooms from 4 to 12 m3 and is equipped with an automatic SABK-9 gas generator with a power of 15 kW. Its weight is small - 52 kg, dimensions WxDxH 400x725x575 mm, firebox wall thickness 5 mm. An open heater that can hold 100 kg of stones.

Design of the gas sauna stove “Zhara”

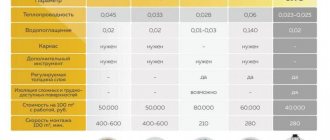

The StandardGas and SuperGas models are designed for heating steam rooms from 10 to 24 m3 and are equipped with a more powerful 30 kW SABK-10 gas turbine unit. The mass of the units is 92 and 124 kg, respectively. Their technical characteristics are presented in the table.

Attention ! The combustion process of all Zhara gas heating units is carried out only from the adjacent room (from the dressing room or washing room).

Gas stoves are additionally equipped with a chimney and water tanks with a volume of 50, 73 and 90 liters. It is very important to choose the right volume of the water tank, since its small capacity will not provide all visitors with hot water, and a tank that is too large will take a long time to heat up. There are reviews from customers who have encountered this problem.

Advice! When choosing a water tank, proceed not only from the required volume of water, but also from the power of the heating unit. It is important to understand whether it is capable of heating this volume simultaneously with the room? According to all standards, no more than 10% of the furnace power should be spent on heating water. In addition, it is more convenient to heat water in small portions: first you need a small amount to steam a broom, later to wash yourself before entering the steam room, then some more to rinse after entering the steam room. Based on the maximum consumption at a time, you need to choose the volume of the tank, and not calculate the total amount of water that may be needed for the entire bath procedure.

Technical characteristics of gas sauna stoves “Zhara”

Advantages

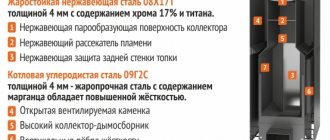

Advantages of the model range of stoves “ZHARA on coal”:

- the combined thickness of the most thermally loaded part of the firebox is 14 mm. ;

- the rear wall is reinforced with a welded sheet and has a total thickness of 12 mm;

- the cylindrical arch of the firebox guarantees the integrity of the welds; the manufacturer provides a guarantee for the stove for up to 20 years, depending on the model;

- high heat transfer - heating the steam room to 100 Cº is possible in 50-90 minutes;

- for convenient loading and safe placement of coal, the bottom of the combustion chamber is sloping into the firebox;

- removable plates installed in the firebox act as a screen from infrared radiation to the floor, protect the firebox and direct bulk fuel to the grate - into the active combustion zone. In case of burnout, they can be replaced with new ones, which extends the service life of the stove.

- The direct flow of hot gases in the stove design is eliminated - the movement of gases is directed along the heater, which contributes to more intense heating of the stones and economical fuel consumption;

- the air supply system to the combustion zone and the chimney have been enlarged, taking into account the characteristics of coal combustion;

- a special comb for cleaning the grate allows you to stir up ash and slag without opening the combustion door;

- the removable cast iron grate is reinforced; in case of burnout or severe deformation, it can be replaced;

- the volume of the ash box is increased by 2 times;

- the design of the stoves provides the possibility of firing from the dressing room or from the street ;

- Additionally, a removable heater has been developed , which is placed on the back wall of the stove. The buyer, at his discretion, can equip the stove with a mounted water tank or a mounted heater (not included in the delivery set);

- Mounted tanks (additional option) made of corrosion-resistant steel are optimally selected in volume and are designed for installation on the rear wall of the furnace. They have the ability to regulate the boiling time of water and are easily dismantled;

- coal stoves have many additional options (chimney elements, heat exchangers, water tanks on a pipe and heaters of various designs);

- maximum reliability and simplicity of design with high heat transfer provide the best price-quality ratio

Heat-super 800

Visually, the oven is not much different from the Heat-Standard 650 oven. As for the thickness of the metal of the firebox pipe, Zhara-super has it, it is 2 mm larger (10 mm).

Oven "Heat-super 800"

Technical characteristics of the Zhara-super 800 oven

| Steam room volume | 18-32 cubic meters |

| Power | 34 kW |

| Width | 530 mm |

| Depth | 815 mm |

| Height | 795 mm |

| Firebox roof thickness | 10 mm |

| Weight | 160 kg |

| Mass of stones | 120 kg |

| Firebox volume | 140 liters |

| Heater volume | 46 liters |

| Water tank volume | 60-100 liters |

| Price | 25500 rub. |

Scheme of the “Heat-super 800” furnace

Attentive readers, looking at the diagrams, have probably noticed that in order to increase the power of the furnaces, the outlet of the chimney pipe is shifted relative to the outlet of hot gases from the firebox. Thanks to this simple trick, it is possible to increase the intensive heating area of the upper part of the firebox, above which the heater is located.

Finally, a slightly silly video that advertises sauna stoves produced by .

SIMILAR ARTICLES:

Gentlemen!! How can I order a sauna stove from you?? How to pay? deliver to Ivanovo?

Sergey, at the moment, we do not work with suppliers, i.e. You cannot order a stove from us.

You can send it to Minsk.

Sergey, at the moment we do not sell stoves - the site is purely informational. We are looking for a partner who could supply stoves to various regions after ordering on the website baniwood.ru

Ready to help in production. We have extensive experience working with metal products

There are some interesting things in your design, but overall it’s rubbish. The developer specialist is bad. I would not install such a stove for myself. My stove was made in a bathhouse by a craftsman; he installed it back in 1997, what a stove! YES, I can draw a drawing... at a reasonable price. YOU WILL NOT REGRET. You will definitely make money on it. Think about it. Write. NO offense. Business is business. Nothing personal.

What kind of miracle is this oven? From a 14mm oil pipe? Which will weigh around half a ton? I know such stoves…….. They only heat so much due to the thickness of the metal and size… So now you can buy a stove that is smaller, lighter and with high efficiency…… Which will heat just like yours, and melt 2 times faster. ...

We know how craftsmen do it...

please tell me, is the vault 8mm its height?

The thickness of the firebox arch is the thickness of the metal from which the upper part of the firebox is made - 8 mm. The oven height is just the string "height"

The idea is good, don’t listen to the skeptics. (They are complete suckers - I’m not afraid to say it, just suckers). Over the years I’ve made them, even at one time I cooked a pyrolysis boiler for the sake of experiment. (It’s okay to remember the past) So, here’s the idea is good, but some points need to be improved, the ash pan must be made lower than the main pipe, that is, make a square box with a door under a round pipe and preferably with a box for ash, all doors (furnace, ash) must be sealed (no air leaks, and accordingly smoke in the bathhouse), be sure to have a valve on the chimney (close the chimney when not heating), and of course expand it (increase the number of stones), FOR SMART GUYS (SKEPTICS) Of course, you know how many stones are needed for 1 m3 of steam room. So, for narrow-minded people Let me explain, the number of stones in the heater directly determines what kind of steam there will be in the steam room: wet, dry or overheated. So, for 1 m3 of steam room you need 7-8 kg of stones in the heater. The steam will be amazing. (for everyone) Well, and what is also important, it is advisable to make some kind of screen around the stones (well, it depends on who), otherwise you may be left without hair on your legs. Verdict——The idea is ideal and budget-friendly, any man with the slightest hand can make such a stove at home in 2-3 days. Having a minimum set of tools. Take heart, people, you won’t find drawings so easily, especially with a size chart. Sorry if I offended anyone. Sincerely, Igor Igorevich

Installation Features

There are some specifics for installing Heat stoves (gas and wood):

Installation diagram of Zhara stoves

- If the floor where the stove is installed is made of flammable materials, then protection should be installed with a metal sheet over a 10-mm layer of asbestos cardboard so that the edges of the metal protrude 250 mm around the perimeter. The distance from the floor to the bottom of the stove should be 100 mm; it is recommended to use a foundation laid in a quarter of a brick.

- To protect the hot metal body from the intense heat, a protective screen made of brick or other fire-resistant material is installed around the stove. The brick screen is made in ½ or ¼ brick at a distance of 40–50 mm from the furnace body; in its lower part, air passages are arranged in increments of 250 mm. To lay a protective convection screen made of brick, it is better to use oven bricks, and prepare the mortar from sand and red clay.

- The partition between adjacent rooms into which the heating unit is installed, in the immediate vicinity of the stove on the left, right and top must be made of fireproof materials of at least 500 mm. Read more in the article “How to install a metal stove for a bath.”

- The chimney must be at least five meters high. Plan a straight option for its placement with a minimum number of knees.

Warning! The manufacturer categorically does not recommend making the connections between the stove and the chimney and the water tank non-separable. This is necessary to prevent fires and ease dismantling.

Design Features

The quality of the stove's operation largely depends on how successful the design of the firebox is. The manufacturer guarantees that “Zhary” fireboxes are welded from high-quality thick-walled pipes (5-10 mm), which are used for laying oil pipelines. The shape of the firebox is cylindrical. This is the option that was considered the most optimal, based on the courteous many years of experience of admirers of the Russian steam room.

The main thing in a sauna stove is a successful firebox design

For additional money you can purchase a “branded” chimney. Previously, it was made straight, but with this design, too much firewood literally “flies down the chimney”: a large amount of heat goes away along with the smoke and “heats” the street. The chimney from “Zhara” is a coil. This allows you to save firewood, evens out the draft, and the convenient collapsible design (the collapsible unit is also not included in the package, but must be purchased separately) makes cleaning easier. The grate also has its own characteristics: it is a specially designed removable design that makes it easy to clean and change if necessary.

Many people like to steam, but everyone has their own ideas about how to do it. This also applies to the organization of the firebox. Some people prefer to add firewood without leaving the steam room, others think that the best option is when the firebox is located in the dressing room or locker room, and others even think that it is necessary to add firewood from the street. Zhara has stoves with all these firebox options. Here everyone can choose according to their taste.

Model “Heat-standard 500” with remote firebox

Well, the last detail of the iron stove is the water tank. In Zhara ovens it is made of stainless or ordinary steel, and can have different volumes. It is easy to install and dismantle. This part is also not included with the stove, but must be purchased separately.

If you are planning to make a stove with your own hands, we recommend taking a look at the drawing of the Zhara-Standard 500 metal stove.

What to drown with

A heat sauna stove requires the correct choice of fuel, since this determines how long it will work, what the heat transfer and efficiency will be. It is recommended to burn with dry logs up to 100 mm thick and 50 to 100 mm long.

Before placing firewood in the firebox, you need to light the chamber. The following types of materials are suitable for this:

- Shavings

- crumpled paper

- Split logs

- Birch bark

The kindling material should fill the chamber only halfway so that the water in the tank boils gradually. Before lighting a fire, you need to check that there is water in the water tank, filling the container two-thirds full.

For kindling, do not use flammable mixtures such as acetone, gasoline, or solvent.