Date of publication: April 16, 2020

Stove and fireplace equipment is a source of not only comfort, coziness and warmth, but also a fire hazard. The risk of fire is associated with the use of flammable fuels, as well as high temperatures of internal and external surfaces. It is important to understand that proper installation of heating equipment and components eliminates the risk of fire. It is always possible to make a heating device and chimney absolutely safe for use if you follow the established rules, fire safety standards, and follow all recommendations for installation and insulation of equipment.

This article will discuss the use of mineralite, an insulating material that is used to protect surfaces from the effects of heated areas of fireplaces and chimneys.

Areas of application

The versatility of mineralite justifies its demand for various types of work.

- Fiber cement boards are suitable for installing screens around hot stoves, hot fireplaces and heat-emitting equipment in saunas.

- Fire-resistant partitions are built from mineralite slabs, dividing the area into fire zones, equipping a safe exit during evacuation. Using a certain technology, walls, ceilings, chimney systems, and ventilation ducts are sewn up in fire hazardous areas.

- High moisture resistance allows the use of this material where there is excessive dampness and humidity (showers, swimming pools). In this case, additional waterproofing treatment (aqua blocks) is not required.

- Can be used as a base for facing tiles and other waterproof materials for final finishing.

- Thermal insulation and excellent adaptation of the material to temperature changes suggest its use for cladding interior spaces and exterior walls of buildings, including loggias and balconies.

- Serve as a smooth, waterproof base under wood stoves, wall and floor tiles.

With moderate weight, the slabs are characterized by increased strength, impact resistance and durability. It is also important that the components of mineralite contribute to the self-cleaning of the surface of the slab. And in addition to excellent structural properties, the material is endowed with aesthetic capabilities. The slabs are produced in different color variations. A variety of decorative colors on the front part of the coating allows you to cover facades with mineralite during the reconstruction and construction of residential and administrative buildings.

Minerite: technical characteristics

Minerite is a fiber cement board. The main component in its composition is cement; cellulose fibers are used as reinforcement. Mineral fillers are also added. The slabs do not contain asbestos, so the products are classified as environmentally friendly building materials. The positive qualities of the slabs are:

- heat resistance;

- high waterproofing characteristics;

- good sound insulation performance;

- durability and wear resistance (plates are not subject to rotting and decomposition).

Ease of installation and processing is another advantage of the material. You can cut Minerite, cutting out fragments of the required size and configuration, with a regular hacksaw, and fasten it using self-tapping screws. The material is produced in different interpretations, which makes it possible to choose a product that meets the purpose and requirements of the consumer.

Magol's first guns

The first Magol guns were simply ordinary pipes made of ceramic or stainless steel. The essence of the invention is very simple - to deliver water for evaporation to the lowest hottest stones, located in the very “hell” of the stone laying.

Here on the Vulcan stove there are already 4 guns installed, which “worked” perfectly - they produced excellent steam, surprised and delighted the guests.

At one time, the Feringer plant launched the production of several models of stainless steel guns. The guns were part of the standard set of Feringer steam and Lamel ovens. There was a natural process of choosing the best gun design.

At the beginning of 2021, the plant stopped producing and equipping its furnaces with guns. The gun in the Lamel series furnaces was replaced by the Fehringer PIF steam evaporator. The last copies of the guns were purchased by the Magol company, but at the moment they are almost gone.

Prevention of poisoning

Today, the answer to the question of whether asbestos is harmful to health is already obvious and beyond any doubt.

Therefore, it is extremely important to remember that the use of amphibole mineral is strictly prohibited under any circumstances. When using the more common chrysotile, the following instructions must be observed:

- when coming into contact with asbestos materials, use protective equipment;

- waste and dust should be stored in a sealed container, then disposed of using a special technology;

- use only dense products: they should not crumble;

- the mineral cannot be sprayed in the air;

- periodically monitor the permissible level of asbestos fibers in the production area;

- undergo regular medical examination.

When working with building materials that contain asbestos, it is extremely important to protect the respiratory system Source laboratoria.by

The chemical composition of sheet asbestos is identical to the material discovered in the Urals. Having decided to remove the asbestos roof, you should prepare a change of clothes. Upon completion of all work, it is better to dispose of it. Some builders recommend lightly moistening the slate with plain water on the eve of dismantling. In this case, asbestos dust will not be able to rise into the air.

Today, asbestos-cement slabs are practically not used in construction. If possible, they should definitely be replaced with a building material of similar characteristics, but safer. Panels containing asbestos continually release harmful microfibers into the environment. And people nearby will inhale them every day.

Asbestos-cement panels release harmful microfibers into the environment, which, when inhaled, are harmful to human health. Source samstroy.com

Nuances of choice

A wide variety of species often makes you doubt the correctness of your choice. To avoid problems and to avoid regretting your decision, you need to decide on the material that will protect the walls next to the stove, chimney or fireplace.

For finishing walls around stoves and in boiler rooms

Fireproof finishing of walls around furnaces and in boiler rooms is prescribed by fire safety rules and is mandatory.

- Fire-resistant plasterboard panels can be used as a basis for cladding walls near the stove.

- Using fireclay bricks and/or mortar, create fireproof protection in the form of a screen near the furnace. The surface inside the furnace is laid out (lined) with bricks, and cracks and cracks are sealed with mortar.

- But the most effective protection for surfaces adjacent to fireplaces and stoves is made of stainless steel. Steel sheets are used to construct fireproof screens. They are mounted at a distance of 1-5 cm from the body of the stove or fireplace.

- Thermal protection can be further increased by fiberglass laid under steel sheets.

- Cast iron screens are also popular.

- Basalt rolls and mats, flexible and lightweight, are also used for shielding stoves and fireplaces.

- Terracotta or porcelain tiles are ideal for fire protection of boiler rooms, as well as baths. They do not deform or burn, and are also easy to maintain - they are easy to clean and wash. Due to their high decorative properties, they can also be used to decorate various surfaces.

For pipe

To avoid fire, chimney outlets must be reliably thermally insulated. For this purpose, mullite-silica boards and cardboard are used, which are excellent for processing. You can cut holes in them of any configuration for chimney pipes and other structural elements of stoves.

For the bath

The walls of the baths are finished with heat-resistant materials so that they have fire-resistant properties. For this use:

- “pie” made of a metal reflective coating and a heat-insulating gasket;

- superizol;

- fire-resistant plasterboard;

- glass magnesite;

- minerite;

- terracotta tiles.

Fire protection for sauna stoves is also provided by products made from foamed vermiculite. For the layer between the first rows of the stove masonry and the wooden floor, vermiculite boards are preferable, since they are stronger than cardboard.

For the fireplace

The main product used for facing the fireplace, along with fire-resistant plasterboard, is fire-resistant ceramics:

- terracotta tiles or majolica as its variety;

- tiles;

- clinker tiles;

- porcelain stoneware

All of them are moisture resistant and resistant to temperature changes. Choose tiles marked A - they are of higher quality than tiles marked B.

Advantages of a block chimney

Until the end of the last century, chimneys were predominantly made of hollow brick, since it is lightweight, as well as of individual building blocks, which differ from the usual brick in larger size and material. But they began to use a designed chimney block, which already has a given shape with a smoke shaft inside, not so long ago.

In practice, this is a ready-made factory chimney riser, cut horizontally into convenient fragments. Previously, high risers (up to 2.1 meters) were produced in factories, but they were heavy, massive and very difficult to install. Now you can assemble a good chimney with your own hands from blocks, working alone and without extensive experience and special knowledge.

Our advice. You should not immediately start planning the installation of this type of structure; perhaps you will be more satisfied with a concrete chimney, the installation technology of which has been proven for decades.

First, try to evaluate the advantages that chimney blocks have:

Advantages of mineralite slab

1. Fire resistance

The bathhouse is a fire hazardous building. Every bathhouse has a stove, and some also have a heater. They heat the room to the desired temperature and produce hot heat. Therefore, the issue of safety and protection of the building should come first. Today, there are many special materials that can protect a building from fire. One of them is a mineralite slab. By fencing off the wall from heating stoves and heaters with such fiber cement panels, you can be sure of the fire hazard. They will serve well and with dignity, since they absolutely do not burn or ignite. This fire resistance meets the most stringent fire safety requirements. Minerite is a completely non-flammable building board with an excellent degree of fire resistance, so products are often used to protect flammable elements.

2. Environmental friendliness

The difference between mineralite board and other building materials is the absence of any substances hazardous to health in its composition and the ability to self-clean. Thanks to environmentally friendly technologies, the tiles do not emit harmful vents when heated. As a result, such insulation can be confidently used when creating thermal insulation for baths, saunas, and steam rooms. Thanks to this material, it will be possible to create an absolutely reliable and harmless indoor microclimate.

3. Resistant to mold and rot

The main component of the tile is cement, which creates an alkaline environment. Therefore, the formation of mold, fungi and other microorganisms is absolutely excluded.

Moisture-resistant plywood does not rot or decompose, which is very important when used in rooms such as a bathhouse or sauna.

4. Strength, wear resistance and durability

Minerite plate differs from many similar special materials in its increased impact resistance. Such a panel with an impact-resistant surface is practically not deformed and can withstand heavy physical loads. The decent strength qualities of the mineralite slab influence operation, during which there is an almost complete absence of deformation.

5. Ease of installation

Minerit slabs stand out for their specificity and ability to be used in places where it is very difficult or even impossible to use other building materials. During construction, panels can be installed at any time of the year. Installation is easy and quick, so you can handle this task yourself.

6. Sound insulation

This building material has excellent sound insulation properties. Minerite is a tile with a very small thickness, which ranges from about four to twelve millimeters. But thanks to such a small thickness, it turns out to significantly reduce the noise level in the room. In this regard, this heat insulator is also considered an excellent sound insulator. 7. Versatility

Minerite is considered a universal material. It can be used not only for insulation, but also for decorative finishing.

8. Frost resistance

9. Resistance to acids, alkalis, oils and salts.

Minerite slabs do not have any significant drawbacks, except that they do not have a very presentable appearance. However, today there is decorative mineralite, which looks much more aesthetically pleasing than ordinary gray. Perhaps he should be given preference when finishing the inside of the bathhouse, even if it costs a little more.

Taking care of fire safety

In individual private sector homes, owners are increasingly installing fireplaces that not only perform a heating function, but also add zest to the interior. And in country cottages there are also Russian stoves. In such cases, it is advisable to protect the home from possible fire. For these purposes, various materials are used, often choosing Minerite, which is a fire-resistant slab. It belongs to the non-flammable class. And when heated, due to the absence of asbestos and other harmful compounds, it does not emit substances harmful to health.

Therefore, mineralite panels are used to shield stoves in bathhouses and saunas, construct fire-resistant partitions, and line walls and ceilings, thereby increasing fire safety.

When carrying out such work, owners sometimes ask themselves the question: Superizol or Minerite, which one is better to use? The quality indicators of these materials are almost similar. However, experts consider the low moisture resistance to be a significant disadvantage of Superizol. As for Minerite, it is harder, denser and somewhat heavier. Therefore, the choice in favor of one or another option should be based on the specific purpose of the work where the material is planned to be used. A clear analysis of the requirements for it will help you make the best choice.

Minerite, whose price is reasonable and competitive, is easy to use, can be combined with other building materials, can withstand high temperature loads and has proven its effectiveness in various fields of application.

- Baths

Do you need to insulate the walls from the stove in a bathhouse or sauna? The solution is the Minerit Sauna Stove!

Minerit facade slabs are smooth Finnish-made panels made of cement (90%) with the addition of reinforcing fiber and mineral fillers. The colors of the slabs are white, red, black and green. It should be noted that Minerit cement fiber boards are environmentally friendly, since asbestos is not used in production, unlike domestic fiber cement products. When installing a heater in a steam room of a log bath or sauna, first of all, it is necessary to comply with fire safety rules. In other words, it is necessary to reliably insulate the wooden walls of the bathhouse from the heated elements of the heater.

One of the most heat-resistant and at the same time environmentally friendly materials is mineralite, which is produced in Finland. Manufacturers recommend installing mineralite on the walls of a steam log bathhouse in 2 layers as follows: the first sheet is installed on the wall, then ceramic spacers (tubes) follow, after which the second sheet is attached. However, from construction practice, one correctly installed sheet for thermal insulation of the walls of a log bathhouse is quite enough.

To insulate the floor of the bathhouse, a sheet of mineralite is placed under the stove-stove. Before installing a mineralite bathhouse on the floor, the floor must be thoroughly swept so that the sheet does not bend or crack in the future. The mineralite is laid close to the walls (when installed at an angle of 45 degrees, the cut corners are laid on the sides - see the picture), after which it is immediately screwed to the floor with self-tapping screws (otherwise debris will get under it, which can lead to bending and damage to the mineralite). The edge of the sheet is cut to the level of the open oven door. For greater aesthetics, the corners of the mineralite before firing the heater can be cut at an angle of 45 degrees (the length of the cut edge is 50 mm) and processed with sandpaper.

Minerite sheets are also installed on the walls of the log bathhouse (with self-tapping screws through ceramic or metal tubes 30 mm long). The air gap between the wall of the bathhouse frame and the mineralite is therefore 30 mm. The gap between the floor of the steam room and the bottom of the sheet is 20-30 mm. The bottom gap is very important, as it ensures air circulation between the wall of the bathhouse frame and the heat-resistant mineralite sheet. If this is not done, the air between the wall of the bathhouse log and the mineralite will heat up to several hundred degrees!

When installing mineralite, you must remember that it is not a deformable material. That is, if you attach it to the wall of a log house or bathhouse, which is still shrinking, the mineralite may burst. Installation to the “living” wall of a log house is possible, but in this case, vertical cuts must be made in the mineralite, along which the self-tapping screws will slide when the log house shrinks. The lower gap between the floor and the mineralite sheet screwed to the wall of the bathhouse frame is in this case ensured by inserting spacers under the sheet (for example, from mineralite scraps). When the frame has completed its final shrinkage, the mineralite is leveled and screwed permanently.

It is not recommended to move the stove after installing it on a mineralite sheet, since the mineralite can be scratched. To install the stove in another place, it must be raised and lowered again.

Thermal insulation must be installed not only between the heater stove and the walls of the log house, but also behind the “bare” (that is, not insulated with mineral wool and a sandwich-type casing) pipes. As a rule, this is at least one bend (1 meter) extending from the stove. That is, the height of the mineralite sheets (one or several) should be the height of the furnace plus the height of the “bare” pipe.

The minimum distance from the heating parts of the heater (including “bare” pipes) to the mineralite sheet is 100 mm.

On glue

As the only method of fastening exclusively with adhesive mass, it is rarely used and only under ventilated facades. For plastering work, additional reinforcement with umbrella dowels is required. However, this method has its own characteristics that need to be considered separately.

Firstly, there are two types of adhesives:

The dry mixture is sold in bags and requires dilution. Adhesive foam is sold in cans and does not require preliminary preparation. The latter is a little more expensive, but the convenience is worth it.

Sets the bottom bar, which will be the starting point of thermal insulation. The dry mixture is applied to the slab itself.

In the case of a dry mixture, you need to apply the glue to the slabs in several pieces and spread it evenly over the entire surface using a comb. After this, the insulation board is fixed to the wall. Typically, the installation of mineral wool or other materials begins from the corner and always from the bottom row.

Adhesive foam is applied around the perimeter of the slab and in several strips in the middle. After application, press the slabs flat. The foam hardens in 30 minutes to 2 hours. During this time, it is possible to slightly adjust the position of the slab using a level.

Dry mixtures are often used:

- EK THERMEX;

- Ceresit CT 190;

- Ceresit CT180.

Popular foam options:

- Ceresit CT 84;

- Soudabond EASY;

- Insta STIK.

The cost of one cylinder is from 200 to 500 rubles.

We discussed the basic principles of how to attach insulation to a wall using adhesive. You can decide what exactly to use by reading a couple of opinions.

For large differences in walls, it is recommended to use polyurethane foam, specifically for polystyrene foam. It is also called “liquid foam”. If the wall curvature is one to three centimeters, this is not a problem at all. I bought it at Epicenter a year ago, glued the sheet on just for fun - a year has passed, everything is holding together, the sheet cannot be torn off. The foam breaks, but holds up.

What is minerite?

Minerite is a name given to cement-fiber boards, the main purpose of which is finishing facades. However, if you dig deeper, you can see that mineralite has received much greater importance and application in construction.

Due to the excellent performance properties of mineralite slabs (as is known, they do not burn and are not afraid of moisture), their use is much more widespread. For example, mineralite is widely used for insulating stoves and fireplaces, as well as various other fire-resistant structures.

In addition, due to its excellent soundproofing qualities, mineralite is often sheathed on balconies, loggias, etc. However, this material is most widely used for finishing facades, plinths and other building elements.

Minerite composition

The main component of mineralite is cement, which occupies almost 50-70% of all components. These primarily include mineral additives and reinforcing fiber.

Minerite does not contain asbestos and this is very important - the slabs do not emit harmful substances when heated strongly. Depending on the area of application, the composition of mineralite may vary

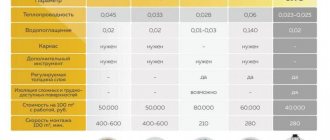

Characteristics of mineralite

The color of mineralite slabs can be different, which is explained primarily by the brand of cement used. Depending on their type, the characteristics of mineralite can also be different.

For example, Minerit-Sauna slabs have excellent fire-resistant properties; they can be used as a screen, to protect floors and walls, from hot stoves and fireplaces.

Minerit VZ slabs, on the contrary, are used to protect external structures from the effects of wind and moisture. Accordingly, they have good waterproofing properties.

Lime-gypsum mortar

Inexpensive to produce, lime gypsum mortar is actively used in finishing and plastering stoves. When cement and a large amount of lime are added to it, this composition can easily be used for laying a brick chimney pipe. The advantage of using it is the ease of working with it and faster setting. You just need to correctly calculate the ratio of components and achieve the desired consistency of the prepared mass.

Before firing the stove for the first time, you need to thoroughly dry the masonry, which will eliminate the danger of cracking the chimney.

Installing a stove in a steam room

The installation of a wood-burning stove in a log bathhouse is regulated by building rules and fire safety standards. Thus, a stove in a wooden bath must be installed on a heat-resistant, non-flammable base. It can be made of heat-resistant brick, concrete, porcelain stoneware, ceramic tiles.

Brick ovens most often have this weight. The foundation for a brick stove is laid along with the main one at the initial stage of construction of the bathhouse. The depth of the foundation, in this case, is made the same as the depth of the general foundation of the house. But in terms of size, the stove foundation is made 15-20 cm larger than the heating structure with a screen.

The installation of a wood-burning stove in a log bathhouse is regulated by building rules and fire safety standards

So, installing a heating structure in a bathhouse has the following stages:

- Selection of heating design;

- Choosing a location for installation;

- Organization of the foundation (if necessary);

- Preparation of a heat-resistant base;

- Installing a stove or laying a brick structure (for this, a masonry diagram is prepared in advance and materials are purchased);

- Chimney installation;

- Installation of elements provided for by the design (damper, firebox doors, etc.).

Before putting into operation, the stove in the bathhouse is heated. At the same time, the oven may emit unpleasant odors. This is due to the burnout of industrial oils, the internal enamel of the metal structure, the combustion of dust, etc. Therefore, the first time the bathhouse is heated empty, with maximum ventilation.

Overview of species

Construction, HD modifications. A universal material suitable for cladding buildings inside and out. Such cladding does not deteriorate due to critical changes in temperature and humidity. The panels are distinguished by high strength. Sheet thickness is 3.2-10 mm, determined by purpose. The most popular slabs with a thickness of 8 mm.

Flat PC panels for mounting on facades. This type is based on HD modification slabs. The material is primed on both sides, and a durable acrylic layer is applied to the front part of the panel. Colored panels are presented in four versions, differing in size.

“Pastel” facade slabs with a hydrophobic coating and a smooth painted surface.

Heat-stable, fire-resistant sheets. Designed for installation on wall and ceiling structures to protect them from the influence of heat, for decorative lining of fireplaces, etc.

Decorative. Manufacturers produce products with a textured surface that imitates various finishing materials. For example, mineralite “like a stone” is a very good option for arranging living spaces and steam complexes, for creating conditions for fire safety, sound insulation with insulation and visual aesthetics. Along with the declared strength, they look very decent. Many consumers prefer colored slabs for interior work, despite the fact that it is somewhat more expensive. The color of the slabs comes in different shades, depending on the brand of cement used.

Minerite fastening

Minerite slabs for insulating the heating of the walls of the bath during its heating can be mounted in the following versions:

- When the stove is located at a fairly large distance from the wall, the mineralite slab is attached directly to the wall;

- When the stove is located at a distance of about 50 cm from the wall, the mineralite slab is attached to the wall with a gap of about 3 cm, with ceramic bushings installed in the gap between the slab and the wall;

- With a small distance between the stove and the wall of the bathhouse, place two sheets of mineralite. In this case, one sheet of mineralite is fixed directly to the wall, and the second sheet is mounted at a distance from the first with a gap, which is determined by the length of the ceramic bushings.

In order to prevent breakage of mineralite slabs when heated from the furnace, when installing them, the holes for fastening with screws are made in the form of grooves.

When installing mineralite in a steam room on the walls, it is necessary to leave a gap between the lower edge of the mineralite and the floor of the bathhouse, which must be at least 30 mm. This is necessary in order to ensure air circulation between the mineralite and the wall and prevent the wall of the bathhouse from heating up, especially if the bathhouse is built of wooden beams.

When installing mineralite slabs on walls, inserts are installed in the gap between the floor and the slab, for example, from scraps of mineralite, which are removed after the walls of the bathhouse shrink, and the screws securing the slabs are finally tightened.

It is recommended to install mineralite slabs on a bath pipe, at a height of about 1 meter, which has thermal insulation with a casing.

When designing a new bathhouse building, the distance from the furnace wall, including pipes without insulation, to the mineralite sheet should not be less than 10.0 centimeters.

The material mineralite is a heat-resistant and environmentally friendly material.

Fire retardant materials

To generate a large amount of heat you need either electricity, gas, or wood. Thus, we cannot avoid the use of fire hazardous items in the bathhouse, such as stoves. But it is in our power to surround them with fire-resistant materials - this is an urgent need for a bathhouse, because bathhouses burn down more often than they are destroyed for any other reason.

There are three “nodes” where such materials are used. At the same time, both the tasks and the materials themselves will be different.

Non-combustible insulation for chimneys

A chimney can be considered no less (or even more) dangerous than a stove. Gases flow through it at a temperature that is higher than the ignition temperature of wood. And the sparks that fly out of it can set the roof on fire.

Therefore, it is advisable to install a spark arrester on the top of the chimney, inspect the chimney itself regularly, do not burn coniferous trees, because they cause many problems, and most importantly, keep all flammable materials from the chimney at a safe distance.

When passing through the ceiling, the last problem is solved with the help of metal boxes lined with mineralite slabs, and inside filled with non-combustible materials - for example, expanded clay, ceramic fiber. If the GOST dimensions are observed, such a box will protect the wooden floor, preventing it from heating up to the ignition temperature.

We wrote about the box here.

Fireproof for the stove

Steam rooms are rarely large, which means it is not always possible to move the stove away from the wall to a safe distance so that it does not burn the wall. Therefore, for a bathhouse you need a fireproof material for the stove that will protect the wall.

For example, mineralite slabs successfully cope with the task, but on the condition that you install them not flush against the wall, but with an air gap of a couple of centimeters, which is provided by ceramic bushings placed on the fasteners. This technology is applicable to wooden walls.

You can also experiment with brick. When the firebox goes through and goes into another room, a cutting wall is made of brick. The section of the firebox passing through the wall can be insulated using modern materials - the same ceramic fiber that can withstand more than 1200 degrees!

ATTENTION! Regular mineral wool will not last long; you will need to check its condition from time to time. You can also cover the stove itself with brick, creating a casing for it.

It must have vents with doors. But keep in mind that a brick casing is good for those who love a Russian bath and who have a closed heater in their stove. The casing will increase the heating time of the steam room

You can also cover the stove itself with brick, creating a casing for it. It must have vents with doors. But keep in mind that a brick casing is good for those who love a Russian bath and who have a closed heater in their stove. The casing will increase the heating time of the steam room.

At the bottom of the stove, either an individual foundation is made, or just a brick pedestal, and a stainless steel sheet is also placed in front of the firebox.

There should be a pre-furnace sheet in front of the firebox

Manufacturers and prices

When the owner of a house or vacation complex has chosen an object that he likes to install a fireproof slab for the stove, the question of the company and cost remains open.

They will be construction companies that have proven themselves with quality, abundance of products and branches in different cities.

It is worth considering that heat-resistant materials for stoves are quite expensive, so you should choose average or close to expensive prices.

It is quite possible that their company may turn out to be a “one-day” company and no one will answer you for the refractory material and its product quality and it will also be impossible to return the invested funds.

It is not reasonable to indicate uniform prices, because the price market is quite flexible and everything changes too often.

Installation

Installing mineralite is not a difficult task, but requires certain knowledge

Since this is a dense material, it is very important to leave a ventilation gap between the wall and the finish. For this you should use ceramic bushings.

Experts recommend sticking basalt cardboard onto the wall itself, if the distance allows. If there is no cardboard, then experts recommend installing a metal frame similar to that used for installing drywall and stuffing basalt wool under it.

This installation concerns the protection of flammable materials from stoves in bathhouses and other places. But there is also the use of mineralite on facades, which is done in compliance with the following steps:

- Assembly of the horizontal frame. This can be a vertical rail made of metal or wood.

- Laying insulation under the frame. For our climate zone, penoplex or mineral wool can be chosen. Both options can be used in combination with mineralite.

- Pulling the windbreak. It must be attached to the frame, with a slight sag, so that there are no cracks or tears in the fabric.

- A vertical guide is placed on top of the horizontal frame. The facade will be located on it. The distance between the guides is calculated individually so that there is an interception between the façade finishing elements.

- We fix the facade. To attach a mineralite sheet, you need to make holes in it. If they are not there, then it is convenient to do them using a drill and concrete drill. After fastening, the holes must be closed with rivets, otherwise moisture will get in there and the fasteners will deteriorate.

The result is a façade that protects the building from fire due to external factors. It has a pleasant, attractive appearance, with a high degree of protection from moisture, and is impact-resistant. There are many options on sale that will allow you to decorate office buildings, shops, private homes and other premises.

Effective methods of protection

Among the most effective methods of protection against exposure to high temperatures and heat are screens made of:

- mineral wool

- basalt wool

- foam glass

- glass wool

- vermiculite

- drywall

- minerite

- of stainless steel

Using the materials listed above, as a rule, so-called screens are created - surfaces of a certain width, length and thickness, installed in close proximity to the heating product and sections of the chimney.

Floor

The insulation process should begin from the floor. There are two floor design options:

- leaking;

- leak-proof.

Solid

Thermal insulation of non-leaking (solid) floors is carried out by analogy with floor insulation along joists. A subfloor is laid along the floor beams, and mineral wool slabs are laid. A layer of waterproofing must be laid on top.

Leaking

Leaky floors require a slightly different approach. They must allow water to pass through, which spills onto the floor in the washing compartment or in the steam room combined with the washing room. At the same time, they should not let the cold from the ground into the room.

The most common option is a heated floor on the ground with an insulating layer of polystyrene foam or EPS. In cross-section, the structure consists of the following layers:

- foundation soil;

- compacted sand layer;

- gravel drainage bedding;

- rough screed;

- insulation;

- waterproofing;

- reinforcing mesh;

- finishing screed.

Removable antiseptic wooden ladders are laid on top of the finishing screed, acting as a finishing floor. After all procedures are completed, the ladders in the bathhouse are raised and dried.

Protective screens

Speaking about fire safety in the bathhouse, first of all it is worth highlighting the protective screens that insulate the stove in the bathhouse from the walls.

On the construction market, the most common metal protective screens are made of steel or cast iron. Many manufacturers of iron furnaces provide thermal insulation for their products, providing them with special casings.

Choosing protective screens is quite simple, because depending on the side of the furnace to be insulated, you can purchase a front or side panel. Installing such screens will also not cause difficulties, because the manufacturer provides special legs that can be easily attached to the floor.

What types of slabs are produced?

Manufacturers produce several types of mineralite fiber cement boards. Among the modifications are the following and are in demand:

- Windproof panels. They are used in the construction of ventilated and non-ventilated facades, in frame construction technology, where the slabs simultaneously serve as a structural material and act as wind and hydraulic protection. The manufacturer produces Minerita VZ slabs with sheet sizes of 900x2700 mm and 1200x2700 mm.

- Construction slabs Minerit HD. This is a universal material designed for finishing buildings, both indoors and for external cladding. They are not afraid of strong changes in temperature and moisture. The panels are durable and are available in various thicknesses from 3.2 to 10 mm, depending on their purpose. The most in demand are 8mm slab samples.

- Flat PC façade panels. They are based on HD modification slabs, the material is coated with a primer on both sides, and the front side is also painted with an acrylic composition that ensures a long-lasting color. The panels are presented in 4 variations of standard sizes, 6 and 10 mm thick.

- “Pastel” facade slabs have a hydrophobized coating, a polished surface and are painted.

- Heat-resistant and fire-resistant Minerit boards. Designed to protect wall and ceiling structures from thermal effects, for lining and decorative finishing of the inside of stoves and fireplaces.

The slabs also perform a decorative function. Manufacturers offer products whose surface resembles various finishing materials. An example is Minerite, a decorative stone look. It will be the best option when arranging structures in residential and bathing areas to ensure their fire safety, insulation and sound insulation.

Recommendations for organizing the process

be sawed correctly, without moving them or causing strong blows. Cutting machines are placed in dry rooms. Cut the panel, placing it face up. The cut is thoroughly cleaned (using a compressor or a brush with soft bristles) and coated with a hydrophobic compound. Only dry slabs can be cut and drilled.

It is important that the cut is smooth and without chips. If a stationary saw is used, pay attention to the diameter of the clamping flange used. It should be approximately two-thirds the diameter of the panel. This prevents fatigue fracture. To summarize, we note the following. Exterior finishing of buildings with fiber cement boards from well-known brands, in particular Japanese ones, makes houses beautiful and durable. The material is not dangerous for corrosion or fire; it is easy to install. You need to work with it while observing safety precautions. During the cutting process, dust is generated, from which it is important to protect your eyes and respiratory organs. You can cut the slab with a hacksaw or saw, depending on its thickness and the desired result. Inaka-Fasad employees will provide qualified assistance in cutting Kmew façade material.

How to work with slabs?

During construction, it is possible to install mineralite panels in any season. Since cement-based material is not an effective thermal insulator, when heated it transfers heat in sufficient quantities, which is risky for the wooden structures located underneath. It is necessary to lay basalt cardboard under fiber cement panels or mount it on ceramic bushings, and sometimes place a second sheet through ceramic insulators.

When installing mineralite slabs in a bathhouse, the installation method depends on where the installation is taking place. If the stove is located at a distance from the wall, the stove can be mounted directly on the wall. If the stove is adjacent to the wall, you will have to install two stoves at once. Moreover, screw one onto the wall itself, and fix the next one onto the previous one, maintaining a certain gap.

When installing mineralite, to prevent breakage, it is necessary to make holes-grooves for fastenings. In addition, a small gap must be left between the floor and the bottom edge of the slab

This is important for the free circulation of air masses. To ensure the distance between the slabs, ceramic inserts or fragments of mineralite slabs are laid

Especially if the cladding of buildings is being carried out, which continue to shrink. In this case, over time, the inserts are removed and the fasteners are tightened.

What to cut and drill with?

Most men can cut fiber cement siding on their own, but the task will not be easy

Despite the fact that the slab is quite easy to process, its structure is quite fragile, so it is necessary to proceed with caution. Cutting the slab into fragments at home is done with a regular hacksaw.

You will need a tool with a fine tooth to ensure a cut without nicks or chips.

The second method is cutting the siding with mechanical scissors. This tool is powered by high air pressure. The principle of their operation is similar to that of ordinary scissors. You can cut the slab with a knife, similar to what happens when working with drywall. The difference is that instead of a regular minerite knife you will need a carbide blade.

Carbide inserts are also suitable for cutting fiber cement boards. You will need dust protection for your mouth and eyes. Fiber cement boards can be conveniently cut with a diamond-edged disc. The saw is considered the most effective device for cutting slabs of this type

When working, it is important not to neglect the protection for the safety of the installer’s health. Because there will be too much dust

It is more convenient to cut the canvas on the smooth side. Using a marker, a line is drawn and a carbide knife is drawn along its contour several times. Then you have to lift the fiber cement board and lightly press on the notch on the side opposite to the cut. When the slab bends in half, you need to make a series of cuts along the fold so that one of the pieces separates from the other. In this simple way you can cut such a slab yourself.

Let's summarize: for cutting mineralite sheets, an ordinary hacksaw will do, but if you have to cut a large volume, you will need a mechanical saw or hand scissors. When starting work, you need to understand that the scale of the cut is determined by the size of the blade, and you shouldn’t save money on working tools and your own protection.

Installation Tips

Typically, slabs are mounted horizontally, preferring denser and thicker products with better thermal and sound insulation. Installation of facade panels does not present any particular difficulties. First of all, a load-bearing profile is mounted on the walls in two directions - horizontally and vertically. During the fastening process, it is necessary to provide gaps to account for thermal expansion. The value of such a gap should be within the range of 6 mm per 3 m of fiber cement sheet.

Specially designed self-tapping screws are used for fastening. When they are screwed in, the hardware makes a hole with a larger diameter than its own cross-section. Installing mineralite directly on a wooden wall is unacceptable, since the material transmits the infrared radiation of the furnace, heating up and risking a fire. The mineralite must be fixed with a ventilation gap, or insulation, for example, basalt cardboard, must be laid under it. A parallel metal frame can be built as a base. Which installation method to choose is determined by the distance to the stove.

Reflective wall cladding

The second option for protecting walls from fire is special sheathing, which is made from non-combustible materials. The working element of this protection, which reflects IR rays that are dangerous for flammable surfaces, is a reflective material, for example, stainless steel.

You can assemble this version of protective casing yourself. To do this, you will need a non-flammable thermal insulation material, which will be discussed in more detail below, as well as a sheet of stainless steel.

Stainless steel can be replaced with a cheaper option - galvanization, however, when heated, it can release harmful substances, so we strongly do not recommend using it. When starting work, secure the insulation to the wall, and then cover it with a metal sheet.

To ensure that such thermal insulation for a sauna stove is as productive as possible, polish the metal surface. This will allow IR rays to be better reflected back into the steam room, and the reflected rays will be better perceived by humans.

You can use the following materials as thermal insulation:

- Basalt wool is absolutely safe for baths. It retains heat well, in addition, it is highly hygroscopic and does not burn at all;

- Basalt cardboard is a good option for a bathhouse. It consists of thin sheets of basalt fiber that retain heat well and do not burn;

- Asbestos cardboard is a strong and durable heat insulator, which is also suitable for a bathhouse;

- Minerite for baths is also an excellent material. Non-combustible plates are specially manufactured for shielding hot surfaces in baths and saunas;

Before covering the wall near the stove in the bathhouse, familiarize yourself with the correct technology for its construction. The most important thing is the installation order and compliance with the gaps.

The ideal design has the following structure:

- Wall;

- The ventilation gap is 2-3 cm;

- Insulation 1-2 cm;

- Stainless steel sheet.

Minerite: technical characteristics

Minerite is a fiber cement board. The main component in its composition is cement; cellulose fibers are used as reinforcement. Mineral fillers are also added. The slabs do not contain asbestos, so the products are classified as environmentally friendly building materials. The positive qualities of the slabs are:

- heat resistance;

- high waterproofing characteristics;

- good sound insulation performance;

- durability and wear resistance (plates are not subject to rotting and decomposition).

Ease of installation and processing is another advantage of the material. You can cut Minerite, cutting out fragments of the required size and configuration, with a regular hacksaw, and fasten it using self-tapping screws. The material is produced in different interpretations, which makes it possible to choose a product that meets the purpose and requirements of the consumer.

https://youtube.com/watch?v=oPcjklVM2Gk

Applying paint

Painting fireplaces requires preparation, just like any other construction work. First you need to make sure that you have purchased exactly the composition you need.

You also need to prepare the following tools:

- soft cloth;

- sandpaper;

- water;

- brush;

- roller;

- copper sulfate solution;

- sulfuric acid solution;

- spray.

First, prepare the surface that will be painted. It is cleaned of dust and dirt. Metal parts are cleaned with fine sandpaper. Be sure to remove greasy stains with a soft cloth soaked in a solution of water and salt. Soot can be easily removed with a solution of hydrochloric acid, and rust with a 10% mixture of copper sulfate.

It is recommended to apply the paint to a slightly warm surface using a brush, roller or spray - whichever is more convenient. In total, you need to make 2-3 layers, each of them should be allowed to dry thoroughly before applying the next one. The fireplace must be allowed to dry for several days; it cannot be used until the paint has completely hardened.