For Russian people, a bathhouse is a place where they cleanse the body and spirit, improve their health, and relieve stress. Over time, the people's love for the bathhouse remains unchanged, however, its arrangement has changed. In particular, now you don’t have to think about which stove to install, but simply buy a ready-made one.

Everyone understands that the quality of bath procedures depends on the stove. Therefore, your choice should be taken seriously. Moreover, the range of models for every taste is very wide.

And each is designed for its own type of fuel and has its own combination of functions. But any sauna stove, made of any material, must meet the general requirements for such devices of any design.

Design Features

Ermak sauna stoves are multifunctional units equipped with a water circuit and a powerful heat exchanger. Their expanded functionality is achieved due to the ability to choose a model that runs on wood, coal, gas or electricity.

The manufacturer also offers combination type options, in which you can use both gas and traditional firewood. Such models are equipped with a gas burner, special automation, a stepped chimney, a pressure control unit, and a temperature sensor.

In this type of product, the heating system turns off automatically if the gas supply stops.

Ermak bath equipment is available in two types: regular and elite.

Budget heating systems are made of durable steel with a thickness of 4–6 mm. As a rule, such material is supplied with additional grate bars made of cast iron. “Elite” series products are made from stainless steel with a thickness of 3–4 mm. A fire-resistant glass door is attached to such models during production.

The manufacturer pays special attention to increasing efficiency. Many similar furnaces emit up to 50% of the generated heat into the atmosphere. Ermak products can save fuel by removing the vast majority of energy and directing it to heat the room.

The safety of the furnaces is ensured by protective covers. They form convectors, forcing air to circulate throughout the bathhouse. This reduces the likelihood of users suffering accidental burns.

Thanks to effective protection, even restless children can stay in the steam room. The manufacturer's assortment also includes excellent models with solid and presentable heaters.

Burnout of Ermak's furnace

One of the most common complaints is burnout of the walls of the combustion chamber and steam room.

Sergey Baranik, 47 years old, Perm The firebox and one of the walls of Ermak 12 burned out during a year of operation. We bought the stove new, in the showroom, and installed it according to all the instructions. We used the sauna every other day, so we quickly noticed smoke coming through the side slot. Based on the results of the investigation with a representative of the company, it turned out that some of the water overflowed into the firebox, and the steel simply rusted. Anton Alekseevich, 35 years old, Moscow Bought Ermak 16 on the advice of the master who built the bathhouse. During the first heating, I received a scolding from him for incorrectly placing stones in the heater. It turned out that the stone needed to be laid in layers, sequentially. The master said that Ermaki are the most reliable, but if you hammer the heater to capacity, if it overheats, it will break the welding seams, and then the firebox will definitely burn out. I have been using Ermak for 7 years and have no regrets. Anatoly Petrovsky, 28 years old, Salavat After installing Ermak, we noticed that the mounted tank to the stove did not warm up, the water did not even boil. It turned out that a gap almost 6 mm wide was formed between the housing wall and the tank. The stove installers were to blame; the body simply fell to one side after loading the heater. We leveled it, replaced the hanging tank with a chimney version, and the steam room in the bathhouse came to life. Andrey Zavarsky, 40 years old, Tver I have been repairing Ermakov for almost 10 years. Those who have had to deal with servicing Teplodarov will certainly appreciate the simple and reliable design of Kirov stoves. Most of the problems arise either due to incorrect installation of Ermak, or a disregard for the stove as a technical device. In such conditions, imported models simply burn out after just a few months of operation.

Ermak sauna stoves cannot be considered among the most outstanding achievements in the design of stove equipment. At the same time, the product turned out to be nice and quite reliable. According to reviews, steam room owners purchase Kirov stoves for their baths based on their own experience, or on the advice of friends, which indicates the good quality of the stoves.

- Do-it-yourself soundproofing of walls

- DIY inspection hole

- How to veneer walls with your own hands

- Tinting of balconies and loggias

Varieties

The Ermak trade and production association mainly produces 2 types of sauna stoves: wood-burning and gas-wood-burning. Each group includes several types of models, differing in power, functionality and design.

Wood burning

Their design is generally similar to similar products from other brands, but they are distinguished by their good quality and aesthetic shape. The body of wood-burning stoves is made of black steel, which looks impressive in a stainless steel frame. The door with heat-resistant glass in the center gives the design a special charm.

The external appeal is complemented by an ergonomic internal design. The manufacturer decided to move away from the standard firebox shape. In Ermak stoves it has an unconventional cylindrical shape and is made of stainless steel. This promotes better heat transfer and guarantees a long service life of the unit.

It is also worth noting the following distinctive design features of this furnace:

- External air convectors perform two functions - uniform heating of the air in the steam room and protection from harsh thermal radiation.

- The thickness of the case in places of the highest temperatures is 6 mm;

- The flue is made of stainless steel 4 mm thick.

The key element of the Ermak wood-burning stove is the firebox. An ash pan is placed at its base, with which you can change the intensity of combustion and remove unburnt fragments and ash.

The grate is located directly above the scoop; solid fuel is placed on it. There are flue ducts on top, with the help of which steam and heat are distributed in the heater, and cleaning holes.

Each model can be equipped with additional options:

outdoor mesh heater

hanging tank for heating water

heat exchanger for organizing a bath heating system

This principle of combining several options is the original idea of the manufacturer under the name “FT - Free Transformation”.

For your information! All models of Ermak stoves have the “Elite” modification, in which the body is made entirely of high-quality stainless steel. Depending on the required power parameters, you can choose a steam room installation from 6 to 50 sq./m.

Gas-wood

The company began production of these stoves in 2005. Gas-wood stoves are produced jointly with the Ulyanovsk Gas Equipment Plant.

Currently, 2 modifications of this equipment are produced:

Uralochka 20

Uralochka 20 N

The operation scheme of these models generally repeats the wood-burning models described above. But the Uralochka series has less inertia and the ability to precisely control the burner power. Essential is the ability to change the fuel type to wood: you just need to install a standard firebox door.

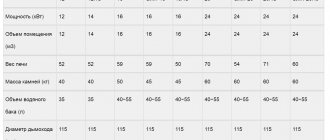

Specifications

You can connect a tank to the stove to heat water in a bath.

Stoves and fireplaces from the manufacturer Ermak have good technical performance. The devices are made of fire-resistant materials and supplemented with elements made of heat-resistant substances, capable of withstanding temperatures up to 2000 degrees and indoor humidity levels up to 30%. Innovative materials and advanced technologies are used in production. Each unit is distinguished by high quality welds and other parts, and fully complies with international fire safety standards.

The design of the furnace is thought out to the smallest detail; the devices have a modular structure, which allows them to be supplemented with auxiliary parts. The stoves maintain the optimal atmosphere and temperature in the room and cope well with their main functions as a heating device. All units of the brand comply with European standards and are guaranteed by the manufacturer for up to five years. One of the main advantages of Ermak garden and home heating stoves is ease of installation: it is enough to install the device on a prepared surface and connect it to communications.

The heating process of the ovens is fully automated; to connect the device, just turn the switch handle and set the desired temperature value. When installing the stove in the steam room, the most comfortable conditions are created for the units. The devices can be additionally covered with brickwork, and remote water tanks can be installed. The optimal length of the firebox of each stove allows you to install a combustion door with a pipe in an additional room.

To prevent possible injuries, the stove can be equipped with a wooden frame. It should be located at a short distance from the device; when manufacturing it, you need to remember fire safety measures.

Advantages and disadvantages

Ermak sauna stoves have the following advantages:

- body made of high-quality, high-strength, environmentally friendly and safe materials;

- small dimensions,

- the ability to perform a compact installation with your own hands;

- safety and ease of operation;

- the materials of the case and other parts do not emit harmful substances and do not melt when overheated;

- possibility of partial replacement of worn parts and elements;

- optimal and comprehensive heating of the heater;

- possibility of removing the pre-furnace tunnel;

- long service life.

Despite many advantages, Ermak stoves also have some disadvantages:

- cool quickly;

- after installation, the equipment must be used several times with the doors open, as it takes a lot of time to get rid of harmful oil residues;

- If thermal insulation is not carried out correctly, the power drops sharply.

General requirements for sauna stoves

When choosing a stove for a bath , it is worth taking into account the general requirements for them.

- It will be best for the consumer if the purchased stove does not require complex maintenance, is convenient and easy to use.

- The stove must maintain the temperature of the stones from 200 to 700°C; this is the only way to obtain high-quality steam.

- The fuel must burn evenly so that the room warms up gradually and there is no excessive heating that is dangerous to human health. So for a bathhouse with a volume of up to 20 cubic meters, the stove must have a power of at least 20 kW, up to 35 - 30 kW.

- Smoke, carbon monoxide and other combustion products must be removed through a special and safe system.

- The housing material must be heat-resistant. Heating equipment must meet all fire safety requirements.

- The sauna stove must provide an air temperature under the ceiling of up to 100°C and above the floor of at least 45°C.

- The design should include a heat accumulator and a steam generator to change the operating mode if necessary, as well as a convection regulator.

- The presence of furnace surfaces whose temperature is more than 150°C should be minimal.

General requirements help when choosing a stove for a bath. Taking them into account, you can make the bathhouse a safe and comfortable place to relax.

Most popular models

Ermak stoves are presented in models of various years of manufacture. Outdated models can be purchased for literally several thousand rubles; modern devices are more expensive. The highest cost is for premium class stoves. According to reviews from buyers and users, several models of different price categories are recognized as the best.

Ermak 12

Applies to 2012 model year. At a cost of about 10 thousand rubles, it will please you with its performance and compactness. Made in a steel case. Equipped with a box for collecting ash.

The thickness of the firebox walls of the model is 6 mm. This ensures a long service life of the oven. The door is lined with glass for flame control. Unit power 12 kW. This is enough to heat an area of 14 cubic meters. To operate the stove, you will need to install a high chimney with a diameter of 11.5 cm. The weight of the Ermak stove is 51 kg.

Advantages of the model:

- The optional adjustable-length tunnel is an excellent solution if users are going to pay attention to the design of the sauna.

- Protective screen-convector.

- Mesh heater for lovers of hot steam.

- Hanging tank for heating water.

Ermak Uralochka-25

A universal wall-mounted sauna stove designed for use in saunas with a steam room volume of up to 24 cubic meters.

The thermal power of the unit is 24 kW. The material of the firebox and body is steel up to 6 mm thick. The door is finished with glass. The stove can operate on two types of fuel - wood and gas. The gas used is liquefied gas from a cylinder.

The heater of this model can hold up to 60 kg of stones - this is quite a lot, so the steam will be thick and rich, as it should be in a real Russian bathhouse. The oven weighs 55 kg, so there will be no problems with installation. The diameter of the connected chimney is 11.5 cm.

Ermak 30 Mesh Lux

A luxury model, which is reflected in the price - from 75 thousand rubles in the version with a steel firebox. A model with a cast iron firebox will cost almost 97 thousand rubles. The most expensive stoves are Ermak 30 Mesh Lux with a stainless steel firebox, costing from 127 thousand rubles. But stainless steel boasts the longest service life, which justifies the high price.

The stove is designed for installation in dry and wet baths and is capable of heating steam rooms and adjacent rooms at the same time. Consumers can choose from models of various configurations. For example, it is possible to supply a stove with a steam generator. It is also possible to connect remote tanks with heat exchangers to produce hot water.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

If you want a stove with a water tank and a solid heater, you should choose the Ermak 30 Mesh Lux model.

Ermak 16 Economy

The model is quite budget-friendly and affordable for buyers with any income. But based on the assembly materials, the stove will not let you down. These are the same 6 mm steel for the firebox and 4 mm for the walls of the body and other internal components.

The Ermak 16 model is distinguished by a rigid design and a ventilated heater. The cost of the Ermak 16 (economy) stove is about 15 thousand rubles. It runs only on wood, the design is simple, as befits economy-class units. The model does not have a glass door, and you need to look into the firebox more often.

The stove is more suitable for use in dry Finnish saunas, since its heater is very small - enough to create a minimum amount of steam (for example, for aromatherapy with essential oils). The volume of the steam room varies from 8 to 18 cubic meters. At any time, the heater can be replaced with a hanging tank for preparing hot water.

Ermak 12 Premium

This model is available in 3 modifications, differing in firebox material. The cost of a model with a steel firebox is from 20.3 thousand rubles, with a cast iron firebox – from 25.8 thousand rubles, with a stainless steel firebox – from 29.4 thousand rubles.

Features of the stove: excellent design, glass door, many options:

- steam generator;

- closed or open heater;

- remote and mounted tanks.

This set allows you to adapt the Ermak 12 Premium stove to any user needs.

The oven can accommodate logs up to 50 cm long; self-cooling handles are used to safely load firewood. The volume of the steam room varies from 6 to 14 cubic meters. The model itself is extremely compact, which makes it suitable for installation in small baths and saunas. When using a heater, you can load up to 30-40 kg of stones into it. The chimney diameter is 115 mm.

Sauna stove Ermak 16

This design differs from the previous 12th model of the sauna stove in the dimensions of the combustion chamber and the dimensions of the body. All other parts and elements are almost the same type. If you believe numerous statements from owners and reviews, the Ermak 16 sauna stove is considered the optimal choice for a home bath.

The weight of the stove in a “dry” state is only 50 kg or 45 kg, depending on the body material. To this you need to add a heater backfill of 40-45 kg and a hanging tank for the same weight of boiling water. As a result, it turns out that the mass of hot material in the steam room of the bath will be more than 100 kg. This is already enough to confidently maintain the air temperature from 80°C to 40°C for 2-3 hours.

For your information! The increased mass of the furnace structure is guaranteed to dry not only the steam room room, but also all the condensate that collects on the built-in furnace coil or hanging tank.

If the Ermak 16 stove is cleaned and dried after each fire, then the service life can be confidently extended by 20-25% of the 10 years guaranteed by the manufacturer. It is clear that if you use the stove and do not pay proper attention to it, the combustion chamber will burn out in 3-4 years.

Installation features

To achieve maximum operating efficiency of Ermak stoves, you should adhere to the following rules when installing:

- Before installing the stove, be sure to thermally insulate the room. As a rule, mineral or glass wool is used for this.

- Special attention should be paid to the floor covering on which the device will stand. Don’t forget about the wall to which the equipment will be attached. After all, it is these parts of the room that are most exposed to the action of the mechanism. Only after quality work has been carried out can you comfortably steam in a sauna room without worrying about safety.

- After thermal insulation, a detailed sketch of the future furnace is drawn up. It’s better to immediately make a drawing for gas and a diagram for metal. The drawing needs to reflect all the elements of the future device. The compiled image will help you avoid serious mistakes when installing equipment.

- The stove is mounted on a reinforced base. It is recommended to make it from a durable metal sheet of large thickness. The main body of the product is attached to it. The procedure is carried out using welding. The design is quite strong, reliable and durable.

- The installation of the chimney deserves special attention, since the operation of all equipment largely depends on it. Before installation, additional thermal insulation must be carried out to ensure safety. A special metal tap should be placed at the place where the pipe crosses the ceiling. This design will prevent excessive heating of the ceiling and roof from the chimney.

Tips for use

To increase the duration of maintenance-free use of equipment, it is recommended to adhere to a number of rules:

- Before lighting the stove, make sure the joints are tight and there is draft. Open the chimney duct and bring a lit match closer to the chamber. The flame should deviate from the vertical.

- The optimal intensity of filling the firebox is no more than 3⁄4 at a time. The dimensions of solid firewood must be such that they can be easily stacked transversely and longitudinally.

- The combustion process must be controlled. The heater should not be heated until it turns red.

- To reduce the amount of soot generated, every third or fourth firebox should be accompanied by the laying of dry aspen or other deciduous wood.

- Twice a year it is necessary to carry out a preventive examination of the stones. Remove cracked and too small ones. Periodically remove the stones and clean the inside of the heater using a soft rag with a cleaning solution. This will remove dust and vapor products in a timely manner.

- Water is poured before kindling begins. If you fill the heat exchanger after ignition has started, there is a high risk of damage to communications.

Advice! Many users of Ermak stoves claim that at the beginning of their operation, emissions of harmful oil residues appear in the baths. Therefore, after purchasing a stove, it is worth heating it several times with the door open. This will get rid of such substances.

FAQ

When lighting an Ermak sauna stove for 12 square meters, smoke goes into the room for 30 seconds, and then everything returns to normal. What factor influences this?

The reason for this is the insufficient performance of the chimney. Smoking is caused by weak draft. When the chimney warms up, the draft increases and smoke stops penetrating into the room. Most likely the chimney was not made very correctly. Perhaps the chimney is not long enough.

Should the joints of the cast iron firebox of the Ermak 16 Premium stove be sealed with sealant?

Yes, some elements are assembled in production using sealant. The design and joint are made in such a way that there is no need for additional sealing. But if you want to play it safe, you can additionally coat the joints with heat-resistant sealant.

Smoke is pouring out of the gap between the firebox and the stove. Should there be some kind of gasket there?

This shouldn't happen. No gasket provided. There may be a problem with the draft in the chimney and the smoke is taking an easier path.

Steam room 12 cubic meters, Ermak 16 stainless steel stove installed. with a gas burner (natural gas), the temperature does not rise above 65 degrees, and the heater cools down quickly when you pour water on it. Vertical chimney 4.5 meters, starting pipe with convector. Good traction hums, but there is little use. What is the reason?

This problem happens, and it is usually not related to the furnace. It is necessary to understand whether everything is installed correctly, from the stove itself to the chimney and ventilation. 90% of problems that arise in the operation of sauna stoves are due to incorrect installation.

Chimney device

If possible, you should choose a straight chimney design, but if this is not possible, then you need to minimize the number of bends. For a stove that runs on solid or liquid fuel, it is important to organize a safe passage through the ceiling. If you neglect this point, then overheating of the junction of the pipe and the ceiling is inevitable, which means there is a high probability of fire.

There are several ways to organize a containment shell:

- Installation of a metal box larger than the pipe. Slag, expanded clay or basalt wool are placed in the space between the pipe and the box.

- The pipe is covered with bricks, starting from the thrust pad.