The iron sauna stove is characterized by its pleasant appearance and excellent thermal conductivity. However, if it is operated incorrectly from a technical point of view, there is a risk of fire. It is because of this that you should know certain nuances.

The simplest homemade structures for a bathhouse are “potbelly stoves”. They consist of a box with a pipe and a door; they give off an insufficient amount of heat, but at the same time they require a significant consumption of firewood. At the moment, it is already a relic of bygone years.

Now, metal bath units are much safer than their predecessors. Most of them are made from sheet iron, with a chamber provided for filling the stone.

Often, a container for liquid is also provided, the capacity of which can reach up to seven tens of liters. However, it is important that the unit is necessarily lined with special refractory bricks, since this eliminates burns and ensures uniform heating of the air.

Varieties

Sauna stoves are distinguished by type of fuel:

Electric

Provides a housing with heating elements and materials for thermal insulation.

Gas

It is a unit with a thermostat for the ability to regulate power. A mechanism that immediately stops supplying fuel when the flame goes out is responsible for the safety of the device.

Wood-burning

Such units heat up slowly, but will delight you with the warmth of a natural fire and a pleasant smell. The disadvantage is that they will require a significant amount of fuel with simultaneous constant maintenance.

Device

The construction of a potbelly stove is quite simple. It is a rectangular metal box on support legs, equipped with:

- a firebox with a door into which firewood is placed;

- ash pan, which must be systematically cleaned;

- an all-metal chimney pipe (length 5 meters or more: the draft force depends on this parameter).

The main fuel for a potbelly stove is wood.

The furnace operates as follows: the heated flow first passes through the chimney pipe shifted to the side, and then only rushes beyond its limits. The fuel burns, the stove heats up, and the heat is transferred to the room in which it is installed.

The ash enters the ash pan through a special mesh, so the volume of the furnace working area does not decrease.

Advantages and disadvantages

Metal sauna stoves have undeniable advantages:

- The most important thing is that the steam room heats up in a short period of time , approximately in an hour or two. The metal is characterized by excellent thermal efficiency.

- The likelihood of carbon monoxide poisoning is practically reduced to zero. Specific design features provide for the removal of all harmful substances that are formed during fuel combustion through the chimney.

- Very compact dimensions are very useful in modest baths.

- To build them, a lightweight foundation is required , which will significantly save time and money.

With all its positive qualities, we should not forget about the disadvantages of such units:

- Significant energy consumption with low efficiency.

- They cannot accumulate heat and soon cool down.

- They do not have the ability to heat overly large areas.

- The fire safety level of an iron stove is significantly lower than that of a brick stove.

Independent laying of stoves for a bath

Before laying the stove, it is necessary to pour the foundation, and then put waterproofing on top in the form of a piece of roofing felt. Next, you can begin laying the first row of bricks, on which you also need to lay roofing felt. This will prevent moisture from penetrating into the brickwork, which could cause the oven to collapse.

When laying bricks, keep in mind that you will need to install ash doors, grates, and fire doors. It is also necessary to organize a chimney through which smoke and carbon monoxide will be removed from the stove. It can be made from a pipe (metal, expanded clay or asbestos) or laid out from fire-resistant bricks. If desired, a water tank is installed above the heater.

Important! Laying bricks must begin from the door in order to firmly and securely fasten it into the structure.

Brick or iron?

The period of warming up the sauna room with a brick stove will take from three to five hours. This means that it must be melted in advance, which is not very comfortable.

Basically, brick ovens operate on the principle of periodic operation. This means that you should initially light the bathhouse, and only after the fuel combustion procedure is completed will it be possible to use the steam room. An iron stove operates on the principle of constant operation.

A good iron stove can heat a sauna in 1 hour, but it will cool down quickly - in half an hour. Therefore, combustion should be constantly maintained.

During installation, care should be taken to take certain additional protective measures for the bathhouse against fire. The difficulty is that the walls are made of thin material and get very hot, which can cause a fire in nearby elements or wall decoration.

You can install the device in a bathhouse of a decent size, but this will not be a rational solution. In this situation, for high-quality warming up, you will need to increase fuel consumption several times. And for a modest-sized bathhouse this will be the ideal solution.

By purchasing an iron stove, you will spend much less money compared to building a brick version. The main issue here is not the cost of materials, but the payment for the work of a professional stove maker. To build a brick stove with your own hands, it is not enough to have only masonry skills; you will need special knowledge.

Installation of a metal stove

Installation of a sauna stove takes into account strict rules.

- Potbelly stoves made of metal are mounted from the walls at a distance of at least 1 cm.

- If there are wooden walls in the bathhouse, the one closest to the stove is additionally protected with special bathhouse foil that has a layer of insulation. This will prevent overheating and possible fire of the wood.

- It is imperative to insulate the chimney;

- After you install a potbelly stove for a bathhouse with your own hands, if you wish, you can cover it with bricks, which will significantly transform its appearance and also save you from accidental burns.

Do-it-yourself oven

Furnace drawing

The construction of an iron stove will not cost too much, but at the same time it will look presentable.

The entire structure is designed to warm up the dressing room, sink and the steam room itself.

What you will need:

- steel sheet with a thickness of 8 millimeters or more or a simple iron pipe with a diameter of 50 cm;

- fittings with a diameter of 10 millimeters;

- grate;

- pipe for installing a chimney with a diameter of 100 millimeters;

- doors for the ash pit and firebox;

- liquid tank made of durable iron with a capacity of 1 cubic meter;

- welding machine;

- Bulgarian;

- cutting and grinding wheels;

Creating a furnace step by step:

- First you need to cut a piece of pipe one meter long.

- For the tank, you also need to cut a pipe 70 centimeters long.

- 20 centimeters wide and 6 centimeters high should be made in the lower part of the pipe

- An iron plate must be welded to the upper edge of this hole.

- You need to make holes in this plate to secure the grate in the ash pit.

- For direct combustion, it is necessary to cut a hole with a diameter of 30 centimeters in the middle of the pipe.

- Next you need to weld all the curtains and locks for the door.

- A heater is mounted above the firebox by welding a pipe with a diameter of 30 centimeters perpendicular to the wall of the firebox.

- The heater must be filled with stones.

- Next, you should weld the chimney pipe and its outlet either through the heater or separately.

- A reservoir for heating the liquid is installed above the heater, at a height of 15 centimeters. It must be equipped with a removable lid for filling with liquid and a tap for draining.

- The use of a grinding wheel will make it possible to eliminate the consequences of welding.

What is the principle for choosing a ready-made iron sauna stove:

- First of all, it is necessary to pay attention to the material from which the structure is made. These units are mass-produced from different materials - structural steel, heat-resistant stainless steel, and a combined method is also possible.

- The thickness of the steel is of no small importance , since the thicker it is, the longer the service life of the unit will be.

- It is also necessary to pay attention to the fuel used for kindling.

- The number of stones is also important. The stove requires polished stones at the rate of three to five kilograms per cubic meter of steam room space.

- The best solution would be to purchase a unit from a high-quality and reliable manufacturer , since this guarantees the purchase of a certified product, as well as safety during the period of operation.

- Good manufacturers care about the warranty period , so they sell their own products on the market with a warranty period of at least two years.

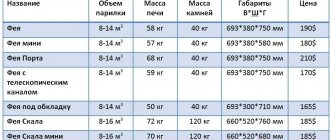

In fact, there is now a wide range of products on the market at a variety of prices, which will depend on many factors, including even the appearance of the product itself. The price range is very wide - from ten thousand rubles and further to infinity.

Installation video:

Pages of history

This type of stove got its name because of its unique appearance. In America, at one time, a stove was widespread - the fat belly. It was actively used for heating small internal volumes, premises of railway stations, freight cars, temporary premises such as guardhouses and other similar types.

Such stoves came to Russia along with the American occupation corps at the turn of the First World War and at the dawn of the Civil War, and immediately attracted the attention of local residents, who immediately appreciated the simplicity and, at the same time, proper efficiency of the stove. And then, along with the civil war, devastation came and simple but effective designs became in great demand.

In general, the potbelly stove has spread across the country. Heat, along with food, is a fundamental factor in a minimally equipped life, and an individual stove, even if it was heated with trees from the family garden or marvelous half-chairs made by the English master Gumbs, could be afforded by fairly wealthy people, in a word, bourgeois.

Potbelly stoves successfully survived the civil war and devastation, collectivization and the Stakhanov movement, worked conscientiously in the dugouts and dugouts of the Great Patriotic War, and confidently entered the post-war life of ordinary Soviet people, heating barracks, dachas and sheds. The decline of stoves of this design came at the time of the mass introduction of centralized heating systems in the country, and now, when industrial technologies make it possible to do things cheaply and cheerfully, and manual electric welding has become commonplace, such stoves are experiencing a rebirth. How is it structured?

Brick laying

When laying out the first row, you should measure the gaps from the walls of the oven to the brick.

The approximate margin is from five to ten centimeters. Bricks are laid in half-brick increments, in a checkerboard pattern. The reinforcing mesh is spread on top of each row. It should not extend beyond the edges of the display, as this will spoil the appearance. The seams must be immediately rubbed with the remaining solution.

To guarantee constant air circulation around the structure, holes should be provided in the masonry itself. On each side you need to make 4 holes - from the bottom to suck in cool air, and from the top to release already heated air.

The laying of bricks is carried out to the very top of the furnace.

Historical excursion

The history of the term “potbelly stove” takes us back to the beginning of the 19th century, when their first designs appeared. Initially, the stove was used as a heating device in the apartments of especially wealthy citizens. This is where the name “potbelly stove” comes from.

During the NEP it was also popular. Then each family received a plot of land for use - a “suburban garden” (the same dachas). There, small-sized, unpretentious stoves were used.

Potbelly stoves were produced in large quantities at factories and for the needs of the Red Army. And more advanced designs, artistically designed and decorated, were even exported outside the USSR.

The stove is smoking

If the stove starts smoking during the first attempt at operation, then the reason must be sought in incorrect installation or defects in the design itself. This requires experienced specialist advice.

The problem may be in the pipe. For example, according to the documentation, the chimney must be higher than the ridge of the roof. If this condition is not met, the entire unit will not function properly. The solution here is to increase the pipe to the required height.

The problem could also be in the roof. If it has holes, then this may affect traction. Cracks in the chimney can also cause smoke. In the worst case, the chimney will have to be replaced.

There are also cases when the stove suddenly began to smoke. Here the reason may be the most banal - the chimney is clogged with soot. Here the problem can be solved by simply cleaning the pipe.

Additionally: wood treatment with impregnations

Fire regulations require that wood be treated with special impregnations that reduce its flammability. However, we know very well that impregnation in a bathhouse is not particularly desirable, because at a high temperature inside the steam room, all the chemicals begin to be released into the air and poison a person. That's not why we go to the bathhouse.

And yet, not all rooms experience such a temperature load as a steam room, so it would be reasonable to treat at least them with fire retardants, as well as the attic, especially since a considerable proportion of fires occur due to sparks flying from the chimney (here Also install a spark arrester or a deflector with it).

The composition should be applied in two or three layers at least 6 hours to dry between stages . Yes, and pay attention to the presence of pigments to indicate impregnation if you do not want the wood to become, for example, a bright pink color. (That is, the color is not from chemicals, it is added specifically to distinguish treated wood from untreated wood.)

So, now that you have an idea of how to install a stove correctly, it’s time to put your acquired knowledge into practice. Write comments, we are interested in your opinion about what you read.

If you have not yet decided on the type of stove you need, then you should familiarize yourself with the characteristics and models of different types: gas, wood, electric. The variety of types of designs, sizes and prices provides the widest selection of stoves for baths and saunas. And which one is better, everyone has the opportunity to decide for themselves.

Range of applications

Potbelly stoves are universal and are used:

- for heating cottages, country houses, rooms or garages;

- for cooking in the country: in houses, on verandas or even in the yard;

- as a camp kitchen if the model is compact;

- to provide hot water (if the model has a storage tank).

Read More at pechinfo.ru/material/iz-metalla/konstruktsiya-metallicheskoj-pechi-dlya-bani?preview_id=818&preview_nonce=a837fab63d&preview=true © PechInfo[/box]

Frequently asked questions

Users choosing a wood-burning stove for a sauna often have the same questions. These can be answered in advance so that people don’t have to waste time thinking:

What is better, a stove with or without a water tank?

It is always recommended to prefer stoves with a water tank - they do not increase the cost too much and have virtually no effect on fuel consumption, but they provide a lot of additional options.

Do you need extra power for a wood stove?

Necessary and even necessary. The efficiency of a wood-burning stove is not infinite; in winter frosts, without a power reserve, you will have to warm up the bathhouse for too long, which means high fuel consumption. It is much easier to slightly reduce the supply of firewood, but be able to increase heat transfer.

Which model is better to choose, domestic or imported?

Most imported stoves are much more expensive than domestic ones. However, price should not be the main determining factor. First of all, we need to consider the technical characteristics, especially the firebox material.

What size water tank is best?

A large tank will require a long time to warm up the water. Therefore, it is customary to be guided by the following criteria - for one person you need to install a capacity of 50 liters, and for a company of several people - twice as much.

Which furnaces require a separate foundation?

According to SNiP, a separate foundation is required for stoves weighing over 700 kg. If the base for the bathhouse is a monolithic slab, a separate foundation for the stove is not required. It is necessary to take into account that for structures whose weight approaches the maximum, it is better to immediately build a separate support system.

When choosing a wood-burning stove, you need to take into account the size of the bathhouse, the size of the interior, the type of foundation and other features. There are domestic and imported models on sale. They differ little in performance indicators, except for the price - foreign analogues are more expensive.

In addition to the main qualities, you should consider the presence of additional functions (for example, a water tank), take into account the size of the heater and other features. This will help you choose the most successful model. If brick structures are preferred, you will have to allocate time to build and shrink the stove. At the same time, its ability to heat the room will be significantly higher than that of metal ready-made models.