When the wooden sauna has been built, all the finishing work has been done and you can’t bear to take a steam bath in it, it’s time to purchase a stove. But you shouldn't buy the first one you come across.

Before purchasing, you need to answer a number of questions:

- What type of oven do you prefer: wet steam or dry;

- What is the area of the internal rooms of the baths;

- Check out the prices for Topi-Moysya stoves;

- Are you planning to relax in the sauna with a large group of people?

- How quickly should the stove heat up and warm up the bath?

- How much area are you willing to devote to the oven?

If you understand the main tasks of the stove and its functions, you can proceed directly to choosing one of the most suitable options.

How to choose a stove for a bath - perhaps the most serious among the interior items and household items of a given room. After all, you can arrange a cozy steam room in which it will be pleasant to be, furnish a luxurious room for relaxation after the steam room, and make a mistake with the sauna stove. Namely, she is responsible for the heat in the steam room.

Today there is a huge selection of heating elements for steam rooms, which are offered by Kirov companies - Raduga, Termofort, Zharstal and others. They are divided according to different parameters. The most important thing is the division of furnaces into “hot” and “cold”. The bottom line is that “hot” stoves warm up the room by heating the elements of the stove itself, and the walls can heat up to 1000C. The principle of operation of a “cold” stove is that its walls are heated to a temperature of 40 to 500C, and it warms up the steam room by taking in cold air, heating it and supplying hot air heated to the required temperature through the channels.

There is one significant advantage of hot stoves “Topi Moysya” - it can be placed in any room, and cold stoves cannot be installed in a room without constant heating, because it is not able to warm up the room on its own.

The next type of classification of sauna stoves is the type of building material from which they are made. There are two subspecies - brick and metal.

Let's look at the pros and cons of each oven:

Do-it-yourself sauna stove, drawings and procedures

The humidity and temperature of the air, comfort and benefits for the body depend on the stove in the bathhouse. A sauna stove must be equipped with a tank for heating water, a chimney and a heater pocket for stones.

If you have a great desire to build a sauna stove with your own hands, and not to hire specialists, be sure to read this article several times, you can even print it out on a piece of paper and use it directly as a cheat sheet. At the same time, you will save significantly and gain invaluable experience, which will allow you to build similar structures for money in the future. External decoration plays an important role, because a bathhouse is a place of relaxation, both physical and moral, and the appearance of the stove plays an important role in this! After external finishing, the stove in your bath should become its “highlight”, an exclusive decoration that is simply pleasant to look at, like a painting.

The sauna stove is placed either with a combustion door into the adjacent room, or directly into the steam room, where firewood is stored. Naturally, it is better for the firewood to be supplied from the next room; if the size allows you, do just that.

Water tanks are mounted either behind the stove body on supports (floor or wall mounting), or they are mounted directly above the stove firebox. At the same time, a stationary floor mounting of the tank is safer than a wall mounting.

Choosing a homemade stove design

Metal homemade sauna stoves are welded not only from pipes or cylinders, but also from sheet steel - whatever you have in stock. Sheets are usually used to make a rectangular body, which is inferior to a cylindrical body according to the following criteria:

- Difficulty of manufacturing. An iron pipe is an almost finished firebox, but the sheet metal still needs to be cut, cut into blanks and assembled into one whole by welding.

- For the same reason, the price of a round product will be less, unless you do all the work yourself.

- The cylindrical shape of a sauna stove made from a pipe is better in terms of heat exchange with the surrounding air.

- A round cross-section is always preferable to a rectangular one from the point of view of flue gas movement.

- The flat wall of the fuel chamber will last less and burn out faster than a pipe of the same thickness made from the same grade of steel.

Any cylindrical tank is suitable for the body of a bath heater - a propane cylinder, a railway receiver, and so on.

The task of making a stove from a pipe or gas cylinder is usually solved in 2 ways: to make the body horizontal or vertical. Both options have the right to life and have their own pros and cons. A vertical sauna stove is more compact than a horizontal one and is appropriate in a small steam room, where every square meter counts. But it is inferior in terms of combustion duration and heat transfer efficiency, which is important.

You will find more information about the designs of homemade long-burning potbelly stoves in the corresponding article.

During combustion, most of the heat rises to the top; the side walls do not heat up so much. And at the top the exchange surface area is small, but there is an exit to the outside through the chimney, where the heat happily rushes. The processes do not work this way in the horizontal design of the stove, where the chimney pipe is located far away and on the way to it, the hot gases will give up some of the heat to the semicircular arch of the body.

Ready-made stove with stone mesh and remote firebox

The efficiency of a horizontal metal furnace welded from a pipe with your own hands will always be slightly higher than a vertical one.

The situation is similar with firewood burning. Inside the vertical firebox, the flame engulfs the entire fuel mass if you do not cover the air supply with the ash pan door. But you can’t heat a bathhouse this way, because the task of a heat source is to produce a lot of heat in a short period of time. In an elongated firebox, the flame moves from the front to the back, burning wood gradually and more efficiently. One caveat: such a heater takes up more space and is not suitable for every steam room.

Video instructions: how to weld a metal sauna stove with your own hands

Calculation of tank volume for a sauna stove

The volume of a water tank is calculated by taking from seven to ten liters of water with a temperature of at least fifty degrees per person. So, if you plan to visit a steam room with 3-4 people at the same time, you should choose a tank with a volume of at least 40 liters.

How to calculate the volume of the steam room and firebox of the stove?

It is not enough to measure the dimensions of the room. You also need to take into account the material of the surfaces. If the room has windows, a glass door, surfaces made of tiles, bricks, concrete, their area should be measured. For each square meter of area of such surfaces, add one and a half cubic meters to the volume of the room, which will be taken into account when choosing the size of the stove. The minimum power of a sauna stove is 8-10 kW.

Oven requirements

A sauna stove must be safe (both in terms of fires and for human health - not cause burns if accidentally touched and prevent smoke from entering the room), the temperature must be regulated, and the dimensions must correspond to the volume of the room.

Preparing the foundation

- in the place where you plan to place the stove, make a hole 0.5 meters deep, the length and width can be increased to 0.7 meters;

- approximately 0.3 meters high, fill the prepared hole with very fine crushed stone and carry out thorough compaction;

- prepare a cement composition based on cement-sand in a ratio of 1 to 4, dilute the mixture with water and pour it onto the crushed stone;

- within 24 hours the base will dry and become hard - place several sheets of roofing material on top for reliable protection from moisture;

- prepare a concrete composition of cement, sand, fine gravel and water in a ratio of 1:2:4 and pour it onto the roofing material;

- carefully level the base using a building level;

- after drying, make a brick platform approximately 0.7 meters in width and height;

- also arrange a protective brick screen up to 1.2 meters high - in the future the stove will be located in close proximity to it, approximately at a distance of 0.2 meters.

Metal heater stove, is it suitable for a bath?

Metal stove heater

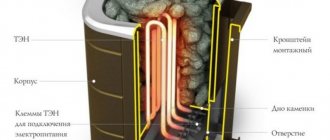

This furnace design is the simplest. For work you will need sheets of steel with a thickness of at least 5 mm, a welding machine and a grinder (or a gas cutter), pipes for water supply and drainage, refractory bricks, stove clay solution, stones, pipes for the chimney, tap, stove doors with latches and hinges, metal profile for mounting the stove support.

Sample furnace heater

The structure itself consists of a water tank with pipes and a tap connected to it. The tank is heated from the back wall of the stove, the internal space of which, in turn, is zoned into a firebox and an open heater. Flue gases are disposed of through a chimney exiting the firebox through the heater and the walls of the bathhouse.

First of all, it is necessary to cut out the bottom and side walls of the future stove from steel sheets and connect them by welding. We weld corners inside the stove - they will support the sheet of metal on which we will lay the stones.

Making a frame for the stove

On the front wall we cut out a rectangular hole for the door, and from the cut out rectangle we make a door. You can weld it around the perimeter with strips of steel for a tighter fit. We drill several holes in the lower part of the door or front wall of the firebox to allow air to enter the stove. We weld the door hinges and the hinge for the bolt.

We line the interior of the furnace with fireclay bricks

To make a chimney, we will prepare a pipe and make a hole in the sheet of metal on which the heater will be located. We weld the pipe to the steel sheet.

Metal stove for a bath

Let's start installing the water tank. It consists of three walls and a bottom, hermetically welded together and the back wall of the furnace. We weld the inlet and outlet pipes for water to one of the side walls of the tank. Then we weld the tap at the bottom of the tank. We install the entire structure on a frame made of steel profiles or on a brick base 20-30 cm high. We cover the metal parts of the stove with fireproof paint. We lay stones on top (soapstone, porphyrite, basalts, etc.) ranging in size from 5 to 12 cm. We install the chimney and chimney, pour water into the tank, cover it with a lid and ignite the finished stove, checking the structure for the presence of draft and the absence of smoke in room.

To modernize a potbelly stove for a bath, you can equip it with an ash pit with a grate and a box for collecting ash. This will greatly simplify cleaning the stove, and the ash door will help to better regulate the draft, and, accordingly, the temperature and rate of fuel combustion. For the same purpose (regulating the heating temperature of the stove), as well as to reduce heat loss through the chimney, it is equipped with a valve. It can be a gate type or any other.

OUR OVEN IN THE BATH WITH THE STOVE DOOR WALL REMOVED

STEAM GENERATOR, DRY PIPES OR DRIPPER.

The steam generator is a large-diameter thick-walled pipe (90 mm) or a thick corner welded horizontally into the bottom of the heater. The lower part of the pipe is blank, and the upper part has holes for steam to escape. This pipe is connected to a small water tank located next to the shelf. Water with flavorings (various infusions, NOT OILS!) is poured into the tank in advance. Due to the fact that the lower part of the steam generator is in the flame, it heats up quickly and strongly, and during the process of steam release it quickly restores its temperature, and due to its large mass it has a large heat capacity. When you open the tap on the tank, water flows by gravity into the steam generator and begins to boil as if on a hot frying pan. The resulting steam exits through the holes at the very bottom of the heater and, before it comes out through the heater door, it must also pass through all the stones laid in the heater, which are also hot! Accordingly, the steam will be overheated and very DRY, because will have time to mix with the air among the stones. The sensations are very pleasant: the heat very gently envelops the body without the scalding effect of the classic succumbing to the heater with a ladle. But you can also use a ladle, i.e. It turns out TWO TYPES OF STEAM: Dry and wet, for every taste.

SMOKE PIPE FOR OUR BATH STOVE.

An important condition for the successful operation of the stove is a properly constructed chimney. We use pipes with a diameter of 108 mm and it is desirable that the chimney is no thinner. The pipe must be higher than the roof ridge. It is better if its length is more than 3 meters. If a pipe from an old furnace is used, it must be thoroughly cleaned in advance to remove soot, scale and rust. Even a slight narrowing of the chimney can greatly affect the draft in the stove. When purchasing a stove, many people ask whether the chimney is included in the price. They don’t realize or don’t think that baths come in different sizes and heights, which means the length of the pipe will be different. In addition, the pipes can be different: just steel, a special sandwich for direct combustion stoves, or brick. Each of them has advantages and disadvantages, and we know them, and we can offer the client any option.

SPARK EXHAUSTING IN OUR BATH STOVES

Sparks will not fly if the stove is welded correctly and smoke does not enter the passage, and you will heat the stove carefully and economically, opening the blower door only 3-5 mm. Then the length of the pipe is limited only by the height of the roof; with the right stove, a meter pipe above the roof will be enough. In our furnaces, we achieve the spark extinguishing effect with the following designs:

- chimneys go from the sides of the firebox, so the flame does not accelerate along the draft and the wood burns with a calm fire,

- spark cutters are the bottom of the heater and the bottom of the hot water tank located on top,

- Well, an “umbrella” over the pipe wouldn’t hurt either!

Sauna stove made from a pipe or an old cylinder

The difference between this design and the previous one is that the water tank is located directly above the firebox. For work you will need: a pipe for the stove and tank (wall thickness 1 cm, diameter 50 cm, height 150 cm); pipe for the heater (the wall thickness is the same, and the diameter is 35cm); mortise valve; metal fittings; hinges for doors; steel sheets with a thickness similar to pipes; tools for welding, metal cutting.

Pipe sauna stove

Firebox door for stove

Door for heater

Tank cover

Thus, from the simplest materials you can quickly and cheaply build a sauna stove with your own hands, and it will not be functionally different from its purchased counterpart! By doing the work efficiently and slowly, you will get a result that will delight you and your guests for many years!

Materials for the stove: what and how much

Bricks that can withstand repeated temperature changes are suitable for masonry. There are two fairly strong, fire-resistant bricks:

- Fireclay brick . Heat-resistant material of a creamy-yellowish color that can withstand heating up to 1400°C without loss of strength. Such a brick accumulates heat without harm to itself and at the same time has high thermal inertia (slowly heats up and cools down). The parameters are superior to other varieties, but they are also more expensive, which is why they are used mainly for laying out the firebox (20-30 pieces are required).

- Solid red brick marked M (not less than M150). The body, chimney and decorative elements are laid out of it. For a modest structure, 250-280 bricks may be enough; for a large project, 800 (or even 1000) ceramic bricks will be needed.

This fireclay brick will withstand application temperatures up to 1350°C (marking ШБ) Source nsk.zoon.ru

In addition to brick, other materials and tools will be needed:

- Masonry mortar . Consists only of clay and sand. It does not use cement, which crumbles when heated and causes destruction of the masonry over time.

- Furnace casting . Cast iron doors, steel containers for water and stones, a grate (grid), and a view (oven damper) are used.

- Thermal insulator . Any material that can withstand temperatures up to 1200°C is suitable - for example, basalt wool in thin sheets.

- Tools . You will need trowels, a tape measure and a building level.

Do-it-yourself row masonry of a sauna stove - photo report

Everything is very simple, just look at the photos and do exactly the same, of course you need to use suitable materials and mixtures!

The brick stove for the bath is ready

Zero row of the oven base:

The second row of the furnace base: The second row and the blower chamber The fourth row - we block the ash pit We put the grate The second row of fireclay bricks We leave a gap between the fireclay brick and the facing brick The third and fourth row of fireclay bricks We cover the fireclay brick with ordinary We put the fifth row of fireclay bricks We make a fireclay grate We make a release channel We install the combustion door We draw out the register We attach the upper part of the door The finished combustion door The appearance of the furnace at this stage We make a grate on which the stones will lie The second row of a pocket for stones We display the upper level of the register What the furnace should look like if you do everything correctly Necessary places for laying fireclay bricks The outermost row of fireclay bricks Making holes in the fireclay bricks Preparing the valve for installation (fitting in) Laying the valve Covering the valve Closing the opening above the core Narrowing the chimney Laying the chimney Installing the second valve Fitting the top of the chimney to the ceiling If you did everything correctly, your sauna stove should look like this like this

Congratulations, it turns out that you completely coped with the task on your own!

Did you like the article? Save so you don't lose!

Source of the article: https://dom-srub-banya.ru/kak-sdelat-pechku-topi-moysya-v-banyu/

Advantages and disadvantages of a brick kiln

No matter how profitable and easy to use metal stoves are, owners with worldly experience prefer proven brick structures. A brick sauna stove has the following advantages:

- Heat capacity . The stove is capable of retaining heat for 6-8 hours and heating several rooms (depending on location).

- Energy independence . A wood-burning stove is an ideal option if there is no gas supply and there are power outages.

- Savings during operation . There is no need to install a gas pipe or run wiring and then pay bills. Firewood will cost much less (especially if you prepare it yourself).

- Comfort . Such stoves produce rich, but not scalding (light) steam and soft heat. The atmosphere of the steam room does not make breathing difficult and is ideal for those who like to steam frequently and tastefully.

Compact brick structure Source tproekt.com

- Environmental friendliness . Both the brick from which the stove is made and the firewood are environmentally friendly materials that are safe for health.

- Design . There are real masterpieces of stove art with stunning architecture and design.

- Fire safety . Provided with design features that fully comply with SP 7.13130-2013.

Brick kilns are inferior to other designs due to disadvantages:

- Difficulties in execution . The masonry process has nuances, and it is not easy to find a competent stove maker.

- Size . A large stove eats up precious steam room space.

- Price . The pleasure of making bricks is not cheap: you need to build a foundation, purchase high-quality bricks and pay for the services of a craftsman.

- Time . The stove heats up, and the steam room takes a long time to heat up.

- Care . Systematic cleaning of the ash pan and periodic cleaning of the chimney are required.

A brick stove emits soft heat that is as comfortable as possible for a person. Source tutknow.ru

See also: Catalog of companies that specialize in the installation of fireplaces and stoves.

Let's go through the prices

| Furnace name | Volume Cub.m. | Furnace price, RUB. | Components*, rub. | Installation, RUR | Total: | |

| * The standard set of components includes a tank, double sandwiches to a height of 3 meters, a passage through the ceiling, a passage through the roof, a sandwich start, a head and all fittings. | ||||||

| Dry air blowers “Topi-Moisya” | Zharstal Fairy (without takeout) | 8-14 | 8500 | 10000 | 14000 | 32500 |

| Zharstal Fairy (With takeout) | 8-14 | 9000 | 10000 | 18000 | 37000 | |

| Zharstal Fairy Rock (without removal) | 14-22 | 11000 | 10000 | 14000 | 35000 | |

| Zharstal Fairy Rock (With takeout) | 14-22 | 11500 | 10000 | 18000 | 39500 | |

| Vira with take-out | 12-18 | 10000 | 10000 | 18000 | 38000 | |

| Homemade oven, not factory made | 12-24 | 12000 | 7000 | 14000 | 33000 | |

| Russian bath | Fehringer "Steam Baby" | 10-16 | 21000 | 10000 | 18000 | 49000 |

| Feringer "Steam Classic" | 12-20 | 34000 | 10000 | 18000 | 62000 | |

| Thermofort "Skoropark" | 10-18 | 26000 | 7000 | 18000 | 51000 | |

| Troika stoves for brick No. 06M2 | 8-16 | 31000 | 20000 | 40000 | 91000 | |

| Troika stoves for brick No. 06M1 | 12-20 | 36000 | 20000 | 40000 | 96000 | |

What is order?

In order

call a detailed masonry diagram indicating the order of placement of bricks in each row. For work, you should choose the order of the stove corresponding to the size of the steam room. For example, if the heater is located above the firebox, to ensure maximum heating, the firebox is made at least 0.5 m. For a steam room volume of up to 12 square meters. m and a 40 liter water tank, the size of the heater with dry steam will be 0.77 × 0.5 m. The height of the firebox should be about 0.5 m.

In the absence of proper experience, it is better not to change the scheme. If the room is non-standard, and any changes are still required, it is better to show the adjusted order to an experienced specialist.

The masonry diagram in any drawings always starts from the zero row. It is necessary to bring the foundation to the floor level. It is not difficult to determine the height of the future structure: in the diagram, each division is 10 cm and is equal to the average height of the brick.

The two pictures below show an example of a brick oven with a water tank and its arrangement. The diagram shows that the bricks are laid in different ways: with a spoon (on their side) or with a bed (the wide part) down.

Stove-heater with tank

Arrangement of a heater with a tank located at the top

How to heat a sauna

Over the entire history of bathhouses, stoves have undergone a real evolution. Heating the bath in different ways. It all started with an open fire and a pile of stones around; the stones heated up and served as an excellent heat accumulator. Now there are a lot of different types of stoves for different types of baths. Let's look at the most popular ones.

Brick kilns

Brick kilns are divided into three types:

A stove without a chimney is intended for “black” baths. It is a large brick heater with many stones placed inside it. The smoke passes through the stones and heats them. The steam in these ovens is simply GREAT! Thanks to heating from an open flame, the stones heat up to the required temperature and, by splashing water on them, you get finely dispersed steam (Light steam). You can read about black baths in our other articles. Here we just note that by splashing water on the stones, you get not only light steam, but also a bunch of soot around.

Brick stove for baths in white - Completely brick, but its difference is that it already has a pipe with a chimney to the street. Such stoves were used until the beginning of the 20th century. Until iron stoves came to replace them. The stones are placed in a special compartment with a closed heater. They are heated by open flames and passing smoke. These ovens also have excellent light steam. The disadvantage of such stoves is that they require constant care. To prevent the stove from cracking, it must be periodically plastered and whitewashed. Otherwise, cracks may form through which carbon monoxide will escape.

Iron stoves lined with brick - such stoves are less capricious, but the brickwork still requires maintenance. A thick-walled iron stove is taken as the basis; it is lined with brick, forming a kind of sarcophagus. The stones are heated through iron, or directly from the fire; thanks to a closed heater, the stones can reach the required temperature of 400 degrees, but for this you will have to burn more than one armful of wood. This stove can also produce excellent light steam.

Iron furnaces

This is where the fun begins. Iron stoves have replaced brick stoves on the market for quite some time. They are much easier to maintain, heat up quickly and consume little wood. These ovens are much cheaper in price. In turn, iron stoves are divided into stoves with an open and closed heater. Also now gaining popularity are stoves without stones , but with a built-in automatic steam generation system.

You can read about steam conditions in a bathhouse in our article Russian bathhouse for a fool. The process of steaming in a modern bath is described in detail there.

Electric heaters

Electric ovens use electricity as a heater. Through special heating elements, the stones of the heater are heated and also heat the steam room. Such stoves not only heat up quickly, but they do not have a chimney, which greatly simplifies the installation of the stove and its maintenance.

Steam generators

This new product on the market is electric steam generators for baths. I haven’t held it in my hands myself, but the effect should not be bad. The point is that the steam room is heated by hot steam, which comes from the steam generator. The water in such a generator is broken into steam using a special ultrasonic device. You can see these devices in ordinary apartment humidifiers, only this steam is additionally heated and supplied by a fan. The steam produced is quite fine and of high quality, since water, when broken by ultrasound, enriches oxygen with negatively charged ions, as in the Chizhevsky chandelier. In general, it needs to be tested, but the atmosphere in a bathhouse with such a stove is close to a Turkish hammam. Accordingly, the wall decoration must be strongly protected from moisture.

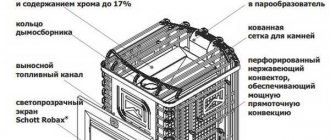

Popular ovens, topi wash

The most popular stoves today are iron stoves - Topi-Moisya. They heat up very quickly and accordingly warm the steam room space. Such stoves can only create the conditions of a dry-air bath and sauna. As a rule, they have an open heater. Although recently there have been stoves with a closed heater, such as Fieringer, as well as with a built-in steam generator, such as the “Skoropark” from Termofort. Also, other manufacturers of iron stoves began to offer cheaper analogues. A closed heater warms up the stones much better, which can produce that very “Light Steam”. But all metal stoves have a number of disadvantages:

- The need for a special ventilation system, which you can read about in our article on ventilation

- They cool down quickly, without having time to properly dry the bathhouse

- They emit "hard" infrared radiation

- Burn negative oxygen ions

Knowing all these disadvantages, manufacturers are trying in every possible way to eradicate them. Many good designers manage to get rid of them, but then the price of their stoves rises accordingly.

Make two iron tubes 30 cm long; you can weld the neck of one of them. Place one end into the lowest stones that are directly above the firebox. These stones will be hotter, and the steam from them will be much finer and of better quality.

Installing the oven correctly

When installing stoves, you must follow a number of rules; now I will describe some rules that are not even specified by the manufacturers.

Everyone needs "Easy steam"

All steamers want to feel the treasured “Light Steam”, but not many people know what it is. It turns out that steam can be both light and heavy. What does this depend on? Of course, it depends on the temperature of the hot stones. In an open heater, if the stones are not heated by direct flame, as is the case with a black sauna, their temperature reaches no more than 350 degrees, in practice even less. After splashing a ladle of water on them, you will hear a characteristic hissing sound, but note that the stones do not dry out instantly, this happens within 5-10 seconds. Steam from such stones will not bring any benefit, but only harm. It will burn your skin and airways.

Light steam, it turns out, comes from stones with a temperature of 400 degrees and above. By splashing steam on such stones, the result is finely dispersed. It was he who received the nickname “Light” among the people. This steam does not burn you; the water breaks into small particles of steam, which will caress your skin and bring you great pleasure. This temperature of stones can only be achieved in closed heaters.

Even better, the stones are heated over an open fire, so those stoves that need to be covered as they burn benefit from better steam.

The sauna stove is the heart of the steam room

A sauna stove is important not only in itself - as a source of heat and steam, but also as a means of keeping the sauna house intact. The pleasure of visiting the steam room and the condition of the walls of the bath itself depend on how well and reliably the stove works and how quickly it warms up the house.

ADVICE! The selection and installation of the stove in the sauna house is carried out before the start of construction work. This scheme is preferable, which is why specialists use it.

Until recently, all private baths had bulky and clumsy brick stoves, which took a long time to heat up and took up a lot of space in small steam rooms. Today, more and more specialists in the process of choosing a stove for a bath are leaning towards stoves with the general name “Topi-Moisya”, which not only work great and guarantee the presence of heat and steam, but also take up very little space. In addition, they look quite attractive, so the appearance of the steam room will not be affected by the installation of such a stove.

FACT! The Topi-Moisya sauna stove is absolutely safe, so there will be no problems or injuries during its operation.

Preparatory stage

If you have doubts about whether the bathhouse has been cleaned, you need to play it safe. It is mandatory to clean the premises after winter, before the start of the new season.

A scoop and poker will help with the work. Taking them in hand, they carefully remove the old coals and rake out the ash from the stove. Many gardeners then use it as fertilizer by sprinkling it on their garden beds.

The chimney is cleaned of carbon deposits. Periodically it is worth checking its permeability; to do this, light a match and bring it to the exhaust hole. If the chimney is clean, the flame is drawn in by the air flow. But there may be no traction. This means that the channel is dirty or foreign objects have entered it. It is cleaned with brushes of a suitable size.

Iron stove, or the simplest and most affordable option

A ready-made iron stove is one of the simplest solutions for those who are solving the issue of heating in a bathhouse.

There are quite a few models, the price tag is acceptable (especially when compared with the cost of brick structures). You can easily buy metal heaters at the market or in a store and install it on the same day. So, the advantages of ready-made iron stoves include...

- Affordable price tag;

- Small sizes;

- Possibility to buy at any time, including without pre-order;

- Quick and simple installation (installed without a foundation, a chimney is placed on top);

- Speedy heating of the steam room (approximately 40 minutes);

- Possibility to heat the steam room up to 160 degrees (for those who like it hot).

But you should understand that despite all the “advantages”, such a stove will not produce the so-called “Russian steam”.

In other words, the iron model creates a microclimate typical of a Finnish sauna with dry air. It is not very comfortable to be in such a bath-sauna, as the skin begins to “burn”. The structure may become red-hot when overheated. And this creates additional danger in operation. However, the metal cools quickly, which leads to the need to periodically add fuel. In addition, hot metal emits hard infrared radiation, to combat which you will have to build a protective screen.

How to heat a sauna

The sauna is most often heated with birch logs; ash and oak are also considered good options. But newcomers to the bathhouse business may be put off by their high cost, so such firewood is purchased by bathhouse lovers.

When kindling, firewood is placed in the stove. First, they lay down some paper and make a hut from small wood chips on top of it. It is good to use small branches for this.

When the fire flares up, logs are added to the firebox. The stove door is opened slightly for greater draft. The valve is not closed, then carbon monoxide does not enter the steam room and sink.

Dry steam evenly heats the bathhouse walls and shelves and removes dampness. To test steam, no more than 100 ml of water is poured onto hot stones. The steam should not burn. If this effect is observed, the steam room is dried.

Beginners often pay attention to the fact that after water gets in, the color of the stones changes, they turn crimson. This confirms that everything was done correctly when lighting the bath.

Firewood is added to the stove several times. It is necessary to ensure that they do not burn out completely, otherwise the stove will cool down, and then the combustion process will have to start again.

Brick oven: cladding features

Brick stoves are suitable for cladding like no other, since brick and cladding have approximately the same coefficient of thermal expansion, which cannot be said about a metal structure. The brick oven heats up gradually, and the lining has time to warm up evenly. The most popular facing materials are:

- Clinker tiles . Clinker is characterized by high refractoriness and heat capacity; it does not deform over time and gives a cozy appearance to the steam room. During production, dyes and fireclay clay are mixed into clinker.

- Terracotta . Pressed unglazed clay that has been fired. The tile has a characteristic red-brown color and excellent strength indicators.

The fashion for tiles spread in the 17th and 18th centuries and has remained in demand to this day Source forumhouse.ru

- Majolica . Tile material obtained by pressing; an improved version of terracotta. A colored design is applied to the tiles and covered with glaze.

- Tile (a type of tile). Special box-shaped tiles, often handmade, decorated with a sophisticated pattern and filled with glaze, were originally invented for lining stoves. The tiles have a special design on the back side and are fastened with special metal pins into the seams, simultaneously with the stove masonry.

How to heat a bathhouse with wood: preparatory stage

Before heating the bathhouse, it is necessary to clear the interior space of debris, wood chips, pieces of soap, and broom leaves. Shelves, benches, basins are carefully treated with antiseptic solutions. Wash the ceiling, walls, floor of the steam room and washing compartment with hot water. Then open the windows and doors to ventilate the room and dry the wooden surfaces.

The remaining ash is removed from the stove. Firewood is prepared by selecting well-dried, medium-sized logs. It should be taken into account that wet firewood takes a very long time to melt and produces a lot of smoke. Do not use bitumen, plastic products, wood coated with varnish or paint, or roofing felt for kindling, as these materials emit harmful toxic substances when burned.

Do you need a foundation?

Such a structure will have significant weight, so a solid foundation must be built before installing it. Some experts argue that if the building is built on a solid foundation, a separate construction for the furnace is not required. However, in swampy areas or in northern regions, where due to temperature changes even carefully compacted soil will “play”, it is better to provide a separate foundation

.

It is undesirable to cut load-bearing beams and logs for its construction, rafters and floor beams for the removal of the chimney, so it is better to choose a place for the stove before the construction of the building begins.

Important! Such a foundation should not be tied to the main one, since due to the large temperature difference during heating, the expansion coefficient will be too large. The distance between the main and furnace foundations should be at least half a meter.

Foundation for a sauna stove

What kind of firewood to use

Frequently used firewood for saunas includes birch logs. When well dried, they light quickly and provide a light, even heat. Essential oils entering the surrounding atmosphere fill the room with a pleasant aroma.

Coal and other wood species are also used, but their effectiveness is lower.

During sanitary pruning, firewood can be harvested from twigs and thick branches of fruit trees.

Sand-clay solution

Cement does not tolerate high temperatures well, so it is not used for ovens. Masonry is made using a solution of clay, mined at a sufficient depth without impurities of earth and other foreign inclusions, and sand.

Start of masonry

Before starting work, the clay should stand in water for several days and soften. Before combining with sand, it is thoroughly mixed with water to the consistency of thick, thick sour cream. The remaining lumps can be broken up using a construction mixer or a drill with a special attachment.

To prevent pebbles and small stones from getting into the narrow seams, the sand is carefully sifted. For laying refractory bricks, clay and sand are mixed in a ratio of 1:2

. To prevent the solution from drying out, the batch is prepared in small portions. The solution should be slightly rough, as elastic as possible and should lie without tears.

But the fat content of clay varies, and the fatter it is, the more sand should be in the solution. That is why experienced stove makers check the viscosity by shaking it from a stick or trowel.

The normal thickness of the layer remaining after shaking is 2 mm. If it is less, clay is added. If the consistency of the solution resembles plasticine, and after shaking, more than 3 mm of solution remains, more sand should be added to the mixture.

Laying tips:

• in order to ideally select bricks in size, each row of them is first placed dry without mortar, the excess length is carefully trimmed, the bricks are numbered, and then assembled in a row using mortar; • a stove laid out unevenly will not last long, so even the slightest deviations should not be allowed: after laying each row, it is better to check the horizontal and vertical using a level; the accuracy of the angles is additionally determined using plumb lines or a corner; • in order for the grate and doors to last as long as possible, it is better to choose not steel, but more refractory cast iron; • in a wood-burning stove, the grate and door are located at the same level; when heating with coal, the grate should be 20 cm below the firebox; • when laying the grate, be sure to leave gaps for thermal expansion; To do this, if necessary, the brick is cut to the required size;

Grate installation

• a small ventilation slot should be provided above the door, which will protect it from overheating, or bricks should be cut in this place with a wedge; • to ensure better air flow and complete combustion of fuel, grate bars are laid only along the blower channel; • halves and quarters are best used in the top rows; • to prevent the clay from cracking over time, the oven can be reinforced with clay and a steel mesh; the fastening wire for it is already provided in the masonry.

Construction of pipes and chimneys

Iron chimneys have a serious drawback: when temperature changes, condensation forms on them, which “attracts” soot, so it is better to build them from brick.

Important! Only whole bricks are placed in the chimney. Due to the risk of them falling out, the use of halves and cracked parts is unacceptable. The chimney wall must be perfectly flat. Otherwise, lumps of soot will accumulate in the corners, and the shaft will quickly become clogged. It is advisable to round off the protrusions along the entire smoke path.

When installing a chimney, several rules should be followed: • high

called the system of passages connecting the chamber with fuel and the chimney; the size of its lower part depends on the width of the firebox and on average is 3/4 of a brick; its cross-sectional area should be about 60-65% of the total area of the chimney; • all places where smoke passes should be cleaned immediately and the remaining solution should be completely removed; • it is unacceptable to narrow the chimney channel - it must be the same along its entire length; in addition, its cross-section cannot be less than the cross-section of the hail, and its total length from the edge of the pipe to the grate is at least 5 m;

Chimney laying

• when laying a chimney and firebox, it is better to place the bricks with the most burned side facing the fire and smoke; • if the chimney is too short

the smoke will not have time to cool down, and the heat will simply fly away into the chimney; • to protect against fire where it passes through the ceiling, the pipe is additionally lined with bricks and wrapped in heat-resistant material;

Finishing the junction of the pipe and the ceiling

• the height of the pipe after the roof ridge must be at least 0.5 m; • so that damage can be easily determined, the pipe is whitewashed with lime mortar: in this case, the places of smoke leakage can be easily identified by traces of soot.