Many greetings to dear reader!

Today I want to touch on our bathhouse topic... Recently my brother and I were in the specialized store “Everything for Baths and Saunas.” He couldn’t resist and decided to say something about the quality of iron casting. The “professional reins” jumped. His education is as a mechanical engineer, and the first thing he noticed was the casting quality of the cast-iron stove for the Russian bath.

What else could you pay attention to? Yes, a lot of things, but I examined the cast cases with passion. I didn’t notice any mechanical or thermal burns, I didn’t find any hot spots, build-ups or scuffs, and other defects (blockages, wrinkles, effusion, warping, etc.) weren’t particularly visible. Apparently, the foundry workers are specialists and “keep” GOST standards. In general, a solid four plus - that’s my brother’s final verdict. The Soviet defense industry did an excellent job, but now who can..., I don’t know..., maybe the Germans or the Japanese with their “sophisticated” technologies.

I got carried away, our topic is the Karelia stove for a bath. It was mentioned above.

The advantage of cast iron and the advantages of cast iron stoves

- Cast iron conducts and accumulates heat well.

- The linear expansion of cast iron when heated is small. There are no deformations during operation. The parts hold their shape well.

- The injection molding method for producing parts allows you to make all the necessary structural elements (booms, bosses, etc.) immediately into the part. This sharply reduces the total number of furnace parts, machining operations are reduced, and the number of fasteners is reduced. The injection molding method makes it easy to obtain ribs that increase the heat-transfer surface; artistic drawings, ornaments. Parts of complex shapes and walls of variable thickness are available by casting.

- Cast iron is chemically neutral and has greater corrosion resistance than structural carbon steel.

- Cast iron stoves are more durable than welded ones.

- Most cast iron stoves do not require a foundation.

- Cast iron stoves heat up faster than brick stoves and cool down slower than welded ones.

About the manufacturer:

It is called "PetrozavodskMash - TNP". He has been making iron casting for fifty years, and he began casting furnaces thirty years ago. I’m talking about this because cast iron, as a material for a bathhouse, is excellent. However, without experience and professionalism, the result is something awkwardly short-lived. By the way, the abbreviation “ATB” is an old name, but many people remember it and remember it only with positive emotions. The plant is located in the Republic of Karelia. Hence the name of their products...

Design features of cast iron stoves "Karelia"

- All stoves are prefabricated. This creates a noticeable advantage during transportation and installation. The entire stove fits in 2-3 NEFAB plywood boxes - this is how it gets to the bathhouse. And then the furnace is transported in detail to the installation site and assembled. Assembly occurs by simply placing parts on top of each other. No tools or fasteners are required. The heaviest part weighs 40 kg. (the combustion chamber).

- The furnaces have a round shape - ideal for thermally stressed parts. Heating occurs evenly in all directions; destructive stresses and linear expansions do not occur.

- The main part of the furnace - the combustion chamber - is a monolithic part.

- The chimneys of stoves are a unique multi-turn design. After the combustion chamber, the flue gases make three 90° turns; spread in two streams along a horizontal annular channel; meet, make an upward turn of 90° and end up either in the smoke exhaust pipe (for some stoves) or in a closed heater - chimney (for others). Along the entire path, heat is transferred to the parts of the furnace and from them to the room

- Numerous ribs on the outer surfaces of the parts increase the already considerable heat-transfer surface by 30%.

- All furnaces have the ability to conveniently remove soot deposits. All channels are available. No disassembly of the ovens is required. There is no need to disconnect the chimney.

The convenient cleaning function is impeccably implemented in the Classic series stoves - removing one part provides excellent access for cleaning the stove chimney

An important feature of the furnace design is deep detailed unification. There are many identical parts in ovens. For example, any stove has a combustion chamber and a combustion chamber cover.

Consumer qualities of cast iron stoves "Karelia"

- All Karelia stoves have an efficiency of at least 60% and therefore meet the standards of GOST 9817 “Household appliances running on solid fuels”. Multi-turn chimneys, finned parts with a large heat-transfer surface help reduce losses from chemical underburning and losses from flue gases. Tests by accredited laboratories confirm an efficiency of 65-67%. The result is fuel savings and a reduction in the time it takes to heat the steam room to the required temperature.

- The mass of the furnaces reaches 230 kg, ensuring high heat capacity and thermal conductivity.

- The power of the stoves is very high - 20 and 40 kW and is suitable for most bathhouses.

- Karelia stoves also meet regulatory requirements in terms of water heating speed (35-45° per hour of heating). The round hanging tank receives heat from almost all parts of the stove. In stoves with a remote tank, the water heater is located directly in the firebox: it heats itself and heats the water as efficiently as possible.

- The temperature of stones in ovens with an open heater reaches 350°C. This is enough to get the usual steam. In stoves with a closed heater, the temperature of the stones rises to 600°C and promotes the formation of fine steam - the most comfortable and useful.

- Temperatures on the walls of the furnaces and control knobs do not exceed standard values.

- When operating furnaces, there is periodically a need to clean them of soot. This work in relation to Karelia stoves does not cause any difficulties.

- Karelia stoves are well balanced. Reaching the desired temperature in the steam room, on the stones, and water in the tank occurs at the same time.

- Stoves with a portal, designed for firing from a room adjacent to the steam room, have a door with glass, which allows you to admire the play of fire.

- If necessary, it is possible to purchase and easily replace any part of the furnace.

- The owner of any Karelia stove, if desired, can change it fundamentally - by removing some parts; having purchased and installed others. There is no need to replace the entire oven. Moderate financial and labor costs - and you have a new stove with different characteristics.

- Karelia stoves are very durable. The “Classic” series stoves, produced in the 80s of the last century, still serve their owners today.

Why cast iron is the most suitable material for sauna stoves

Because it provides:

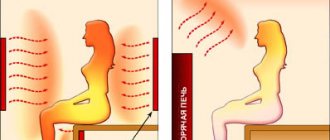

Comfortable warmth

The comfort indicator is determined by the wavelength of the spectrum of electromagnetic radiation. The longer it is, the more pleasant the emanating heat is for a person. I’ll say it differently: for example, a steel stove heated to the same temperature will create more “harsh” thermal radiation, which is less beneficial to the body. Even simpler: a cast iron stove “burns” less oxygen in the steam room. Therefore, some manufacturers of steel products are trying to equip their furnaces with so-called screens that reduce acute heat.

Durability of use

This is a particularly strong point in relation to steel and brick stoves. Cast iron has higher corrosion resistance than carbon steel. Therefore, he has more time to burn out. According to experts, the service life of a cast iron stove is approximately 1.5-2 times longer than a steel one. In addition, cast iron is much less susceptible to expansion caused by high temperatures. Accordingly, there is less deformation during the process. In other words, “the parts keep their factory shape.”

Speaking about brick “brothers”, their durability is within 7 years, since any brick crumbles and cracks over time. Somewhere earlier, somewhere later. And to restore brickwork, a specialist is required.

For information: the passport of the Karelia ATB furnace states: the minimum service life, subject to operation of 170 hours per year (that is, ≈ 3-3.5 hours per week), will be 15 years. By the way, many stoves produced by the plant in the late 80s still heat well. And the factory warranty for a cast iron Petrozavodsk stove is 30 months (in contrast to factory steel ones, which are guaranteed for 12 months).

Unfortunately, there is no 100% protection against ignorance. This is why stove manufacturers curse when they are told about problems that arose during the warranty. Many of these problems are caused by the buyer's failure to comply with basic operating rules.

Regarding such an indicator as the rate of heat accumulation, I will inform you: a cast-iron stove is slightly inferior in heating time to a steel stove, but superior to a brick one. If we talk about cooling, the opposite is true: steel takes longer to cool, but faster than brick. I think you know this yourself.

There are other advantages, however, I do not consider them significant.

Furnace models

Cast iron stoves for baths and saunas “Karelia” currently offer a wide, modern, constantly updated range of stoves.

Karelia-5

The Karelia-5 series of stoves is a basic model range that includes 6 stove models. Each furnace consists of 9 unique castings. All elements of the stove are made of cast iron: firebox, ash pan, chimney. For laying stones, the stove is equipped with a stainless steel casing, which can be regular or enlarged depending on the stove model. The stove creates a “Finnish sauna” mode with air temperatures up to 120°C and excellent “dry” steam.

Stove "Karelia-5" classic

The unique stove of the fifth series is a stove with a closed heater: here the stones are heated to a temperature of 600°C and held for a long time. After the sauna has heated to the desired temperature, open the lid and splash water on the heater. Red-hot stones will produce amazing, incomparable finely dispersed steam.

The fifth series stoves are used in individual baths with a steam room volume from 8 to 30 cubic meters. m. The larger the volume of the steam room, the more powerful the stove should be. Available in 20 kW and 40 kW models.

The choice of stove model also depends on the layout of the bathhouse. If the washing room is combined with a steam room and the stove is heated from the steam room, then your model is Karelia-5 classic. If you prefer to heat the stove from the dressing room, choose the Karelia-5 model with an external portal; it has a cast-iron door with glass, through which it is pleasant to look at the fire in the firebox, and garbage along with firewood will not be brought into the steam room.

Karelia-2

Stove "Karelia-2" with a portal, tank 60 l

Stoves of the Karelia-2 series are ideal for lovers of Russian baths.

The stoves are equipped with a round water tank, which, due to its shape, has greater contact with the cast iron surface of the stove itself, and, as a result, the water in it heats up faster. The stove is assembled from 11 cast iron castings; its collapsible design is convenient for transportation and installation. The series includes two models: classic and with a portal.

As you know, the Russian bathhouse is distinguished by the fact that the steam room creates an atmosphere with high humidity of up to 70% at temperatures up to 90°C. During the bath procedure, water is supplied to the heater in small portions. As it evaporates, it saturates the room with steam. A pleasant feeling of warm, but not burning inhaled air - “light” steam...

Karelia-4

Stove "Karelia-4" with a portal, cast closed heater-chimney, tank 75 l, 40 kW

Cast iron stoves of the Karelia-4 series are the best solution for lovers of the Finnish sauna. The stoves have a remote tank for hot water made of stainless steel. Install it in the washing compartment separately from the stove. This room should not be combined with a steam room - in a Finnish sauna, dousing in a steam room is not recommended. The water heater, installed directly in the combustion chamber of the furnace, is made of heat- and corrosion-resistant steel.

Pipes for connecting the heater to the tank are included in the delivery set. The tank capacity can be 60 or 75 liters at your choice. The tank has a rectangular shape, making it convenient to mount on the wall.

In a Finnish sauna, the temperature is quite high and reaches 90°C-120°C, and the relative humidity, on the contrary, is low - no more than 15%. A person can easily tolerate the high heat of a sauna, thanks to the dry steam and intense evaporation of sweat.

The sauna is very good for health, provides good relaxation of body and spirit, improves emotional state, blood circulation, strengthens the immune system, and increases performance.

Karelia-5 PREMIUM

Cast iron stove Karelia-5 PREMIUM, 40 kW, “LOG” lining

For true connoisseurs of baths, we offer a series of stoves “Karelia-5 PREMIUM” with talc-magnesite lining. The series includes 4 stove models in 4 cladding options. A soapstone stove is heated evenly from bottom to top, and the room is heated with it.

Comfortable heat radiates evenly and softly from the stove throughout the entire room, heating it for a long time. This is such a gentle heat that the surface of soapstone never becomes scalding hot. Thanks to the lining, the stove will cool down slowly, which will prolong your enjoyment of the bath procedures.

Official website of the company https://pech-karelia.ru