Design Features

The developers of Teplodar stoves managed to implement the rule of the “golden ratio” in their products.

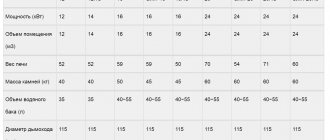

Main design features of the units:

- A body without sharp corners, which is ideal for steam rooms with different areas and interiors . This shape prevents the risk of injury during maintenance.

- Equipped with a two-chamber mesh for stones . The Sahara Profi and 16 series configurations have a dome design and are equipped with a central chimney. The firebox in the stove has a symmetrical shape, the chimney is removed from the walls of the steam room. It also has convection channels that allow you to quickly heat the steam room.

- Converters with a special funnel . From it, water enters the apparatus and circulates through channels that are heated to a certain temperature, which leads to its evaporation. The grate is made of cast iron.

- Dispenser taps on the tank . Thanks to them, it is possible to regulate the humidity level in the steam room of the bath. The feeding force can be adjusted from jet to drip mode.

- The chimney diameter is 115 mm, the most common . Chimney outlets are located in different ways: offset or centrally.

The manufacturer provides additional equipment:

Gas-burners;

Models with built-in water tanks can be equipped with mounted or remote tanks.

Model range overview

The Teplodar product range is not limited to equipment for baths and saunas. It includes heating boilers for the home, fireplaces, and electrical equipment. But the basis of production is stoves for saunas and baths.

Teplodar offers consumers the following models:

Siberia – sauna stove. Allows you to get high-quality dry steam and warm up the room in 30 - 40 minutes. Low humidity combined with high temperature, which the model creates, will allow you to feel the effect of a classic Finnish sauna. The Siberia Panorama modification with a door made of heat-resistant glass is available for sale. This option allows you to feel like you are sitting in front of a fireplace.

Sahara - the model also belongs to sauna stoves, but has a more advanced design. Owners of this unit can get dry and wet steam, since the oven can operate in 2 modes at once. A two-chamber heater, allowing the stones to be heated from 5 sides simultaneously, will ensure their uniform and rapid heating. The model provides the possibility of installing a multi-section steam generator capable of “organizing” good steam after just 20 minutes of combustion.

Siesta is a model that will not only warm up the steam room, but also allow you to cook a barbecue. Siesta will efficiently heat a steam room with a volume of up to 20 cubic meters. A vertical firebox closed on all sides by a convector and a closed heater in the rear part of the structure will allow the stove to be installed even in small steam rooms. The device is equipped with a built-in steam generator, an Anti-Smoke system and dampers in the chimney and door that allow you to regulate the intensity of combustion.

Sibirsky Utes is a stove equipped with a forged mesh. It is endowed with high efficiency and has excellent heat transfer dynamics and the ability to create light steam. Excellent convection, obtained due to the presence of free space between the fuel channel and the stones, helps to achieve the effect of a Finnish sauna with heating temperatures of up to 140 degrees. Thanks to the large volume of stones, the steam is light and comfortable for the body to perceive.

Kuban is a bright model equipped with 2 heaters. Closed, located inside the body, thanks to the supply of water to it from the dispenser built into the tank, it helps to obtain light steam. Open allows you to quickly warm up the room. The model is designed for storing firewood from the dressing room. This allows you to keep the steam room clean.

Blast furnace is a new product in the line of Teplodar furnace models. Equipped with a vertical stainless steel firebox and a casing that closes on top. The main feature of the unit is the presence of a heater inside the firebox. This design allows the stones to be heated to ultra-high temperatures and produce finely dispersed steam.

Cascade - models that stand out from the entire range with their magnificent design. The body of these kilns has smooth contours and holds a lot of stones. The firebox of the Cascade model is made of high-quality metal with a thickness of 4 mm, which extends the service life of the unit.

Rus is a specialized line of wood-burning stoves for Russian baths. The use of these units allows you to create an optimal balance of temperature and humidity, characteristic of a Russian steam room.

Bugrinka - a model that will appeal to true connoisseurs of the Russian bathhouse, because a large mass of stones placed in the stove participates in the formation of the microclimate. A powerful mesh stove is installed and heated from the steam room. A reliable door with a locking mechanism prevents accidental opening and spillage of hot coals.

TOP 5 best models

Teplodar is a company that has gained recognition in the bath equipment market. All the furnaces it produces are of high quality and performance. But some models have become the most popular and are recognized by buyers as the best.

Rus 18 L

A universal model that has long earned people's love. Designed for steam rooms with a volume of up to 18 cubic meters. Closed type of heater. The main fuel is firewood.

Pros of the model:

- uniform heating of stones;

- convenient location of the chimney in the center;

- durable steel body;

- high-quality and fast heating of the room up to 90 degrees.

- The disadvantage of the model is the thinner material used to make the convector.

Rus 18 LNZP Profi

This model from the previous series is designed for larger-than-average rooms. The convector in it is made of stainless steel.

Advantages of the model:

- door with panoramic heat-resistant glass;

- the stove is heated from the adjacent room

- The disadvantage is that the stones may not heat up quickly enough.

Siesta

One of the advantages of this interesting model can be considered the barbecue mode. The Siesta stove has a very aesthetic appearance. Can heat a large space (up to 40 cubic meters) without additional heat sources.

Advantages of the model:

- Possibility of use for heating residential premises;

- choice of dry or soft steam.

- Disadvantages include difficult movement of the levers after the body warms up .

Siberian Cliff Panorama 20 LP PROFI

A representative of the mesh stove, this means that the stove is not only a stylish solution, but also provides a lot of soft heat. Due to the presence of a gap between the stones, air flows better and the stove heats faster. The heated volume of the model is 20 cu.m.

Advantages of the stove:

- high power firebox;

- convenient location of the chimney;

- unique convector.

Flaws:

- high consumption of firewood is possible;

- Some stones may not heat up quickly due to the space between them.

Cascade-18 LP Panorama

A model with stones arranged at an angle, which allows you to get unusual steam in the room. The glass oven door allows you to admire the flames while visiting the steam room.

Pros of the oven:

- high-speed vaporization;

- economical fuel consumption;

- Possibility of choosing dry or wet steam.

- The disadvantages of the model include the inconvenient location of the remote tank.

Strengths and weaknesses of a coal sauna stove

As we undoubtedly remember, ideal things do not exist in nature, however, any object has a certain set of strengths and weaknesses. The stove we are considering is no exception. Let's start, as usual, with the good. In fairness, we note that the listed requirements are overwhelmingly relevant for metal structures:

- Low operating costs. Sufficiently high fuel efficiency, especially when using anthracite group coals, characterized by low parent ash content and extremely high calorie content, or otherwise, specific heat of combustion;

- Durability. A stove made from materials, especially its hot parts, can be used for 10-12 years;

- Good maintainability. Current repairs are not complicated and their implementation does not involve any special technological or instrumental difficulties;

- Resistance to temperature fluctuations. Tolerates long breaks from work well;

- A large selection of ready-made structures made taking into account the basic technological requirements;

- Relatively low cost of self-production or purchasing a finished copy;

- The construction of a separate foundation is not required;

- Flexibility in terms of placement or adaptation of the stove for use in various rooms, both in volume and configuration.

Now, about the main and critical shortcomings:

- When used in tandem with a closed-type heater and a large volume of inert stone backfill, a stove of this type can take a long time to accelerate and slowly reach the nominal temperature regime in a steam room;

- Due to the high surface temperature, it is necessary to take special measures to reduce the fire hazard of the room and erect a protective fence to avoid burns in the event of unexpected contact with the furnace;

- There are special requirements for the thickness and heat resistance of the metal used in the manufacture of critical elements of the furnace. Substandard raw materials can cause deformations and burnout of hot parts;

- The steam generated by a stove of this type is quite harsh and is more suitable for dry baths than for classic Russian ones.

A word from Experienced! It must be said that a coal-fired sauna stove, which is made of metal, should not have metal sheets less than 4 mm thick as the basis of its design. The only exception may be factory furnaces of famous foreign brands that use high-alloy heat-resistant special steels as raw materials.

We count the power

The thermal power of a furnace is one of the main and fundamental indicators that characterizes its efficiency and functionality.

The generally accepted practical volume norm for one person in a bathhouse is 9-11 cubic meters. m. For heating 1 cubic. m. bath room to a temperature of 60 degrees Celsius requires 55 kcal. at one o'clock. A metal sauna stove, when using ordinary coal of the DGr grade as fuel, can generate 320 kcal. from 1 sq. m of working surface. Thus, for heating to a nominal temperature of 10 cubic meters. The volume of a steam room requires 550 kcal. thermal energy, therefore, the working surface area of a coal-fired furnace to maintain the specified parameters cannot be less than 1.73 square meters. m. taking into account the minimum or close to it level of losses.

Attention! The main quality of a sauna stove is not so much the thermal conductivity of the material as its heat capacity. The heat capacity of steel is very low, so you need to be prepared for the fact that in order to maintain the temperature in the steam room for a long time, the oven will need to be heated. A good alternative to this feature of a steel stove is the use of cast iron. Cast iron casting is very close in heat capacity to masonry, so “long-lasting” sauna stoves are possible only on the basis of a cast iron “skeleton”.

Features of the furnace firebox

It is clear that using coal as the main fuel, it will not be possible to completely abandon firewood. The overwhelming majority of the main brands of coals require sufficient temperature for reliable ignition, which can be initiated by a wood stack.

A starting filling of finely chopped firewood or wood chips is used in a ratio to the main starting portion of coal, approximately 1 to 4. There are some brands of coal that ignite with a smaller amount of firewood, others require a ratio of 1 to 2 and are difficult to ignite.

Important! It should be said that grade T coals, the so-called lean coals or semi-anthracites and grade A-anthracites are used in the secondary stack, that is, when the starting stack of firewood and the primary stack of long-flame coals have created a thermal bed of sufficient volume and temperature. It is almost impossible to light such coals directly from firewood.

An important condition is the correct use of the furnace vent. At the moment the kindling starts, it is covered; as the stove flares up and reaches the nominal operating mode, it is opened, thereby regulating the air flow and the rate of combustion of the supplied portion of fuel.

Coal grades K and Sp, coking and caking require constant work with a poker in order to break the crust of the coal pie and provide the necessary air flow to the entire volume of the coal bed. In addition, coke group coals have a very high calorific value and, when placed in their pure form, can cause burnout of the grate.

To complete the information picture, we consider it correct to present the main characteristics of the calorie content and volumetric weight of the main grades of coal in the form of a table:

| Coal grade | Calorie content, kcal. | Volumetric weight, kg/cub.m. |

| Long-flame dry, grade D | 7950 | 1,23 |

| Long-flame fatty gas, grades DG, G | 8200 | 1,24 |

| Coke fat, KZh brand | 8400 | 1,24 |

| Coke, grade K | 8450 | 1,26 |

| Fat, grade J | 8750 | 1,27 |

| Leaned-sintered, OS grade | 8600 | 1,30 |

| Skinny, T brand | 8500 | 1,31 |

| Semi-anthracite, PA grade | 8400 | 1,32 |

| Anthracite, grade A | 8200 | 1,62 |

Brief recommendations for self-production

It is quite possible to make a coal stove with your own hands, the main thing is to follow the basic technological principles.

Let's consider the main types suitable for production in artisanal household conditions:

- Potbelly stove. In many ways it repeats the classic, well-known potbelly stove and differs from the latter in the presence of a tray for stone backfill. Overall dimensions, as a rule, do not exceed 420 mm in height and 470 mm in width. The foundation for such a furnace is not equipped; the function of a heat-resistant cutoff from the floor is performed by a piece of basalt slab, which, in addition, evenly distributes the load. The maximum volume that this stove can heat should be considered 22 cubic meters. m. and no more. A direct type chimney with a total height of about 4200-4500 mm. The draft is regulated not by a gate, but by a sliding damper, which blocks part of the passage holes in the stove door. It should be taken into account that the 2 passage holes should not overlap in any way. A stove of this type, due to the good draft of the direct chimney, allows flooding during cleaning. The maximum volume of liquid for a one-time supply of steam is no more than 0.25 l. and an interval of about 20-25 minutes.

- All-welded stove without the use of stone lining. The most primitive design, capable of effectively heating a steam room with a volume of up to 25 cubic meters with overall dimensions of height and width of 750×600 mm. m. The chimney diameter is at least 100 mm. organized through a sleeve with a diameter of 110-115 mm using a metal pipe with a wall thickness of at least 2 mm. A blower with an opening area of about 30-35% of the area of the fire door opening is formed in the face of the stove. The grate is installed along the firebox line from a set of reinforcing rods with a diameter of 15 mm cut to size and welded into a flat package. The thickness of the furnace body in cold parts is 4 mm, in hot areas 6 mm.

- Metal welded stove in a case. It is basically a brick stove, enclosed for higher heat transfer in a metal case made of cold-rolled steel with a thickness of at least 3 mm. The metal case heats up to a temperature of 100-120 degrees Celsius, so a prerequisite for such an oven should be the presence of an enclosing screen that blocks direct contact of body parts with the hot surface. Allows the use of a foundationless arrangement. Laying the hot part from refractory fireclay bricks using expansion joints. Suitable for use in both a dry sauna and a Russian steam bath. A coal stove for a bath of this type is capable of effectively heating a steam room of up to 40 cubic meters with overall dimensions in height and width of 1120×550 mm. m. A water heating circuit is easily integrated into the design, which provides hot water at a temperature of about 50 degrees Celsius. The cycle of heating a steam room to the nominal temperature does not exceed 120 minutes; flooding during washing is undesirable; the heat retention time at the nominal temperature is at least 60 minutes.

Important! When using a metal casing for a stone stove, you cannot use a stone casing for a metal one. Such a technique, due to the large difference in heat transfer between stone and metal, “locks in heat” and leads to the operation of a metal furnace and its firebox in critical temperature conditions. As a consequence, temperature deformation and rapid burnout of even a thick-walled cast iron stove.

In general, you should remember a simple rule: the higher the mass of the furnace frame and stone backfill, the more inertial the furnace is. That is, it takes a long time to accelerate and reach the nominal warm-up temperature, but it also maintains it longer, cooling more slowly.

When carrying out welding work, you should be guided by the rules and techniques for obtaining critical, highly loaded seams, followed by annealing and control testing at full speed of the furnace for 120 minutes. If defects are detected in the seam, it is cut and welded again, followed by control annealing 24 hours after the welding work.

Advantages and disadvantages

The range of equipment from the Teplodar company meets the requirements of lovers of Russian baths or Finnish saunas and is distinguished by reliability, efficiency and aesthetics.

Advantages of the units:

- improved heat transfer and hot air circulation system, water and steam supply;

- wide model range, includes 12 models in 60 modifications;

- housings designed to meet all safety requirements and protect against accidental injury;

- a large selection of models of varying power, which are suitable for heating rooms with a volume of 4 to 70 cubic meters.

- the ability to convert almost every model to gas.

- profitable price.

Teplodar stoves have few disadvantages and they are mainly related to design features.

The following characteristics cause inconvenience to real users:

- inconvenient and very heavy ash pan;

- inability to hang the door;

- a grate attached to the ash pan;

- metal crackling when the body heats up too much.

Model selection criteria

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Relaxation in the bathhouse will be useful and enjoyable if the stove installed in it is chosen correctly and meets the necessary parameters. It is important to take into account the characteristics of the room and evaluate the technical capabilities of the stove. Only in this case will the heating of the air in the steam room be optimal and it will be possible to obtain an appropriate microclimate in the room./expert_bq]

What characteristics need to be taken into account when selecting a stove?

Power

This is the main criterion for selecting a model.

It depends on the volume of the steam room. Standard indicators are from 4 cubic meters / m to 18 cubic meters / m. Most models of Teplodar sauna stoves are suitable for such premises. When selecting power, you need to pay attention to the heat loss of the steam room, the most common of which are surfaces with high heat capacity (glass, tile), insufficient wall insulation, and operation in winter. Commercial baths require stoves with increased service life. Teplodar also has these in its assortment, they are marked with the PROFI icon.

The most powerful, created specifically for commercial use in steam rooms with a volume of up to 70 cubic meters, is the KomPar gas furnace.

Kamenka

The microclimate in the steam room and the rate of steam generation depend on its design features.

Among the Teplodar assortment, you can choose options with the following types of heaters:

Open means rapid heat exchange. The hot stones in it are in direct contact with the environment, the room warms up faster - only 1 hour and the steam room is ready. Stoves with an open heater can be of two types: classic - Sahara, Taman, Rus, where the stones are distributed at the top of the stove, mesh stove - Siberian cliff, Cascade, where the stones fill the entire height of the heater.

Open heaters are often chosen for Finnish saunas - the air in the steam room will be drier and hotter compared to saunas with a closed heater. It also performs a decorative function. Specially selected, beautifully arranged stones complete the laconic design of the stove.

A special type of open heater is the open ventilated one in the Rus and New Rus models. The models provide the ideal microclimate of a Russian bath.

Closed heater - a traditional type of heater for a Russian bath - models Laguna, Siesta. The heat lasts for a very long time, even after the fuel has completely burned out. Thanks to the internal water supply system, closed heaters will appeal to lovers of soft, moist steam - these are ideal conditions for steaming with brooms and comfortable long relaxation in the sauna. The peculiarity of stoves with a closed heater is that their design is more reliable and safe. It is almost impossible to get burned by hot steam from such a stove.

A combined heater is a design in which stones are placed in two heaters: closed and open (models Domna, Kuban). This method of laying stones allows you to independently choose the mode of steam supply and air humidity, so if desired, it is possible to arrange a Finnish sauna or Russian bath.

Firebox door

The Teplodar plant produces stoves with 3 types of doors:

Standard blind steel partition separating the combustion chamber from the room. This is a traditional option, which is presented in most modern models. Firewood can be laid from the steam room or dressing room. The latter option is more common: it is easier to use and the steam room remains clean.

Standard steel with a small viewing glass . Used in some modifications of Rus and Sahara stoves. Such a door is equipped with stoves with an extended fuel channel for loading firewood from the adjacent room.- Panoramic - has a purely decorative function. Through heat-resistant glass you can observe the live fire and monitor the fuel level. A number of sauna stoves from the Teplodar company have modifications with panoramic doors - models New Rus Panorama, Sibir Panorama, Sibirsky Utes Panorama Profi.

Fuel type

Sauna stoves are traditionally heated with wood. The smell of burning logs and the beautiful sight of a live fire encourage relaxation. All Teplodar sauna stoves are wood-burning, except for the gas model KomPAR.

Firewood is an economical, simple type of fuel that carries with it the traditional romance of a bathing holiday. But at the same time, this is a more complex way of lighting a stove - the wood needs to be dried, chopped, stored somewhere, constantly added to the firebox and the ash removed after burning.

There are also modern models of sauna stoves that use gas as an alternative source. In modern sauna stoves from many manufacturers, if necessary, a special gas burner and a special chimney are installed.

This feature is provided in all Teplodar sauna stoves, except for models with a panoramic door and Rus 9. Such stoves are connected to a gas pipeline or gas cylinder. This is convenient because you do not need to monitor the fuel level, empty the ash pan, and wash the bathhouse from soot and ash.

Important! Installation of a gas stove for a bath can only be carried out with the permission of the gas service and with the help of qualified specialists.

Design and principle of operation

Firewood, in many regions of the country, has been steadily rising in price lately. Not everywhere there are conditions when the boundary of a personal plot abuts a forest, where the forester is a good friend and the chainsaw is not a wretched Chinese craft, but a branded Swedish or Canadian unit. In general, not everyone is lucky with firewood and, sometimes, the price tag for delivery of ready-made firewood makes you think about something sublime and unearthly. That’s when various thoughts about alternative fuels, for example, coal, come to mind.

At the moment, there are a great variety of different sauna stoves on the market that use coal as fuel. They are united by a single design basis, which is based on a number of general principles:

- Firebox. It is decorated with a massive combustion chamber with a grate in the base of the combustion space and a combustion door on the front side of the stove;

- Ash pit. Can be designed in the form of a classic ash pan and an ash pan;

- Kamenka. A box containing a stone backfill that accumulates and radiates heat into the space of the bathhouse;

- A chimney that has a vault in which the concentration and primary accumulation of flue and flue gases flows through the sleeve and then out into the pipe, which has a direct direct connection with the atmosphere.

The coal stove operates on the principle of convection of air masses, that is, it ensures effective circulation of internal air volumes heating the bathhouse with the simultaneous formation and high-quality removal of flue gases.

The main art of engineering is the simultaneous provision of good traction and high-quality and economical heating of the internal volume of the bathhouse.

Attention! The principle of using a coal stove in a bathhouse is a categorical ban on using it as a heat source in black baths. There are many reasons: the formation of toxic combustion products that are difficult to remove, the release of coal tar and soot.

Operating rules

The manufacturer recommends heating new sauna stoves for 60 minutes with windows and doors open to completely remove the paint smell. When using for the first time, load the firebox completely, fill the water tank, and leave the heater empty. This is necessary to burn out the technical lubricants and products used in production.

After the stove has cooled, the water is drained, the bathhouse is ventilated, and stones are filled in. The oven is ready for use.

During further operation, you need to follow a number of the following recommendations:

- make kindling with small, dried wood chips 2/3 of the volume;

- put firewood on the grate;

- do not burn paints and varnishes or tires in the firebox;

- after half of the wood has burned out in the stove, good draft is formed, at this moment you should add 2/3 of the wood to the firebox and open the ash pan;

- when the bathhouse warms up, close the ash pan, throwing logs into the firebox from time to time to maintain heat;

- At the end of the bathing procedures, the stove is heated again to dry the room.

Advantages of wood-burning sauna stoves

Wood-burning sauna stoves have a number of undeniable advantages; you will understand more than once that you have made the right choice, because:

- A sauna with such a heater can be built anywhere and heated at any time, since it operates autonomously and does not depend on power supply. Do not be afraid of possible interruptions in the power supply - a wood-burning heater will not let you down under any circumstances. This is especially true for suburban dacha plots, where fuel can be found in any copse.

- Fuel for a wood-burning stove is not in short supply and has a very affordable price, even if you decide to purchase high-quality firewood specifically designed for a bathhouse. Firewood for a sauna must be well dried, only then can the desired effect of creating a healthy sauna microclimate be achieved.

- A wood-fired stove will heat the stones faster than an electric one.

- Firewood, when used in a bathhouse, is a safe and environmentally friendly fuel.

- Burnt and smoldering firewood retains heat in the stove for a long time, and therefore heat in the room, while an electric stove cools down much faster, almost immediately after the power supply is cut off. A stove heated with wood remains warm for up to 12-14 hours, especially if it is made of regular brick, which also cools slowly and helps retain heat internally.

User Questions

During operation of the Taman 10 stove, smoke began to emerge from the door. What to do and what is the reason?

Problems with traction. You need to clean the chimney from the roof side with a hard metal brush. Clean the furnace manifold through the structural gap on the side of the fuel channel using a flat metal object.

The factory recommends a distance between the control panel and the gas burner of no more than 1 m. Is it possible to increase this distance to 2 m?

The length of the conductor from the thermal cylinder to the thermostat is 1 m. You can increase the distance from the burner to the control unit and, accordingly, change the installation location of the thermal cylinder in a steam room only by extending wires with an electrical contact (Ev2 or network wire). It is impossible to extend the thermal bulb and its tube, since there is freon inside. You can try replacing the entire thermostat with a longer thermostat wire.

There is a gap in the area of the smoke collector ring and the sandwich mesh fastening. Can sealant be used?

The outer diameter of the smoke collector ring on sauna stoves is 112.9 mm, the inner diameter of the sandwich mesh is about 116 mm. Therefore, there is a gap of about 3 mm during installation. It is a design feature and does not need to be sealed. If the gap bothers you for some reason, you can seal it with heat-resistant sealant or silica cord.

When installing the stove and screen below, a “gap” or through hole is formed between the steam room and the adjacent room. Should it be like this or should I cover it with something?

This is how it should be, it is necessary for the convection of the oven in the steam room. You can cover it, but not tightly. You can use any non-flammable material (ceramics, metal).

Does the mesh convector in a Bugrinka 16 T. oven with a large load of stones affect its service life?

No. A mesh convector with a large mass of stones does not affect the service life of the stove.

I severely peeled off the paint on the Rus stove in a couple of places. What paint is used for painting and where can it be purchased?

For painting stoves, heat-resistant paint such as “Certa” is used. A can of spray paint can be purchased from the same store where you purchased the stove. In order for the paint to set, after touching up the stove will need to be heated, and a smell may appear, which will subsequently disappear.

Does the Sahara stove have one hole for the chimney or can the pipe be moved closer to the back wall of the stove?

The chimney outlet in Sahara stoves is located in the center of the heater. This arrangement was chosen specifically - it simplifies the installation of the chimney and does not affect the ergonomics of the stove - it is convenient to use the heater.

Wood-burning sauna stove Teplodar - video review

Brick sauna stove

A stove built of brick can be massive, or it can be neat and compact, it all depends on the area of the bathhouse. It can also be installed in two ways - with a firebox in the dressing room or in the steam room.

Sauna with a brick stove with a firebox in the dressing room

The stove itself can become part of the wall between two rooms. By looking at the diagrams of different stove designs and stone laying, you can choose the size and shape of the option that suits a specific sauna room.

Possible design options

In addition to these models, there are stoves with a built-in water tank, which is installed during the construction of the building. Its back wall is adjacent to the side wall of the firebox, and a piece of asbestos material is laid between them, which will protect the metal from burning through.

Another option for installing the tank could be to install it on top of the combustion chamber, but in this case, its bottom must be protected from burning through with one layer of brick or cast iron panel.

- To install a brick kiln, a foundation is required, and its construction begins from there. The foundation is laid in a pit buried 40-60 centimeters into the ground. It must be strengthened with reinforcement. In size it should be 10-15 centimeters larger than the base of the stove.

- Further, if the stove does not act as a wall, then the wall, built of wood, must be insulated with a sheet of asbestos or heat-resistant plasterboard.

Approximate layout of the stove in the sauna

- A sheet of roofing felt waterproofing cut to size is laid on the finished foundation.

- The furnace laying begins on top of the waterproofing. It is produced according to an orderly scheme that will correspond to the selected model.

- When laying out the walls of the stove, the evenness of the rows is controlled using a level, and verticality using a plumb line. It is very important to follow the exact layout of each row and install additional elements (doors, grate, etc.) exactly on those rows and in those places that are indicated in the order.

- The doors, when installed, are secured with steel wire, and sometimes temporarily supported with bricks, which are removed only after the door is well fixed with masonry. Strips of asbestos are laid between the masonry and the walls of the door, or it is wrapped with asbestos rope.

- The grate is also placed on strips of asbestos; it is not secured with anything else. It is quite heavy and will be located in the recess above the ash pan, so it will not move anywhere.

- The heater is brought into the steam room; it is heated by the firebox, which is adjacent to the back wall. A chimney can be passed through it, which is then connected to a straight chimney.

- The passage of the pipe through the ceilings is organized in the same way as when installing a metal furnace.

In conclusion, I would like to say that laying a brick stove should be done only from high-quality material and with a properly selected heat-resistant mortar.