Feringer stoves are recognized by experts and connoisseurs of baths as one of the best. They are available in several versions and have two categories:

- Ovens with a closed heater to create the atmosphere of a Russian steam room (temperature 55-70°C, humidity 40-75%). In the catalog they are located in the “Steam ovens” section.

- Stoves with an open heater for dry-air saunas (temperature from 80° and low humidity 10-15%). They can be found in the “Golden Ratio” section.

- Not so long ago, in 2011, a third line appeared - “Lamelle”. It is distinguished by the presence of a cladding made of natural stone, and some changes have been made to the design of the stove, allowing you to confidently heat steam rooms in log houses from sub-zero temperatures.

The stone fastening system of the new stoves is interesting: a holder with hooks is mounted on a stone cut into plates. These hooks are used to fix the stone slats in a special groove. The system is simple but effective, and installation is very easy and takes less than an hour.

This is what the new Feringer Lamel oven looks like

Design Features

The designers of the Feringer plant regularly experiment, so the furnaces of this company demonstrate high combustion quality, low heat loss, and a perfect steam creation process. The design of the stoves makes their operation as convenient as possible.

Features of the design of Feringer furnaces:

Solid bent firebox

“Extra parts” have been replaced in the furnaces. Instead of a system of elbows and adapters, the designers created a firebox that is radically different from all previously developed ones; the firebox is made of high-alloy stainless steel and reinforced with stiffeners. It may become slightly deformed over time, but this does not affect the operation of the oven.

Closed heater

Popular sauna stoves mainly have an open heater and a small closed one inside it. Feringer has a completely enclosed heater. Its main task is maximum heating of the stone. It envelops the firebox. In the furnace at the factory, the stone was heated to 600 degrees! At the moment, no indirect heating sauna stove has more indicators.

Steam generating cassettes

This is a water distribution system using special funnels. When choosing which of the three zones you want to get steam from or from all of them at the same time, pour water there. It does not fall on the upper stones, but, distributed along the given channels, ends up on the steam generating cassettes.

Overheating, the steam passes through all layers of the filling and takes heat from each stone. The steam obtained from the cassettes gently envelops the entire space, and also prevents the destruction of stones and the entry of stone dust into the steam and air.

Lack of grate

This design has advantages compared to grate furnaces. Firewood is placed in such a firebox in a special way. Place the largest ones at the bottom, medium ones in the middle, and wood chips and small firewood for heating at the top. The fire, with such combustion, immediately begins to warm the stones and evenly goes down. Feringer ovens are one-piece ovens.

No need to add fuel

One tab is designed for a vaping cycle. When the wood begins to burn out, you need to open the ashpit and close the top valve. Thanks to this manipulation, the coals from the firewood will burn out completely and, if the firewood is of good quality, only ash will remain.

Vortex system

The smoke tooth, thanks to which non-exhaust gases make a spiral-shaped circle in the firebox, are burned and come out as waste. With a vortex flow system, efficiency increases to the maximum.

Top ignition

The unique combustion system allows you to warm up the room for a full session from one tab. But if you want to prolong the pleasure, you can add additional logs.

Clean glass system

There is a gap above the glass of the oven door. Due to this, the “cold” air that penetrates through the inlet flows down the glass and cuts off smoke and flames. This keeps the glass clean. This principle is often used in fireplaces.

Special chimneys

It has been proven that the more efficient the chimney, the faster the steam room will warm up. Fehringer chimneys are designed so as not to remove smoke immediately, but to remove heat from gases and speed up heating.

The real decoration of the bathhouse is the chimneys lined with natural stone using Lamel technology. This is a continuation of the stove, preserving aesthetics and protecting against harsh infrared radiation.

Feringer stoves use 3 types of chimneys:

Convector

Provides maximum air exchange in the room and helps warm up. Built-in channels distribute air flows, taking cold air from below, warming it up and releasing it at the top using a regulator. The kit includes a draft regulator - gate.

Economizer

A chimney that provides quick heating of the steam room. It contains 4 pipes of 60 mm each. Each has a built-in spiral swirler that prevents heat from freely escaping outside. It enters the convection channels, and then directly into the room. The economizer increases the efficiency of the furnace.

Register

The main purpose of this chimney is to heat water for showers and baths. The design has a built-in register made of heat-resistant stainless steel with a thickness of 1 mm. It effectively uses waste heat from the stove, heats the water and provides air convection in the steam room.

Fehringer steam evaporator - a special design part

PIF effectively solves the problem of quickly warming up and saturating a steam room with moisture, as well as creating comfortable conditions for steaming. This unit has been produced since 2021.

The mutual fund performs the following tasks:

- increases fire safety by reducing the temperature of the chimney;

- increases efficiency by 10% due to temperature extraction from exhaust gases.

Heating of the PIF occurs as a result of intense heat transfer from gases. The part experiences heavy loads due to temperature changes and in order for the PIF resource to correspond to the firebox resource, it is made of heat-resistant stainless steel with a thickness of 2 and 3 mm.

The plant produces 3 modifications of mutual funds:

Standard

Pro

Station wagon

Dekron

This decorative module is designed to aesthetically complete the chimney system installed after a special chimney in front of the PPU. Closes the chimney system in the steam room and creates a finished look in the steam room. Decron is made of natural stone and a metal frame.

Available in 2 versions:

- with clamp, for installed chimney system.

- for installation.

This element is manufactured according to the individual parameters of each furnace and installation location. To order Decron with a lock, you need to measure the height from the open convection cover to the ceiling.

Reviews from owners of Feringer sauna stoves

We did not take into account the impressions about using the stoves that are on the manufacturer’s website. We present only those posted in discussions on the forums.

I had a Malyutka with a closed heater. Great stove. But then Lamel appeared, and I bought it for my new bathhouse, and with a portal. It looks very nice in the rest room. Compared to Malyutka, it takes 20-30 minutes longer to heat. But I now have an Optima, and this comes with the cladding of an additional 200 kg of stone. My wife likes it better, she says the warmth has become softer. But I miss the powerful sound when steam comes out that Malyutka had. This one has enough steam, but there is no sound. I'll remake this model of the gun so that it also hisses. But these are my problems, but everything works fine.

Philip, Priozersk

What I like is that the Lamel can be installed without a screen. I measured mine with a pyrometer. The lid at the top (I have a stone one) heats up to 170°, the lamellas at the top up to 120°, the middle - up to 70°. So everything is fine with fire regulations. You just need to insulate the combustion tunnel well. Here it is heating up harshly.

Nikolay, Moscow

Today I heated the Lamelya Optima bathhouse after a three-week break. During this time it froze completely. Everywhere it was -10-12°C. It took me two bookmarks and three hours. Only then did we go to take a steam bath. The temperature was already around 45°. While we were warming up, she grew up. But I won’t take any more breaks like this. It took a long time for everything to thaw out.

Vladimir, Peter

Models

Feringer sauna stoves are divided into 2 types: stone and metal. Metal ones are suitable for budget steam rooms. But if you want to feel the full effect of a Russian bath, there is only one way out - choose a stone.

The cladding completely eliminates infrared radiation from users. You cannot get burned from the furnace body. The only downside to the stoves is the price. A stone-clad stove with the cheapest stone costs on average three times more.

Metal stoves are made from exactly the same metal and thickness. Everything is identical except for the missing stone. Great respect to the founder of the company that he does not skimp on budget stoves, but produces the same quality ones from metal as from stone.

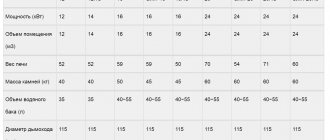

In terms of power, there are three options for stoves designed for different volumes of steam rooms:

Baby – 8-16 cubic meters/m

Classic – cubic/m

Harmony – 12-30 cubic meters/m

In 2011, a new line of stoves appeared - Lamel. It is distinguished by the presence of natural stone cladding. Some changes have been made to the design, allowing you to confidently heat steam rooms in log houses from sub-zero temperatures.

The stone fastening system of the new models is interesting: a holder with hooks is mounted on the stone cut into plates, with which the lamellas are fixed in a special groove. The system is simple but effective, and installation is very easy.

Brand series

Two popular and unique series of stoves for baths and saunas differ significantly from other manufacturers.

The brand has two types of equipment:

- Series "Lamelle". Such stoves have a beautiful finish made of natural stone. Stone lamellas can even be used in cladding the walls surrounding the heating device. Such units have a closed heater - first the stones are heated, then the steam room itself heats up from them. Thanks to the “Upper Ignition” combustion system, such stoves are very economical - one load of firewood is enough to heat a room for 3-4 hours. The Lamel series has several types that are suitable for different room sizes: Mini, Optima, Maxi. Facing lamellas can be made from the following types of natural stone: serpentine, jadeite, Silviaro marble, Rossolevante marble. There are often combinations of different types of stones in one piece of equipment.

- Series "Steam ovens". Devices of this type help create ideal conditions for a true Russian bath, because a large amount of soft, fine steam heals the body. This type of oven does not have a grate, which simplifies the process of maintaining the equipment. An important feature of “Steam stoves” is maintaining the most comfortable temperature for a person in a steam bath. This series also varies in size: Baby, Classic, Harmony.

- The “Golden Ratio” is a wood-burning stove for saunas. They have three subtypes, depending on the volume of the room: Malyutka, Classic, Dobrynya. The firewood should be short in length and should be stacked on top of each other, filling only 3/4 of the stove. You can use chopped pieces of firewood.

Advantages and disadvantages

Advantages of Feringer ovens:

- the oven heats the stone as much as possible, resulting in light steam;

- good quality high-alloy stainless steel increases service life;

- The vortex system increases the efficiency of the furnace.

- fuel economy;

- non-hot outer walls, making it impossible to get burned from a melted stove;

- clear glass system.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

The disadvantages of stoves include the difference in operation from other varieties. When kindling the Feringer, you need to strictly follow the instructions and get used to it a little.

TOP 4 best models

Feringer stoves are always popular among lovers of Russian baths. The following models received the best reviews.

MINI

The model is designed for steam rooms with a volume of up to 16 cubic meters. The combustion chamber is made of heat-resistant stainless steel, the door is equipped with a viewing glass.

The MINI model can be used in rooms with a volume of up to 16 cubic meters. Its design includes a phytocontainer for aromatherapy and a steam gun, which will help make your sauna experience feel like visiting a spa salon.

Advantages of the model:

- minimum convection in the oven;

- stylish design;

- creates good steam.

- The disadvantages include the need to select a certain size of firewood: shorter than standard ones.

OPTIMA

Stylish stove released in 2021. The model is suitable for a steam room that needs to be equipped in the form of a Russian bath. The volume of the room should be no more than 18 cubic meters.

The heater type in the model is closed. It can hold up to 100 kg. The stove unit is installed “through the wall”, that is, the heater is located in the room, and the remote portal is in the next room.

Advantages of the model:

- possibility of facing with 10 types of stones;

- installation using the “through the wall” method.

- The disadvantage is the high cost.

MAXI

The large Feringer oven is designed not only for cleaning, but also to make you feel light and calm. The unit is designed for rooms up to 30 cubic meters. The buyer has the opportunity to choose one of 10 colors of stone for cladding the equipment.

Advantages of the model:

- steam gun and phytocontainer included;

- saving on fuel;

- modern and reliable design solutions.

- The only drawback is the high price.

DOBRYNYA

The model is suitable for steam rooms with a volume of up to 13 cubic meters. The oven is easy to maintain and is equipped with a reliable convector. The remote tunnel is covered with a special casing. A water container is mounted in the upper part.

The Dobrynya stove allows you to create the necessary heating in a room with a volume of up to 22 cubic meters. It is considered very effective for steam rooms with wet hot steam. The stove is absolutely safe to use, durable and reliable.

Advice! It is recommended to line the sides of the Dobrynya stove body with bricks.

Types of devices and their brief description

Feringer stoves are made for saunas and baths.

Depending on their purpose, they are divided into devices:

- with a closed heater, “steam installations” for a bath . The internal structure of such units is the same, only the size differs. Such baths have either a panoramic screen or doors made of glass or cast iron and are called “Lamel”, as well as “Steam ovens”. The Russian bath mode, at the same time, can be provided by three categories: Malyutka for small steam rooms up to 16 cubic meters;

- Classic steam room for medium-sized rooms - up to 18 cubic meters;

- Harmony - for large steam rooms up to 30 cubic meters.

- Baby - for a steam room up to 16 cubic meters;

Installation rules

Installation of the stove and smoke ducts must be carried out by qualified employees of a specialized construction and installation organization. If you decide to do it yourself, it is important to follow the recommendations and technology.

Housing installation

The furnace is installed on a refractory base with a height of 150 mm. If the floor in the room is wooden, to protect it from fire, it is covered with two layers of brickwork with clay mortar. Between the floor and the bricks there must be a layer of basalt cardboard with a thickness of at least 10 mm. The size of the base or brick platform should protrude beyond the dimensions of the stove at the back and side by 100 mm, and at the front by 500 mm.

The distance from the stove to the wall made of combustible materials must be at least 500 mm. They can be reduced to 200 mm if there is protection with a metal sheet over a 10 mm thick layer of basalt cardboard or brickwork. The protection height is at least 700 mm from the top of the stove. The distance from the oven door to the opposite wall must be at least 1250 mm.

The section of the ceiling above the stove and connecting pipe must be made of non-combustible materials. The combustible ceiling is covered with a metal sheet over a layer of fireproof insulation with an area exceeding 1/3 the area occupied by the stove, while the overall dimensions of the insulation must be at least 300 mm larger than the plan dimensions of the stove.

If the furnace is located on the border of two rooms, the partition for installing the tunnel must be made of non-combustible materials. It is best to use brick to a height of at least 1600 mm. To prevent thermal deformation of the brick, basalt cardboard with a thickness of 10 mm and a basalt slab with a thickness of 40 mm must be laid between the tunnel and the masonry.

The wall on the stove side must be protected by a fireproof metal sheet with a thickness of 0.5 mm, a width exceeding the width of the stove itself by at least 200 mm on each side and a height to the ceiling. The floor in front of the firebox must be protected with a metal sheet measuring at least 700x500 mm.

To install the stove “through the wall,” make or pre-design a hole in the wall with dimensions such that there is free space around the tunnel, approximately 40-50 mm.

Unscrew the self-tapping screws on the front panel and remove the stove facade with the shelf. Install the stove in the steam room on a prepared base with a tunnel into the wall. Seal the space between the tunnel and the wall with fire-resistant mineral wool. Install and secure the portal.

Important! If in the future you plan to install a decorative portal in natural stone cladding, provide an additional gap between the stove body and the wall to avoid additional costs.

Installation of mutual funds

When installing the steam evaporator, proceed as follows:

- Install the PiF on the top surface of the firebox, and the starting pipe on it.

- Fill the heater. Place the stones in a cold oven, preferably at an angle of 60 degrees.

- Install a base plate on the stove with a built-in installation for distributing water supply to the stones and P&F.

- Water is poured into the PiF through a water supply container oriented into the middle channel of the built-in water supply system in the support plate.

- Install a water supply container.

First firebox and subsequent operation

The first fire of a fully finished stove with stones placed in the heater must be done in active mode so that the fireplace and the stones warm up. Then let it cool slowly.

Attention! During the first fire, it is strictly forbidden to supply water to the PiF. This is necessary to relieve stress in the nodes after welding. At temperatures of zero degrees and below, the presence of water in the PIF housing must not be allowed to avoid deformation, damage and leakage.

Using mutual funds

In order for the steam evaporator to work correctly, it is important to follow the instructions:

- Open the distribution valve, pour water into the PiF. Add in portions of 50-100 ml. at short intervals of 10–15 minutes in a heated PIF will speed up the warming up of the steam room, which is especially important in the cold season.

- PiF, heated by flue gases from 300 degrees with a noise effect, evaporates water. The steam mixes with air, forming a steam-air mixture, is heated from the chimney and exits into the steam room, further heating the room.

- Pouring water in a large volume of 1–1.5 liters will speed up the heating and humidification of the steam room. The water in the container boils and steam comes out through the exhaust channel with a temperature of up to 150 degrees, then the steam mixes with air, forming a steam-air mixture, is heated from the chimney pipe and exits into the steam room, heating and humidifying the room.

- After heating the stones to 300-500 degrees, close the steam distribution valve and pour 1-1.5 liters of water into the PIF. The resulting steam, passing through the heater, overheats and, forming a steam-air mixture, enters the steam room. This will create the conditions for a pleasant procedure. Water can be refilled.

Important! During operation, it is prohibited to install devices at the outlet of the steam evaporator that prevent the free exit of steam.

FAQ

I bought a Feringer stove, but I'm not very happy with it. Takes too long to warm up. Can I somehow fix it?

The use of damp firewood leads to prolonged heating. The resulting steam sharply reduces the flame temperature, and heat transfer to the underlying layers is slow.

The combustion tunnel of the Feringer Classic stove heats up red-hot. This is fine?

No. Firewood is burning in the tunnel, but this should not happen. They should lie in the combustion chamber, up to the side. The tunnel itself is made of less alloyed metal and is not designed to withstand open flame temperatures. Over time, he may be led away.

To warm up the steam room to 70 degrees, I heat the stove for up to 8 hours. Is it possible to somehow fix it, that is, speed up the warm-up?

The reason may be that the stone is laid too tightly. Close the damper by a quarter as soon as the fire is well lit. Open the stone blower and remove the phytocontainer.

Design of sauna stoves - with open heater

There are fewer requirements for sauna stoves, and their structure is simpler. Their main task is to quickly heat the steam room to the required temperature, and then ensure its maintenance.

Design of sauna stoves from Fehringer

There is almost no steam in dry-air steam rooms; if you occasionally add one or two ladlefuls, then more for aromatization. Therefore, the volume of the heater is small - it should be enough to heat the steam room. They do not perform any other functions.

Adjusting the combustion intensity is the same as in sauna stoves: a valve above and below the fuel door.