I wanted to have my own bathhouse at my summer cottage. I have already built the base, and now I am working on a stove with a water tank. I decided to use a samovar-type tank because of some of its advantages, but before that I studied two other design options. Next I will talk about sauna stoves with tanks for water in the bathhouse and, in particular, a little about installing a samovar-type water tank.

Source kakprosto.ru

Common types of tanks

Various samovar-type tanks for bathhouses are widely used today. All of them are practical, effective, and differ in the area of contact with heating surfaces. For all of them, the same task is not to bring the water to a boil, so that coarse steam that is difficult to breathe does not form in the steam room.

Types of tanks:

- pipe;

- remote;

- external;

- built-in

Most often, owners use pipe-type tanks. They are practical, the area of their contact with the heating chimney is very large. Such tanks for sauna stoves are located in the steam room, in the attic of the sauna.

There is an important point to consider here:

- ease of use;

- method of filling the tank with fresh water;

- no direct contact with the oven.

The container does not have contact with the heater and allows it to warm up at full strength. The pipe tank is capable of maintaining the heat of the water for a long time, obtained after it has completely warmed up. The required water temperature is maintained by low combustion of the heater.

Remote-type tanks are convenient because they can be placed anywhere in the steam room. Such tanks receive heat from the stove through a heat exchanger installed on the chimney; in design, these schemes most closely resemble samovar-type tanks for sauna stoves. Two pipes are stretched from the heat exchanger to the tank, ensuring natural circulation of water according to the law of physics - warmed water will rise upward, and it will be replaced by cold water coming from the lower pipe. This method of heating water is considered the slowest; the water almost never comes to a boil.

External tanks with a heat exchanger device are highly valued by dry steam lovers. They are convenient when the bathhouse is divided into two compartments - a steam room and a washing room. In this case, the container is installed in the washing room. Water circulation is accelerated when using this scheme by additionally installing a water pump. Practice shows that using this scheme, water takes a long time to warm up: in the summer - in 1.5 hours, in cold winters - in 2-2.5 hours. But at the same time, the steam room is filled with dry heat. There is a minus to the bathhouse design with a remote tank - in winter, if the remaining water is not drained, it will freeze in the heat exchanger pipes, especially when using flexible corrugated pipes.

Most often, built-in tanks are used in Russian baths. Practice shows that they provide the highest efficiency indicators. Heating of water occurs faster than in furnaces built according to other schemes, since a large area of the tank is in direct contact with the fire in the fuel compartment of the furnace.

At the same time, when installing a stove with a built-in tank, some nuances must be taken into account:

- the volume of tanks used is limited by the design of the furnace;

- rapid heating of water leads to its boiling, the formation of coarse steam, which increases humidity;

- to prevent early boiling, the owner monitors the heating of the water, constantly draining the hot water and replacing it with cold water;

- the water tank can take heat away from the stove, preventing it from heating up; Completely filling the tank and heating it above 100 degrees requires the furnace to release all the thermal energy and interferes with the normal heating of the stones.

A stove with a samovar-type tank is shown in the photo.

The photo shows a samovar-type heat exchanger:

Mounted

This design option is hung on a standard metal sauna stove. The presence of metal walls of the furnace is mandatory, since heat is transferred through one of them to the water in the tank. This design is not widely used due to low efficiency, but its main advantage is maximum simplicity.

A hanging tank for a bathhouse is usually made of thin stainless steel. It is placed outside the stove and located in a visible place in the bathhouse. Stainless steel is not only an ideal material for water tanks, but also has a beautiful appearance.

When you need the simplest tank for hot water in a bathhouse, wall-mounted installation is best. With it, you don’t even need to do pipe routing. The tank is delivered completely ready.

The bath tap for hot water is also included with the tank upon purchase. The spigot is located at the center of the lowest point, and the bottom is usually flat or has a conical stamping.

The inconvenience of this location of the tap is the small distance from the floor. In addition, the stove is often placed in the corner of the bathhouse. One side of it is occupied by the door, and the other by the tank. Thus, it turns out that the tap is in a very inconvenient place. This problem is solved by installing a pump.

Information. For a wall-mounted tank, the sauna stove should be standard. This is either a ready-made structure, or a home-made one, but having at least one flat metal wall of the appropriate size for the tank.

Wall-mounted tanks have either a removable lid or a filler neck with a diameter of at least 10 cm. A filler neck is much more common. It makes cleaning and processing the internal space somewhat more difficult, but makes the structure more durable.

The cheapest designs of hanging tanks are welded from sheet steel and galvanized. The service life of such structures is short. Stainless steel thin-walled structures are gaining popularity.

Due to their small wall thickness, they are affordable. Steel enameled tanks are rarely used as hinged tanks on the stove.

Pros and cons of samovar-type systems

Tanks installed on pipes leading from the furnace are called samovars. They are an integral part of the elbow on the chimney pipes. This installation is convenient and provides quick and uniform heating of water. In addition, the design is compact and can easily be placed in any bathhouse.

Negative points

- inconvenient filling of the container with water; this issue is solved by placing the upper part of the boiler in the attic with a water supply;

- possible miscalculations in using tanks of inappropriate volume, as a result of which the water quickly reaches the boiling point.

Positive points

- correct choice of container material – stainless steel; it is not afraid of corrosion and serves its intended purpose flawlessly for a long time;

- the high coefficient of thermal conductivity of stainless metal ensures rapid heating of water in the samovar tank;

- the strength of stainless materials does not allow the container to deform due to temperature changes;

- safety of the purchased ready-made samovar tank.

A wood-burning bathhouse is a place of high fire danger. When using home baths, you must follow precautions to avoid burns from hot water or fire. If all conditions stipulated in the Fuel Tank Operating Instructions are strictly followed, the likelihood of unforeseen injuries and dangerous situations is prevented. It is important to remember to fill the container with water in a timely manner, do not flood the stove with an empty boiler, so that the high temperature of the fire does not deform it or damage the welds. In winter, when the bathhouse is not heated, it is necessary to drain the water from the system so that it does not freeze to ice - this can lead to rupture of the metal.

What is the design

- The principle of operation is that from a large tank to a small one, cold water flows through the drive pipe, is heated in the small tank, which is called a heat exchanger, and returns through the outlet pipe to the main tank, already heated.

- If the drive and outlet pipes are positioned at the correct angle, then the water will successfully circulate by gravity thanks to natural physical laws. But in order to avoid the formation of air pockets in the system and ensure faster and more uniform heating of the water, the tank for the heat exchanger in the bathhouse is equipped with an electric pump for forced circulation of liquid in the system.

- The heat exchanger can be located directly next to the firebox itself, in which case it is installed at the stage of construction of the furnace inside the structure. Or it may have the so-called samovar operating principle, when a small tank is mounted around a metal chimney for a bathhouse directly next to the firebox.

- But regardless of the location of the tank, professionals prefer systems in which the liquid circulates freely, without additional pressure.

And a little about scale in boilers

If a summer house or cottage with a bathhouse is located in a region with hard tap water, scale will form in the boilers. It is deposited in the place of extreme temperature heating, reduces the rate of heating of water, and significantly reduces the conductivity of heat in the pipes. Scale from hard water constantly builds up in an uneven layer and has a high coefficient of heat resistance.

The appearance of scale inside the pipes reduces the strength of the samovar sections of the chimney, reduces the service life of the entire structure, and deteriorates the samovar-type heat exchanger. If pipes and boilers are not cleaned of scale in a timely manner, water floods the fuel compartment of the stove.

- Advantages and disadvantages of metal siding

TOP 5 popular myths about plastic windows

We are building a house, what should we pay attention to?

Recipes for folk remedies against scale

- Baking soda . In the tank, bring the water to a boil, pour a pack of soda into it. Then let the water cool and bring it to a boil again. Drain the water and soda, fill the tank with clean water, pour half a glass of vinegar essence into it. Bring to a boil, leave to cool. Bring to a boil again and pour out after half an hour. The influence of soda and acid loosens the scale; it is removed with a hard sponge or brush.

- Lemon acid. Not sparing the bags of lemon, pour it into a tank of cold water, then bring to a boil. Let it sit for a while, drain the water with citric acid, fill the tank with clean water, and bring to a boil. The acid breaks down all the scale deposits, the tank is rinsed with clean water. The method is cheap, fast-acting, but has a significant drawback: the acid, acting on scale, affects the metal material, its surface will be rough, and fresh scale will quickly appear again. It will become more and more difficult to clean the boilers with lemon each time.

- Vinegar . Pour a glass of vinegar into the filled tank and boil for 20 minutes. The acid acts effectively, its disadvantage is the residual odor. You need to clean the boiler with the windows open, then rinse the system thoroughly and ventilate the room for a long time.

Today, all methods of heating water in home baths are widely used. The designs of the various systems are well thought out, easy to use and safe. It is important to fulfill all installation conditions efficiently.

Which material to choose?

Cast iron tanks

Cast iron tanks

The popularity of cast iron tanks has decreased markedly with the advent of stainless steel tanks. However, in most old baths you can see just such tanks, traditionally bowl-shaped, built into the stove. Large tanks were additionally secured with metal chains suspended from the ceiling beams to reduce the load on the stove.

Water boiler suspended on chains in a black bathhouse

Advantages of cast iron:

- very durable material;

- has the ability to retain heat for a long time;

- not subject to corrosion;

- resistant to high temperatures;

- easy to clean from dirt.

Flaws:

- weighs a lot;

- takes a long time to warm up.

Enameled tanks

Enameled tanks

Enameled steel containers are excellent as remote tanks. In the absence of direct contact with fire and careful handling, they are very durable. There are models for installation on a pipe, mostly rectangular in shape

The most important thing when installing and operating enameled tanks is to avoid mechanical damage. In places where the enamel is chipped, unprotected metal begins to rust very quickly

Minor damage can be repaired with special paint, but if the chips are large, the tank will have to be replaced.

Advantages:

- relatively light weight;

- aesthetic appearance;

- ease of care.

The only disadvantages of enameled products include low resistance to mechanical damage.

Stainless steel tanks

Stainless steel tank

The most popular type of sauna tanks. Due to the variety of models, such tanks can be mounted in any of the described ways - built into stoves, mounted on a wall or around a chimney. The main thing here is to choose the right wall thickness and container volume.

Stainless steel tanks of various shapes and sizes

Advantages:

- long service life;

- resistance to deformation and corrosion;

- light weight;

- variety of models in shape and size;

- hygiene;

- heat resistance;

- high thermal conductivity;

- attractive appearance.

Open stainless steel tank in a bathhouse

Flaws:

- high price;

- cool quickly.

DIY sauna tank

Small heating stove

Small additional oven

It can serve as additional heating, increasing the flow of hot air. On one side there will be a water tank, lined with bricks on the inside.

Stove from the store

The simplest option is to find, select and buy what you need without resorting to physical labor. The choice in specialized companies is now quite wide, so you just need to decide on it.

Heat exchanger on pipe

Heat exchanger for pipe

The temperature of the gas leaving the sauna stove is quite high, so it is advisable to use it. Accordingly, the heat exchangers, which will be discussed further, are attached only to the single-wall metal pipe of the furnace.

Heat exchangers for chimneys are also called samovar. The water in them heats up evenly and quickly enough, circulation occurs very quickly, and fuel savings are achieved. Additionally, such heat exchangers are a kind of fuses that prevent any leakage of smoke from the chimney into the room.

The heat exchanger and pipe are joined using heat-resistant sealant (up to 1000 degrees) and clamps. The pipes are connected using the technology discussed above.

Connecting the heat exchanger on the pipe

It is not necessary to make such a heat exchanger yourself; the cost of factory-made products is presented in table form.

Technical characteristics and prices of heat exchangers

Chimney diameter 105 mm Chimney diameter 115 mm Chimney diameter 130 mm Price, rub. 279028905290

| Volume, l | 8 | 8 | 20 |

| Steel | Stainless steel – 0.5 mm on the sides and 0.8 mm on the bottom/top | Stainless steel 0.5 and 0.8 mm | Stainless steel 0.5 and 0.8 mm |

| Weight, kg | 2,5 | 2,5 | 4,5 |

| Height, mm | 500 | 600 | 665 |

| Fittings | 3/4″ x 2 | 3/4″ x 2 | 3/4″ x 2 |

Samovars for baths

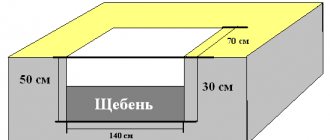

remote water tank

The main material for the manufacture of such a stove is a “potbelly stove”. It already has a water container inside. We place a chute for stones on top. We make the stove and register from sheet steel four to five millimeters thick. We make the tank separately and install it above the register itself. The register and tank are connected using tubes (a hose may also work).