Termopool wood heaters are ideal for heating water in frame, inflatable and stationary pools. The water heater runs on wood and other types of solid fuel. The spiral of the wood heater is made of stainless pipe 32x2 mm. brands AISI 304 (Volcano Pro series) and 32x1.5 AISI 304 (Volcano Lite and Basis series) Often used for watering heat-loving plants in garden plots. Simple and fast connection to the system. The spirals of the TERMOPOOL wood heater are guaranteed to withstand 15 atmospheres. When water boils, the heaters are not damaged!

| Water heaters for pools and hot tubs (VOLCANO / BASIS) |

GO TO CATALOG WATCH VIDEO REVIEWS FROM OUR CLIENTS ›

Heating methods

Among the main methods of heating a pool, used in most cases, are:

- Electric running water heater;

- A heat exchanger with a pump that delivers heat from the main fuel boiler used for heating or heating water in the house to a frame or permanent pool on the street;

- Heat pumping equipment for moving cold water into the water heater, and warm water back into the pool bowl;

- The most modern device for heating water is a solar collector;

- Heating water naturally is the most economical option, but loses in speed.

Electric heater

One of the most popular and relatively inexpensive devices is a flow-through electric heater, characterized by ease of installation of all components in any room and a high degree of security. The principle of operation of the device is based on the rapid heating of the water entering it using a powerful electric heater installed inside the housing and powered by a 220 W city network. The price of a heater for a pool with a volume of 50 m3 is within 24 thousand rubles.

You can select a flow-through heater for heating a pool based on the size of the reservoir. The standard power calculation scheme for maintaining heat is 1 kW per 5 m3 of water.

The main disadvantage from which the heater is not protected is the huge consumption of electricity. To heat water in a pool of standard volume you will need about 1.5 thousand kW.

Heat exchanger

If a solid fuel boiler is already installed in the house or when planning to install any stationary heat source, an excellent alternative to an electric heater would be to heat water using a heat exchanger with a circulation pump that takes heat from the source (for example, a boiler) and redirects it to heating an indoor pool.

The cost of the boiler is equal to the cost of the electric heater. The boiler runs on solid fuel and does not depend on electrical networks, and therefore can be used in houses heated with wood or coal. More modern high-power models use gas fuel.

Heat pump

A more economical option for heating pool water using electricity is to install not a separate heater, but a heat pump, the operating principle of which is similar to an air conditioner.

This type of water heater is expensive, but it pays for itself with its efficiency. When operating, the heat pump consumes 7 times less kW of energy than a standard electric heater. The water heater will pay for the difference in cost of approximately 60 thousand rubles in 2-3 seasons of maintaining heat.

solar collector

The least energy-consuming, but not too powerful way to heat water in a frame pool in a small country house, outdoors or indoors, is to install a solar collector that operates without fuel and uses the energy and heat of the sun for heating. The principle of operation of the device is very simple, and consists in delivering water to the coil, passing it through a tubular structure, where the liquid is heated, and then delivering it to the pool. The movement of water in the tubular heater is carried out by the operation of a small electric pump, which is controlled automatically, and the heat of the water in the pool is regulated manually.

Heating using a heat exchanger

If a winter pool is installed or with a large tank, then heating is installed based on a heat exchanger. It connects directly to the heating system of the house, powered, for example, by a gas boiler. Made in the form of a coil in a flask through which hot water flows.

The coolant moves due to the circulation pump. The liquid enters the flask, where it is heated by the coil. With each new circle it heats up more and more. Then it returns to the bowl. The process is automatic and does not require special control. The user only sets the temperature on the thermostat.

The heater is selected based on the dimensions of the pool. On the first day, turn it on at maximum power, then maintain the optimal temperature. In this case, sudden changes should not be allowed.

- heats large volumes with less energy consumption;

- ease of use.

The technique is used for frame and inflatable models. In winter, organize additional insulation of the structure. Otherwise, most of the heat will escape into the atmosphere.

Lifetime.

Spirals made of stainless steel are not subject to corrosion, even when used in salt pools with cleaning based on a chlorine generator, their corrosion will be less than 0.01 mm/year. Thus, the service life of a pool heater is practically unlimited and is at least 15-20 years.

| Stainless steel pipe |

Spirals made of black steel are susceptible to corrosion and aggressive environments, so their service life is much shorter than that of stainless steel spirals and averages 5-7 years. Termopool does not manufacture heaters from stainless steel

| Hot rolled pipe. |

Gas

Gas heaters occupy a worthy place in the line of water heaters for swimming pools. According to operating conditions, they are the most economical. High power (115 kW) allows you to heat large stationary pools. Natural gas or propane is used for combustion. They allow you to quickly heat up the water in the pool and easily maintain a constant temperature.

Gas heaters, compared to wood heaters, require virtually no special maintenance. This is understandable - when gas burns, it leaves behind no ash, ash, or soot. But when using a gas water heater, problems of a different order arise.

Installing a gas boiler requires not only special skills, but also permission from the gas service. Therefore, issues of gas supply, gas pipelines and installation of gas equipment require the intervention of professional specialists.

The principle of operation of a gas heater is simple - gas, burning in the combustion chamber, releases heat, which heats the water. With proper installation and timely maintenance, gas water heaters can operate uninterruptedly for about six years.

Pool heating with wood

Heating a pool with wood is the easiest and most inexpensive way. Moreover, in addition to firewood, you can use coal, which burns longer.

The advantage of a wood-burning water heater is its ease of use. The wood-burning water heater has a second name - titanium.

The cost of a wood-burning water heater for a pool starts from 18,990 rubles.

The principle of operation of a wood heater

The main idea is a coil that is heated by fire. Water is pumped through the coil and heated. It's a kind of oven. If you do it yourself, you can use:

- A large ready-made tank made of durable metal, or weld the container yourself.

- A metal hollow coil will be placed inside the tank. At one entrance of the coil, with the help of a pump, water is expelled from the pool. From another exit she comes out warmed back into the pool. This is how wood heating of a pool occurs.

- The pump must be powerful enough to prevent the water in the coil from boiling.

- Using adapters and clamps, strong garden hoses or plastic pipes are attached to the coil, through which water is collected and supplied.

Some have come up with the idea of boiling a coil in the form of a tank where firewood is placed. This method is even simpler in design. The convenience of such a home-made stove is that you can heat an outdoor pool both at the dacha and while relaxing in nature. Where there will be enough firewood. If you use coals, they will smolder longer and retain heat in the tank.

You can also heat the water in the pool with wood using a ready-made stove, which can be purchased in a store or made to order. It is similar to a samovar, in the container of which there is also a coil. Thanks to the sleeve attached to the body, smoke will be removed and heat will be better retained. In addition, such a device looks aesthetically pleasing and does not spoil the appearance of the site.

The choice is yours. Firewood today is cheap and environmentally friendly. Besides, the flames from the fire are a kind of romance! You need to be able to enjoy any day spent in good company in nature, away from the concrete jungle!

Equipment and accessories.

The flagship of the TERMOPOOL heater line is the VOLCANO PRO 50 model. Its package includes everything necessary for complete and fast heating of water. Namely: A 36m spiral reinforced with stainless wire (stainless steel pipe AISI 304 32*2mm), coated on the inside with heat-resistant enamel up to 1000 degrees. The lid is made of stainless steel AISI 304, (3mm) with reinforcements from a 15mm stainless steel square and decorative elements also made of stainless steel. The chimney is made of stainless steel. Consists of two pipes 0.5 m, diameter 140 mm, a valve and a deflector. A 0.8mm stainless steel screen that completely covers the spiral. The stand (made of 5mm steel and made using laser cutting) is covered with heat-resistant enamel. The grate is made of cast iron 20mm thick. Stainless steel ash bowl. Ring/Casing with decorative cut and door for convenient removal of ash. (made of stainless steel 0.8mm thick) height 180mm.

VOLCANO Pro package |

For those who want to cover the heater with stone or install it in an existing stove, we have produced a series of BASIS 2021 heaters. The standard Basis kit includes:

Spiral (stainless steel pipe AISI 304 32*1.5mm), coated on the inside with heat-resistant enamel up to 1000 degrees. The stand (made of 5mm steel and made using laser cutting) is covered with heat-resistant enamel. The grate is made of cast iron 20mm thick. Ring/Casing (0.8mm thick stainless steel) around the stand, height 150mm.

| Standard kit BASIS Pro |

Additionally for the BASIS series you can purchase:

A cover that will increase the power of your pool heater by 15-20%. The cover is made of 3 mm. steel painted with heat-resistant enamel. The lid hatch allows you to install a cauldron, smokehouse or grill in its place. Combine heating your pool with cooking!!! The lid has an outlet for the chimney.

| Heater cover |

| Basis series standard set on the left, with screen and cover on the right. |

The protective screen gives the finished look to the spiral. It protects you from heat and, unlike the coil itself, which is covered with soot and condensation smudges, keeps the heater looking beautiful for many years! The protective cover will protect the pool from heat and sparks.

Spiral power.

To heat the water in the pool, a large amount of thermal energy is required. Among the possible heating methods, we offer the most economical and effective - heating the pool with wood. The power of water heaters varies from 18 to 55 kW, depending on the number of turns. To heat water in a small-volume pool, you will need a Basis heater - 18 kW. For owners of large swimming pools, you will need a Volcano Lite 50/Volcano Pro 50 heater with a power of 55 kW. Heating a pool with wood is the most economical way to heat water, because the consumption of dry birch firewood for the most powerful Volcano 50 model is only 20 kg/hour. Efficiency = 70% All water heaters are tested for tightness with a pressure of 15 atm. (Electric welded pipes burst under a load of 170 atmospheres).

| Pool water heating table (BASIS series) |

LEARN MORE ABOUT BASIS›

| Pool water heating table (VOLCANO Lite/VOLCANO PRO series) |

LEARN MORE ABOUT VOLCANO ›

GO TO CATALOG ›

We personally measured the power of our pool heaters, and we can guarantee this result, the above power can increase or decrease, it all depends on the intensity of combustion, the type and moisture content of the wood, we give average stable performance when burning birch logs.

Watch the video:

| Video. Power measurement. |

| Video. Termopool Volcano after a year. |

Wood burning stove

Solid fuel stoves can handle any volume of heated water in the pool, they are easy to operate and economical.

You can choose the right stove for heating a pool by determining the task that the equipment faces:

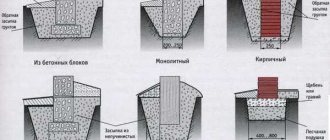

Heating year-round pools with a large volume of water, maintaining a constant temperature. To solve this problem, massive brick furnaces with a heat exchanger, long-burning boilers of the Stropuva type, and pyrolysis boilers with a shaft structure are ideal.

The advantages of such stoves are the ability to maintain the same temperature in the heat exchanger for a long time and regulate the heating rate, long battery life without loading, and the ability to heat a pool using indirect heating. The downside is the relative high cost of the equipment and complex plumbing.

Quickly heat up a seasonal indoor pool and maintain the required temperature. The main requirement for equipment is high power. It can be calculated by knowing the volume of the pool, the difference in water temperatures, and heat loss. To heat 1 liter of water by one degree in 1 hour you need 0.001 kW. Heating 1 thousand liters in 1 hour will require a power of 1 kW.

Taking into account heat loss, you need to multiply this figure by 1.2-1.3. Thus, a 25 kW boiler will heat 1 cubic meter of water by 1 degree in 15-20 minutes. The water heater must be permanently installed; it is better to use a flow-through heating circuit.

Quickly heats up a small outdoor pool at low ambient temperatures. The main requirement for a boiler for this mode of operation is high power and mobility. The light weight and compactness of the stove will be a pleasant addition.

Budget Alternatives

If a small pool is installed outdoors, for which it is ineffective to use complex, expensive electric heaters, you can use one of the alternative budget heaters to heat and maintain heat.

Boiler or kettle

Using a boiler to heat water in an outdoor pool is only possible if electrical safety rules are followed, prohibiting the simultaneous use of a live electrical appliance and body contact with heated water.

Very small children's pools of the "Splash Pool" type can be filled with warm water from a kettle. The disadvantages of this method include the rather large volume of the pool, into which several kettles of warm water will have to be poured, and the rapid transfer of heat, that is, the cooling of the liquid. It is better to use outdoor children's pools in the warm season, when the sun's heat warms the water well without any water heaters.

Snail

The snail is a twisted watering hose (preferably dark in color) located in the sun, through which water is delivered to the pool. Water passes through a hose heated in the sun as if through a coil, and its temperature rises by several degrees.

This simple method is suitable for use in sunny weather, since heating in this way cannot provide a significant difference between the air temperature and the warmth of the pool water.

Thermal blanket

The water already collected in the pool can be heated to a slightly warmer state by “capturing” solar energy. To do this, the entire surface of the water is covered with a special thermal blanket. The cover absorbs significantly more sunlight than water, and therefore heats up more efficiently, and the heat is delivered inside the pool.

Heating with wood

To use firewood as a heat source for heating a swimming pool at the dacha, it is necessary to build a solid or gas fuel stove and a heat exchanger of sufficient power through which water will pass. Water delivery to the heat exchanger is ensured by a circulation pump, which delivers cold water to the device and drains it back into the pool bowl. The principle of operation of a wood-burning boiler is simple and in many ways similar to the operation of a gas water heater, where the heat source is gas, and the water is heated by passing through a copper-plated tubular radiator.

This type of pool heater is justified only if there is already a stove or boiler on site, since the installation of this heating equipment is an expensive and time-consuming process that requires strict adherence to fire safety rules. If a boiler or furnace for heating the pool has not yet been built, then it is better to choose simpler and easier-to-use automatic water heaters for a heated pool.

What parts and tools to buy for making your own winter hot tub with a stove

During the brainstorming process, the user abandoned the cast-iron bathtub, replacing it with a factory-made font.

If you build an outdoor font, then with a bowl volume sufficient for several people.

To build the hot tub, Pit7pit bought:

- font for 3 cubes;

- wood stove;

- profile pipes;

- 4 cubes of unedged boards with a cross-section of 15x5 cm, for covering the frame of the font;

- two-inch plastic bends;

- PVC pipe with reinforcement for supplying water from the stove to the font;

- clamps;

- fittings;

- tap for draining water from the font;

- hinges for the door to climb under the podium;

- self-tapping screws;

- metal drills.

Tools also required:

- welding inverter;

- “grinder” for brushing wood;

- gas cylinder with burner for burning wood.

Let's move on to making an outdoor font.

Heat pumps for heating water

Heat pumps take heat from external heat sources, convert it and transfer it to the heated environment. To increase the temperature of the water in the pool, air-to-water devices are often used. In this case, energy is taken from the air and transferred to water.

Externally, the device resembles an air conditioner. Most of these devices are so automated that once you connect it, set the mode and desired temperatures, you don’t touch it again. Control is possible from a remote control or a panel on the case.

The heat pump looks like the outdoor unit of an air conditioner

Heat pumps operate from a 220 V network and consume 1-2 kW depending on the power generated. But in this case the energy is not used to heat water, but not to pump heat from one medium to another - it is needed to operate the motor and compressors. By spending only 1-2 kW, you can get 5-12 kW - depending on the type of system.

Like most automated and technologically complex devices, heat pumps cost a lot. About 130-180 thousand rubles.

Specifications

Further:GO TO CATALOG › TO GET A CONSULTATION > |

Attention!Precautionary measures:Pool heaters - TERMOPOOL, can only be used with the pump turned on; if the pump is turned off, then gradually (in small portions) fill the fire with water until it goes out completely, to avoid negative consequences!!! If you do not put out the fire, the water in the spiral will heat up to a boil and begin to throw portions of boiling water into the pool, which can lead to burns!!! Fire safety rulesInstall the pool heater no closer than 5 meters from buildings, especially wooden ones. Make sure to keep flammable liquids and objects within 2 meters of the heater. The rest area around the heater, approximately 10 meters, should be cleared of dry grass. Try not to leave the heater unattended (especially during intense combustion); if you need to leave, ask an adult to supervise the operation of the water heater. It is prohibited to install heaters under tree branches. |

Wood heater

The essence of the method, which will be described below, is fundamentally reminiscent of solar heaters. Only the main element is not a natural, but an artificial source. Let's consider the general scheme. The components can be easily replaced with those that are available in a particular case. To work you will need:

- plastic pipe or hose that can withstand the temperature of hot water;

- old radiator or battery;

- circulation or suitable centrifugal pump;

- metal barrel 200 l;

- firewood.

Before starting assembly, you need to find a place on the site where you can freely light a fire. It should not be too close to the pool, because... may damage it if it is made of PVC film or wood.

- A metal tank is installed. You don't have to use it exactly. You can build improvised stands from bricks.

- A radiator or an old battery is placed on top.

- Nipples with fir-trees at the ends are screwed into the outlet holes, onto which you can put a hose. This could be an adapter with two threads for screwing on a pipe.

- We connect the pipe to the outlet and lower it into the pool.

- We install a filter tip at the bottom of the pool according to the principle as described above.

- We connect the intake hose to the pump.

- From the pump we make a connection to the battery inlet.

- We make a fire under the radiator and turn on the pump.

Water heating radiator

If desired, a pool with 11 thousand liters of water can be heated to a temperature of 27°C in one day. If you continue to warm up, then you will get an impromptu jacuzzi.

You can make a portable device that will be used on an ongoing basis. To do this you will need a metal pipe with a diameter of 200 mm. Its height should be 80–100 cm. A square sheet of metal measuring 30×30 cm is welded to the bottom. A copper tube of the desired diameter is wound in a spiral along the outside. The upper end is connected to the hose through which water enters the pool, and the lower end is connected to the supply. In order for the entire system to work, it is necessary to light a fire inside the sleeve and constantly add firewood. The water, rising along the snake, will warm up and then release its temperature into the common container. To increase the efficiency of the installation, you can find another sleeve of a larger diameter and install it as a casing, then heating will be carried out even faster.

How to do it yourself?

A wood-burning boiler has a simple, even primitive design that is easy to replicate on your own. To do this, you need to purchase special materials and have skills in working with a welding machine.

The main elements of a solid fuel boiler are a spiral and a firebox. If we talk about a do-it-yourself device, it could just be a coil, inside of which a fire is lit. However, the presence of a housing allows you to heat water faster, so it is advisable to make one too.

Necessary materials:

- thick steel in sheets;

- stainless steel tube;

- heat-resistant enamel;

- clamps for connections;

- metal loops;

- self-tapping screws;

- heat-resistant sealant;

- hose (it is better if it is reinforced).

Equipment and tools:

- grinder + cleaning and cutting disc;

- welding machine + consumables;

- air compressor;

- 2 circulation pumps;

- pipe bending machine;

- screwdriver and pliers;

- hammer.

Manufacturing process:

The walls for a square or cylindrical frame are cut from sheet steel. Parts for the door and ash drawer are cut out separately.- The parts are connected to each other by welding. The door, ash box and chimney pipe are manufactured separately.

- The metal tube is bent into a spiral, the outer diameter of which is not greater than the distance between the walls of the body, and the height is not greater than the height of the firebox. The ends of the spiral must be left long to prevent the hose from catching fire.

- A hole is cut in the upper and lower walls to release the coil tubes. The diameter of the holes must match the outer diameter of the tube.

- A hole is cut for the chimney and ash box.

- The coil is installed in the housing, its ends are released out through prepared holes. The joints between the tube and the body are treated with sealant.

- The hinges are screwed to the body and door. All joints are sealed with sealant.

- The chimney pipe is welded to the body.

- A handle is welded to the door. It can be made from a piece of steel tube or fittings, but it is advisable to make its shell from a material that does not heat up so much. You can use wood, but it is better to sand it first and varnish it.

- A compressor is used to check for leaks. To do this, air is forced inside and the seams are lubricated with soapy water. If bubbles appear, these places must be cooked.

- Weld seams are cleaned with a grinder and treated with sealant.

- The heater is painted with enamel and left until completely dry.

- Hoses are put on the ends of the coil and secured with clamps. On the other side, the hoses are connected to the pumps.

A side-loading firebox can be made from an unnecessary gas cylinder. Details of making a wood heater are in this article.

Do-it-yourself wood-burning pool heater, video instructions: