Many steam lovers have heard about Vesuvius bath and sauna stoves - in recent years the company has become a leader in the Russian market. The reason for its popularity is simple - the notorious price/quality ratio, which is perhaps the best in these ovens.

But this does not mean that any of these stoves will suit you!

The company's product range is very extensive. How to choose a stove for a wood-burning bath or sauna? Today we will tell you how different Vesuvius models differ from each other. And most importantly - which oven is right for you!

Vesuvius stove range

Actually, there are two model ranges: steel and cast iron stoves. The first includes 7 items:

- "Optimum";

- "Scythian";

- "Typhoon";

- "Rusich";

- "Lava";

- "Russian steam";

- "Premium".

The entire model range covers a wide range of steam room sizes - from a volume of 6 m3 to 40 m3. The characteristics of each series will be discussed in more detail below, but now we will present a list of names of cast iron sauna stoves:

- "Legend";

- "Hurricane".

Here the range of steam rooms is a little narrower: from 8 to 30 m3, as is the number of modifications. The fact is that cast iron products are significantly more expensive than steel products, which is why the demand for them is less. Which does not at all mean that the quality of the products is poor; at the moment, reviews of the Vesuvius brand are overwhelmingly good.

Recommendations for use

The manufacturer of equipment for Vesuvius steam rooms prescribes recommendations for operating the device in the instructions for the models. You should familiarize yourself with them in advance and strictly follow them. This affects the service life of the device and the company’s warranty obligations. When working with company equipment, it is prohibited:

- Use peat, coke, gaseous and liquid materials as fuel. This does not comply with fire safety regulations. The combustion temperature may exceed that for which the device is designed.

- Firewood must not exceed the permissible dimensions of the firebox.

- Do not use the device if the tank is not filled with water.

- Install in residential areas for heating.

- The chimney can only be closed when the fire has completely gone out.

- Do not burn soot from the smoke duct.

- Make changes to the original design of the furnace.

Important! To prevent the destruction of cast iron, you should familiarize yourself with the rules for laying stones. You can water the stones for steam generation at a minimum interval of 5 minutes.

If these simple requirements are met, the company undertakes to eliminate all defects during the entire warranty period or replace the device free of charge.

Overview of steel furnaces

The model range opens with the “Optimum” series, which is designed for heating a small steam room with a volume of 6 to 14 m3 and includes 2 modifications. The difference between them is that one stove is fired directly from the steam room, and the second from the adjacent room. The length of the remote firebox is 25 cm. The design of the heaters can be seen in the figure:

Despite its small dimensions (650 x 560 x 490), the Vesuvius “Optimum” stove is quite massive - 53 kg. The reason is the thickness of the metal from which the combustion chamber is welded; the diagram shows that it is 5 mm. In addition, a metal partition is installed inside the firebox, which prevents the direct passage of combustion products into the chimney. This increases the heat transfer of the chamber, which is surrounded on all sides by a ventilated open heater.

The rest of the design is classic; a grate is built into the bottom of the firebox, and under it there is a drawer for the ash pan. With its help, the combustion air supply is controlled. These Vesuvius bath stoves are equipped only with a blind loading door and are considered a budget option.

Series "Skif"

The difference from “Optimum” here is expressed in the configuration of the partition, which forces the flue gases to transfer heat more efficiently, bending around it. In addition, the upper and rear walls of the combustion chamber are reinforced; the metal thickness there reaches 8 mm. At the same time, as planned by the designers, the side walls “lost weight” to 4 mm. By the way, stainless steel is not used in the manufacture of Vesuvius stoves, hence the reasonable price of the products. The structure of the Skif furnace is shown in the diagram:

From the diagram it is noticeable that the structure of the ash pan and heater remained the same: respectively, a drawer and a cylindrical mesh for holding stones. The series includes 5 lines of stoves, each of which is designed for a specific steam room size, ranging from 6 m3 to a volume of 40 m3.

Bath heaters Vesuvius "Skif" cover the widest range of thermal powers, the series includes the largest number of stoves - 36.

Wood-burning stoves "Skif" are equipped with an expanded package of options. This includes a hanging tank for heating water with a capacity of 30 liters, heat-resistant and panoramic glass instead of a blank loading door. Thanks to the combustion chamber pushed forward, it is possible to heat it both directly from the steam room and while in an adjacent room.

Installation features

Installation diagram

The brand recommends involving specialists in the installation of equipment. If the owners have the skills or tools, self-installation is allowed. The process goes like this:

- Laying a red brick base to a height of 6 mm or a fireproof foundation made of 20 cm thick material.

- Removing the product from the wooden wall by 50 cm.

- Wall covering with metal sheet. In this case, the distance is reduced to 38 cm.

- Making a half-brick superstructure with preliminary cutting of the wire frame of the furnace.

The walls can be covered with slab apothecary bricks.

The manufacturer's instructions note the specifics of installation of a particular modification of the stove.

Legend Series

Installation work involves assembling the chimney taking into account the location of the rafters and load-bearing beams:

- Installation of ceiling trim in section. A hole 130 mm in diameter is made along the axis of the chimney with an angle of inclination along the corner of the roof.

- Fixation on the outlet pipe of a single-circuit, starting pipe or tank with sealing of the gap.

- Installation of further elements - tap through the boards with a mallet or hammer.

- Installing the throttle valve and putting the chimney on it. Passing the starting sandwich through the hole and organizing the support clamp.

- Laying heat-resistant heat-insulating material - basalt wool, mineral wool.

- Further assembly of the chimney using sandwich elements along the condensate line.

- Place a cone clamp on the chimney and tighten it further.

- Installation of the last sandwich and covering it with an umbrella-head.

After checking the strength, tightness of connections and draft, a test fire is carried out.

Sauna stoves

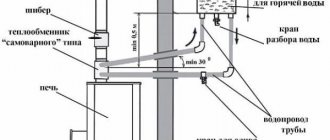

The equipment is located in the steam room, and the tank is located in the sink. For convenience, a samovar-type heat exchanger is used to heat the water. This increases the efficiency of the device and eliminates heat dissipation through the pipe.

Fireplace installation

The units are installed in rooms with good air flow. The optimal height of smoke channels is 600 cm. The pedestal is made of non-combustible materials. To remove ash, a flood zone is created from a sheet of metal 40 cm in front of the firebox and 10 cm on each side. The distance from the fireplace to the ceiling is from 1.2 m.

The Vesuvius line of stoves provides high-quality heating of the bath, is efficient and economical. The manufacturer produces cast iron models designed for long service life.

Typhoon Series

Under this name, 9 units are produced, adapted for heating rooms from 6 to 30 m3. The design of the Typhoon's fuel chamber and gas duct system does not shine with originality and almost completely replicates the Skif model. The difference lies in the shape of the heater, which has turned from cylindrical to rectangular. The heater is ventilated and also open on all sides.

The manufacturer declares that some elements of the stove that are most exposed to fire are made of 12 mm thick carbon structural steel. True, he does not indicate what these elements are. Otherwise, the metal remained the same - 4 mm on the side walls, 8 mm on the back and top. All stoves have a firebox with an external channel. The extension size is standard, 25 cm.

If we talk about options, the Vesuvius “Typhoon” stove boasts 2 types of viewing glasses:

- heat-resistant, built into a standard fuel door.

- panoramic, with dimensions 41 x 41 cm.

In modifications with sight glasses, it is possible to regulate the air supply to the firebox using a special damper. There is also an option to install a hanging tank for heating water.

What is prohibited?

To avoid troubles and unforeseen situations, you should follow certain rules when heating and do not:

- lighting the stove using flammable substances, for example, kerosene, gasoline, acetone and other similar substances;

- use liquid or gaseous fuels to fill or pour into the firebox, use coke, peat, place too long logs in the firebox;

- dry clothes and other things on the surface of the body and pipe;

- close the pipe valve without making sure that there is no combustion at all;

- use the unit for heating in kindergartens and schools;

- pour water on the stones at intervals of less than five minutes.

The Vesuvius Legend stove is very comfortable to use, there is soft steam in the bathhouse , and after visiting you feel light and cheerful. It is these stoves that have won the gratitude of many users.

Series “Rusich”, “Lava”

These 2 series include 24 and 27 modifications, respectively, installed in steam rooms from 6 to 30 m3. The internal working part again remained unchanged, as did the thickness of the metal walls. But the rectangular or cylindrical heater here is open only at the top; on the sides it is fenced with a convection casing with grooves made for the passage of air.

“Rusich” or “Lava” is well suited for those people who cannot tolerate the direct heat emanating from the stove in the form of infrared radiation. The barrier in its path is the convection casing, and the heater is ventilated through it.

In fact, all furnaces have the same body (“Rusich” is rectangular, “Lava” is round). A variety of modifications is achieved through various configuration options, which include:

- an external channel for the firebox from the adjacent room;

- fireproof and panoramic glass.

According to company representatives, purchasing and installing a stove from one of these series will provide the fastest heating of the steam room, while the temperature of the heater can reach 350 °C. So the presence of an outer casing in the design is very useful here.

Which model to choose

The question of purchasing a heating stove becomes relevant upon completion of the construction of a bathhouse or when it is necessary to replace an outdated structure. Having decided that Vesuvius is the most win-win option, the buyer can only choose the appropriate model according to his taste and budget.

Stove "Vesuvius Elite"

The range of sauna stoves includes open and closed heaters. In open furnaces, the firebox is placed in a casing made of high-strength metal mesh. The absence of a closed housing allows you to heat the room in a very short time. This design feature is especially relevant for Finnish saunas, where it is necessary to heat the air to high temperature limits.

For a Russian steam room, where moist rather than dry air should be present, it is advisable to choose a closed model with a shielded firebox body. This will ensure a gentle supply of heat, without excessive overheating of the bath.

For those who are interested in heating the room adjacent to the bathhouse, it is wise to opt for a sauna stove with an external firebox. The installation of a fuel door in the dressing room protects the steam room itself from excessive combustion of oxygen.

Requires careful attention and selection of a steam generator. Some stones used as filler can release carbon monoxide into the steam room. It is better to choose stones for the stove in specialized stores, where the buyer will be offered only certified products.

Based on operational characteristics, each model is marked according to a number of characteristics. For example, the abbreviation “VK” means that the furnace firebox refers to an external structure. The digital combination indicates the volume of the steam room that certain modifications are designed for.

Furnace installation

Regardless of the specific modification of the furnace, it is necessary to adhere to the general rules and installation requirements. When installing any model of the Vesuvius stove, fire safety is a priority. You should purchase a special metal sheet and fencing in advance to arrange the place where the unit will be installed.

The surface of a wooden wall must be protected from the stove with basalt wool and a protective board. Even at the design stage of a bathhouse, it is important to determine the need for additional ventilation. As a rule, factory-purchased stoves do not require lining with insulating material. However, a homemade barrier made of brickwork will prevent the device from cooling down quickly.

Installing a stove in a bathhouse with an external firebox requires special skills. Installing a unit with a remote firebox presents some difficulties. Before installing such structures, you need to pay attention to the dimensions and configuration of the dimensions, and also carefully study the design features of the steam generating device.

The thermal power of the unit must be taken into account. The main thing that needs to be provided is the possibility of fully opening the combustion door. In some cases, it is necessary to consider the option of taking the firebox outside.

To effectively move steam, experienced bath attendants recommend laying stones only on top of the structure.

“Russian Steam” and “Premium” series

The somewhat elongated round shape of the Russian Steam heaters is due to changes in the internal structure. Here, directly above the combustion chamber and the secondary flue, there is an additional completely closed heater, which removes heat from the hot flue gases.

Thanks to this, its maximum temperature can reach 400 °C. Outside there is a second heater bounded by a powerful cylindrical mesh, which surrounds the firebox body on all sides. To fill the internal cavity with stones, a separate opening is provided in the upper part of the furnace.

The line includes only 5 modifications, providing heat to rooms with a volume of 14 to 30 m3. The package includes the same accessories as in previous series. They also became the basis for the development of premium-class stoves “Elite”.

This means that the Vesuvius “Skif” sauna stove was taken and the outside was decorated with decorative stone (talcomagnesite or green coil). For another modification, the basis was the “Russian Steam” unit; in total, under the name “Elite” there are 5 heaters for steam room volumes of 12-30 m3.

Cast iron stoves

Structurally, these units are almost identical to their steel “brothers”. A similar combustion chamber with an ash drawer, a two-pass smoke circulation and the presence of an open-type heater fenced with a mesh. The difference is that the firebox is a 12 mm thick cast iron with external ribs. They perform 2 functions: they give rigidity to the body and provide intense heat transfer.

The Vesuvius cast iron stove is produced in two names - “Legend” and “Hurricane”. Accordingly, modifications 11 and 3 are intended to serve steam rooms with a volume of 8–30 m3. The design is as varied as that of steel heaters - different types of glass, a remote tunnel and a tank for heating water for washing.

Advantages and disadvantages

If we compare the units in question with other types of furnaces (made from other types of metal) from well-known manufacturers, we can highlight three main advantages.

They are concluded:

- in practicality and durability . Cast iron in its effect is as close as possible to brick stoves;

- strength _ When exposed to high temperatures and intensive use, cast iron does not deform and can withstand high loads;

- high thermal conductivity and safety of use . A cast iron stove does not burn oxygen in the steam room and does not emit large quantities of infrared radiation. It heats up quickly, but cools down slowly.

The disadvantages include the large weight of the structures and considerable cost. However, there is good value for money.