A chimney damper is a damper that is installed at the very beginning of the chimney to regulate the draft in the stove. Ready-made mass-produced dampers always come with one or more small holes in order to prevent the air flow from the stove to the chimney from being completely blocked.

They come in two types: retractable and rotary. The most common is the retractable one, because due to the simplicity of the design, it works reliably and can be built into most stoves. The rotary valve is less common, as it has a more complex design and is most often used where it is not possible to install a retractable valve.

Furnace valve design

A special horizontal plate that increases or decreases the cross-section of the chimney pipe by its position is a retractable damper.

It is by decreasing or increasing the cross-section of the chimney that the draft force is regulated. According to fire safety rules, the chimney should not be completely sealed, so there must be a small hole in this plate. As a rule, a horizontal damper is intended for brick stoves, although sometimes it is also installed in steel chimneys. A double-walled or rotary gate is a plate mounted along an axis. The position of such a gate is adjusted by turning. The only, but serious, drawback of the rotary gate is that its welding often burns out, and this rather unpleasant phenomenon is observed more and more often. This is most likely explained by the dishonest attitude of some manufacturers towards the quality of their products.

These two types of gates have fundamental differences in their design. A horizontal damper for a bath, or a damper for a chimney, makes it possible to regulate the flow area of the chimney. And the throttle, or “hog”, of the rotary damper only allows you to completely open or close the chimney, but not to regulate the flow area of the chimney. True, some bath attendants have gotten the hang of fixing the position of such a gate using a chain.

The furnace valve is a structure consisting of three parts:

- Cast iron body - frame (sometimes steel is used instead of cast iron) with side grooves.

- The locking part is in the form of a panel damper, thanks to the movement along the grooves of which the sealing of the chimney is controlled.

- The control part on the panel damper is in the form of a handle. This makes it easy to operate the panel damper manually.

The shape of the valve must completely coincide with the shape of the chimney; according to this parameter, they can be rectangular, square, or round.

Criterias of choice

In order to choose the right valve for a chimney pipe for specific application conditions, it is necessary to take into account the following number of parameters:

- Conditions of use . It is not recommended to equip a sauna stove with a rotary damper.

A sliding gate valve is ideal for equipping a stove in a bath Source parma.center

- Frequency of operation . For stoves used periodically or seasonally, it is better to install a pull-out valve. If you choose a throttle model, the chimney above the plate will constantly become damp, since when closed it still allows damp air to pass through, and below it a large amount of soot will accumulate during combustion.

- Type of equipment . To equip combustion product removal systems for gas heating boilers, it is recommended to use a throttle valve. Since the design ideally complies with the technical conditions, according to which the channel cross-section should not overlap by more than 40%.

In addition, when choosing a damper, you must make sure that its dimensions exactly match the cross-sectional area of the chimney channel into which it will be installed.

The dimensions of the gate must exactly match the diameter of the pipe Source parmaster.ru

Summer flap and its meaning

Often in stoves there is such an element as a summer damper, which has a specific purpose. The summer damper is used in fireplaces or Russian stoves, which are heated irregularly or periodically at long intervals. For example, in stoves in a country house or village house, when it is heated only in the summer season.

The summer valve has some design features and a special location, which makes the combustion process much easier after prolonged cooling, even in the most severe weather conditions.

The operation of this design is carried out in this way: The stove must be lit with the summer valve open, then, when the flame in the firebox flares up and some of the firewood has completely burned out, the valve must be closed to prevent heat loss.

Stoves with a summer damper installed in them have a number of advantages, for example, by pulling out the summer damper and ash pan, you can use the stove at any time of the year as a classic open fireplace. With the help of a damper you can easily get rid of excess heat in the room. However, it should be remembered that it is recommended to heat such a stove for no more than 20 minutes, since the temperature can rise significantly, which is a feature of such fireplaces.

The German word Schieber in Russian has not changed either its pronunciation or meaning. If we talk specifically about stove heating, then a damper, as well as a damper, is a shut-off device that blocks the chimney channel.

When arranging a smoke exhaust duct, a valve is installed in the upper part of the base, which is located in the room, so that, if necessary, it is possible to manually regulate the movement of gases, and at the same time the quality of draft.

This is what the gate looks like when extended. When retracted (when the stove is already heated), the valve is almost invisible, only its “eye” protrudes outward.

A damper on the chimney duct is required for the traditional version of a brick stove. By retracting it partially or completely, you can reduce the draft or block the movement of heated gases.

The damper is fully retracted when the stove is heated and gases harmful to health stop flowing into the channel. There are known cases of deaths of people who were burned by a stove that was “closed” early.

If you are late in closing the damper, the heat from the heated bricks will go into the pipe, and the temperature in the room will quickly drop. A timely retracted damper is a guarantee that the house will be warm for at least a day. As you know, in village houses during the cold season the stove has to be lit every morning.

Factory-produced steel gate valve with a diameter of 200 mm. To simplify installation, it is sold together with a piece of steel pipe, built-in.

There is an opinion that dampers, which are mandatory for brick stoves, are absolutely not needed for steel stoves (although they are offered by manufacturers), as well as for models with an installed deflector.

The argument against their use is the fact that the chimney quickly becomes clogged with soot when the damper is closed. Its upper part is cooled by cold air entering the pipe, which, when in contact with a hot steel pipe, forms a large amount of condensate. This situation requires more frequent chimney cleaning.

Safety precautions

When talking about gate valves, first of all we should focus on safety precautions. Already from the definition it becomes clear that this device is capable of completely blocking the natural flow of air from the room through the stove and chimney to the street. The oven can be in such a locked state only under one condition - there is nothing in it that is still smoldering even a little, much less burning.

As you know, burning wood in a stove leads to the release of carbon monoxide, which is poisonous to humans. The danger of poisoning with this gas is that a person may simply not feel the harmful effects of the gas until he begins to lose consciousness, and then it may be too late. This danger should not be underestimated: for example, it is known that the famous French writer Emile Zola died in Paris in his bedroom from carbon monoxide.

We recommend a video review of the features of gate valves of various designs.

An attentive reader may notice that valve manufacturers produce them with special holes that prevent complete blocking of the chimney. However, with regular use over time, soot and resin accumulate on these holes, which gradually reduce their throughput, and then can completely block them. Obviously, the chimney periodically needs to be cleaned and the damper is no exception, but in practice this procedure is carried out much less frequently than required by safety regulations.

A few words about rectangular valves

A rectangular valve can be of various sizes from small to very large, when the length of the valve reaches up to 600 mm. Large options are usually suitable for Russian stove chimneys, fireplaces, barbecues, etc. The purpose of the design is the same - to block the flow in the air ducts.

The smallest furnace valve has dimensions of 13x13 cm, and the largest is determined according to the individual requirements of the consumer. The most popular size for these structures is 26x13 cm, since these are the dimensions of the chimney of an ordinary Russian stove.

Thanks to square or rectangular stove valves, you can not only stop the air exchange in the pipe, but also adjust the intensity of the fire by changing the chimney draft and throughput. For this purpose, simply close the damper not completely, and then gradually pull the handle towards you, thereby controlling uniform combustion in the firebox.

Round furnace valve or view

A round-shaped stove valve is otherwise called a view. This is a special valve with a slightly different design than the regular version.

The view consists of the following parts:

- The housing is in the form of a plate, which can be round or square with a round hole.

- A shut-off element in the form of a disk that closes the hole and blocks air exchange in the pipe.

- The control part, in the form of a regular handle in the center of the disc valve.

You cannot use a view to control air exchange, since you need to remove the damper from the air passage manually, which is almost impossible in a heated stove, in addition to exhaust gases. The design is used exclusively as a locking element, often as an additional damper for a complete result before igniting the stove and after it goes out.

It is recommended to install both types of cast iron stove valves far from the firebox.

The damper is an integral part of the stove, which closes the chimney after it is fired. In combined stoves, such as cooking and heating stoves, this design allows you to move between smoke exhaust channels.

The damper is usually installed in the chimney when laying the stove, secured with several rows of bricks. Often two valves are installed, especially in rooms in cold climates, when temperature changes are more significant, which leads to rapid heat exchange.

The view is installed in the chimney in the same way, but is usually used in Russian stoves. This valve is closed from the outside using a special door. If it is necessary to ventilate and cool the oven, all this can be done with the view door closed.

The design of the stove view makes it possible to eliminate the installation of an additional valve, because it completely copes with sealing the smoke exhaust pipe. When using the second valve, it is installed below the view.

Principle of operation

When the plate moves inside the device, the channel capacity decreases or increases. The further the damper in the pipe is moved, the sooner the smoke is removed and the combustion of the fuel in the stove accelerates. Completely blocking the hole in the chimney allows the heat to remain in the stove and work to heat the room air throughout the day.

The plate can be completely retracted only in a heated hearth, when substances harmful to human health cease to be released. If the valve is closed too early, there is a risk of suffocation among family members. Sometimes failure to comply with this rule leads to the death of people.

Boiler models are produced with built-in baffles, so installation of a damper is not necessary. Other heating units, furnaces, boilers require the installation of a valve. It is installed in ventilation and exhaust pipes.

Chimney deflector (Photo: Instagram / deflector21)

A gate made of what material will serve best?

In most cases, chimney valves are made of cast iron. The problem is that cast iron is a fairly heavy material, and the process of installing a cast iron gate is quite complex and time-consuming. In addition, cast iron gates are installed only in brick kilns.

Steel gates are much more convenient and practical. With a thickness of only one millimeter, they have a special mechanical density, withstand temperatures up to 900°C and are resistant to corrosion. In addition, the steel gates are very smooth, they are even specially polished to a shine, and therefore soot does not settle on them at all.

In addition to structural differences, types of gate valves may differ in the material of manufacture. The only possible option is metal, since it is the only one that does not burn or deform at high temperatures, and over time, even in an aggressive environment, does not change its characteristics.

For production, either cast iron or stainless steel is used. It is not possible to build a damper from cast iron yourself, since this requires, at a minimum, a forge. However, you can find both nondescript and beautifully designed cast iron dampers on sale.

Cast iron rotary gate with a comfortable handle. This design is suitable for a brick chimney with a rectangular cross-section, capable of supporting the fairly heavy weight of the device

Steel products look simpler, but their characteristics are similar to their cast iron counterparts. The advantage of steel fixtures is their light weight.

If a cast iron damper for a stove chimney is installed only on a durable, permanent structure, then a steel damper is suitable for any smoke exhaust ducts - brick and steel, rectangular and round, solid and light.

Samples of a galvanized steel damper, chimney cross-sectional diameter – 150 mm. Galvanization, unlike ordinary steel, does not react to moisture (condensation) and does not corrode

When choosing a material, you need to focus on the characteristics of the chimney pipe and the features of the interior.

For a country heating stove, a modest steel valve is sufficient, while for upgrading a Russian stove in a cottage, a custom-made cast iron valve is better suited.

Do you need to close the damper on the sauna stove? And when.

Yes. You stir the coals, collecting them in a pile above the ash pit. If the coals flare up with a blue flame - close it early - burn CO. If the coals are red-yellow, you can close the damper (and the blower).

In addition, modern gates are not made airtight - 3...5% of the cross-section remains always open - a safety net.

If there is excess traction, it is better to reduce it. But it is better to do this in the hottest and calmest weather (the worst traction).

You can install an automatic draft regulator (the best solution) - then the draft does not depend on the weather or temperature. But is it wise to do this for a bath? - take a look yourself …

Automatic is certainly not reasonable))

How to determine excess thrust, as you understand, I don’t have and never will have any measuring instruments))

I don’t quite understand if the traction is the worst in the hottest and calmest weather. then why reduce it at this particular time? Logically, on the contrary, it is better not to touch the gate.

I determine by eye - by the “rage” of the flame. : An adjustable blower (with a working and sealed door) is quite sufficient to adjust the flame.

If there are a lot of cracks, the blower no longer helps - you have to reduce the draft. The process is dangerous.

>I don’t quite understand if the traction is the worst in the hottest and calmest weather. then why reduce it at this particular time?

You don’t understand: now (in winter) let’s say you have excess cravings. You went and reduced the diameter of the pipe. Summer has come. And it turned out that in hot weather there was no longer enough traction. We'll have to extend the pipe back.

To avoid this, they use automatic thrusters. But it is reasonable to do this on boilers (constantly burning), and to optimize combustion (efficiency). But a boost fan (or smoke exhauster) completely eliminates the problem of changing draft. And if, on top of that, the fuel seems to be free (firewood) - just spit and forget everything I wrote

I don’t feel sorry for the wood, but for the time to run and throw it in))

In the summer, of course, I’ll open the gate. And in general, I will open the gate when lighting and close it as needed. Although of course you need to get used to any stove/boiler))

How to close a furnace valve, operating rules

The operation of the furnace valve itself is quite simple, but it is definitely associated with some risks that threaten human health. If you close the structure in a stove that is still burning or if the fuel is not completely burned, then exhaust products can enter the room, poisoning the air.

Therefore, the use of a valve, which allows you to save heat in the furnace for longer, should be used extremely wisely, that is, the structure should be closed on time. It is known that due to the cast iron valve, the heat in the stove and, accordingly, in the room remains for a long time. The use of fuel such as coal increases the temperature inside the furnace by approximately 60-700C.

Sometimes, in order to save fuel, the valve is closed earlier, before it is completely burned, which is extremely undesirable. After all, human health and life are higher than any savings. Closing the damper earlier than necessary increases the risk of carbon monoxide poisoning. Carbon monoxide is a combustion product that is poisonous. Therefore, to avoid such situations, you need to use the chimney valve correctly, following some rules:

- Before closing, be sure to stir the coals to avoid the presence of completely unburnt pieces.

- During the initial attenuation of the coal, when the blue flame is no longer visible on the surface, the damper should be slightly closed, but it is not recommended to close it completely. After all, the presence of coals does not mean that they are completely burned out. If there is a need to seal the pipe, this should be done after complete combustion of the coals.

- Next, you need to open the ashpit so that a draft is formed, and the remaining coals are completely turned into ash and ash.

How much wood should I put in the firebox?

Another mistake that leads to smoke in the room during ignition is too much firewood in the initial stack and/or its stacking too tightly. If the furnace power is selected correctly, it is enough to fill the firebox to a third of its height. Be sure to leave gaps between the logs. Otherwise, there is a risk of cutting off the air supply to the combustion zone. After the logs do ignite, the stove will become hot and overheat the room. As a result of regular overload, the walls of the firebox become deformed and burn out.

Rule three

: a reasonable amount of firewood - controlled climate in the steam room and preservation of the working life of the metal stove.

How to make a gate valve with your own hands

Let's look at how to make both types of chimney valves - retractable and rotary. Each of them has its own manufacturing and installation nuances. Let's start with the retractable view.

To create the simplest model of a retractable gate, galvanized steel is suitable. It is lightweight, thanks to its smooth surface it is easy to clean from soot, and if necessary, the moving part can be easily replaced.

Millimeter steel will not work, as it bends easily, and if deformed, it will be difficult to slide the plate into the chimney. The minimum sheet thickness is 1.5 mm, and preferably 2-2.5 mm

The main tools are a welding machine, electrodes, a grinder, metal scissors (choose depending on the thickness of the sheet), a drill with a grinding disc, metal drills, and a file.

It is better to carry out work on a workbench with a vice. Among other things, you will need a sheet of paper for a template, a tape measure, and a marker.

Removing dimensions must be taken seriously, since even a few millimeters can cause the chimney to malfunction. To find out the dimensions of the frame, you should use a tape measure to measure the cross-section of the smoke exhaust duct - it will coincide with the dimensions of the inside of the frame.

To this value you should add 20-30 mm on three sides and calculate the outer side of the frame.

Drawing of a damper with a wire frame. A wire frame is more difficult to secure to brickwork than a profile with flat wide sides

In order for the latch to slide out easily, without effort, its width should be slightly narrower than the width of the frame (taking into account the outer sides). To simplify the calculations, it is necessary to draw a design diagram and indicate all possible dimensions, so that in the future, when working with metal, you can navigate by them.

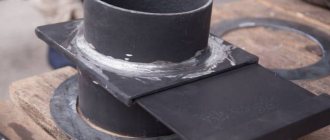

For metal pipes, a flat damper design is usually combined with a chimney fragment located perpendicularly.

Design dimensions for a rectangular pipe. The valve must completely block the chimney, but at the same time have small holes for air penetration, drilled with a drill, or a gap

For brick chimneys, a flat frame made of wire or profile with a moving valve along guides on two parallel sides is sufficient.

Having determined the exact dimensions, we cut out the frame for the gate. If the chimney is small, for example, in a bathhouse or in a summer kitchen, you can use thick wire, bending it in the shape of the letter P.

A more comprehensive frame is a durable corner profile. To make it, we cut out a strip from sheet steel and bend it lengthwise at an angle of 90º. To give the profile the desired shape, in the places where the corners are marked, we cut one of the planes. When folded, we get a frame. We weld the bends.

Next, we cut out the damper itself. It should be approximately 5-10 mm narrower than the width of the frame. We adjust the length so that when closed, only a small fragment of the valve peeks out. It can be decorated in different ways: in the form of an ear with a hole or simply a folded edge.

We clean the edges of the cut gate with a disc so that the closing/opening process is easy and silent. Parts cannot be painted.

The photo shows the stages of installing a factory-made gate. A homemade device is mounted using the same principle.

Image gallery

Photo from

In accordance with the diagram of the furnace, we determine the installation location of the gate valve and mark the bricks that need to be trimmed

We take out the bricks that serve as the basis for installing the damper and cut them to the size of the gate frame with a grinder

To fix the valve we use masonry mortar. We apply it to the installation site, and then to the edges of the frame from above.

The valve “stands” on the same level as the rest of the bricks, so there are no obstacles to further masonry; it is carried out in the usual manner - according to the ordering scheme

Step 1 - determining the installation location

Step 2 - cutting bricks around the perimeter of the hole

Step 3 - planting the gate on the solution

Step 4 - brickwork above the gate

The installation height of the damper largely depends on the design of the stove; in sauna stoves it is lower, in home heating stoves it is higher. The minimum height is 0.9-1 m from the floor, the maximum is about 2 m.

Frequent errors and problems during installation

Good draft ensures high efficiency of the furnace. With good draft, the fuel in the stove burns completely and its consumption is low. If the draft is poor, the wood does not burn out completely, and there is even a risk of reverse draft occurring. In this article we will try to understand what a bath gate is, what are the features of its design and whether it is possible to make it yourself.

We invite you to familiarize yourself with the Shelves in the bathhouse (104 photos): drawings and dimensions, step-by-step installation instructions, how to make one in the steam room with your own hands

The damper is a draft regulator that ensures the fire safety of stove heating. When the wood in the stove burns, the chimneys are partially blocked by valves, and after complete combustion of the wood, the valve closes the chimney pipe completely. The damper in the heating system exists precisely to regulate the draft force. A modern analogue of a damper is a draft stabilizer.

To install the throttle valve, it is necessary to make markings on the pipe in order to drill holes according to the welded valve structure.

To do this, you need to measure the pipe using a measuring tape and make marks for future holes. After making sure that the marks are symmetrical, use a drill to drill holes for the future rotary handle.

The throttle valve is installed as follows:

Next, you can install the resulting structure in the chimney pipe. To do this, the first piece of pipe is put on the furnace pipe of the stove heating, onto which a structure with a gate valve is installed on top. The next piece of metal pipe is put on the gate. All connections are treated with liquid silicone sealant.

Installation of a retractable damper in a brick chimney occurs during the masonry process. To do this, after 6-8 rows of bricks, a layer of cement masonry mortar is applied, on which a wire frame is installed with the open side facing the performer. You need to insert a latch into the frame and bring it into the closed state.

The frame is covered with mortar on top and bricks continue to be laid according to the standard pattern.

Today, there are two main ways to install a damper on a chimney:

The above options for using valves for chimneys and ventilation systems are used everywhere. It is worth noting that today you can find a huge variety of stoves and fireplaces, which differ from each other from a constructive point of view. This variety of heating devices also influenced the range of gate valves.

The gate, made of stainless steel, is usually polished to perfect smoothness. Soot settles on it poorly, but still settles. Therefore, it must be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it out to the maximum and applying a special solution. Rotary - cleaned through the chimney with a special plastic brush. You should also ensure that the damper moves freely along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

How to install a valve on a chimney

The valve is usually installed during the construction and assembly of the stove. The process is carried out in several stages:

- Laying bricks around the fittings in a selected location at a certain stage of chimney construction. In this case, the dimensions of the hole left must completely coincide with the dimensions of the valve. Often, wire is installed in the corners of the body, mounting it into the body of the masonry.

- Installation of the valve frame with fixation of the upper part using cement mortar.

- Applying cement mortar around the perimeter of the frame and wire about 1 cm thick, followed by laying a row of bricks.

- Installing a damper in the chimney.

A conventional cast-iron stove valve is locked with a panel damper, which is mounted in the frame body through a slot. It can be installed after mounting the frame. The damper on the view is closed manually, so a special door needs to be installed above the body of this design, with which you can control the lid.

After this, installation of the chimney continues accordingly.