Before installing a heat source that requires gas, solid or liquid fuel in a private house, bathhouse or outbuilding, it is necessary to prepare a design for a combustion product removal system. Today, classic designs made of brick or asbestos-cement pipes are replacing convenient and practical chimneys made of stainless steel, for the installation of which ready-made elements are used.

Types of stainless steel chimneys

You can connect any type of heating boiler, metal or compact brick stove, or fireplace to the universal modular chimney. You can assemble the smoke channel yourself by choosing the right system. They differ in design, purpose, and metal characteristics.

Types of stainless steel chimneys

There are a huge number of different types of stainless steel chimneys. Let's look at the main ones.

Chimneys with one wall - such a device is most often installed indoors and it is necessary to thermally insulate such a device.

- Such chimneys are used directly indoors to remove combustion products from gas boilers operating on any type of gas.

- In addition, this type of chimney is excellent for removing smoke from the premises from the heating of any kind of stoves and heating devices.

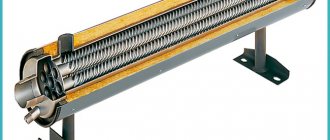

Chimneys with a double wall (sandwich chimneys made of stainless steel) - in such a chimney it is assumed that two walls are used.

- The diameters of such stainless steel chimneys differ.

- Most often, the outer pipe reaches a diameter of one hundred and fifty millimeters.

- Thus, an empty space is formed between the two walls of the pipes, which is usually filled with a special heat-insulating fiber.

- Thanks to this way out of the situation, the inner pipe has the ability to heat up and not form condensation.

- The main feature of such chimneys is that it is installed outside the heated room.

As for the devices to which it is possible to connect such a chimney, everything is simple. Such heating elements are connected to both gas boilers and stoves.

Chimney pipe diameters

Each type of product under consideration has two diameters: external and internal. The selection of products by size must be carried out taking into account the equipment used. The lower the boiler power, the smaller the diameter of the flue is needed for its installation.

In the table below you can see the main sizes of stainless steel pipes for a chimney.

Sandwich pipe size chart for chimney. D—pipe diameter, H—segment length

It is important that the internal size of the flue is equal to the cross-section of the boiler outlet pipe. It is the inner surface of the starting tube that receives the main impact from the exhaust gases. Therefore, it must match the diameter of the outlet pipe. The main parameters of heating units are specified in the requirements of SNiP.

The dimensions of chimney pipes can be as follows:

- fittings - tee angle: 135, 90, 45 degrees, bend: 90 and 45 degrees;

- thermal insulation size - from forty to sixty millimeters;

- length of the pipe product - from 0.5 to 1 meter;

- steel thickness of the inner pipe (sandwich) - from 1 to 0.5 millimeters;

- outer diameter - from two hundred to four hundred and thirty millimeters;

- internal section - 200, 150, 120, 115, 110 millimeters (there are options up to 300 mm).

There are many additional components that facilitate the installation of a flue structure.

There is a wide variety on sale:

- braces, clamps and brackets;

- support platforms and protective aprons;

- head, plugs and weathervane caps;

- roofing seals;

- decorative overlays for passage units;

- compensators necessary to regulate changes in the linear dimensions of sandwich structures when changing temperature conditions;

- inspection tees designed to remove contaminants.

The presence of a large assortment of additional components can greatly reduce the cost of erected structures. Sandwich chimneys are easy to assemble. Their installation can be carried out independently, without the involvement of specialists.

Features of choosing a chimney

To choose the right device for your heating system, you need to study the list of parameters that these chimneys must have.

This list includes:

- Indicators of operating temperatures, which should range from minus fifty to one hundred and ten degrees Celsius.

- Indicators of working pressure, which should be from fifteen bar.

- Bend radius indicators. This figure should be from three to fifteen centimeters.

- Thermal conductivity indicators are seventeen watts per meter Kelvin.

- Indicators of surface roughness, which should be zero point eight thousandths units.

- Safety indicators, that is, fire resistance.

- Wear resistance indicators.

- Resistant to weather conditions such as rain, hail, snow and wind.

- Resistant to fungi and mold.

- Resistance to humidity.

- Resistant to strong winds.

It is worth noting that you need to choose the right chimney, because it is an integral part of the entire heating system. Therefore, incorrect installation or poor-quality materials can lead to troubles and malfunctions.

Frequent errors and problems during installation

- Incorrect configuration. Unjustified deviation from verticality, sharp bends and excessive horizontal lines reduce the traction force in the circuit.

- Insufficient or excessive shaft height also reduces the efficiency of the chimney.

- If the pipe head enters the wind pressure zone, it provokes a backdraft effect.

- The use of stainless steel of insufficient strength leads to its rapid wear and threatens to burn out the steel.

Recommendations for chimney installation

For proper installation work, you need to study the recommendations of chimney installation specialists. Let's look at the most basic tips:

- It should be taken into account that the structures should never be installed next to electrical wiring, wires or gas systems.

- It is impossible to connect each element of the chimney structure in the place where it passes inside the wall.

- Horizontal chimney fragments are made with an allowable length limit of one meter.

- The position of chimneys must not be changed more than three times.

- It is worth covering chimneys that are installed on the streets with heat-insulating material.

- It is necessary to install devices that are capable of extinguishing sparks at the exit of smoke ducts.

- The chimney must be installed taking into account the fact that its height must be at least five meters in order to be able to effectively remove smoke.

All these recommendations must be carefully followed, because installing a chimney is a rather painstaking and complex process, so you need to pay attention to every little thing and detail.

Where do unscrupulous manufacturers save money?

In conditions of handicraft production, it is impossible to achieve precise geometry of products, tightness of joints and a high service life of chimney systems. This is due to manufacturers saving on materials and the lack of an automated production line.

Cheap steel chimneys are obtained by using:

- Thin sheet steel less than 0.5 mm with a small chromium content of less than 13%. It quickly loses its properties, deforms and collapses under the influence of high temperatures. Perforation corrosion occurs in less than a year.

- Construction mineral wool (up to 300°) instead of technical wool (up to 600°). The insulation is stuffed by hand and crumbles over time. The pipe heats up unevenly and becomes deformed.

- Old equipment for rolling sheets. In this case, the exact geometry of the products is not ensured.

- Welding occurs with an overlap or a mechanical connection in a lock; the high temperature causes the seam to separate.

- Zigging method for connecting parts. Soot accumulates at the joints, making cleaning difficult.

Advantages of chimneys

As you might guess, stainless steel chimneys are very popular. Before choosing this chimney element, you should carefully study its advantages.

The advantages of stainless steel flue exhaust include:

- Full compliance with thermal safety regulations - these heat sinks fully comply with state safety standards.

- Such chimneys adapt well to different weather conditions.

- Stainless steel chimneys can withstand high temperatures and do not corrode.

- This type of chimney does not form condensation.

- When heated, stainless steel does not emit hazardous substances and, thus, cannot poison the environment and, in particular, the owners of the premises.

- Such a chimney is quite easy to install yourself, since the weight of the structure is relatively small.

- The chimney does not take up much space.

- Such a chimney can be installed in a finished house.

Cost of sandwich systems

The price of such structures depends on many factors, including the selected type of system model, the area for its placement and components.

Before purchasing a sandwich chimney, you should take the required measurements at the installation site and make appropriate markings. The cost of the purchased system depends on the accuracy of such work, so it is necessary to approach this process as responsibly as possible.

When choosing a chimney, the material from which it is made is not the main criterion for evaluating the product. It is important to take into account the technical characteristics of sandwich systems: a high-quality chimney means good draft, ease of use, safety, etc.

The average cost of one pipe ranges from 1,500 to 3,000 rubles. The specific price depends on the following parameters:

- internal section of the product;

- thickness and material of the thermal insulation layer;

- degree of strength of stainless steel pipes;

- presence or absence of coating on system elements;

- module length.

The sandwich system consists not only of straight modules, so you will need to select other components: tees, elbows, adapters and corners. Such elements have a high price, for example, the cost of one product can reach 4,000 rubles.

Disadvantages of stainless steel chimneys

Despite the huge number of advantages, there are still some disadvantages in stainless steel chimneys. And the main one is the price of such stainless steel chimneys.

Despite the fact that stainless steel is a fairly cheap material, in the form of a solid chimney this price increases. Another disadvantage is the poor thermal conductivity of metal, that is, when buying or creating such a chimney yourself, you need to provide it with thermal insulation or buy an already insulated one.

In addition, such stainless steel chimneys are not only flexible, but also soft. That is, if something happens, the chimney can change shape. This can only be avoided if, in addition to stainless steel, there is some other metal in the chimney.

Thermal insulation layer

Thermal insulation plays an equally important role in DS. She must:

- maintain the temperature in the inner pipe so that working draft is created in the chimney and flue gases are removed from the firebox;

- do not transfer high temperature to the structures enclosing the chimney to prevent fire.

Low-quality thermal insulation loses volume, settles, forming voids through which high temperatures will be transferred to the outer shell and, accordingly, to flammable materials. This is fraught with fire.

And also low quality insulation can absorb moisture, bake or coke. In these cases, it immediately loses its characteristics, forms cavities and exposes the outer shell to high temperatures.

The best option for a chimney would be a heat insulator that does not contain adhesive binders that burn out at temperatures of 500–600 °C.

Important! Ask the seller to show the insulation in the pipe. If it is printed from individual fibers, then within the first six months or a year it will lose its characteristics. High-quality insulation will be wrapped around the pipe like a blanket or consist of 2-3 segments.

Unscrupulous manufacturers use a trick - they create an illusion: they install rings consisting of high-quality segmented thermal insulation into the edges of the chimney, and fill the main space with low-grade material.

Photos of stainless steel chimneys

Popular device circuits

When choosing steel, metal thickness and insulation, we recommend focusing on the type of fuel you plan to use. The height depends on the power of the heating device and the diameter of the heating device.

For sauna stoves operating on solid fuel, we recommend using steel with a thickness of 0.8 mm.

To assemble a smoke exhaust system of any complexity, Ferrum has provided a bell-shaped design for assembling the structure. It consists of a hermetically sealed connection of two elements into one due to mounting extensions at the ends. The sockets are produced by cold forming of high-quality low-carbon steel while maintaining the plasticity of the materials during manufacturing. The alternative crimping technology does not provide a tight seal and leads to the accumulation of soot at the joints and creates difficulties during cleaning.

Elements of smoke exhaust systems

Required parts during assembly: boiler adapter, single-wall meter chimney, damper, start sandwich, sandwich pipes, polyurethane foam, roof trim and cap, as well as clamps.

The sandwich is the main element of the system for removing flue gases in straight sections. It consists of two pipes nested inside each other, between which thermal insulation is placed. This design has the following advantages:

- extremely low amount of condensation;

- soot practically does not accumulate;

- higher fireproof properties compared to single-wall chimneys.

This option is not connected directly from the furnace, as this could cause the pipe to burn out.

The boiler adapter is the starting pipe component of the future chimney. It is necessary for condensate assembly, as it reorients the turn during installation.

The gate blocks the flow of flue gases if necessary, representing a valve with holes to prevent combustion. The start sandwich is an intermediate element in the transition from single-wall to double-wall construction.

A ceiling-passage assembly (CPU) with mineralite is a mandatory element when maintaining fire safety at the point of passage through roof and ceiling slabs. PPU contains fireproof insulation material, an air layer and an area for placing an additional layer of thermal insulation.

The groove on the roof insulates the chimney from rain and snow. The increased rigidity of Ferrum structures will protect during snow melting, preventing leaks.

Clamps are used to fix the chimney relative to the installation plane. Steel fasteners are needed to position the system so that it does not rest on the stove or fireplace.

The role of the tee in the smoke exhaust system is to change the direction of the smoke channel, drain condensate downwards using a condensate drain and facilitate maintenance. Ferrum tees have sealed joints obtained through laser welding and the use of cold metal drawing. There are designs at 90° and 135°.

When assembling a chimney for a bathhouse, we suggest focusing on the Ferrum assembly diagram.

You can make a more accurate selection in the Constructor section, which in real time allows you to completely assemble the device taking into account the size of your bathhouse.