The most important condition for comfortable use of a swimming pool is high-quality water heating. But how can this be ensured, given the large volumes of liquid used and the high heat loss of an artificial reservoir? The most reasonable solution is to systematically exchange water at different temperatures: cold and hot. This process can be organized using a heat exchanger. To understand the features of this heating option, we suggest taking a closer look at the main operating device - we’ll tell you what a heat exchanger is, what to look for when choosing it, how power is calculated, and how to make and install the device yourself.

Structure and principle of operation

Structurally, a pool heat exchanger is a cylindrical body with two circuits: in the first, which is the immediate cavity of the device, liquid from the pool circulates, and in the second there is a device through which the coolant - hot water - moves.

Either a tube or a plate acts as a device for heating the liquid. The heat exchanger itself does not provide water heating - with the help of external fittings of the second circuit, it is connected to the boiler of the heating system and acts as an intermediary in heat transfer: first, water enters the device from the pool, then it moves along the body, comes into contact with the heating device, and takes from it the heat and then, already heated to the required temperature, returns back to the bowl. The larger the contact area of the heating element, the faster the heat transfers from hot water to cold.

How does a pool heat exchanger work?

How long does it take to heat up on average?

Let's consider how long it takes on average to heat water in bowls under different conditions.

In a tank on the street

The water in the outdoor tank warms up within 2-4 days (primary heating). The temperature is then simply maintained, although the process depends on the type and performance of the heater.

In room

Pools located indoors heat up on average in 1-3 days (primary heating). Heat loss in such bowls is much less, so heating time is almost halved.

Selection factors

When choosing a heat exchanger, take into account the following characteristics:

- Type of heating device: tubular or plate.

Advice. Experts recommend choosing tubular heat exchangers, as they provide a larger area of contact with water and are less sensitive to the quality of the circulating fluid.

- Bandwidth.

- Case material: stainless steel, plastic, titanium.

- Type of heater to which the heat exchanger will be connected: gas or electric boiler.

- Thermal power.

The last characteristic is the most important, because it significantly affects the performance of the heat exchanger. Based on this, a logical question arises: how to calculate the power of the device for your pool? For simplified calculations you will need the following data:

- V – bowl volume (l);

- ΔT – the difference between the required temperature of the heated water and the base temperature of the water in the pool (degrees);

- t1 – expected water heating time (hours);

- C – specific heat capacity (always equal to 1.16);

- q – heat loss from the water surface (W/sq.m.)

Important!

Average heat loss rates: for an outdoor pool - 1000 W/sq.m., for a partially indoor pool - 620 W/sq.m., for a fully indoor pool -520 W/sq.m. Calculation formula: P = ((VхСхΔТ)/t1) + qхS

Let's assume that you have at your disposal a fully open swimming pool with a volume of 40 liters and a water surface of 24 sq.m. To heat water in it in 4 hours, subject to a temperature difference of 15 degrees, you will need a heat exchanger with an approximate power of P=((40x1.16x15)/4)+1000x24 = 24 kW.

How to speed up the heating process?

To speed up the water heating process, it is necessary to reduce heat loss as much as possible . One effective way is to install a heat-saving coating on the water surface. A special film will stop the process of evaporation of warm layers of water rising to the top, which will reduce losses and accelerate the rise in temperature.

Another option is to use high-performance heaters that have power reserves for a bowl of a given size. This is important for public swimming pools, where it is not possible to stop using the bowl and wait for the water to heat up to the standard value.

Usually the equipment is run at full capacity in order to get the desired result in the shortest possible time.

Manufacturing and installation

If for some reason you do not want to buy a heat exchanger for your pool, you can build it yourself. To do this, prepare:

- steel cylindrical tank;

- copper pipe;

- power control device;

- anode.

Connecting the heat exchanger

First, make two holes at the ends of the tank: the inlet for cold water from the pool, the outlet for the return of heated liquid. Then roll the copper tube into a spiral-like structure. Fix the resulting heating element in the tank and bring both of its ends to the outside of the container, having previously made appropriate holes in its walls. Next, connect the power regulator to the tube and install an anode in the tank - it will protect the container from temperature changes.

Now you need to connect the heat exchanger. It should be installed after installing the pump and filter, but before attaching various types of dispensers. As a rule, the heat exchanger is located below all pipes, filters, and air vent.

The device is mounted in a horizontal position: the inlet and outlet of the tank are connected to the pool circuit, and the inlet and outlet of the heating tube are connected to the coolant circuit from the heating boiler. The easiest way is to use threaded connections. All connections are made using shut-off valves. After the circuits are connected, a control valve with a thermostat is installed at the coolant inlet pipe from the boiler, and a temperature sensor is installed at the water outlet into the pool.

Advice. If the circuit from the heating boiler to the heat exchanger is too long, install an additional circulation pump in its line to ensure uninterrupted operation of the system.

As you can see, a heat exchanger is a simple but very useful device that can guarantee uniform heating of water in a pool of any volume. You can buy an already assembled device, or you can make it yourself - in both cases, follow the above recommendations to accurately get the desired result: always warm and comfortable water in your pool.

Gasketed plate heat exchangers

In this article we will look exclusively at plate-type gasketed heat exchangers for swimming pools. You can often come across opinions that a tubular design is better due to the fact that it is not so clogged with dirt and debris. But water enters the heat exchanger passing through the filter. If you don’t forget to install it and maintain it on time, then no dirt can get into the unit. Plate structures are more efficient due to the large heated surface area.

Installing the heater directly in the tank is ineffective and also dangerous. Therefore, the heat source (electric, solar, gas) has a separate circuit. The heating and heated liquids do not mix. Temperature transfer occurs using a heat exchanger.

What materials are they made from?

Heat exchangers for heating water in a swimming pool, with rare exceptions, are made of two types of material: stainless steel or titanium.

Stainless steel is used due to its strength, corrosion resistance, it can easily withstand water hammer, and lasts for 10 years or more. In terms of price, the metal is much cheaper than copper or titanium and is the leader for heating fresh water.

Titanium is used for seawater pools. Despite the high cost, the material does not interact with fluorine, salts, or chlorine. It is also light, durable, and not afraid of heat.

Operating principle of a plate heat exchanger in a swimming pool

The device is a water-water device. The principle of operation is simple: there are 2 circuits inside the case. The primary receives hot liquid from the boiler. The secondary pumps cool water from the pool. Rubber seals prevent media from mixing. Heating occurs by transferring heat from the heating medium to the heated medium through a package of plates inside the heat exchanger.

The water in the second circuit is heated and enters the pool. The cooled liquid in the primary circuit returns to the heating device, where it is heated. The contents of the contours are never mixed directly.

Types of structures

To heat the large volume of water contained in the tanks of sports swimming pools, collapsible plate and shell-and-tube heat exchangers are used. Each type of equipment has both its own operational advantages and individual disadvantages that do not allow the use of a certain type of heat exchanger in certain pools.

Gasketed plate heat exchangers

The coolant and heated water move along contours formed by a package of metal plates. Rubber seals attached to the working surface of the plates prevent leakage of circulating liquids. Each plate is washed on one side with hot coolant, and on the other with cool water coming from the pool. A metal partition with a thickness of 0.5-0.6 mm does not interfere with the process of transferring thermal energy from a heated liquid to a cold one. Fluid flows moving at high turbulent speeds clean the plate channels from small mechanical debris.

Advantages of plate heat exchangers:

- heat exchange efficiency 90-95%;

- small dimensions and weight;

- low coolant consumption;

- the ability to connect all pipelines on one side;

- the ability to regulate the thermal power of the heat exchange unit by changing the number of plates in the package;

- simple operational maintenance;

- replacement of failed heat exchange plates by a full-time plumbing team.

Disadvantages of plate heat exchangers:

- increased requirements for the quality of cleaning of circulating liquids;

- the need to ground the heat exchanger body due to stray electrical currents that can damage the metal plates;

- noticeable hydraulic losses.

You can view the cost and description of devices of this type in the section of our catalog of heat exchangers for pools.

Shell and tube heat exchangers

The heat exchange process in shell-and-tube heat exchangers for pools is carried out through the surface of metal tubes. The hot liquid of the heating system enters the inter-tube cavity of the heat exchange tank and comes into contact with the surface of the tubes, through the internal channels of which the heated liquid from the pool flows. The hot coolant gives off thermal energy to the metal of the tubes, which transfers it to the cool water. Cold water is pumped into the receiving manifold of the heat exchanger, distributed through heating tubes, passes through them, receiving a certain amount of thermal energy, collected in the outlet manifold and sent to the pool. The more tubes installed in the heat exchanger body, the higher its power.

Advantages of shell and tube heat exchangers:

- simplicity of design;

- large heat exchange area;

- resistance to hydraulic shocks;

- the ability to carry out high-quality heat exchange between the coolant and the heated liquid with a slight temperature difference;

- low demands on the quality of purification of heated water.

Disadvantages of shell-and-tube heat exchangers:

- lower (than plate heat exchangers) efficiency;

- lack of possibility to increase power;

- lack of access to tubular channels when checking for cleanliness during maintenance;

- large dimensions and metal consumption of the structure, requiring the preparation of a special installation foundation;

- the need for thermal insulation of the heat exchanger body;

- inability to detect liquid leakage from heat exchange tubes without disassembling the heat exchange unit;

- replacement of failed heat exchange tubes - only during a major overhaul of the heat exchanger.

As can be seen from the above comparison, plate heat exchangers are easier to maintain, have higher efficiency and are small in size. However, pool owners try to purchase shell-and-tube heat exchange units, since they:

- have a larger heat exchange area;

- do not create hydraulic interference for the passage of heated liquid;

- less clogged during operation.

Service maintenance

The main malfunction of any heat exchangers (both shell-and-tube and plate) is the formation of scale on the surface of the heat exchange plates and tubes. Because of this, the performance of heat exchangers decreases, since the thermal conductivity of water stone is tens of times lower than the thermal conductivity of stainless steel. In addition, the decreasing cross-section of the channels increases the hydraulic resistance of the circuits.

Such problems are eliminated by flushing the heat exchange units.

Washing plate heat exchangers

Plate heat exchangers that need cleaning are disassembled. Using a metal brush and a high-pressure jet, clean the heat exchange plates from scale and dirt.

Dismountable washing allows you to visually assess the quality of the cleaning performed and determine the suitability of heat exchange plates and sealing elements for further use.

Flushing shell-and-tube heat exchangers

Shell-and-tube heat exchangers that cannot be disassembled are washed using a chemical method in-place, so the work is carried out by service organizations that have special flushing reagents, equipment and qualified engineers. An incorrectly selected flushing agent will easily damage metal heat exchange tubes.

During chemical washing, it is impossible to directly assess the quality of the washing, however, by measuring the hydraulic resistance of the heat exchanger before and after washing, one can conclude about the effectiveness of the cleaning performed.

Periodic washing should be carried out once every three years. Unscheduled - when the heat exchanger ceases to maintain the required temperature of the water in the pool.

Source

POOLS

Installation of heating equipment - heat exchangers

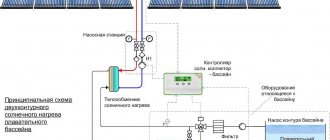

Options for heat exchanger piping schemes along the coolant circuit

An option with imaginary savings or a time bomb.

The absence of a coarse filter (FGO) always leads to a malfunction of the electromagnetic valve (EMV), due to the ingress of dirt particles of various origins, the valve stops closing and, as a result, the coolant flow does not stop, the pool water is constantly heated.

An option for the most economical. What does it mean? The absence of an EMC does not allow the coolant flow to be blocked; the coolant passes through the circulation pump (CP) even when it is not working. The absence of a check valve (OK) in the case when the pressure in the return is greater than in the supply, leads to the fact that the heating of the pool never stops.

| The maximum option for piping the heat exchanger along the coolant circuit with measuring pressure and temperature before and after the heat exchanger. It is used where temperature and pressure are documented in a log, usually in large public swimming pools. EMK - electromagnetic valve FGO - coarse filter M - pressure gauge T - thermometer Ksh - ball valve CN - circulation pump OK - check valve |

The heat exchanger is mounted in the supply line of water purified by a sand filter using metal-plastic couplings. Plastic heat exchangers and metal heat exchangers from some manufacturers (Bowman) have a PVA coupling for gluing. The need for a metal-plastic coupling is that when the water flow in the pool , the coolant of the heating boiler circuit continues to transfer heat to the heat exchanger and the metal-plastic coupling protects the PVC connection from excess heat. Let's consider the case when, instead of a metal-plastic coupling, an ordinary PVC transition is screwed in. The transition is screwed onto FUM tape or, possibly, onto flax. With strong heating, and 90 degrees for PVC fittings is an excessive temperature, the transition softens and in this case, upon subsequent cooling, it loses its geometric dimensions, it decreases. There is a loss of tightness and a leak will occur at this connection. That's it, this connection will never restore its qualities; it will need to be repaired, in other words, replaced, as required by technology, with a metal-plastic coupling.

Tying the heat exchanger battery.

Source

What materials are they made from?

For swimming pools filled with fresh water, heat exchange units are made of stainless steel. Stainless steel does not release iron ions, so it does not turn the pool water dark. It can easily withstand thermal shocks and can be easily repaired if necessary.

The chemical composition of stainless material is quite inert, so a heat exchanger made of anti-corrosion steel will last at least ten years before major repairs. And the main advantage of the material is its relatively low cost compared to other (not subject to corrosion) structural materials.

If the pool tank is filled with seawater, then the heat exchanger made of stainless steel will not last long. Titanium heat exchangers are manufactured for such operating conditions. Structural titanium:

- chemically passive (practically does not oxidize and does not react with chlorine, fluorine, and various salts);

- has high temperature resistance;

- lightweight and durable.

The performance characteristics of titanium fully compensate for its significant cost.

Calculation of parameters and selection of heat exchanger

Competent selection of a device requires a fairly scrupulous approach. You will have to calculate quite a few parameters before purchasing:

- Volume of the pool bowl. It’s quite easy to calculate using formulas; you can also use online calculators.

- Heating time . The lower the power of the device (and its price), the longer the water will take to heat up. The average acceptable value is considered to be about 4 hours before full heating. Outdoor pools require the installation of more powerful devices than would be needed for indoor ones.

- Set water temperature. Installed in the network, measured at the output of the device circuit.

- The volume of water heated per unit time. If the working system has a circulation pump that purifies water and, accordingly, circulates it, then the coefficient given in the technical data sheet will indicate the flow rate of the working medium.

Description and principle of operation of the heat exchanger:

When choosing a heat exchanger, consider all of the above parameters. Calculate the required criteria yourself using an online calculator. Keeping an eye on your budget and calculation results, as well as taking into account your additional preferences, you can safely go shopping.

Professional installation and maintenance of pool heat exchangers - BigPul

A pool heat exchanger is a device that transfers heat from a hot medium to a cold medium. It is indispensable for comfortable use of the pool. All heat exchangers have a cylindrical shape, inside which there are two circuits where water circulates from cold to hot.

Basic operating rules

The efficiency of the plate unit reaches 90–95%. However, scale is actively deposited on the walls. Therefore, to heat water, its hardness must be softened.

The hydrogen activity of the liquid pH should be in the range of 7.4–7.6. It needs to be monitored every day. You also need to remove debris and leaves from the water - their rotting increases the pH.

The filters must not be damaged by debris getting into the pipes. Chlorine is added in more than one place and mixed thoroughly.

If these rules are violated, accelerated damage to the heat exchanger occurs.

Introduction

According to the current sanitary and hygienic rules SanPiN 2.1.2.1188-03, the temperature of the water contained in the bowl of sports swimming pools should be within 24-28°C. And in the pools of water parks that accept visitors under seven years of age, they are required to heat the water to 30-32°C. Due to the physical characteristics of water, maintaining the above-mentioned temperature conditions without using additional heating equipment is quite difficult. Therefore, both large sports complexes and large water parks widely use recuperative heat exchangers for pools, with the help of which they heat the water to a temperature that is comfortable for humans.

Tips and tricks for DIY pool heating

Solar collectors can heat the pool up to 30 °C. This performance is achieved due to complete tightness and installation of water heating in accordance with the manufacturer’s instructions. It’s not that difficult to build the structure in question with your own hands. You will need the skill of construction work with the installation of elements strictly according to the instructions provided.

Knowing how a pool heating system works on a gas or electric boiler, you can bring your planned project to life. This does not require a lot of money and effort.