Design requirements

First of all, the ladder must be reliable and durable in order to withstand the loads of a person’s weight without deformation. But even with sufficient strength, there is a factor that poses a danger - water. It reduces friction and increases slip. To eliminate the risk of falls and injuries, it is necessary to provide non-slip steps, handrails, and round all sharp corners.

The safest steps are at least 80-120 mm wide. You can firmly place your foot on them and transfer your body weight without fear of staggering.

Hygiene is a mandatory requirement for pool ladders. Small algae, bacteria and protozoa multiply extremely quickly in water, covering all accessible surfaces with a slippery coating. If the material is easy to clean and disinfect, colonies of microorganisms are destroyed, and the water in the pool does not become dirty so quickly.

In a humid environment, most metals begin to actively deteriorate and rust appears. Corrosion processes occur even in concrete. For stairs located inside the pool, it is necessary that the material is resistant to corrosion or protected from water penetration by reliable waterproofing.

And finally, we must not forget that the pool is a component of the recreation area, so all its elements should be conducive to pleasant contemplation. A nice staircase design is just as important as the decorative finish of the pool or the surrounding beautiful landscaping. The design should look neat and modern.

Basic rules for making a homemade ladder

The main task of a bathing ladder is to ensure safe descent and ascent.

Therefore, during construction, important factors should be taken into account:

the ladder must be strong and durable;- it should be securely fixed - mounted to the pool or put rubberized tips on the legs;

- the steps are also, if necessary, covered with anti-slip pads;

- the ladder must be placed in a well-lit place, regardless of the time of day;

- height depends on the height of an adult or child;

- The age of the swimmers should also be taken into account - the elderly should be provided with additional safety.

Materials

The staircase is in quite aggressive conditions. High humidity combined with oxygen in the air are factors that cause corrosion of metals and rotting of wood. Therefore, the choice of materials for pool stairs is not so great:

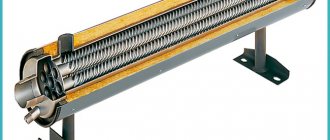

- Stainless steel or aluminum. Lightweight, hygienic and corrosion-resistant metals can be used to make stationary or portable stairs. Most often, a pipe with a diameter of 40 mm is used, which ensures the strength of the frame and handrails. The steps can be made of corrugated sheet or in the form of a lattice to reduce slipping.

- Wood treated with antiseptics. It is advisable that the wooden parts are not in water. This is dictated not only by the fact that wood rots quickly, but also by safety. Wet wood becomes covered with mucus and algae and becomes slippery. And this is a direct path to falling and injury.

- Stone, concrete. In stationary pools there are no restrictions on the use of these materials. As a rule, concrete steps are lined with tiles or stone. It is worth focusing on special types intended for use at high humidity.

- Plastic. Resistant to water and corrosion, but afraid of ultraviolet radiation. For the manufacture of stairs, it is advisable to use plastics with UV protection. Information about this can be found in the technical documentation or material labeling.

If the bottom of the pool is made of waterproofing film, it must be protected from punctures. The lower part of the ladder, which rests on the bottom, is insulated with overlays with non-sharp edges.

How to choose

A pool ladder can be:

- Foldable. Simple and easy to assemble, it can be stored away during the cold season.

- With transition platform. Allows you to stand up and take a comfortable position. Optimal for children or elderly people.

- With or without handrails. Handrails provide safety, but may not be installed if the design provides for the ability to hold on to other parts of the frame.

- Single or double sided. Single-sided stairs are designed to go up or down only, while double-sided stairs can be used both up and down.

- Inclined. The most convenient and safe. The sloping part is located in the bowl itself and occupies some of its volume, so it is rational to use them in large pools.

- Vertical. Very compact, can be installed in any limited space.

- Roman. It is a structure of cascading diverging steps. Sustainable, safe and original. Suitable for large stationary swimming pools.

The choice of staircase type depends on the type of pool (stationary, temporary), its depth, the height of the sides and the desired options. If the pool will be used primarily by young children, it is recommended to provide handrails and a transition area.

How to calculate dimensions

A pool ladder can be very compact. A width of 50-60 cm is enough for one person to move around without discomfort.

The height is determined based on the position of the top of the sides relative to the ground (podium) and the bottom of the pool plus 60-80 cm for the handrails. The racks can be the same length or different sizes.

The steps need to be distributed at equal intervals - 30-35 cm for an “adult” staircase, 25-30 cm for a child’s staircase. The slope can be arbitrary, since the staircase has a narrow purpose and there are no special requirements. The main thing is that it should not take up too much space in the pool and not interfere with water procedures.

Work methodology

You need to start work by making the upper and lower racks. As soon as the necessary pieces are prepared, their ends should be cleaned. From the set of components, tips are taken, which consist of a cradle and a leg. The tip should be placed on the stand. The cut of the stand will be hidden by the cap. Once the racks are prepared, they can be installed in place.

Fastening is carried out by mortgages with an internal diameter of 25 mm. Before you start making a pool ladder, a drawing should be prepared. It will help you understand how to avoid mistakes.

DIY staircase made of stainless steel pipes

Before production begins, the depth of the pool is measured, the width and height of the steps are determined, as well as where the handrails will be located. It is recommended to draw up a detailed drawing.

Sequence of work:

Cut blanks for the frame and handrails according to size.

Prepare the steps. For them, use a channel with a height of 80 mm. Select grooves at the ends that correspond to the cross-section of the frame pipes. You should get the following details.

Bend the edges of the steps slightly with a hammer so that they do not stick out later, but fit snugly against the pipe.

Connect the frame elements using stainless steel welding. Scald the ends of the steps.

Stainless steel is welded using an inverter-type welding machine using tungsten electrodes or other types designed for corrosion-resistant metals. The edges of the pipes are tightly joined and connected on a short arc. Until the seam has completely cooled, the parts cannot be moved.

Clean the weld seams with a grinder, and you can assemble the ladder.

First, the frame parts for the side posts and handrails are welded. Then the steps are installed and welded at regular intervals. They must be perpendicular to the posts and positioned strictly horizontally relative to the ground.

Ring-shaped decorative overlays are strung onto the supports, and fastening plates are welded to the ends of the supports. The ending should look like this.

Once again, all connections are cleaned, and the staircase to the pool made of stainless pipes is ready.

Separate categories of descents

There are several types of descents into the pool, which differ significantly from the above “classic” types. By creating a swimming pool with their own hands with a platform and interesting accessories, every apartment owner wants to make the structure not only comfortable and safe, but also exclusive.

Perhaps the most interesting descent for swimming pools can be called balneological-type structures. Installing a ladder in a pool of this type will not be easy.

Stainless steel pool stairs - buy stainless steel stairs and handrails Stainless steel pool stairs - buy stainless steel stairs and handrails Stainless steel stairs to the Pool: Manufacturing, Installation Stainless steel stairs to the Pool: Manufacturing, Installation

This is due to the fact that the design is supplemented with built-in nozzles. Their task: to massage the human lumbar and spinal ridge. They can be used for both therapeutic and preventive purposes, strengthening the health of swimmers.

It is also worth mentioning the slopes for children. They have more steps. They are much smaller than “adult” playgrounds. In addition, the design is always complemented by low railings, and the interval between steps is minimal.

From plastic pipes

Such stairs can be recommended for temporary pools that are used for a short time. They are easy to carry, and at a low height - 3-5 steps - they are installed without rigid fastenings.

Polypropylene and polyethylene pipes are welded using special equipment, which in everyday life is called an “iron”. PVC products cannot be welded; they are connected using fittings.

For stairs, pipes with a diameter of 32 or 40 mm are used. They are quite strong, but flexible. Therefore, metal rods can be installed inside to provide stability. It is possible to strengthen the structure by making it double, which, given the inexpensive price of the pipes, is very affordable.

To assemble the stairs, the same technology is used as for installing a water supply system. The parts are cut according to the drawing using a hacksaw or special scissors for cutting plastic. The cut must be smooth, perpendicular to the axis of the pipe.

For welding, heating nozzles of suitable diameter are used. The heating temperature is set in the range of 260-300°C. Sections of pipe sections are connected using couplings, tees and corners. The number of fittings must be calculated in advance, since there will be a lot of assemblies to weld.

Pipe soldering procedure:

- Nozzles are installed on the heating element.

- The soldering iron is plugged in and the temperature is set.

- After the indicator signal, the pipe and fitting are put on the nozzles.

- Warming up is carried out during the interval specified in the instructions supplied with the device.

- The elements are connected to each other without excessive effort.

The assembly must be cooled in a stationary state, otherwise parts may shift.

To simplify the work, the staircase must be assembled in a certain order. First, individual volumetric parts are welded - the lower one with steps and the upper one with handrails. Then they are connected together.

To prevent the ladder from damaging the pool cover, the frame supports are wrapped in an elastic material, such as pipe insulation. You can attach the legs to a flat platform with non-sharp edges.

Made of wood

It is better to use wooden stairs where the wood does not come into contact with water, that is, outside the pool. But even when exposed to air, the tree needs to be treated with antiseptics. Special chemicals penetrate deep into the fibers and create an environment unfavorable for the proliferation of microorganisms. This significantly extends the service life of structures.

The wood is impregnated with antiseptics both before and after mechanical treatment. If possible, it is better to use kiln-dried wood. It is denser, cracks and warps less.

The strength of the stairs is ensured by boards and bars with a thickness of at least 40 mm. The wood is carefully planed and sanded so as not to leave splinters.

If the edge of the pool is strong, the ladder can be made into an extension. There are grooves in the upper part for support.

For frame or inflatable pools, a ladder on its own supports is suitable. It is assembled from two parts - inclined beams (stringers) with steps and a vertical frame with racks. You can arrange a small horizontal platform at the top of the flight, and rest a plastic ladder on it, which lowers into the water. For small children, railings or barriers are desirable.

Manufacturing begins with the preparation of parts for the side load-bearing beams, steps, frame posts, and reinforcing crossbars. For assembly, galvanized nails, screws, corners, and overlays are used. You can combine mechanical fasteners with waterproof glue, which is used to coat the joints on the inserts.

The finished staircase is coated with exterior paint or yacht varnish. To prevent the steps from slipping, they need to be lightly sanded.

Stone or concrete

The construction of such a staircase involves laying stone or pouring concrete into the formwork. If it will be located in the pool bowl, the materials must be sufficiently waterproof, including the masonry mortar. For this purpose, special additives are used to reduce porosity and increase density.

Waterproofing will help reduce the harmful effects of water. For concrete, the most effective means are deep penetration agents that cause crystallization in pores located at a depth of up to 12 cm.

The water permeability of masonry decreases when film-forming paint waterproofing is applied, but most of the products contain toxic substances. Therefore, durable polypropylene films are used as the main method of protection against water. They are placed in a pool bowl made of brick or concrete. External steps are lined with non-slip stone.

Expert advice

The surface is cleaned with sandpaper. In order to improve the appearance of the product, it can be burned with a gas burner. This will make the wood texture more expressive. The boards are attached at the next stage using self-tapping screws; the final step is to apply varnish. It is worth remembering that wooden pool stairs, although quite simple to manufacture, are short-lived. When exposed to water, they quickly become unusable.

Step ladder

For a small pool, you can use a ready-made structure - a construction stepladder made of aluminum. Durable and lightweight, it is not subject to corrosion and is a ready-made frame with steps. They are already corrugated, that is, non-slip. All corners are covered with plastic covers for safety.

Stepladders come with their own support legs, attached or vertical. Steps can be located on only one side or on both. In telescopic versions, the height of the retractable part is adjustable.

Many stepladders have spacers that provide stability. They fix the inclined parts of the structure in a certain position, but limit the height of the pool side. If necessary, the stepladder can be disassembled and modified, for example, adding vertical posts and a stable platform to the ladder.

Stepladders for 3-4 steps do not have spacers. They maintain their position due to grooves on the upper platform. They can be used for low pools; it is enough to install additional steps on the support frame.

Do-it-yourself ladder for a frame pool: manufacturing features

The design of a frame pool is a rigid frame made of plastic or metal rings, covered with polyvinyl chloride film. It absorbs lateral loads from water pressure and is not at all intended for any objects to rest on it, including stairs.

The frame can simply “play” under a point load from a person’s weight. At best, the side will tilt slightly, at worst, it will seriously bend and warp. Therefore, in frame pools, the ladder is not supported on the side, but is installed on its own stops. The platform should not touch the top of the bowl, then the frame will not be in any danger.

The same restrictions apply to inflatable pools. The air-filled shell is soft and not strong enough. If handled carelessly, it can become deformed or even tear.

Choose wisely

Any stairs for swimming pools are subject to the general requirements that apply specifically to structures located near water. This:

- Reliable fastening of the ladder to the side (if it is a non-recessed bowl design).

- Anti-slip pads on steps or non-slip tread material.

Material

All products that come into contact with water must be made from materials that are highly resistant to moisture. In the case of a swimming pool, we are no longer talking about high humidity, but about water in its pure form. The product is lowered into the water in one sector, and Roman-type underwater ladders “live” at depth, like some kind of manatee. Accordingly, there is no question of making a wooden staircase, even if you cover it with ten layers of water-repellent coating. you need to choose either stainless steel or special acrylic compounds.

Your seasonal country pond

Seasonal inflatable pools rise above the ground. To reach the side you will have to climb a ladder

When choosing a ladder for a summer inflatable product, pay attention to the following important parameters:

- Design dimensions. It needs to fit perfectly to the shape of the pool. The length of the ladder should be greater than the height of the bowl, since the structure is inclined.

- The size of the handrails. Look at the photo above. The rounded handrails are high enough for your child to grab onto comfortably.

- Upper platform. It should practically lie on the side of the pool. Do not rise high, but also do not be lower than the side, naturally. This point logically follows from point one. If the height of the staircase is chosen correctly, then it will harmoniously fall into place.

- Bottom stops. Ladders for swimming pools, so-called mobile ones, stand on the ground. They must have non-slip stops that are firmly pressed into the ground. The ends of the stops should be “shod” in rubber shoes.

- Steps. Based on who your staircase is intended for. If for children, then the crossbars should be frequent so that small legs do not have difficulty in lifting. The material for the steps, as mentioned above, should not slip. It is ideal if the steps are dressed in rubber “clothes”.

Stationary pool at your home

It's not just Americans who splash around in their private pools. Many Russians living in private houses have such luxury. Their pools are also equipped with stairs. What kind of stairs should be used for swimming pools?

First, we need to clarify that stationary pools also come in two types. Recessed in a dug pit and rising above the floor like a bathtub. In accordance with this, stairs for home pools are divided into two main groups:

- underwater wide steps;

- an external staircase, similar to the designs for prefabricated pools described above.

Roman stairs

Of course, the luxurious steps of the Roman stairs leading into the emerald water are the ideal solution, respectable and safe. Slowly and smoothly walking along them, you sink gradually. It's okay if you slip a little, the water will soften your fall. The advantage of such a staircase is that you can sit directly on the steps, lower or higher. And how beautifully they shine through in the water!

Roman staircase underwater steps are typically made from pressed acrylic with fiberglass added. They are coated with an anti-slip coating. The Roman staircase is a separate element; it is installed after the construction of the pool bowl.

External staircase

A chrome-plated steel ladder, starting on the floor of the pool and descending into the water, often has not treads, but round crossbars made of profiled pipes. The number of steps depends on the depth of the pool bowl. You can order a staircase that ends in the depths of the bowl, or you can order one that reaches the bottom. By the way, the last option is useful for those who are learning to stay in the water column and not float up.

Stainless steel designs are popular and are very effective in a brightly lit room. In addition, they do not rust and last a very long time. And maintenance for such a product is minimal. Complete with a sparkling ladder, handrails look great, they are mounted into the walls of the bowl and are so convenient to hold on to and do water aerobics exercises.

Watch a video of a Roman staircase located in the mysterious depths of the pool. Isn't she beautiful?