Hello, dear readers!

A concrete screed on the floor in a bathhouse is considered the best option. It is durable. No matter how you look after the wood, after 5-10 years the floors need to be re-laid. Do you understand the humidity...

Concrete does not rot, does not deform, does not require special care, and lasts for more than 40 years. Today we’ll talk about how to fill the floor in a bathhouse with a slope for drainage. It is not easy to do the work of arranging such a floor with your own hands, but it is possible if desired.

Pouring the floors in the bathhouse can be done both in the washing room and in the steam room. A concrete floor is essentially a concrete screed on top of which a waterproof, non-slip coating is laid. Typically, tiles are used for these purposes. When laid on the ground, the slope of the floor is ensured by creating a slope of the very base of the ground. For small areas - due to changes in the thickness of the underlying layer.

Features of the drainage system

First of all, I would like to draw attention to the fact that the installation of sewerage in the bathhouse should be carried out even before the work on laying the floor https://techengroup.ru/pomesheniya/dlya-parkovok/.

At the same time, it does not matter much what material the floor in the bathhouse will be made of. Regardless of your choice of drainage device, before creating a sewer system, you must perform certain preparatory work.

Many people mistakenly hope that all the drainage from the bathhouse will be absorbed by the soil. However, this option for wastewater disposal leads to the soil being polluted and the soil being eroded. If you abandon the idea of creating a water drainage system, then after a short time from the moment the bathhouse begins to operate, you may encounter shrinkage of the structure, its main structures will begin to deform.

If the erected structure for paired procedures is intended for a family of three, and it is used only once a week, then in this case you don’t have to worry about installing a sewer system in the building if the bathhouse is built on sandy and sandy loam soils. In this case, a leaky floor is created to drain water. This work involves fixing the floor boards loosely. They are laid freely with a gap of 5 mm.

This allows you to lift the floor and dry it at any time. The drains that pass through such a floor are absorbed into the ground. If the amount of drainage from the bathhouse is large enough, then in this case it is worth installing a leak-proof floor in the building and creating a sewer system.

Requirements for the drainage system

Since a lot of water will fall on the floor in the bathhouse, it is necessary to organize its drainage correctly and you need to think about this even while pouring the foundation. When constructing on sandy soil, you can simply make a drain hole under the washing room, the bottom of which is filled with large crushed stone. To remove unpleasant odors, vents are made in the foundation.

In the case when the soil is dense, a pit is made under the floor, into which a siphon with a water seal is installed and the water is discharged through pipes into a drainage ditch located outside the bathhouse or into the sewerage system.

It is recommended to drain in the far corner of the washing room , and the slope of the floor should be 1 cm per meter of length. The size of the pit is about 30x40x40cm, it must be concreted and the wall thickness should be about 5 cm.

To drain water, ordinary sewer plastic pipes with a diameter of 100 mm are used. After connecting the pipes, the pit is covered with a metal grill , which will protect you from accidentally getting into it and will not allow large objects to get into the pipe.

The presence of a water seal or a special valve will not allow the unpleasant odor from the septic tank or drainage pit to penetrate into the room.

We fill the floors in the bathhouse with our own hands

The technology for pouring floor screed in a bathhouse, in general, is no different; it is quite simple and accessible to anyone who decides to do it themselves with their own hands. A regular aluminum profile can be used as beacons. It must be remembered that in the bathhouse the entire floor from beginning to end is sloped, in the direction of the intended place of concentration and discharge of water. The guide beacons are set by measuring the slopes with a long rule and a level. Beacons are placed with a meter interval from each other. A pair of trowels of mortar are placed on the base, a guide beacon is installed on them and, measuring with a level, gradually pressing on the desired side, the inclination of each beacon is set to the same level. After the solution has hardened, the beacon settings will no longer be lost and you can safely begin applying the screed. As with most decorating projects, it's best to start at the far corner. The solution is poured directly between the beacons and, if necessary, leveled along them. Professionals, as a rule, do not do these types of work alone, because the solution must be constantly poured and immediately leveled. Therefore, if you are pouring the floor in a bathhouse with your own hands, it is recommended to call someone for help, this will speed up the whole process significantly.

Waterproofing the floor in a bathhouse: general information about floors in rooms with high humidity, the nuances of waterproofing wooden and concrete bases

General leveling of the screed is carried out using a long rule, which is carried out along the guide beacons, smoothing out all the unevenness. If necessary, you will need to add mortar somewhere with a trowel so that there is no hole, and remove the excess somewhere so that there are no bulges in the floor.

Strengthening of the screed occurs in about 2-3 days, but it will finally take place only after 2 weeks. To avoid the occurrence of cracks during this period, the screed should be wetted 2 times a day. This is done so that light spots do not appear - areas in which the cement for some reason dries faster than the rest of the floor, which can lead to cracks. After wetting, the floor is covered with a film so that the water does not evaporate immediately.

Adviсe

In order for the process of installing the floor in the bathhouse to go “without a hitch,” experts recommend following a number of instructions.

- For insulation, you should choose materials that are least responsive to elevated temperatures and humidity. That is, it is better to simultaneously organize not only heat, but also hydro and vapor barrier.

- The bars should be laid correctly so that the liquid can flow down along the joint line.

- If there is a possibility that the space under the floor will fill with moisture, it is necessary to create a gap from the internal backfill on top of the soil to the wooden base. Its size reaches 15 centimeters.

- Fiberglass underlays on the waterproofing floor will make movement on the floor inaudible. They are produced in the form of a thick tape, which is extremely convenient.

Wooden materials must be treated with an antiseptic. It is advisable to use a composition that can destroy all microorganisms and prevent damage to boards and beams. In addition, all wooden parts are pre-dried or purchased already in this form.

If this is not done, the material will curl during use, cracks will appear and the shelf life of the floor will be significantly reduced. If it is necessary to install ventilation, it is important to organize its correct output. Usually a separate pipe follows the path along the wall to the attic

If the foundation is monolithic, then it is recommended to make holes that will connect the ventilation gaps with the air outside. If the steam room area is large, then one drain will not cope with all the water. It will be necessary to think about several so that the material does not rot too quickly. Dry floors not only eliminate moisture, but also lead to heat loss. In this situation, it is necessary to insulate the foundation and base of the log house, and place the sauna stove below the floor level.

- The floor in the steam room rises relative to ground level. And in a separate washing room, on the contrary, it should be lower than in other rooms.

- It is necessary to leave a ventilation gap under the floor. It can be installed at a height of 10–15 cm.

- It is worth installing the finished floor so that there is an angle of inclination in the direction that is directed along the length of the boards, and not in width. This will help extend the service life of the products, since the direction of water is also one of the reasons in the rotting process.

- To prevent the board from bursting when screwing in the screw, you need to work at an angle of 45 degrees.

- Under no circumstances should you use linoleum, laminate or other synthetic coverings in bathhouses, even in the rest room. In any case, such materials will begin to heat up and release substances that can poison the body. In the dressing room, such a covering should be placed on top of a special flooring that allows the floors to dry.

- The selected boards must be edged or tongue-and-groove. Their thickness varies from 25 to 30 mm.

Floor with drain over concrete screed in a timber bathhouse

Here a drain hole has already been installed in the concrete screed and the floor beams have been installed. All that remains is to insulate the underground with sheets of extruded polystyrene foam.

Prev 1of1 Next

Prev 1of1 Next

Prev 1of1 Next

Prev 1of1 Next

The insulation boards are fastened together with sealed foam and laid with a slope towards the drain. A layer of roofing felt waterproofing is laid on the crowns of the log house, on top of which a reflective vapor barrier for the walls of the steam room will be installed in the future.

Finally, the simplest elementary technology for draining a wooden floor from our ancestors. The floor is divided into two parts by a wooden channel running down the center. It is made of three boards and has a cross-section of an inverted letter P. This design with three walls resembles a square pipe without one plane and is installed in the center of the steam room with a slight slope towards the drain. The remaining floor boards on one and the other side of the gutter are mounted so as to form a slight slope towards it. The floor is made solid, without cracks, and all the water flows to the center and exits through the gutter into the sewer system.

Options for installing inclined floors

Example of a floor arrangement with an Envelope type drain

Designing a base with a ramp always begins with choosing the type of slope, which can be of two types:

- “Envelope” is a special type of base cladding in which the drainage system is located in the center of the room. For normal water drainage, the base is conventionally divided into 4 parts in the form of an envelope, making a slight slope towards the ladder;

- From two planes - a design in which the base is divided into two parts and made with a slight inclination relative to each other. At the lowest point of such a system, a drain is installed into which liquid from the floor covering flows by gravity.

Installation of a concrete floor with a drain in a bathhouse

Before pouring the floors in the bathhouse to drain the water, let's look at the sequence of installation of the entire floor structure in the washing compartment.

If your bathhouse building is built on a slab foundation, then you can start pouring the screed directly on the concrete base. Naturally, the slab must have a hole for the fan pipe equal to its outer diameter.

If your bathhouse is on an MZFL foundation or on a columnar / pile foundation, then the floor pie design will be relatively standard for this option.

First of all, floor joists are installed, which will perform three functions at once in this scheme:

- The logs will serve as the basis for the finished floor, which will be concrete in the washing area and wooden in the steam room.

- A subfloor will be attached to the joists, which will support the insulation underneath.

- The insulation you have chosen to insulate the bathhouse floor will be laid between the joists. For example, if you chose standard mineral wool slabs with a width of 60 cm, then it is worth making the distance between the logs 59 cm to simplify the installation of insulation in the bath floor.

After the logs are installed in place, a drainage system from sewer pipes is installed. Pipes with a cross section of 50 mm run from the washing compartment. If you are making a toilet in a bathhouse, then pipes with a cross-section of 110 mm will go from the toilet. After the toilet, wastewater should go either to a cesspool or to a septic tank - a house one or a separate bathhouse.

Should wastewater from the toilet and washing compartment be combined in a bathhouse? You can and should combine them. In this case, wastewater from the washing compartment will clean the pipe coming from the toilet and provide enough water for the operation of the septic tank, if it is equipped separately for the bathhouse.

After the pipes are installed, you can begin installing the subfloor. The subfloor in the bathhouse can be made from either boards or any suitable slab material. It can be DSP, plywood, OSB. If plywood is used, it will need to be impregnated with bioprotective compounds such as Senezh Bio.

After this, a floor insulation is installed between the floor joists, which will rest on the subfloor. As mentioned above, it is better to install the insulation between the joists.

Next, let's look at how to pour a screed in a bathhouse under the drain so that water is guaranteed to collect in one corner near the drain. For this purpose, any slab material is mounted on wooden logs. DSP is best suited for these purposes. Of course, cement particle boards are very susceptible to deformation if they swell from moisture. However, under a concrete screed this material will feel quite tolerable.

The slope of the floor in the washing compartment can be 0.3-0.5 cm per meter. In this case, moderately polluted water will be drained, so there is no longer any reason to make a slope.

After the screed has been made and the drain has been installed, you can begin installing the final floor covering. The best options for this scheme would be to use ceramic or porcelain tiles.

As you can see, a poured concrete floor in a bathhouse with a drain can be made with your own hands and according to a very simple scheme.

First stage

Having prepared the tool and purchased the necessary materials, we begin the preparatory work. First we dig a drainage hole. Its task is the reception and subsequent disposal of wastewater. On the outgoing sewer pipe we install a valve, the so-called drain ladder, which:

- hermetically connects the drain and waste systems;

- thanks to the installed grille, it ensures filtration of incoming water, which significantly reduces the possibility of blockages;

- prevents gases from entering the sewer pits into the room, as it is equipped with a water seal located inside the siphon.

Depending on the location of the drain hole, a drain is used with a straight line (when the pipe exits strictly vertically) or a side connection (if it is horizontal). When purchasing a drain ladder, pay attention to its height, which is fundamental when calculating the height of the coating being formed.

Having prepared the drainage pit, lay out the sewer pipes. If the drain is located in the corner of the room, the pipe is laid along the wall. When the drain is located in the center of the base, the pipes are laid diagonally, avoiding bends as much as possible, which lead to the formation of unwanted blockages. The plumbing elements are connected and brought to the cesspool. When organizing drainage from several rooms, they distribute communications throughout the room. The trenches are filled with sand and compacted tightly. To prevent pipes from becoming clogged with debris while the floor is being poured, they are covered with special plugs or thick fabric.

Installation of bath floors, usually done on the ground or logs

Features of wooden floors

Despite the strength and durability of any wooden structure, over time, under the influence of humidity and ambient temperature, it changes its linear dimensions, which causes shrinkage. In addition, wood is a “breathing” building material, so cracks begin to “spread” along the wooden beams. That is why you should never pour screed onto a fresh wooden floor immediately after building a house. Leveling can begin no earlier than 3 years after the wood base has completely dried and settled.

It is recommended to lay a monolithic concrete slab on wooden joists (on which the floorboards are supported) if the beams are installed on brick columns with a height of at least 300 mm. If the logs are laid directly on the floor slabs (which is most often the case), then you can only install a “floating” screed. In this case, some advise removing the floor boards and pouring the concrete slab in the traditional way, but in this case the screed will be fastened to a wooden base, and at the slightest deformation the flooring will crack. Therefore, we will consider the most reliable technology for laying a “non-cohesive” screed that will not connect to the walls and ceiling.

Materials

According to experts, it is best to make the base of the floor from concrete, especially if you want to build a permanent building made of brick or stone, with several rooms, which will be used throughout the whole year.

The concrete floor must be supplemented with a water drainage system and provided with waterproofing. This design is strong and durable; it is not afraid of water, steam, or temperature changes. Concrete floors can be used for up to 45 years without additional repairs. However, there are certain disadvantages. Firstly, they are cold, so they have to be insulated with an additional coating, for example, tiled or self-leveling. Secondly, concrete floors require significant investments, both financial and labor. Concrete floors can be poured in three stages.

If you are building a small bathhouse that is used only during the summer season, then it makes sense to choose a wooden floor. It is quickly and easily built from environmentally friendly materials (preferably larch boards), looks very attractive and creates a unique atmosphere in the steam room of an old Russian bathhouse.

When installing wooden floors, it is recommended to choose coniferous trees - fir, larch, pine and others. Since such wood contains a large amount of resin, it will be less susceptible to humidity, and the released essential oils will have a positive effect on the health of those taking water procedures. It is worth adding that coniferous floorboards, when moistened, will not become slippery, which means they will prevent falls.

Wooden structures are divided into leaking and non-leaking. The pouring floor does not have insulation, so it is suitable for bathhouses located in the southern regions, or for options used exclusively in the warm season.

The leak-proof floor is constructed from two layers of boards. The upper one, which will go on top, is preferably constructed from pine or hardwood boards, and the lower, dry one can be equipped with insulation.

The logs are installed on the foundation beam in the case of a columnar foundation, or on the edge in a situation with a strip foundation. Contact points are insulated with roofing felt coated with bitumen, Eurobitumen or similar waterproofing material.

Wood floors should not be painted or treated with chemical solutions. This is unlikely to add durability, but it will deprive the boards of the ability to breathe and fill the steam room with a unique pine aroma. The most acceptable solution would be to thoroughly sand the boards before starting construction. You can also cover the floor with a heat-resistant water-based varnish that can withstand up to 120 degrees. The elastic coating prevents moisture, steam and dirt from penetrating the boards.

The two-layer composition is applied to the sanded and disinfected coating using a paint brush. The entire procedure is carried out in a ventilated room at a temperature of 5–30 degrees. Only after the varnish has dried after 2-3 hours is it possible to begin laying the floor covering.

Preparatory activities

To make a poured floor in a bathhouse, the base is prepared as carefully as possible. Otherwise, the base will not have the necessary strength characteristics, which will significantly reduce the service life of the finished floor. The work is performed in the following sequence:

- Removes a layer of soil 40–45 cm thick. This allows you to get rid of organic residues present in the soil;

- The surface is carefully leveled. A pit is installed in the center of the room, in which water will collect during the operation of the bath;

- A drainage pipe with transverse dimensions of 10–20 cm is installed. The pipe is placed at a slope to ensure the outflow of liquid under the influence of gravity. To prevent accidental clogging of the drain pipe, cover it with a lid or simply plug it with a rag. A fence made of boards or pieces of roofing material is erected around the drain pipe itself. This will allow, if necessary, to replace the installed element if the pipe head does not meet the requirements for it;

- The quality of the work done is controlled. For this purpose, a regular or laser construction level is used.

The soil is removed to a depth of 0.5 mSource googleusercontent.com

Before pouring the concrete solution, the base is thoroughly compacted. To sufficiently compact the soil, a vibrating plate or manual tamper is used, depending on the area of work and the configuration of the bathhouse. A layer of sand 5–10 cm thick and gravel is poured onto a carefully compacted base. The thickness of the second layer is 10 cm. The pillow is carefully compacted.

Choosing a design for existing soil

If the soil on the site absorbs moisture well and consists mainly of sand or loose soil, you can install a self-leveling floor for a bathhouse directly on the ground. In a steam room, as a rule, there is no need to equip a water outlet. But for the shower and washrooms, drainage is simply necessary.

The main desire of every owner is to have a heated floor in his bathhouse (read: “How to make a heated floor in a bathhouse from a stove with your own hands”). Excellent protection against cold penetration from the soil guarantees accelerated heating of the bath, long-term heat retention, and maintenance of the required temperature regime. This feature is extremely important during cold periods of the year, when cooled soil takes away a large amount of thermal energy.

When constructing a floor in a bathhouse on a ground base, a number of mandatory steps are required:

- Construction of a drainage system in which used water will accumulate and be discharged.

- A sand cushion is placed under the first screed on the ground.

- The initial layer is poured.

- An insulation and waterproofing layer is laid.

- The top tightening layer is made.

In the photo, this floor design looks like a layer cake.

We fill the floors in the bathhouse with our own hands

The technology for pouring floor screed in a bathhouse, in general, is no different; it is quite simple and accessible to anyone who decides to do it themselves with their own hands. A regular aluminum profile can be used as beacons. It must be remembered that in the bathhouse the entire floor from beginning to end is sloped, in the direction of the intended place of concentration and discharge of water. The guide beacons are set by measuring the slopes with a long rule and a level. Beacons are placed with a meter interval from each other. A pair of trowels of mortar are placed on the base, a guide beacon is installed on them and, measuring with a level, gradually pressing on the desired side, the inclination of each beacon is set to the same level. After the solution has hardened, the beacon settings will no longer be lost and you can safely begin applying the screed. As with most decorating projects, it's best to start at the far corner. The solution is poured directly between the beacons and, if necessary, leveled along them. Professionals, as a rule, do not do these types of work alone, because the solution must be constantly poured and immediately leveled. Therefore, if you are pouring the floor in a bathhouse with your own hands, it is recommended to call someone for help, this will speed up the whole process significantly.

General leveling of the screed is carried out using a long rule, which is carried out along the guide beacons, smoothing out all the unevenness. If necessary, you will need to add mortar somewhere with a trowel so that there is no hole, and remove the excess somewhere so that there are no bulges in the floor.

Strengthening of the screed occurs in about 2-3 days, but it will finally take place only after 2 weeks. To avoid the occurrence of cracks during this period, the screed should be wetted 2 times a day. This is done so that light spots do not appear - areas in which the cement for some reason dries faster than the rest of the floor, which can lead to cracks. After wetting, the floor is covered with a film so that the water does not evaporate immediately.

Applying a tightening layer

At this stage, it is necessary to make the surface perfectly flat and smooth, so apply a small layer of cement-based mortar and smooth it. Since the top layer of the screed has not completely hardened, adhesion will be good, which means that the coating will not be in danger of cracking.

After completing the arrangement of the tightening layer, the floor surface is allowed to dry completely, while continuing to wet the concrete and, if necessary, covering it with film.

Concrete floor in a bathhouse - drainage diagram

It is possible to install a drain concrete floor in a bathhouse, through which water will be drained during bathing procedures, only in the washing department. Why there?

Because if you install a concrete floor in a steam room, the following disadvantages of this material will immediately manifest themselves at high temperatures:

- The floor will become dusty with cement dust during heating, while the atmosphere in the steam room is extremely dry.

- Concrete will become extremely hot, and unlike wood, this heat will not be pleasant to the feet of steam room visitors.

- Concrete screed does not have the same plasticity as wood. As a result of sudden cooling when water spills, the screed will crack.

As you can see, there is a place for a concrete floor in the bathhouse, but it is located in the washing section of the bathhouse.

So, how to fill the floor in a bathhouse with a drain in the bathhouse compartment so that the drainage system works flawlessly?

Before making a screed in a bathhouse to drain water, let's look at how water collects in a bathhouse sink and how it is discharged.

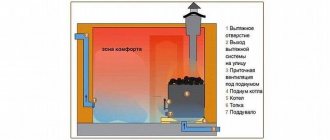

Concrete floors in a bathhouse with a drain work according to the following scheme:

- The floor is arranged with a slope, which allows you to collect all the water in one of the corners of the washing compartment.

- An assembly ladder is installed in this corner through which the water will leave the sink. The ladder is at the lowest point.

- From the drain, wastewater is transported through a drain pipe, which can have a cross-section of 32 or 50 mm. It is not worth making a drain pipe with a cross-section of 110 mm, since no solid fractions flow from the washing compartment into the sewer, but only moderately contaminated water with residues of soap and shampoos.

- The wastewater flows through the pipe into a pit or container under the bathhouse, where a crushed stone filter is usually installed. The crushed stone fraction taken for these purposes is 40-80.

Why is it necessary to use this particular fraction of crushed stone to purify soapy water? Small crushed stone will become washed out too quickly and will stop cleaning wastewater from the bathhouse. Large crushed stone will not provide a sufficient degree of cleaning from the very beginning, since waste water from the sink will “spill” between the large stones.

Why is tilt necessary?

If the degree of inclination is too small, not all the water accumulating on the surface will enter the drainage system.

Tilt of the base towards the drain allows you to quickly remove water from the washing room or steam room in the bathhouse. A rather complex design performs several tasks:

- Prevents fluid accumulation;

- Prevents damage to floor materials;

- Provides quick drying of floors;

- Significantly reduces the chances of developing fungus and mold.

The design of a rough foundation with a slope must be carried out taking into account many technological nuances. If the degree of inclination is too small, not all the water accumulating on the surface will enter the drainage system. If you make the floor slope too large, this will affect the material component of the issue, since it will lead to unnecessary expenses.

Installation of a drain hole in different baths

There are not very many drain designs. They differ rather in the place of application. The design of the drain may be different for different types of baths.

Sauna drain

The floor drain in a sauna may not have the same throughput as in a steam bath: there are no water flows from the tubs, and the font has its own drain. In addition, as a rule, the sauna itself does not need a drain, and the sauna washing area does not need a tiled floor. This means that a classic drain with a drain is used there.

In a sauna with a tiled floor, you can use a classic drain with a drain and a water seal

It is not much different from a sauna drain.

Viega Advantix drain for installation in hammam and sauna

Drain in a Russian bath

Draining in a Russian steam bath is necessary in two rooms - the steam room and the washing room. Bath drains are different, which primarily depends on the design of the floor in the steam room and washing room. They are no different in design if the floors are the same in both. Let's look at different floors and different drains for these floors.

A steam drain can also be ordinary, with a drain

Answers to frequently asked questions

Russian bathhouse in a pine forest

How can you treat floors? Experts do not recommend painting them, because the boards must breathe. In addition, under the influence of high temperatures and humidity, toxic substances will be released from them.

What is the height of the floor? The distance from the ground to the board should be within 30–40 centimeters, while the thickness of the board is chosen to be 25–35 millimeters.

Are there any differences in the construction of the floor in a Russian bathhouse from others? There should be no differences - gender is gender, be it a Russian or some other bathhouse. The only thing is that, according to tradition, the floors in a Russian bathhouse should be earthen. If you want to have these, then deepen the soil, removing its soft layer, fill the pit with a mixture of sand and crushed stone, compact it all and lay boards with small gaps on top of the resulting base. The result will be a leaky wooden floor in the Russian style.

Which screed is best to use in a bathhouse? Currently, stores sell ready-made dry mixtures, which are mixed with water in a certain proportion during operation, and mixing instructions are always on the packaging. Some people prefer to make the solution with their own hands, combining different ingredients. But this is more difficult, and the accuracy in proportions cannot always be maintained, which will affect the quality.

How to properly organize drainage? It was mentioned above how this can be done

It is important here that the concrete base has a slope towards the collection tank. Here, a sewer pipe is installed near the wall, which will connect the collection funnel to the drainage tank

The main thing is that this entire structure is airtight.

Floor layout and basic requirements

The main thing in organizing a wooden floor with a drain is, oddly enough, not the technology for making the finished floor layer, but the proper preparation of the underground space. It is errors in the organization of the underground that become the most common reason that the tree begins to rot ahead of time.

Particular attention should also be paid to ventilation of the space under the floorboards; there must be either special holes for ventilation, or the possibility of raising the boards in order to dry them faster

In addition to the fact that a wooden floor is not as cold to the touch as a tiled floor, it is also noticeably cheaper and easier to organize than a tiled floor, which requires the obligatory arrangement of a layer of concrete screed at least 5-7 cm thick. If necessary, construction the most budget-friendly construction, it is wooden floors that are laid most often, and a small drainage hole is installed directly under the bathhouse as a space for water drainage.

Scheme of organization of design details:

Prev 1of1 Next

The second option using roofing felt:

Prev 1of1 Next

Option number three from an old Soviet book:

Prev 1of1 Next

Next, we will look at examples of various schemes for installing a wooden floor in a bathhouse with water draining through the cracks between the floorboards, the so-called “flow floor”. Also, using the example of finished structures, you will be able to see different approaches to the implementation of the three basic principles of durable wooden floors with a drain:

- The presence of a slope at the surface of the underground so that the water does not linger anywhere, but completely flows into the drain hole.

- A properly organized sewer system that ensures the flow of water without its accumulation in places not intended for this purpose.

- Take measures to ensure ventilation in the underground space in order to effectively dry out the floor wood and support beams.

Beautiful examples

A high-quality concrete screed on the floor will go well with wooden walls and ceilings. The materials for the latter can be boards and lining, forming an original combination. A large window, a laconic stove and simple wooden shelves will ideally complement the interior.

The tiled area under the heater can become a bright accent of the steam room and, echoing the washing room, combine two interiors into one. You can add brutality to the room if you replace it with natural or artificial natural stone. He, in turn, will require inserts on the walls of the steam room itself.

The contrast of light wood on the floor and dark wood on the walls will create a very unusual, memorable room. Benches, flooring and the stove must continue this kind of confrontation.

To learn how to properly make a floor in a bathhouse, see the following video.

Main stages of floor construction

Upon completion of the arrangement of the drainage and sewer system, we begin to form the foundation for the future floor. For this:

We create a cushion for pouring concrete mortar, which allows us to limit heat loss. We deepen the soil by 50 centimeters. Three quarters of the total volume is filled with construction waste that is not subject to rotting processes. We cover the resulting surface with clay and, after drying, pour a fifteen-centimeter shock-absorbing layer of sand with fine gravel or crushed stone. This level will allow the absorption of moisture that results from temperature changes. We carefully compact the layer, maintaining the slope specified by the project. Pour the first layer of concrete mortar. If possible, we use perlite additive - an excellent heat insulator.

When working with perlite, pay attention to its properties - especially fine fraction and minimal weight. When mixing the concrete solution, use a room protected from the wind to avoid increased dust formation.

The thickness of the first layer of concrete when pouring the base should not exceed 4-6 cm. We isolate the joints between the base and the walls from moisture penetration with bitumen. We wait for the solution to dry. It depends on weather conditions, the period ranges from several days to 2-3 weeks. We lay thermal insulation material. To prevent it from being damaged by moisture, it is advisable to additionally use roofing felt for insulation.

The next stage is pouring the floor in the bathhouse with a second layer of concrete mortar. At this stage of work, a reinforcing mesh is used to protect the cement base from cracking during operation. We compact the concrete, trying to get rid of air cavities as much as possible. Leave the surface alone until completely dry. To ensure that concrete sets evenly during the hot season, we moisten the base using a sprayer.

The final stage is applying the cement mixture to the entire surface and leveling the concrete according to the rule. Make sure that the slope of the covering is correct towards the drainage hole. Apply deep penetration waterproofing impregnation to the finished base.

We would like to focus your attention on the fact that if you do not plan to use the bathhouse during the cold season, then when mixing the concrete solution, you can exclude perlite from the recipe. Use the usual cement-sand composition of one to three, adding 1/10 of lime

This will reduce financial costs without reducing the strength of concrete.

How to prepare concrete mortar?

A simple option is to buy a ready-made dry mixture. If you decide to prepare it yourself, then you will need cement, water and sand. For the solution you need to use cement M-400 or higher. For 4 portions of sand you need 1 portion of cement and water. The solution should not be liquid, as in this case the concrete will not be strong enough in the future.

Instead of regular sand, you can use perlite. It has high thermal insulating properties. The disadvantage of the material is its low weight, which makes the sand very dusty, so you can’t work in windy conditions.

To prepare the solution you need to do the following:

- Fill in 2 buckets of perlite or sand and 10 liters of water.

- Add 5 liters of cement.

- Stir, add another 5 liters of water. Stir until the mixture becomes homogeneous.

- Add 1 bucket of perlite and 2 liters of water. Mix.

- Leave the mixture for 10 minutes to make it more flexible.

When the solution is ready, you can proceed to the main work.

Well with a filter at the bottom

The design of a drain pit with a filter bottom is used primarily to purify wastewater from dirt and chemical elements, as well as to retain bacteria. Subsequent filtration of water is carried out directly by the soil layer. But at the bottom of the well, crushed stone, crushed brick or sand are used as a filter.

To ensure the outflow of water from a bathhouse designed for 3-4 people, a well with a diameter of 1.5 m and a depth of 2 m is sufficient. It can be either rectangular or round in shape - the latter option is preferable due to the uniform distribution of pressure on all walls. The cylindrical design will need correction much less often.

Since it is necessary to drain the bathhouse at the dacha without damaging the building itself, it is advisable to retreat from it at a distance of about 3-5 meters. Such a gap will ensure, first of all, the safety of the bathhouse foundation from being washed away, and will also prevent the penetration of unpleasant odors from the well into the bathhouse. But if you locate the drainage hole further, you will inevitably have to purchase additional pipes for water drainage. In addition, it is difficult to ensure the correct angle of inclination over a long distance.

If the soil on your site is dense enough, then simply dig a hole for drainage and lay filter materials at the bottom - sand, crushed stone and broken brick. Additional strengthening of the walls is not required.

According to the drainage diagram in the bathhouse, a trench can be dug from it to the pit, through which water will randomly flow by gravity into the well. However, it is best to equip the drain with pipes made of asbestos, metal, plastic or ceramic, with a diameter of 50-100 mm. In this case, a trench is also necessary, but its depth will depend on the depth of soil freezing, but not less than 50 cm. The pipes are laid at a slope of 20 mm at every meter of distance.

At the design stage, the future design of the drain and the features of the floor organization are thought out in detail. An economical option for draining a bathhouse in a country house is to make the floor sloping towards the drain hole. With this design, wastewater enters the pipes and is discharged directly into the drainage pit.

An alternative to a drainage pit is to use a sealed septic tank, such as one made of plastic. Such a device will be especially relevant in cases where the bathhouse is equipped with a toilet, that is, the nature of the wastewater will require more thorough cleaning.

Septic tank installation

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

Read my detailed article about the installation and installation of a septic tank.

The water is discharged through the pipe either into the ground through a drainage area in the underground, or into a septic tank. It can be made from old tires or concrete rings. To prevent the pipe from freezing in winter, it must be insulated. A septic tank made of concrete rings is a simple budget design. The rings are installed on a soil cushion; the bottom is not concreted so that the water goes into the ground.

Construction of a septic tank made of concrete rings

The optimal option for a drainage device in a bathhouse is chosen based on the structural features, type of foundation and method of further drainage of water.

Bath design

It all depends on what kind of soil is used under the building itself. If these are materials that easily absorb moisture, for example: sand; then you can build a house right on the ground

It is worth paying special attention to the place where you plan to install the shower, since twice as much water will drain there as in the steam room itself. You also need to make sure that your floor can heat up quickly and retain heat for as long as possible.

This is important because the most important thing in a bathhouse is warmth. If the floor reflects the cold from the ground, the heat will not be sufficiently saturated

This is especially important during cool seasons, because at this time the earth cools down as much as possible.

Some mandatory points during floor construction:

- Construction of a drainage pit. It is necessary in order to pump out accumulated drained water from time to time.

- Creating a cushion on your soil for the primary screed.

- Filling, filling the first layer of your floor covering.

- To preserve heat, you need to lay special insulation and waterproofing of the floor.

- The wording of the second screed.

- A tightening table is installed.

Next we will describe all the points in more detail, so if you are interested, stay on this article.

Construction of a drainage hole

In fact, there will not be as much water in the steam itself as in the shower, but, naturally, although in small quantities, it will be present. Typically, the water receiver is located in the corner of the building. It looks like a grate in the floor, but sometimes people just dig a hole to save money. If you have dug a hole, you must line it with clay or concrete. As you already understood, according to the simple design, there will be a slope towards this part of the bathhouse so that all the water flows there.

Water removal can occur in many ways. The most common of them, which we advise you, is to lead an exit from the pit itself to the central sewer system, using sewer pipes. To prevent an unpleasant and unexpected odor from penetrating into the bathhouse through this pipe, you can simply block the access with a specialized shutter. But the holes and pipes don’t end there. Our pit will need not only a pipe that will drain water from time to time, but also a pipe facing the street, so that it will, as it were, ventilate our pit. Thus, ridding it of unnecessary excess odor and moisture.

If your sauna was installed not on the street, but, say, in the basement of your house, which is quite rare, the drainage hole is a small depression on the floor, from which you simply remove water with a bucket after using the sauna.

In fact, to prevent the drainage pit from looking too terrible and out of the style of the bathhouse, people often decorate it with stones, or use it as a small well to give it beauty.

Cushion for primary screed

This stage takes place so that as little heat as possible goes into the ground. A small depression is made about 50 cm from the ground level, which you must fill with materials such as bricks and various large stones. Trees should not be used, as after backfilling they may simply rot due to moisture. Backfilling occurs in the following way: it is necessary to cover it all with durable clay, and pour a little fine crushed stone and sand “about 15 cm” on top. Afterwards it is necessary to level the entire surface, thereby preparing it for the first pour.

A few recommendations

When making a cement screed, you need to carefully calculate its proportions. In general, for 1.5 m2 of canvas you will need 1 bag of cement. If tiles are used as the finishing coating, it is recommended to use special self-leveling screeds, which contain not only cement, but also gypsum with anhydrate.

Filling begins from the corner furthest from the entrance. All excess mixture is moved to a place free of solution. The main condition for success is the non-stop process: as soon as the first layer is poured, laying the second immediately begins.

Allow at least 7 days for the mixture to dry, or even better – 2-3 weeks. The addition of plasticizers to the concrete solution will help speed up the process - special substances designed to bind mixture particles. This will prevent the appearance of cracks during operation and will increase the strength and durability of the surface.

Installation of a drain hole in different baths

There are not very many drain designs. They differ rather in the place of application. The design of the drain may be different for different types of baths.

Sauna drain

The floor drain in a sauna may not have the same throughput as in a steam bath: there are no water flows from the tubs, and the font has its own drain. In addition, as a rule, the sauna itself does not need a drain, and the sauna washing area does not need a tiled floor. This means that a classic drain with a drain is used there.

In a sauna with a tiled floor, you can use a classic drain with a drain and a water seal

It is not much different from a sauna drain.

Viega Advantix drain for installation in hammam and sauna

Drain in a Russian bath

Draining in a Russian steam bath is necessary in two rooms - the steam room and the washing room. Bath drains are different, which primarily depends on the design of the floor in the steam room and washing room. They are no different in design if the floors are the same in both. Let's look at different floors and different drains for these floors.

A steam drain can also be ordinary, with a drain

Dependence of the design on the floor of a Russian bath

The floors in a Russian bath are different.

- Leaky or torrential wooden floors - horizontal boards are not laid tightly, but with cracks for free flow of water over the entire floor area. This is a traditional design that has long been used in Russian baths. The main disadvantage is the need for thorough initial and subsequent regular treatment of boards with hydrophobic impregnations.

- Leak-resistant wooden floors - the boards are laid closely at a certain angle of inclination towards the drain hole so that water flows freely. The slope is carried out using slightly wedge-shaped logs.

- Tiled (only possible in the washing room). They are also laid with a slight slope towards the ladder. The slope is carried out either by creating a concrete base, or by using different thicknesses of mortar.

The drains for different genders of a Russian steam bath are strikingly different in design. But the largest variety of drains is found on pouring or leaky floors.

pouring floor

With the simplest method of water seeping through the entire floor into a drainage pad located under the entire bathhouse, there is no drainage device at all.

Drain through the pouring floor into the drainage pad; no drainage device

A more complex subfloor design: it slopes towards the concrete channel, preferably with insulation and screed. There is also no drain.

When draining into a concrete channel, there is also no drainage device

When draining into a concrete pit, the role of a water seal is performed by the pipe itself, located in a special way - with the possibility of air access.

The pipe in such a pit plays the role of a water seal

If the underground has a drain into the sewer, then in addition to insulating and waterproofing the underground, you need a simple drain with a water seal to prevent unpleasant odors from entering the underground, and from there into the bathhouse through the cracks in the floor.

When draining into the sewer from under a pouring floor, a simple drainage device is required

Non-leakage floor

The only possible solution here is a classic drain. It can be of different designs - from a complex modern drain to an ordinary, familiar siphon. The ladder is a compact and reliable design.

The drain will last a long time and is easy to clean

The siphon is cheap and familiar.

Scheme of drainage on a non-leaky floor in a bathhouse using a siphon

The question is your financial capabilities and the availability of space under the floor.

Available materials for building a drainage pit

The choice of suitable material for the construction of a drainage pit under a bathhouse depends on the design features of the structure, the volume of wastewater and the financial capabilities of the owner of the site.

Barrel pits

Tanks can be constructed from barrels, metal and plastic, of various sizes. Such a system involves the use of one or two drainage containers:

- One container. The bottom of the prepared pit is covered with a drainage mixture of crushed stone and gravel, then a plastic container without a bottom and with a perforated surface is lowered into it. The distance between the barrel and the pit is filled with drainage. A waste pipe is connected to the barrel at an angle. Some of the liquid will flow through the drainage holes into the soil for further cleaning.

- Two containers. Such a system involves the use of two barrels, with the first being installed 25 cm above the second. The containers are connected to each other by an overflow pipe. The wastewater enters the first container, in which foreign impurities and solid waste settle. Next, the purified liquid is poured into a second tank, to which perforated pipes are connected for drainage. Drainage elements are installed in trenches filled with drainage material and a dense layer of soil.

Brick pits

To construct drainage pits, ceramic bricks are used, the masonry of which is carried out with small gaps - they ensure the drainage of wastewater into the drainage pad and soil. The operating principle of such a drainage system is no different from the previous one, the difference lies in the material used. The distance between the brick reservoir and the earthen base is filled with drainage material designed to clean the wastewater and distribute it around the perimeter of the pit.

A brick pit is considered more durable and practical compared to a structure made from plastic barrels.

Concrete pits

Given the technical equipment and financial capabilities, it is possible to build a drainage pit from concrete rings with a perforated surface, which are mounted in a prepared pit. After the installation of the rings is completed, the bottom of the structure is covered with a drainage cushion of gravel and crushed stone.

In the case when the depth of the pit is at least 2 meters and the bottom of the tank is concreted, such a structure can be used both for drainage of wastewater from a bathhouse and for sewerage of a residential building.

Tire pits

Cesspools made from used tires are designed to drain liquid waste, so they are well suited for the needs of a bathhouse.

The arrangement of a drainage system when installing tires can be carried out in various ways, including lateral perforation of the walls, maintaining a technological gap between the installed slopes, cutting off the outer walls while maintaining the internal structure of the tires.

This is the simplest and most popular option for organizing drainage under a bathhouse, according to which the work can be done with your own hands.

Choice of insulation

In order to insulate the floor in a bathhouse, the following materials can be used:

- mineral, fiberglass or basalt wool;

- expanded clay;

- expanded polystyrene;

- construction felt;

- aerated concrete.

The insulation is laid between a layer of steam and waterproofing, which are located between the rough and finishing concrete floor. If the floor is made on joists, then the insulation is installed between them.

To ensure normal thermal insulation of the floor, the thickness of the insulation layer must be at least 150 mm, it all depends on the material used and the climatic conditions of your area.

If you use expanded clay, then it must be laid carefully, since those granules that are broken lose their high thermal insulation characteristics. Despite the layer of insulation, such a floor in a bathhouse will still be cold, so now many people decide to make heated floors.

Briefly about the main thing

A concrete floor in a bathhouse is the right and economical solution. Such a foundation is not afraid of negative external influences. If the work is performed correctly, the foundation can last for many years. This base is fireproof, has sufficient strength and is easy to install. Not hygroscopic. Withstands significant temperature fluctuations. Doesn't rot.

The last factor makes a concrete base more preferable than its natural wood counterpart. This is explained by the fact that the stone base is not so favorable to the development of fungus. In addition, it does not impose any special requirements for care.

Preparing the base

Alignment

Before starting work, remove a layer of soil from the base along with any remaining organic matter. Usually 40-50 centimeters is enough. Then the surface is leveled, making sure to make a pit in the center of the room where the water from the bathhouse will go.

Drainage from the pit is carried out beyond the foundation and is realized through a drainage pipe with a cross-section of 10-20 centimeters dug in the corner under a slope. Thanks to this design, it will be possible to ensure maximum comfort in the operation of the bath and avoid the accumulation of large volumes of water.

Sauna stones

It is very important to choose the right stones for laying in the stove. Not every mineral is suitable for this, since simple stones can be quite fragile

It is optimal to use soapstone, gabbro-diabase or jadeite, the evaporations from which are beneficial for the human body.

For stoves, stones with a rough surface are used, on which water is retained, gradually boils and evaporates. Do not use stones with cracks or defects - they will quickly crack from overheating.

Periodically you need to sort through the stones to remove damaged ones and replace them with new ones. The frequency of this procedure is once a year, subject to weekly use of the sauna. When heating the sauna twice a week, the stones should be inspected once every ½ year. That is, the more often you use the steam room, the more often you need to check the condition of the stones.

The electric furnace is tightly laid with stones in the spaces between the heating elements, but air must pass freely through the masonry.

Wood burning stoves are filled with stones on top of the firebox, so only a few are needed. If the stones are heated by a metal casing, the stove must be heated during the entire time the sauna is used so that the stones do not cool down. Although these stoves heat up faster, they produce denser heat that is harder to tolerate.