The stove, known to many as a potbelly stove, is one of the most popular heating devices. Designs of this kind are found in many private homes. But the peculiarity of a potbelly stove, as well as any other stove, is that over time it loses its original appearance and there is a need for painting in order to restore its former aesthetic qualities. Therefore, today we will talk about how to paint a potbelly stove: what materials can be used, how to carry out this procedure in general.

How to paint a potbelly stove

- 1 Painting a brick structure

- 2 Painting a metal potbelly stove that is not covered with plaster or brick 2.1 Video - Powder painting

- 2.2 Information on heat-resistant paints

Let’s immediately make a reservation that various finishing materials can be used to paint a potbelly stove. The choice of one or another of them depends on both personal wishes and financial capabilities. In addition, the material from which the stove is made is also important.

How and how to paint a potbelly stove - step-by-step instructions

A potbelly stove is an excellent heating device for a private home. Over time, the aesthetic qualities of the potbelly stove deteriorate, so painting may be required. The technique of applying the coloring composition and the direct selection of products for the work are important points that it is recommended to pay special attention to.

- How to paint a cast iron stove?

- Paint selection

- Application sequence

- Final works

- Painting a potbelly stove lined with bricks

- paint

- Lime

- Varnish

- Burnishing for metal furnace

- How often should you paint?

- Conclusion

Lime painting: preparatory stage

A potbelly stove can be made of metal. This design is shown in Fig. 1. The oven can also be made of brick. Stoves can be painted using different finishing materials. Thus, for finishing brick structures, an affordable and fairly high-quality material called lime is often used. To paint a potbelly stove yourself, prepare the following required materials, fixtures and tools:

- Brushes and rollers;

- Bucket;

- Solvent (can be replaced with alcohol);

- Enamel in aerosol;

- Lime;

- Water;

- Dyes;

- Glue.

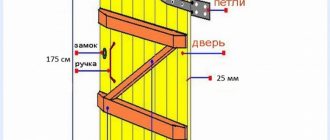

Construction of a potbelly stove made of metal.

Before painting the potbelly stove, you need to prepare a solution suitable for this. Take a bucket or other container, add lime and fill it with the same amount of water. After this, mix the mixture thoroughly and add animal glue to it. You can purchase this glue at a store that specializes in selling various painting supplies. You will need relatively little glue - about 100 g per 10 liters of solution. Before you add glue to the lime mortar, be sure to dilute it in a separate container (an ordinary bucket will do) with a small amount of water.

To understand whether a lime-based solution is ready, you need to do the following: take a small piece of glass, fix it vertically and apply a little solution. If the paint spreads no more than 3 cm, then everything was done correctly, you can begin finishing the stove.

If you want to paint your potbelly stove not white, but some other color, then you will need to add a little dye to the solution. Potassium permanganate, blue or synthetic paints can be used as a dye. The specific option is selected depending on what shade you want to get.

Painting a metal stove that is not covered with plaster or brick

If the heating device in the house is not finished with anything, but it urgently needs to be updated, then you are probably wondering how to paint the potbelly stove in this case. Let’s say right away that not just any paint is suitable for this. The fact is that during operation, the stove can heat up to a very high temperature, and, of course, not all finishing materials can withstand such conditions. Only heat-resistant types of paints made on the basis of silicone and silicon are suitable for painting. Only in this case will the potbelly stove retain its original appearance for a long time.

Video - Powder painting

Information about heat-resistant paints

Using heat-resistant enamels, not only the desired design is achieved, protecting the surfaces of the potbelly stove from the penetration of dirt, but also resistance to high humidity. Moreover, all metal elements will be protected from rust and oxidation. Such compositions are produced mainly in the form of suspensions, and are based on heat-resistant varnishes that contain silicone and silicon.

3 Options for making a potbelly stove

Previously, we talked about how to make different versions of a potbelly stove yourself. We advise you to read this manual right now, see details here

Such enamels are produced in jars or in spray cans (spray). If stone surfaces are painted, the material is absorbed into the porous structure of the surfaces and forms a thin film on them, which, in fact, is a protective layer.

Packaging

You can purchase heat-resistant paints in various packaging - these can be spray cans or jars. From cans, paint is simply sprayed over the surface, and from a can, paint is used with brushes, rollers or special sprayers.

The volume of the cylinder is usually 500 ml. Cans are produced in 400 g, 800 g, 2.5 kg and 5 kg. There are also large buckets of 5-15 kg and barrels.

Exactly how to apply thermal paint is everyone’s personal choice. For some, it will be more convenient to use a brush or roller, while others will opt for a spray can. In the latter case, the material consumption will be significantly lower, and the paint will apply more evenly and evenly.

Pros and cons of silver

People have been using silver paint for more than a century, and during this time no one has had time to get tired of the paint. On the contrary, it is used more and more often for various needs. What is the secret of such popularity? It's all about the huge number of advantages it has:

- Silver does not flake and is quite durable and at the same time thin material. But at the same time, if you need to, you can easily get rid of the paint.

- The paint turns into a protective layer for the surfaces it is applied to. It creates a thin but even, smooth layer, fully displaying the surface texture.

- It is used on various materials - from wood to concrete and metal.

- Long service life, so the paint does not deteriorate in water for 3 years, nominally about 7 years, but in reality even longer.

- Not afraid of high temperatures.

- Invulnerable to corrosion.

- Non-toxic.

- Dries quickly.

- Painted in a pleasant silver color.

- With its help, you can achieve different shades of metal using pigments.

Do I need to paint or is there an alternative?

Owners of homemade metal stoves do not always resort to painting them, apparently believing that this is done purely for the sake of appearance, and if the stove is not visible under a brick screen, then it is not worth spending money on painting it.

In principle, any metal will burn out over time. After all, cast iron stoves last a long time: the thickness of their walls is many times greater than that of steel ones, which means they burn longer.

Stove chariot – burnt factory paint

The paint layer prevents not only the metal from rusting from water, but also its fading (by the way, corrosion). Therefore, painting, in general, is beneficial, but such a coating does not last forever (although there is a guarantee for many years). Therefore, let’s say this: if it’s cheaper for you to weld a new stove than to paint it, then it’s clear that you won’t paint it.

Unfortunately, applying water to the stones still promotes oxidation of the metal. Steel rusts quickly, and even stainless steel without certain additives oxidizes when exposed to high temperatures. And black (carbon) steel usually rusts instantly.

But silicone paints did not always exist; was there an alternative?

Yes, it was. Metal can be blued. Moreover, this applies to both steel and cast iron. With the help of various reagents or reagents and high temperatures, a protective film of oxidized iron is formed on the surface. It is logical to assume that ordinary rust should also be considered protection - this is partly true, but it is loose, so it does not interfere with the further penetration of oxygen.

The film obtained as a result of bluing (= blackening) of metal is much stronger. It can be obtained using acids or alkalis. One way is as follows:

15 grams of tartaric acid and 280 grams of concentrated phosphoric acid are poured into a liter of water. Treat a mirror-clean metal surface with the resulting solution. Wash off excess acid with laundry soap

Then heat the stove to 150 degrees and apply a layer of caustic soda (NaOH) to the surface - you can spray it from a spray bottle, but with great caution - caustic soda leaves chemical burns not only on the skin, but also on the respiratory system

IMPORTANT! When working with chemicals, take care of your skin, eyes, and nasopharynx!

After an hour the surface will turn black. Be sure to preheat the oven!

There are, of course, methods of cold blueing, but there are also other ingredients. If you can get antimony trichloride, mix it half-and-half with olive oil and rub it on a surface prepared with acid and laundry soap (as described above). The paste is applied once a day, the next day it is completely removed and a new layer is applied.

If all these procedures seem too dangerous and time-consuming to you, you can simply cover the stove with a stainless steel or brick screen, but this will not help much to save it from corrosion. Therefore, either dangerous bluing or expensive thermal paint.

How to choose stove paint

You cannot paint a stove with ordinary paints: the maximum temperatures they can withstand are 40-50°C. At the very first fire, such a coating will swell, bubble, begin to change color before our eyes, and also smoke and spread “aromas”. Therefore, it is clear: special compounds that can withstand high temperatures are required.

The degree of heat resistance required depends on the type of oven. If it is an iron sauna stove, it can heat up to 600-800°C or even more: in the combustion zone the temperature is higher, but depending on the design, the outer walls may not heat up so much. For the external surface of bricks, high values are not needed: +200°C is definitely enough.

A very important requirement is that heat-resistant paint for the stove must be suitable for indoor use. For sauna stoves, it is desirable that it protects against high humidity.

Terminology

Heat-resistant, heat-resistant and fire-resistant paints are suitable for painting surfaces with high temperatures. Fire retardants cannot be used. Although the name is similar, the purpose of this paint is different: when heated to a certain temperature (around 200°C), it swells into a bubble, blocking the access of oxygen to the structure, thus preventing its destruction. The effect is useful, but not in our case.

Heat-resistant compounds usually have a range of application up to +600°C. They can be used to paint metal parts of brick stoves and fireplaces, and metal heating stoves. The body of metal sauna stoves should not be coated with such paints: in some places the temperature can rise to +800°C. There are heat-resistant enamels for them that can withstand temperatures up to +800°C or even up to +1000°C.

Fireproof metal paint for stoves can withstand the presence of open fire. Their operating temperature is even higher, but for domestic use such compositions are unprofitable: they are expensive.

There are also high temperature paints. They are used for painting radiators of heating systems or some parts in engines. Most often, they behave normally if they heat up no higher than 200°C. They can only be used for stoves made of brick; they are suitable for painting seams or tinting the surface of a brick stove.

There are also heat-resistant varnishes. They tolerate heat up to 250-300°C normally. If a brick is treated with this varnish, the surface will become shiny and the color will become brighter.

Heat-resistant varnish from different manufacturers. It can be used to protect the brick sauna stove from moisture

What are we going to paint?

To decide what paint to paint the stove with, pay attention to what surfaces the composition is intended for. Often the area of application is indicated in large letters on the packaging. For example: heat-resistant paint for metal. If the scope of application is extensive, it is indicated in smaller font, but it must be present on the can, as well as the company name. If this data is not available, do not buy. Most likely this is a cheap fake, and the combination of questionable quality and high temperatures can be hazardous to health.

Which one is better to use?

How to paint a metal plate in the bathroom? To do this, it is imperative to purchase heat-resistant enamels or silicone paints that can withstand heating up to 6000 degrees. The layer must retain its strength and prevent the formation of rust on the structural steel from which the “units” are used to make cheap bath towels.”

As a rule, dark colors are used, even black. Increase the oven's heat transfer rate. Aluminum based paints are not recommended. Organosilicon glazes from Russian and foreign manufacturers are the most popular. Includes:

- organic resin;

- aluminum powder;

- organic radicals;

- base of silicon and oxygen.

Now let's move on to specific brands:

- The leader among national brands is Cetra. Available for various heating temperatures. Black enamel can withstand heating temperatures up to 9000.

- Another heat-resistant paint produced in cans that has good properties at a low price is Kudo brand heat-resistant enamel.”

- Among foreign manufacturers we can highlight the Finnish Thermal.

How to paint a metal stove in a bathroom from the inside? For this it is better to use fire retardant paint. The only drawback is the high price.

How to choose heat-resistant paint for stoves

When choosing paint to cover the stove, you must adhere to the following rules:

- it must be resistant to steam;

- have a high level of surface protection from temperature changes;

- must prevent the formation of corrosion;

- ability to withstand temperatures from 80 to 750 degrees;

- Possibility of use in dry and wet environments.

There are paints on sale that were developed specifically for brick and metal stove structures . For some ovens, it is possible to use mixtures in various combinations or simply use one type of heat-resistant paint.

The paint must be of high quality. If the paint material is of poor quality, then when heated it may begin to release toxic substances. The product must be certified. The documents must clearly indicate what maximum temperature the composition can withstand and what substances it will release during the heating process. If there is no certificate, it is better to refuse such a purchase, because a low-quality product can have a bad effect not only on the quality of finishing work, but also on people’s health.

Coloring bath equipment

High temperatures, high humidity, frequent heating and cooling cycles cause rust not only of the sauna stove, but also of other metal structures in the steam room. This primarily concerns the tank intended for hot water. It needs to be painted not only on the outside, but also on the inside, since water in it will cause corrosion.

The tank is painted according to the same rules as above. The only difference is that it must be coated with paint at the production stage. Once installed, this will not work.

In addition to the tank, it would be a good idea to paint the heat exchange system and the chimney, which rusts quite quickly. It is better to paint boilers and other metal surfaces that the steam room contains at the same time. When answering the question of how to paint the tank and other metal surfaces of the tub, the already mentioned paint and varnish materials should be mentioned.

In addition to other advantages of paint ovens, tanks and other structures, it is necessary to highlight the fact that hot metal (especially cast iron) can develop cracks when in contact with water. Thus, a painted stove can be safely used in a room with high humidity.

Sawdust firebox

Sawdust is not a high-quality fuel; it burns poorly. But they are easily accessible and popular. The design of a furnace of this modification forms two metal cylinders of different diameters. A pipe with a smaller diameter is placed in a pipe with a larger one, turning into a combustion chamber. A hole with a diameter of 5 cm is created at the bottom.

The chimney is located at the bottom of the outer cylinder. A steel box is welded under the ash. The potbelly stove is equipped with a door. A core of wood up to 60 cm high is inserted into a cylinder of smaller diameter. Sawdust is poured and pressed around it so that it burns as slowly as possible. The core is removed and a fuel chamber is obtained. The stove is ignited through an ash box using shavings and bark. When the fire reaches the top layer of sawdust, the stove is covered with a lid.

So, potbelly stoves have faithfully served people for many years. These unpretentious simple designs still provide heat, although they consume a lot of fuel, which is why they got their name. But modern models have learned to combat the hunger of bourgeois women, giving them a ticket to a long life.

Small in size, easy to use: a potbelly stove for a summer residence

A potbelly stove is a heating structure made of steel, cast iron, or a combination of steel and cast iron .

Such stoves are installed in country houses, garages, construction sheds and other temporary premises. Potbelly stoves are also used for heating greenhouses.

Schemes of a wood-burning stove for a summer residence

Iron potbelly stoves used in the country come in different sizes, shapes, structural features of the combustion chamber, with or without a blower.

They are divided according to the type of work and design:

- to regular (single-chamber);

- to channel;

- long burning of fuel.

Reference. Metal stoves, potbelly stoves, are heated with wood, wood chips, brown and hard coal, and peat briquettes. They burn cardboard, sawdust, and dung.

Coal burns slowly, gives a high temperature ( 1500 degrees and above ), because of this the air, walls, ceiling, and cutting become very hot. That’s why coal is rarely used in country houses . wood, bark and wood chips in potbelly stoves . Let's consider options for potbelly stoves that the owner of a garage or cottage can make with his own hands.

Single-chamber potbelly stoves consist of a solid metal body, which houses a ash pan (ash box), a grate, a combustion chamber, and a hole for a pipe (chimney). An example of such a potbelly stove is a cast iron Soviet army stove, the simplest single-chamber iron stove for heating change houses.

Photo 1. Diagram of a single-chamber stove-stove. The main parts of the device: firebox, ash pan, chimney pipe.

The body of a factory-produced potbelly stove has the shape of a rectangular parallelepiped with dimensions:

- height - 65.6 cm ;

- length (depth) - 50.2 cm ;

- width - 35.8 cm ;

- height of stands (legs) - 19.4 cm;

- the height of the pipe intended for installing the chimney is 6 cm;

- chimney diameter - 11 cm.

The stove weighs 36 kilograms , the thermal power of the potbelly stove is 5 kW. The heater body is made of steel sheet 6 mm . There is a solid steel door for loading fuel, and a drawer (ash pan) for removing ash. Firewood is used as fuel.

This small potbelly stove is designed to heat a room up to 60-70 square meters . The flat top of the body is used as a hob. Holes for the burners are cut out in it, which are closed with rings of standard sizes.

A potbelly stove with a duct firebox has a more complex design. Steel plates ( from one to two ) are welded inside the firebox, which form smoke channels. The channels slow down the movement of flue gases.

Reference. Factory heating and cooking iron stoves are ducted in design.

Long-burning metal potbelly stoves are large in size. Air is supplied to the combustion chamber not only through the blower, but also through the side gearboxes.

In simplified versions, there is no blower, and holes are made in the door, the width of which is adjusted with a special latch.

The firebox is filled two-thirds full. After the fuel ignites, the air flow is reduced by closing the ash pan and opening the upper regulators.

The firewood smolders slowly in the top layer and releases heat for several hours.

Potbelly stoves from a gas cylinder

Gas cylinders have different volumes - from 10 to 50 liters. The larger the cylinder, the more spacious the firebox of the homemade stove.

Industrial enterprises usually do not make stoves from used gas cylinders (such products, according to the accompanying instructions, cannot be disassembled; they should simply be disposed of). But Russian craftsmen have long mastered the production of compact stoves from outdated gas cylinders. The steel from which they are made is very durable , it can withstand the heat from burning any fuel. The body of a potbelly stove is made from one or two gas cylinders.

Scheme of a potbelly stove with a vertical firebox . The heater has the following design features:

- holes are cut out in the cylinder body for a drawer-ash pan, an outlet for a chimney, and a combustion door;

- a removable grate is inserted above the ash chamber;

- the door is installed in an inclined pipe welded to the body;

- a non-removable hob is welded above the body;

- There are partitions inside the housing so that combustion products are retained and better warm up the potbelly stove.

A potbelly stove made from a cylinder with a horizontal firebox consists of a body with a combustion door, an ash pit with a door, a branch for the chimney, and an additional hatch that acts as a burner. Thus, when constructing a potbelly stove, four holes are cut out in the cylinder.

The ash pan is made of sheet steel with a thickness of at least 3 mm , the combustion door at the end of the cylinder is also cut out of thick steel and attached to hinges. If the craftsman does not have experience in making doors and fastenings to them, you can buy factory doors made of cast iron. Fastening is carried out using bolts to steel corners welded to the stove casing. The hull supports are made from rods (construction reinforcement) or angle bars.