Any autonomous device for heating rooms requires a device for removing toxic products of fuel combustion. Stove chimneys can have different designs, heights or diameters, and during their construction a number of technological nuances and features must be taken into account.

The construction of a chimney is the most important stage in the construction of a brick stove, the correct execution of which determines not only the efficiency of its operation, but also the well-being of the residents of the house.

Regulatory requirements for the installation of chimneys

The rules for installing chimney ducts are regulated by a number of building regulations:

- SP 89.13330.2012 “Boiler installations”.

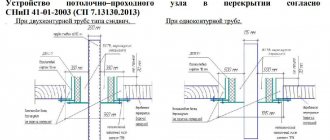

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”.

- DBN V.2.5-20-2001 “Engineering equipment of buildings and structures. External networks and structures. Gas supply."

- NPB 252-98 “Heat generating devices operating on various types of fuel. Fire safety requirements. Test methods".

- GOST 9817-95 “Household appliances running on solid fuel. General technical conditions".

General requirements for the installation of a smoke exhaust system

In general, the basic rules are as follows:

- As a chimney, it is allowed to use pipes that are resistant to extremely high temperatures, moisture, and acidic environments formed when combustion products come into contact with condensate.

- Each heat generator is supplied with a separate smoke shaft.

- Combining ventilation and chimney circuits is not allowed.

- It is prohibited to install chimneys near gas pipes, electrical wiring and other utility networks.

- The position of the smoke exhaust circuit should be as vertical as possible. The average angle of inclination of the pipe should not exceed 30°.

- It is not prohibited to place some of the contours horizontally, but it should be taken into account that any deviation from the vertical reduces the traction force. Therefore, the number of horizontal outlets should not be more than 3, with a length of each no more than 1 m, and the total length of the chimney up to 2 m.

- The speed of the air flow in the smoke shaft with natural draft force should be in the range of 0.15-0.60 m/s.

- The parts of the chimney line must be hermetically joined, and the pipeline itself must be rigidly fixed to the wall. Any sagging must be eliminated.

- For periodic cleaning, the chimney must be equipped with an inspection hatch.

- The section of the smoke shaft that goes outside must be protected from atmospheric precipitation and also be equipped with a spark arrester.

- All structural elements of the building in contact with the smoke exhaust must be made of fire-resistant materials.

Types of chimney pipes

Modern chimneys differ in the material used in the production of pipes and other parts, and in their design. Let's look at the features of the varieties.

Chimneys made of black metal

Ferrous metals include steel alloyed from iron and carbon, for example, galvanization and cast iron:

- Galvanized pipes are not used today as a chimney, as they emit harmful fumes when heated. Due to their low heating temperature, gas boilers are the only type of heating equipment that can be equipped with galvanized chimneys. In addition, galvanization is less resistant to condensation and acidic environments, and therefore requires careful insulation.

- Cast iron pipes are more resistant to high temperatures and moisture, but their rather impressive weight and fragility make installation and maintenance of the chimney structure somewhat difficult. The advantage of cast iron for pipes is its low thermal conductivity coefficient, so using a cast iron chimney is safer.

The absolute advantage of black rolled steel is its low price. The performance characteristics of these metal products for chimneys are significantly inferior to modern materials.

Asbestos cement chimney pipes

Asbestos cement chimneys are cheap and can be made yourself. But today they are practically not used in private construction; even on an industrial scale they are replaced with modern materials for chimneys.

Peculiarities:

- Asbestos chimneys are used in conjunction with low-power gas heat generators, since they cannot withstand heating above 300 °C; if overheated, the pipe body cracks. It is allowed to install asbestos-cement pipes at a distance from the heating device, at the outlet, where the temperature of carbon monoxide cools down to an acceptable level.

- However, this leads to another difficulty - the complexity of achieving absolute tightness of pipes when joining with other materials. In addition, asbestos cement is quite fragile, which makes it quite difficult to cut out an inspection hatch in its structure.

- The rough surface to which soot literally sticks, forming build-ups, worsening the traction force, and increasing the risk of fire, is another disadvantage of asbestos-cement chimney ducts.

- The porous structure of the material tends to absorb condensation, which provokes the destruction of the pipe when it freezes.

- The asbestos contained in the composition is carcinogenic, especially when the chimney is heated.

Brick chimney

Brick chimneys are a classic solution, but with the advent of innovative materials they fade into the background or their design is complemented by modern pipes.

Among the advantages of brick chimney contours are:

- Fire resistance, ability to connect to gas and solid fuel heat generators.

- Long period of operation (from 50 years or more).

- Aesthetic appeal.

However, they also have many disadvantages:

- The complexity of calculation and installation, which, in fact, should be carried out at the time of construction of the house.

- The impressive weight of the chimney structure requires a separate foundation.

- The rough surface of the pipe walls tends to accumulate soot.

- Susceptibility to an acidic environment is perhaps the main reason for the gradual destruction of brickwork;

- The complexity of chimney maintenance.

Stainless steel chimneys

Due to their versatility and ease of installation, stainless (alloy) smoke ducts are popular.

Advantages of stainless steel chimneys:

- Heat resistance (500-700 °C).

- High anti-corrosion resistance.

- Light weight.

- Fast warm-up, minimizing the likelihood of condensation forming in the circuit.

- The low pipe roughness coefficient minimizes soot deposits.

- A wide range of shaped elements that allow you to set the pipeline in the desired direction, complete with ready-made modular parts. The use of special socket pipes speeds up installation.

- Long period of operation of the chimney (minimum 15 years).

Before talking about the disadvantages of stainless steel chimneys, it should be mentioned that their range is divided into 2 categories:

- Single-circuit (single-walled).

- Double-circuit (sandwiches).

So, the main disadvantages relate specifically to single-circuit products. Due to the small wall thickness, their scope of application is limited. They are used only indoors or for lining brick chimneys. To prevent the formation of condensation, single-circuit pipes require insulation.

Sandwich chimneys are a modular design of two pipes of different diameters with an intermediate layer of mineral wool insulation with a thickness of 2 to 6 cm. They are completely devoid of the above-mentioned disadvantages.

There are a variety of grades of alloy steel, so you can choose a product to suit the individual characteristics of your heating equipment. So:

- For a gas boiler, the AISI 304 brand with an operating temperature of up to 300 °C is suitable.

- For a wood stove - AISI 439 or AISI 321.

- For a stove unit operating on liquid fuel, AISI 316 is used, and for peat briquette circuits, AISI 310 is used.

Ceramic chimney pipes

Modern ceramic chimneys are made of refractory clay and can withstand temperatures reaching 1000 °C. Fast heating and slow cooling prevent the formation of condensation and reduce energy costs.

To the listed advantages of chimneys we can add:

- Immunity to temperature changes.

- Anti-corrosion resistance.

- Chemical inertness to acids.

- Ideally smooth surface of the pipe walls.

- Easy installation of the circuit and the ability to do the installation yourself.

- Ease of maintenance.

- Service life - from 50 to 100 years.

The high cost of pipes and components for them leaves an imprint on their demand. After all, there are cheaper analogues that are not inferior in technical characteristics to ceramic ones.

The large weight of the chimney circuit requires the construction of a separate foundation. Smoke ducts made of ceramics can be exclusively straight.

Vermiculite and perlite chimneys

Vermiculite and perlite pipes for exhaust gases are the same as steel sandwich chimneys. The classic mineral wool insulation has been replaced with expanded vermiculite or perlite, a fire-resistant mineral.

This modern material for chimney pipes has a number of positive characteristics:

- Light weight.

- Moisture resistance.

- Resistance to corrosion, acids.

- Resistance to extreme high temperatures.

Some models of vermiculite and perlite chimneys have a two-layer structure, that is, they do not have the usual inner metal layer for sandwiches. The compressed block is usually 5 cm thick and impregnated with a special moisture-resistant compound. However, the relief of a block uncovered by a metal sheet causes rapid overgrowth with soot.

Compared to classic sandwich chimneys, vermiculite and perlite pipes are 10% cheaper and, according to manufacturers, the circuits can last at least 25 years.

Aluminum and steel corrugated chimneys

Corrugated metal chimneys are made from aluminum or stainless steel. Materials have different strength characteristics, and therefore their scope of application is strikingly different:

- Aluminum circuits are less resistant to high temperatures. Not able to withstand temperatures above 110 °C. They are used as household air vents for kitchen hoods or chimney ducts for gas fireplaces and water heaters.

- Stainless steel corrugated pipes, even though they have a thinner wall compared to their rigid counterparts, withstand high temperatures well. Can be installed in conjunction with solid fuel heat generators.

The particular advantage of corrugated products for chimneys is their extreme flexibility, which allows you to quickly:

- Set the chimney contour in the desired direction.

- Connect straight sections of pipes at the desired angle.

- Lining up an old brick chimney.

Plastic chimneys

Heat-resistant plastic is a fairly popular solution for exhaust circuits of low-power kitchen stoves and condensing, gas and pyrolysis boilers. Sometimes plastic pipes are used to line brick chimneys, but only in those areas where the temperature of the flue gases drops to an acceptable 120-200 °C.

Non-corrosion, smooth walls, ease of installation and low price of pipes are the advantages of plastic chimneys.

Varieties

There are several types of chimneys. They are classified depending on their location relative to the furnace itself:

- Mounted pipe. Due to its simplicity of design and ease of installation, it is perhaps the most common. The mounted pipe is mounted directly above the heating structure, being its continuation. Often installed on cast iron or small sauna stoves.

- Root chimney. Such a pipe is mounted next to the furnace on its own foundation, closely adjacent to one of its sides. The basic structure is convenient to use for multi-story buildings, where several heating elements on different floors can be connected to one chimney. For such cases, an accurate calculation of the parameters is required, otherwise the chimney will not provide the necessary draft.

- Wall pipe. Built into the external or internal main wall of the house. The external version should be carefully insulated, since due to the difference in temperatures inside and outside the structure, condensation can accumulate in the chimney, leading to the accumulation of soot and a decrease in draft.

We recommend that you read: Types of chimneys for stoves with a long-burning system and which one is better to choose

Based on their location to the building, chimneys can be divided into internal and external:

- Internal chimneys provide good draft, but are more difficult to install because they require transitions through the ceilings and roof.

- External chimneys are more convenient in terms of installation (especially in an already built residential building) and maintenance. It is not always possible to give such chimneys an aesthetic shape. In addition, the external surfaces of the structure need to be insulated.

Tips for choosing

The choice of chimney is based on the type of heat generator, its power and operating temperatures of the exhaust gases.

The appearance of the circuit products is also important:

- The seam of steel pipes must be welded, and butt welding is considered optimal. Overlapping or rolling does not provide adequate strength and tightness of the pipes.

- The longer the pipe, the fewer joint elements the chimney circuit contains and the less wear it wears.

- The chimney contour must be smooth; any dent in the internal section will become a platform for collecting soot.

- For sandwich products, it is important that the insulation layer belongs to the non-combustible class and is laid as tightly as possible.

- The thicker the wall of the chimney, the stronger and more reliable it will be.

On a note! The quality of the products will be confirmed by markings applied to pipes and other chimney structures according to standards.

Which material is better and approximate price

Only the characteristics of the heating equipment and the type of fuel determine the list of materials suitable for the parameters of the heating circuit. Personal preference in this matter is a somewhat rash decision, unless we are talking about comparing pipe materials that are equivalent, from a technical point of view. But even then it is better to prefer those that will provide at least a 10% safety margin for the chimney.

Calculation of the required cross-section and height of the pipe

The main parameters of the efficiency of the chimney circuit are diameter and height.

To determine the cross section, the following formula is used:

For calculations, calculate the optimal chimney height:

The resulting contour value will have to be adjusted if it does not meet the established standards:

- The minimum height is 5 meters.

- The elevation of the shaft above the flat roof is at least 1.2 m.

- The elevation of the shaft above the gable roof is determined by the distance from the ridge:

- If the distance between the pipe outlet and the ridge does not exceed 1.5 m, the chimney rises to a height of at least 0.5 m.

- If the distance between two objects is in the range of 1.5-3 m, the smoke shaft should not be lower than the level of the ridge.

- For distances greater than 3 m, the minimum height of the edge of the chimney is determined by a line measured at an angle of 10° from the ridge to the horizon point.

Based on the power of the heat generator, the required values for the height and diameter of the circuit can be determined using special tables:

Advantages of a wood-burning stove in a bathhouse and sauna

Installing a wood-burning stove in a bathhouse is undoubtedly a smart decision. Thanks to its features, it is not only practical, but also profitable:

- The low cost of fuel will allow you to significantly save on heating;

- Thanks to the natural heat, the steam room warms up twice as quickly as with gas;

- A wide range of wood-burning stoves will allow you to choose a design that is ideal in size and price;

Find out more about wood-burning sauna stoves, their operating features and advantages.

The chimneys of a wood-burning sauna stove have a number of design features that distinguish them from standard smoke exhaust systems. The most important thing is to make sure that carbon monoxide does not penetrate into the steam room, and soot does not settle on the walls of your bathhouse.

Making a metal chimney with your own hands

You can make a chimney yourself. But the question remains of what to make it from. At home, there is only one solution - plastic sheets of heat-resistant steel, which can easily be bent to form a strong lock-type seam.

Homemade models have one drawback - they can only be made single-circuit.

DIY installation features

The installation process for any chimney:

- Determining the layout of the chimney contour, preparing passage holes through the wall or interfloor ceiling and roof. The chimney can be placed inside or outside the house. The first option allows you to extend the service life of the chimney and use the heat of the pipe for heating. But here it should be taken into account that a chimney placed in a house increases the risk of fire, which means it requires compliance with fire safety measures:

- Passage areas must be lined, filled with fireproof materials, and hemmed with metal sheets.

- When exiting the shaft through the roof, it is important to stay as far as possible from the rafter system (at least 20 cm on each side).

- To seal the passage of pipes through the roofing, only non-flammable heat-resistant materials are used - galvanized sheets, metallized self-adhesive tapes or special polymer aprons (roofs). The junction areas of the pipes are additionally sealed with sealant for external use.

- Mine assembly:

- Assembly is always performed from the bottom up from the outlet pipe of the heat generator, and in this section the pipe must be single-walled.

- Fixation of individual elements is carried out with special clamps, flanges, and heat-resistant sealant, the squeezing of excess into the circuit should be avoided.

- A condensate collector equipped with drain fittings and an inspection and cleaning hatch must be installed in the lower part of the main line.

- All vertical contours should be assembled “along the condensate” (with the socket up), and horizontal ones - “along the smoke” (with the socket down).

- Along its entire length, the chimney is attached to the wall using special support brackets.

- A protective umbrella or deflector and always a spark arrester are installed on top of the pipe head.

- When the chimney is raised above the roof to a height of more than 1.2, the structure must be supplemented with fixing braces.

- Insulation of the chimney duct.

Chimney insulation

The hotter the air, the better the draft and the less likely it is for condensation to form; it is the insulation of the smoke line that improves the operation of the circuit.

Non-combustible materials are used as insulation:

- For steel chimneys - mineral basalt or glass wool.

- For concrete, brick and ceramic chimneys - foam concrete, wood concrete or fire concrete blocks placed between the chimney duct and the lining material of the circuit.

The pipe is wrapped with mineral wool mats and tightly fixed with heat-resistant clamps or binding wire. A metal sheet casing is installed on top of the mineral wool insulation on the pipe, which decorates the chimney circuit and prevents microscopic stone or glass fibers harmful to humans from entering the environment. All end elements of the chimney must be tightly closed with a plug.

The section of steel pipe adjacent directly to the heat generator cannot be insulated. The heating of this element is so high that overheating will cause the metal circuit to burn out.

Installation features

The simplest option for installation is a mounted chimney. How to lay out a pipe with your own hands? Let's consider the method of laying a classic chimney for a sauna stove:

- We calculate the parameters of the chimney using one of the methods given above;

The standard channel cross-section for a sauna stove is 250x120mm, which is exactly the size of a red brick; in addition, you will need half bricks. They can be bought or cut off;

The mortar is laid with a thickness of no more than 1 cm, preferably a clay composition with the addition of cement;

- We prepare everything necessary - bricks, mortar, tools;

- Take measurements for fluff, gate and otter;

- Laying should begin from the stove, checking each row with a building level. Periodically clean the channel of excess solution;

- Advice - after laying the first two or three rows of bricks, fasten ropes at the corners of the future chimney and stretch them to the ceiling (strictly vertically). They are used to control the position of the chimney;

- It is necessary to secure the frame at the installation site of the gate valve;

- Continue laying the brick until it is fluffy. Before installing the fluff, it is necessary to count the number of its rows. In one row, the diameter of the channel increases by ¼ of the width of the brick. The brick terminals must be tightly attached to the floor beams, there should be no gaps between them, otherwise the chimney will wobble

- The fluff should be placed according to the diagram (see above, Fig. 1). It can be changed based on your size;

- After laying the fluff, we continue laying the chimney;

- We begin to lay the otter from the underside of the roof; the increase in the cross-section of the chimney when laying the otter should take into account the slope of the roof slope, gradually;

- Advice - to increase stability, metal plates should be embedded in the otter;

- If necessary, trim the ends of the bricks;

- Head device. To do this, we increase the outer perimeter by a quarter of a brick;

- Finish row. We install a bird net in it. We fasten the protective cap on top with dowels.

Operating rules for repair and cleaning

The rules for operating chimneys prohibit:

- Use the chimney circuit to dry shoes and clothes.

- Light the heat generator with flammable fuel or fuel not designed for the smoke exhaust capacity.

A preventive inspection, during which the draft, integrity, tightness of the circuit, and cleaning of the chimney duct must be checked at least 2 times a year. The thickness of ash deposits in a pipe exceeding 2 mm is an unambiguous signal about the need for a circuit cleaning procedure.

Chimney cleaning can be done in 2 ways:

- Mechanically, using a special brush and other devices.

- Chemically, with the help of “miracle logs” placed in the firebox, which release compounds during combustion, causing soot to peel off from the walls of the chimney.

Design options

Regardless of the format, sauna stoves are made from pipes 530 mm or larger, but the maximum recommended cross-section is 600 mm. This diameter is considered optimal for high-quality heating of the steam room without excessive fuel consumption.

In addition to this, other materials will be required:

- sheet steel for the manufacture of end walls, lintels;

- chimney pipe with a diameter of 100-150 mm;

- ready-made or cut-out doors for the firebox and ash pan;

- hinges for doors;

- stainless steel tank;

- reinforcement bars for grates or finished cast iron grates;

- steel corners and strips.

The thickness of the sheets should be approximately the same as the thickness of the pipe walls Source prom.st

A specific list of required materials and their quantities is determined from the drawing of the selected or independently invented design. For beginners and people far from this area, it is better to use ready-made, proven diagrams so that the stove made from a pipe is guaranteed to be reliable, safe and efficient, with an optimal volumetric ratio of the heater and firebox.