Bath procedures always involve a large amount of moisture and steam, which can destroy any insulation. A vapor barrier for a bathhouse in this case will be an excellent way out. Vapor barrier films and membranes will protect the insulation from moisture and help extend its service life for many years. Let's take a closer look at the types of protective materials and how to use them correctly in bath rooms.

Why do you need a vapor barrier for a bathhouse ceiling?

Vapor barrier of the ceiling and walls in the bathhouse

Since no one has yet canceled the laws of physics, it means that everything in this world remains as before.

Everyone knows from school courses that heat always rushes upward. For a steam room in a bathhouse, this is doubly true. If the vapor and thermal barriers do not work well, then all heat and moisture losses will pass through the ceiling.

And if the ceiling is insulated with mineral insulation (rolled basalt wool, slab mineral heat insulators), what will happen to them? Simply, insulation saturated with moisture will stop working.

There will be practically no effect from its use. You can safely begin to dismantle it and completely replace the insulating layer. This is a thankless job, so it is better not to make gross mistakes during the construction of baths and saunas.

Here is the second negative point, if the vapor barrier of the bathhouse ceiling is not done correctly.

All wooden structures, such as floor beams, rough ceilings, and roof elements, will be subject to premature rotting. High temperature and high humidity have a beneficial effect only on humans, but for wood this is considered an aggressive environment. Repair of the roof and ceiling is definitely guaranteed.

Installing a vapor barrier using a furniture stapler

I recently witnessed a neighbor redoing all the ceilings in a newly built bathhouse. The builders, trying to deliver the project on time, simply did not vaporize the ceiling in the steam room. All the expensive URSA roll insulation had to be thrown away.

Literally after 3-4 times of using the steam room, it became so saturated with moisture that water simply dripped from the ceiling. It’s good that all the work to correct this gross mistake was done almost immediately, and the tree did not have time to suffer much. The situation is unpleasant - money and time are wasted.

Foil vapor barrier for a bath

Modern steam rooms in the bathhouse are heated by metal stoves with a constant fire: the stones warm up during the fire, and if combustion is not maintained, the stones will give off heat through water poured on them and cool down. But the advantage of these furnaces is fast heating, the stones heat up to 300-400 degrees in a short period of time, what happens further without vapor barrier is described above.

To keep the heat inside and prevent it from escaping outside, a foil vapor barrier is used for the inside of the bathhouse. The principle is to create a screen like a thermos: which retains heat transfer energy of all types: heat exchange, convection and radiant or, as it is called: electromagnetic energy of infrared radiation.

Insulation of the ceiling in the steam room should prevent the penetration of heat into the cracks of the ventilation and chimney pipes and through other channels: water pipes, piping the heat exchanger (register), the stove with a container installed in the washing room or in the attic of the bathhouse, electrical wiring. This also applies to the vapor barrier of the ceiling in the bathhouse. Foil material requirements:

- High tensile strength; Low thermal conductivity; High reflectivity of IR rays; Fire resistance; Environmental friendliness.

These requirements are met by foil from trusted manufacturers, such as Aerolam Insulation, which is one of the top ten leading international companies producing reflective insulation material for construction purposes.

The material contains double fire-retardant and IR reflective layers of aluminum foil, between which there is foamed polyethylene with air bubbles enclosed in spherical individual cells. This material structure is most suitable for creating a thermos in a steam compartment.

Technical characteristics of insulating materials Aerolam Insulation.

Roll DimensionsBubble Cell SizeNominal ThicknessIR ReflectionThermal ResistanceTemperature RangeAerolam Premium1.2m X 30m1.2m X 30m20mm97%0.03-0.04-50 ~ 110 CAEROLAM ADVANCE1.2m X 40m10 X 30mm10mm97%0.03-0.04-50 ~ 110 CAeroalm Premium WF1.2m X 40m4 X 10 mm8 mm97%0.03-0.04-50 ~ 110 CAerolam Super WF1.2m X 40m4 X 10 mm4.5-5 mm97%0.03-0.04-50 ~ 110 C

This is a small part of a roll of insulating material for vapor barrier from the inside of a bathhouse Aerolam Insulation. The choice is huge. You can choose a universal vapor barrier material for external and internal insulation.

Rolled foil material can be chosen cheaper. “Alucraft” – consists of 3 layers: foil, reinforcing fire-resistant film, kraft paper. Regardless of what you choose, the foil is attached to the wall and ceiling with a stapler to a wooden sheathing with an overlap of 5-10 cm, the joints are glued with adhesive foil tape, included in the kit.

Advantages of the Izospan brand

Each type has its own characteristics: the possibility of installation indoors and from the facade. A separate category is reflective vapor barrier for baths, which combines several functions. Foamed polypropylene with a surface laminated with foil can withstand a wide range of temperature fluctuations and high humidity with absolutely no loss of quality. A prominent representative is Izospan, the metallized layer of which is capable of reflecting radiation by 90%. A vapor barrier protects against steam inside rooms and resists wind and rain outside. For a bathhouse, you can buy one of the brands, each of which is designed for different construction processes:

1. Izospan A - vapor barrier to compensate for the temperature difference between the heated room and the roof. The density is 100 g per 1 m2 with a roll width of 150 cm, length - 50 cm. It is resistant to ultraviolet radiation, mechanical damage, environmentally friendly, fireproof, thanks to the special additives available. In this group there is a grade AS, consisting of three layers, intended for wall surfaces, AM - for the ceiling of a bathhouse.

2. Vapor barrier Izospan V is laid on the insulation, creating protection for all elements and structures. Density – 72 g per 1 m2 with a width of 130 cm and a length of 50 cm. Used as a barrier in pitched roofs, attic floors, and walls. Prevents corrosion and extends the service life of all materials.

3. A distinctive feature of class C insulation is that it can be laid on a roof with a slope of less than 35. This allows the bathhouse surfaces to remain dry, avoiding condensation. Also suitable for cement screeds and basement floors in buildings without constant heating.

4. Izospan D is the most durable vapor barrier made from laminated polypropylene. The universal membrane is suitable for any structure, when constructing foundations, roofs, concrete foundations, and floors. DM is made from fabric with an anti-condensation coating and is resistant to mechanical stress. The price ranges from 700 to 2000 rubles per roll.

Laying features

The vapor barrier of the walls of the bathhouse and the ceiling must be installed according to a certain scheme. Depending on the properties and purpose of the material, choose the appropriate method:

1. Creating a reliable barrier layer is the first option. To do this, prepare boards with a thickness of at least 50 mm. To prevent the wood from succumbing to dampness for a long time, its surface is impregnated with drying oil. The ceiling of the bathhouse is sheathed with dies, after which a vapor barrier is laid on top. It is necessary to take into account that the material is placed with pile inside the room so that it absorbs moisture well. The canvases are overlapped with a margin of 100 mm using a stapler. A slight sag will prevent damage to the film during temperature fluctuations.

2. According to this scheme, clay is used, which is previously softened for convenience, thrown onto the membrane and insulation begins. For greater effect and reliability, another layer of vapor barrier is installed on top.

3. In some cases, expanded clay about 20 cm thick is additionally poured onto the canvas, which helps protect against cold. This is especially necessary for arranging layers around the pipe through which combustion products exit, since the highest temperature coefficient is in this place.

Vapor barrier of the bathhouse ceiling is carried out according to another scheme:

1. A tongue-and-groove board is attached to the surface, on which the sheathing is installed.

2. Wooden elements are impregnated with antiseptic and drying oil, and a mandatory gap is made between them to remove moisture.

3. Film or foil is placed on them, then backfilled. It is recommended to use expanded clay in bathhouses, since the building is considered a fire hazard. The wall protection scheme also involves creating a frame at intervals corresponding to the width of the roll. This method is not used for thin foil.

4. The cake is mounted in the following order: hydrophobic film, insulation, vapor barrier membrane. Proper arrangement implies the mandatory provision of a ventilation cavity and a gutter with a slight slope to drain condensate.

5. The seams are sealed with mastic or metallized tape. The best cladding option is linden lining.

Basic installation rules

To carry out all installation work, you do not need to have any special experience or have a set of professional tools on hand. You can start and finish the work yourself, following a few tips.

The vapor barrier is always installed under the internal cladding. These can be panels, drywall or lining. In this case, the membrane is joined to the insulation so that its reflective surface “looks” into the room.

It is necessary to leave a gap of several centimeters between the metallized surface of our material and the interior decoration of the lining or panels. The purpose of the gap is to reflect heat as much as possible. Lay the panels horizontally. If you are processing walls, then you need to do this from the bottom up, so that each individual part overlaps the second by 15-20 cm, both vertically and horizontally. Next, using special wooden slats, on which you will later mount the finishing, secure all the panels.

A special connecting tape that can withstand temperatures of 140°C will help you provide additional sealing of the seams. So, you can always save money on heating.

As you can see, the installation itself will not take much time or effort. And you will feel the benefits of using such a layer when using the room for its intended purpose. Separately, we note that the price for Izospan FB always remains within reason. Browse our offers and order the best double-layer membrane for your sauna.

Vapor barrier device for bathhouse ceiling

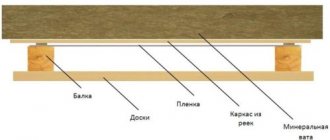

The process of installing a vapor barrier precedes the process of insulating the ceiling.

Therefore, a vapor barrier can be installed either from the outside, from the attic floor, or from inside the bathhouse.

Then a layer of your chosen vapor barrier is laid on top of this material.

It is secured to the floor beams using a construction stapler.

A layer of insulation is placed on top of it.

Then the waterproofing is done and everything is covered with attic floor boards.

If insulation is carried out from inside the bathhouse, then everything is done in the reverse order:

- The waterproofing layer is installed first;

- the second installs insulation between the beams;

- the insulation is covered with a layer of vapor barrier, which is securely attached to the floor beams;

- The decorative ceiling is installed last.

Coating methods

In the construction of any bathhouse, as a rule, the installation method using thick beams or durable boards is especially popular. They serve as supports, and sometimes the ceiling is laid on top directly on the wall frame. Installing a ceiling in your bathhouse begins with how you choose the installation method.

Bathhouse construction process

There is no need to explain that the ceiling is erected only after the finishing work in the construction of the roof, otherwise the unfavorable environment will harm the thermal insulation, reduce its effectiveness and lead to the walls slowly sealing, and the growth of fungus will begin, which is very difficult to fight.

Types of ceiling coverings

The installation of a ceiling in a bathhouse traditionally involves laying a base, which is made up of internal boards. Edged or unedged ceiling boards, which are usually covered with clapboard, are widely used.

Between the floor beams, a layer of protection against moisture and heat preservation is laid on the internal boards. Steam and waterproofing should not have any gaps, joints should be sealed tightly, and boards should be of good quality, without knots. A tight fit of the board and additional overlap will create favorable conditions and protect against the formation of water.

There are several ways to lay a ceiling:

- Hemmed, for large-sized baths;

- Floor-mounted, for small structures;

- Panel, as an alternative to the first two.

false ceiling

The insulation for a false ceiling is usually mineral wool, which has a high level of absorption and drip absorption. It is covered with waterproofing and sheathed with boards on the outside.

If your bathhouse has a superstructure in the form of an attic, you don’t have to worry about the safety of bath accessories and their drying - mineral wool, as high-quality insulation, promotes rapid absorption of moisture and is ideal for such conditions. Cotton wool is produced in the form of pressed slabs and is easy to install.

The floor ceiling does not require external cladding, since it is usually covered with thermal insulation material. This method is not suitable if the bathhouse has an attic. Any manipulations with the attic floor can damage the thermal insulation of the bathhouse.

A more complex flooring option is a panel ceiling. Despite the difficulty of covering, the ceiling is very economical if you decide to go with this option.

It has undeniable advantages:

- It is a prefabricated structure made of load-bearing beams;

- Vapor and waterproofing is installed in the structure box and, if desired, it is insulated with mineral wool;

- The ceiling can be made outside the walls of the bathhouse.

Mineral wool

Group II - Vapor barrier and waterproof membranes

These include - B, C, D, DM .

The main purpose is to protect thermal insulation materials, as well as internal elements of walls and roofs from the effects of condensate vapors emanating from the room. Ensure the preservation of the physical properties of insulation and the durability of structures. They prevent the appearance of condensation, and with it chemical (corrosion) and biological (fungus, mold) destruction. In addition, they protect against mineral thermal insulator fibers from entering the living space.

Brands B, C, D, DM have a two-layer structure. The outer side is rough (this is necessary for more effective retention of moisture condensation), and the inner side is smooth. I think anyone will understand which side the isospan is located towards the insulation.

Group B - consists of two layers of vapor barrier and is intended for use inside a building. Effective for insulation and even thermal insulation of attics, attics, basements, and other elements.

C is a hydro-vapor barrier material used for cold roofs, attics, concrete floors and damp rooms.

D is a universal membrane for vapor and waterproofing of uninsulated roofs, foundations, floors, etc.

DM is a material with increased strength for vapor and waterproofing. Used for under-roof waterproofing when installing cold roofs. And also to protect wooden elements from accidental precipitation in areas of loose roofing and as insulation against internal vapors.

And grades D and DM have increased resistance to solar radiation and fiber strength. They are often used for temporary roof covering. This windproof film resists sunstroke and snow pressure well.

The figures show the logic of placement of Izospan brands of the first and second groups.

Laying a vapor barrier in a steam room

The quality and duration of the main bath procedure depends on the correct device for vapor barrier of the steam room ceiling.

A certain amount of steam is instantly formed, which effectively warms the body of people in the steam room through the skin.

But the steam tends to rise up to the ceiling and go out.

If this happens, you have to heat the heater again and again to create steam.

That is, you have to light the stove again and again.

To perform this procedure as rarely as possible, you should place a barrier in front of the steam so that it does not go outside, but remains inside, in the steam room.

To do this, an additional layer is laid in the ceiling between the hemmed material and the insulation - a vapor barrier.

It prevents steam from escaping and protects the insulation from moisture getting into it.

Creating a vapor barrier in a steam room is associated with a number of problems.

The fact is that quite often the air temperature in the steam room rises to 100 degrees or even more.

And polyethylene film in most cases is not designed for such temperatures.

It begins to shrink sharply and fails very quickly.

It simply bursts.

Therefore, the film should be left for vapor barrier in other rooms of the bath, where the air temperature is much lower.

And in the steam room for vapor barrier, you should use modern materials that have a foil coating on one side.

For example, stizol.

This material can simultaneously perform two functions: vapor barrier and insulation.

Stizol successfully withstands both large amounts of moisture and high temperatures.

This is an ideal material for vapor barrier of the ceiling in a steam room.

Vapor barriers such as foamed polypropylene are also gaining popularity.

This material is laminated with foil and not only does not allow steam to pass through, but also reflects high temperature back into the steam room.

Video about vapor barrier of a steam room ceiling in a bathhouse:

Performing a vapor barrier is not difficult.

The main thing is to be careful not to damage the material.

What else to read on the topic?

When a vapor barrier is not needed

Initially, the bathhouse was a log house. It was not additionally insulated. Today this option is rare, but it is practiced. Here the structures do not need vapor barriers. The only protection for wood is antiseptics, fire retardants, and moisture-resistant agents.

Less commonly, polymer products are used to insulate a bathhouse. These are extruded polystyrene foam, penoplex, which are characterized by vapor permeability close to zero. There is also no need for additional vapor barrier.

In the locker room, dressing room, and rest room, changes in relative humidity and temperature are insignificant. The maximum load on the structure is not constant. The short-term nature of the aggressive environment allows for the refusal of additional vapor barrier in the bathhouse. But here it is necessary to arrange proper ventilation so that moisture leaves indoors as quickly as it appears. The tree breathes, so it will not suffer from the negative effects of steam in such an environment.

Alternative types of materials

There is no alternative to isolon as such, but we would be wrong if we do not briefly talk about materials that in certain cases can replace it.

cotton wool

Cotton materials, which include mineral wool, glass and ecowool, have almost the same heat and sound insulation properties as isolon. Their manufacturers insist that their main advantages are:

- Lightweight and easy to install.

- Low thermal conductivity.

- Strength under compression, mechanical stress, ruptures.

- High sound insulation characteristics.

- Not susceptible to fire.

- Resistance to temperature deformation.

- Biological and chemical resistance.

Mineral wool is available in the form of rolls and sheets and has different softness and thickness. It is extremely easy to install structures using various types of wool:

- The walls must be covered with a steam or hydrobarrier using a stapler.

- The next step is to assemble the frame from special metal profiles, the assembly step is 50 centimeters.

- Then cotton wool is laid, carefully distributed throughout the entire space, avoiding gaps.

- Then the cotton wool is fixed in any convenient way, the structure is covered with sheets of plasterboard, plastic panels, clapboard, fiberboard.

- The final stage is finishing the walls; its type depends on what material you have chosen or what is available.

The disadvantage of the material is its allergenicity; you should work in protective gloves and a mask to prevent contact of the material with the mucous membranes and skin of the hands. It also requires additional vapor barrier, since it loses its properties from moisture. In principle, the technology is simple and you can easily do everything yourself without overpaying to contractors.

Foam plastic or its analogues

The undoubted advantages of polystyrene foam include the following:

- Polystyrene foam is not afraid of moisture.

- It is a good heat insulator.

- Not susceptible to rotting, fungal or mold stains.

- Easy to install and cut.

- Has low weight.

- Heat resistant to low temperatures.

- Does not require waterproofing.

Polystyrene foam also has many disadvantages:

- It is fragile, crumbles, and requires additional protection with a dense base.

- Not breathing.

- Easily destroyed and enters into chemical reactions.

- We love rodents.

Polystyrene foam is used mainly in non-residential premises or for outdoor use. Installation is carried out using an adhesive mixture and requires additional fastening with “fungi”, careful coating of seams, plaster and subsequent painting.

Group I - Hydro-windproof membranes

These include: AQ proff, A, A (with OZD), AS, AM.

The main purpose is to protect enclosing structures from condensation and create vapor barriers in non-residential parts of premises (attics, basements). And also to compensate for temperature differences in heated and unheated rooms. It is necessary to understand how different aspects of a vapor barrier “work.” Although perhaps this is an educational program and all readers understand the physics of the process. So, I includes:

Izospan AQ

Izospan AQ proff is a three-layer durable hydro-steam and windproof membrane. AQ proff is laid over the insulation, without sheathing. It features excellent vapor permeability. The figure shows the main areas of application.

A – vapor-permeable membrane. Purpose: protection from external moisture, wind and roof condensation. Installed on the outside of the insulation. We especially love it for hydro and vapor barrier of pitched roofs. The highest vapor permeability of the entire group (3000 g/m²/per day).

And with OZD (the same, but with thermal protective properties) – it reduces the risk of fire of structures and materials during operation of the welding machine. And also when using a gas burner or blowtorch during waterproofing of enclosing structures. Often used for ventilated facades. Vapor permeability = 1500 g/m²/day.

AS – three-layer membrane film. Purpose – vapor barrier of walls, roofs, as well as insulation from external moisture and steam emanating from the room; Vapor permeability = 1000 g/m²/day. The most durable brand of the entire group.

AM is a high-strength two-layer membrane. Purpose - laid out on top of the insulation and protects it from condensation and wind exposure.

What happens to heated air in baths

The vapor barrier of the bathhouse ceiling made of natural materials could not protect the wood 100% from steam, but after washing, the heat remained in the bathhouse, and the moisture accumulated in the log evaporated during this time. The bath heated up and cooled down slowly.

There was no sharp temperature difference inside the bathhouse and on the surface of the ceiling, just as there were no prerequisites for creating a dew point - the temperature at which warm air saturated with moisture cools down and cannot retain moisture that condenses on cold surfaces. Even if moisture appears on the surface of the ceiling, it will not penetrate deep into the wood, but will form drops on the ceiling, which will stop dripping onto the floor as soon as the bathhouse warms up.

In modern baths, the finishing materials are made of moisture-resistant wood, but the design of the stove, in most modern baths, is designed to quickly heat the steam room. Now imagine what happens during warming up if there is no vapor barrier on the ceiling and walls.

The stove gives off heat almost instantly. The not yet heated walls and ceiling receive heated hot air; Some of the wet steam finds the dew point on the surface of the cold walls and ceiling and condenses on them in the form of droplets.

The dew point does not stand still, it moves as the walls and ceiling heat up.

What happens if there is no vapor barrier on the ceiling in the bathhouse? Warm air penetrates behind the sheathing and encounters insulation, which has a temperature lower than the warm air entering. A condition of temperature difference may be created in which moisture condensation occurs directly in the insulation (internal condensation), and since the insulation has low thermal conductivity, the dew point in it can be maintained for a long time and the insulation will become wet, like a sponge, absorbing moisture.

This is the difference between an ancient Russian bathhouse and a modern one.

For an old Russian bath, there are practically no conditions for condensation of warm air, or they are reduced to a minimum (surface condensation). A modern bathhouse must have steam protection. Moreover, this protection is based on specific conditions, which take into account:

- Stove type: with an open type heater and a constant firebox, and a closed type with an intermittent firebox and high heat capacity; Features of the design of the room; Construction material.

Based on these conditions, choose a protection method:

- Maximum insulated room with impenetrable vapor barrier, protection against internal condensation; Partial vapor barrier, eliminating the formation of dew point in the bathhouse design.

Rationale for using vapor barrier

Today, in order to save money on fuel, the building is additionally insulated from the inside. That is, the dew point shifts towards the premises. Due to temperature changes with humidity, condensation forms in the space between the thermal insulation and the wooden wall, which is destructive for many materials. This is especially true for the ceiling, as hot air tends upward.

Protective measures are aimed at preventing the penetration of moisture into the insulation and the effects of steam and condensation on the constituent elements of the bath. The solution here is a vapor barrier. It is often confused with a hydraulic barrier. The difference is resistance to water and steam.

Where to start insulating bath walls, and what materials to choose

To reduce heat loss, you will need to make high-quality thermal insulation and vapor barrier for the washing room, steam room and, if possible, the dressing room. Although insulating a bathhouse from the inside will require additional financial costs, your efforts will later pay off in spades, and you will be able to save significantly on firewood.

In former times, the walls of the bathhouse were insulated in the old fashioned way - with red moss or sphagnum, hemp hemp, and tow. These natural materials are still used today for caulking wooden baths, but despite all their environmental friendliness, they have significant drawbacks: natural materials are taken away by birds, damaged by moths, and they are not as convenient to use as many synthetic materials.

If you have just started building a log bathhouse from timber, take care of the thermal insulation of the walls during the construction process by laying between the beams material made from flax or jute (flax-jute felt, flax batting, etc.). You will have to deal with the interior decoration of the log house approximately six months after the construction is completed. During this time, the log house will shrink, then you can carefully caulk the seams with the same flax-jute felt, treating them with sealant on top to protect them from moisture.

Video about forcing onions into feathers

The walls in the bathhouse are insulated using the following technology:

- On the surface of the load-bearing walls, a horizontal and vertical sheathing of bars is attached with a thickness exceeding the thickness of the insulation by a couple of centimeters. Such a frame is necessary so that the insulation does not lose its qualities and does not wrinkle.

- Glass wool or mineral wool slabs are installed between the bars as insulation.

- A foil vapor barrier is overlapped over the thermal insulation material to protect the insulation from condensation.

- Joints and seams must be sealed with aluminum foil tape.

- A vertical sheathing of slats up to 5 cm thick is attached to the vapor barrier to create a ventilated gap between the vapor barrier and the finish.

- The sheathing is covered with clapboard.

Foil is usually used for vapor barriers in steam rooms and washing rooms, and kraft paper will be sufficient in the dressing room or rest room. Often, instead of foil, preference is given to dense (from 140 microns) polyethylene. As a facing material inside the bathhouse, you can choose not only the popular eurolining, but also well-planed boards, plasterboard, gypsum fiber, etc.

To maximize the insulation of the bathhouse, after completing work on the walls, do not forget to take care of the windows

To maximize the insulation of the bathhouse, after completing work on the walls, do not forget to take care of the windows. The frames must be fitted closely to the bindings, the cracks must be treated with sealant - then the warm air will remain inside the bathhouses much longer.

Installation of a vapor barrier layer in a washing room

In order for the bathhouse to operate without problems for as long as possible, it will be necessary to provide a vapor barrier in the washing compartment. It also contains excessive humidity, and temperatures are significantly lower, which is far from normal conditions.

Therefore, it is important to ensure not only high-quality vapor barrier for the steam room, but also for the washing room. Although in this case you can do without foil-based material. Diffusion membranes are ideal. They will not allow steam to penetrate into the insulation, and if the membrane on the inside is equipped with a hygroscopic layer, then the moisture contained in the insulation will be retained.

This suggests that if droplets have formed on the rough surface of the membrane, they are retained until they evaporate under the influence of air currents. For this scheme to work, you need to leave a gap for ventilation between the final finish and the vapor barrier layer.

Make sure that the vapor barrier layer is attached to the surfaces with the correct side - the foil facing out. Otherwise, the material will deteriorate very quickly, and you will have to completely replace it, otherwise the bathhouse will be impossible to use.

Vapor barrier with insulation of the bathhouse ceiling according to all the rules

There are various variations of laying an insulated “layered” ceiling, however, when choosing the appropriate option, you must remember that the ceiling in the bathhouse is subject to the influence of high humidity, which means you should definitely take care of proper vapor barrier.

Often, instead of foil, preference is given to dense (from 140 microns) polyethylene

How to insulate a bathhouse with a wooden ceiling:

- Lay fiberglass fabric on the rough ceiling.

- Fill the layer of fiberglass with a solution of clay and sand (1:1), mixed with fine chopped straw or sawdust. The layer of clay-sand mortar should be 20-30 mm.

- Next is a 50 mm layer of clay-sand mortar (1 part clay mortar, 3 parts vermiculite).

- Leave the layer of solution to dry for a period of 3 weeks to 2 months, depending on the weather.

- Lay polystyrene foam (100-150 mm) on the clay-sand layer.

- A layer of cement mortar with the addition of foam chips (1:3).

- If there is an attic above the bathhouse, you need to lay roofing felt or roofing felt on top of the last layer and cover it with a wooden floor.

Lathing is attached to the rough ceiling in the bathhouse at intervals of 500 mm, thermal insulation material (mineral wool) is fixed between the slats, foil is lined, slats are nailed, and the ceiling is sheathed with facing material.

Video about insulating the ceiling in a bathhouse

How to insulate the ceiling of a bathhouse made of concrete floors:

- Install wooden beams 100x100 mm under the ceiling on the side walls inside the bathhouse, maintaining a distance between the beams of 500 mm.

- Attach fiberglass fabric to the concrete slabs.

- Next is a layer of thermal insulation (100-150 mm).

- Cover with a layer of foil or foil cloth.

- Pin the sheathing of slats (thickness 25-30 mm).

- Attach clapboard or other facing material.

- In the attic, place a layer of slag or expanded clay (150-200 mm) on concrete slabs.

- Lay thermal insulation material (thickness from 50 to 100 mm).

- Lay a wooden floor if necessary.

Do not forget to provide gaps on the ceiling inside the bathhouse of a couple of centimeters between the vapor barrier (foil) and the lining to ensure ventilation.

Do not forget to provide gaps on the ceiling inside the bathhouse of a couple of centimeters between the vapor barrier (foil) and the cladding

Such insulation of baths allows you to achieve a “thermos effect” inside the steam room and washing room, maintaining good heat for a long time. It will take you less time to light the sauna, and you will be able to steam longer.

Overview of materials for walls and ceilings

Previously, coating with a mixture of clay and sawdust was used as insulation. The mix perfectly retained steam and heat, creating the so-called thermos effect. Today, well-known aluminum foil and the latest roofing films are used for these purposes.

Vapor barrier and insulation of the bathhouse ceiling are carried out before the final finishing. The main difference between modern vapor barriers is their two-layer structure and special properties that prevent the accumulation of condensation, the development of dampness and the appearance of mold and rot. The most popular developments from the following manufacturers:

1. ISOSPAN FB series is positioned as reflective (energy-saving) vapor and waterproofing. Designed for use inside baths and saunas with steam temperatures up to +140 °C. Produced on the basis of kraft paper with a protective layer of metallized lavsan. Helps reduce heat loss through walls and ceilings, protects against dampness under the finishing coating and getting wet. Used in conjunction with FL termo aluminum tape.

Technical characteristics of ISOSPAN FB:

2. ISOVER VS 80 – a two-layer vapor barrier membrane with an increased level of tensile and tensile strength. Made from polypropylene fiber, it protects insulation and supporting structures from dampness and mold. Buying an ISOVER vapor barrier is not enough; in the kit you need to purchase metallized or reinforced adhesive tape for fastening. When installing, it is required to maintain a ventilation gap of 15-25 mm wide.

3. Yutafol series N 96 Silver and N 110 are used with equal success for both under-roof and ceiling vapor barriers in bathhouses. Retains heat and steam indoors, protects the insulation from dampness and getting wet. Manufactured from polypropylene non-woven fabric, N 110 is additionally reinforced with a mesh of polyethylene strips.

4. Izovek series:

- B - two-layer material for protecting walls from the inside, interfloor ceilings, roofs.

- C – black or blue film with improved performance properties. Universal, used inside and outside buildings.

- D – polypropylene non-woven with reinforcement. It is characterized by increased mechanical strength and versatility.

All types do an excellent job of retaining steam and are suitable for baths and saunas.

Technical characteristics of Izovek:

Installing a vapor barrier in a sauna during the construction of a bathhouse requires the availability of material. The choice of brand depends not only on the buyer’s trust in the manufacturer, but also on the price.

| Name of vapor barrier | Price per roll, rub. |

| ISOSPAN FB | 900 |

| ISOVERVS 80 | 1 100 |

| Yutafol N 96 Silver | 1 200 |

| Yutafol N 110 | 1 500 |

| Izovek V | 680 |

| Izovek S | 950 |

| Izovek D | 970 |

Installation instructions

The main advantage of modern membranes is that they do not require additional maintenance for their entire service life. The task of proper vapor barrier is to retain heat and steam indoors

That’s why it’s so important to ensure that the seams are tight.

Installing a vapor barrier on walls and ceilings begins with preparing the surface. It is cleaned of dust and debris, and the cracks are filled with putty. A waterproof membrane is laid, then the sheathing for the insulation is placed. Upon completion of the work, a vapor barrier film is attached to the frame using a construction stapler. The overlap is at least 10-15 cm. The edges are glued with special tape. A counter-lattice is placed on top, onto which the finishing coating is mounted. It is not recommended to stretch the material.

Bath vapor barrier installation diagram:

Sometimes, instead of membranes, insulation and substrates with an aluminum top layer (Penofol, Izolon F) are used. The most economical ones simply attach plastic film and foil on it. It is better to use professional products, as they are designed to remove condensation, preventing it from settling on the finish coat. A special vapor barrier will protect your bathhouse 100%.

What types can be found on sale?

And again, it’s interesting to figure out what a vapor barrier film for the ceiling is, what can they offer us in the store? In general, it’s probably worth clarifying right away that the class of vapor barrier films is not all that can be found on sale. It is worth talking about such a popular foil, and about foil materials, and much more.

Vapor barrier films

There are polyethylene and polypropylene. The difference, as you understand, is in the polymers. Polypropylene is more expensive, its melting point is 40 degrees higher than polyethylene (better for a bath), but it is more fragile and can withstand frost 10 times worse (PE - up to -50, and PP - up to -5), PP more elastic, but still less durable.

Also, the film may or may not have perforations. Since we are talking about vapor barrier, it cannot be perforated and single-layer. Therefore, perforation is allowed only in the second layer.

ATTENTION! According to the rules, the perforated side faces outward from the insulation.

The advantages of perforation are questionable - during operation, these holes are easily clogged with dust.

IMPORTANT! Do not confuse perforated films and real membranes - they are not the same thing at all, even if they tell you that both “breathe”. Even if you use this verb, they do it differently.

Reinforced and not reinforced . An ordinary film is not reinforced with anything, but you can easily distinguish a reinforced film - it has a thread base made of a different material. The film is reinforced for the sole purpose of increasing its strength. And this really helps, it is more difficult to damage mechanically.

Reflective foil vapor barrier film

Another way to improve the properties of conventional films is foiling. A thin layer of metal makes such a film reflect infrared radiation. On the other hand, fragile foil with a polymer base becomes more durable.

As for anti-condensation films, they are not for vapor barriers and not for ceilings - they are for roof waterproofing.

Foil

But this is generally a favorite of those bathhouse owners who want to both retain heat and provide a reliable barrier to steam. Aluminum foil is completely impenetrable to steam. However, the rolls have a limited width, so you have to overlap and seal the joints, and the seams are always imperfect. So, if any moisture penetrates into the insulation, it will not be the fault of the foil itself.

ATTENTION! Vapor protection is secondary for foil; its main purpose is to reflect infrared radiation back into the steam room. Moreover, it is placed exclusively in a steam bath.

Many people do not like to cover the ceiling in a bathhouse with foil in its pure form because of its

fragility - it breaks easily, in addition, it is easy to cut yourself on it; this material requires great care in working.

combined on sale - foil increases the operating temperature range of the films used, and they, in turn, protect it from ruptures. In addition, the presence of a polymer backing allows you to make the foil layer thinner - in its pure form you simply would not be able to lay it with such a thickness.

Many film companies have expanded their range to include foil materials, so when we get to specific names, just keep in mind that they most likely have them.

Now is not the time to argue about whether foil is needed in the bathhouse or not. In essence, all questions of this kind can be reduced to one thing: does a person know the materials enough to get exactly the desired effect or does he not know. And the circumstances can be very different.

Ruberoid or glassine

Both are the result of impregnation of cardboard with petroleum bitumen . Both can, in principle, be used for vapor barrier of a bath ceiling, but we still would not recommend these two materials over the steam room .

However, you may not listen to our opinion, because the temperatures in the steam room are different for everyone, and the ceilings themselves will not be the same, so in some cases such a vapor barrier may turn out to be quite acceptable.

Since we are talking about fairly cheap materials, they can be used in budget construction, when, for example, a flat ceiling scheme is used. In this case, roofing felt or glassine is placed directly on the flooring boards from the attic side and serves as a backing for the insulation.

Kraft paper

This is an excellent option for those who decide to insulate themselves with ecowool. Vapor barrier kraft paper is a type of cardboard that can be single-layer or double-layer. The coating with a polymer film can be on one side of a single-layer cardboard or between two layers of a two-layer cardboard. , reinforcing mesh can be added , which is also located between the layers of cardboard.

This paper is produced in Finland and is intended for insulating environmentally friendly insulation materials made from cellulose or flax fiber.

ON A NOTE! Without film, construction cardboard is vapor permeable.

Can kraft paper be used with other types of insulation, such as mineral wool? Yes, you can.

Foil Kraft Paper

Izospan

We inquired about the recommendations given by the manufacturer of these products. Izospan RS (aka B) as a vapor barrier there

Well, let's see what he is. This is a material that consists of three layers of polymers, two of them are exactly polypropylene. The first layer of polypropylene is a regular film, it is smooth. In the middle (second layer) there is a reinforcing mesh, the material of which is not specified. The third layer is non-woven material, all made from the same polymer. Non-woven materials (= something like felt) are usually used to create an anti-condensation layer, in this case its use is not entirely clear.

Izospan B for a bath on the ceiling

However, in addition to vapor barrier of ceiling insulation, this type of film can also be used for waterproofing, for example, floors and roofs. Let's classify the rough third layer as waterproofing. Although this is a little strange - if the film is vapor barrier, then it is impenetrable to vapors, if it is waterproofing, it is permeable. What is a universal film, suitable here and there? Mystery. At least for us.

The technical specifications say that Izospan B is vapor-tight, its temperature range is -60+80 degrees. In terms of temperature characteristics, it is not particularly suitable for a steam room. In other rooms, if desired, you can use it.

A little about the manufacturers and their products

Armitex-75 is an analogue of Izospan V. Only without reinforcing mesh, apparently. It has smooth and rough sides. The manufacturer advises facing the rough side towards the insulation.

The Czechs produce films under the Jutafol . They have several types of films only as a vapor barrier, they are all included in the Yutafol N . Among other things, you can find films with a reagent that leads to the extinction of the flame, preventing a fire. Some are reinforced, some are foil.

The Luxembourg company DuPont produces a foil vapor barrier called AirGuard® Reflective .

The Poles make Folder in the following varieties: Minima H 98, Silver H 98 and Alum H 90. The numbers mean grams per square meter. The latter is foil, suitable for baths and saunas. Others, however, are also suitable. Minima is not as durable as Silver.

Russian-Polish film Optima B is suitable for insulating insulation. This is a two-layer film with a density of 75 g/m2, with smooth and rough sides.

The company that produces the popular roofing material ondulin also produces roofing films. There are also vapor barrier ones among them. These are Ondutis R 70, RV, RS and Thermo. The latter is foil, RV does not have reinforcement, but RS does, and RS can be considered an analogue of Yutafol standard 110. Thermo is suitable for steam room ceilings, because the foil there is protected by a layer of polyester with a melting point of 200 degrees!

Step-by-step instructions on how to insulate a bathhouse with isolon

Before work, it is necessary to calculate the amount of isolon according to the area of the walls and ceiling of the bathhouse. To do this, you need to multiply the length of the wall by the width and multiply between them. The resulting figure is 4. Add the ceiling area to the result and subtract the doorway. The material is laid without overlap, so metallized tape is purchased for a hermetically sealed connection.

For work you will need materials and tools:

- A construction stapler with 10 mm staples or a hammer with thin nails.

- Izolon.

- Foil tape.

- Scissors, stationery knife (necessary for adjusting the insulation).

After everything has been purchased, we proceed to insulating the walls and ceiling.

Installation of insulation on the walls and ceiling of a bathhouse

It is necessary to insulate the walls and ceiling of the bathhouse with isolon between the finishing and the inner wall. A ventilated gap of at least 0.5 cm must be left between them so that moisture can evaporate.

The work is carried out in the following stages:

- The walls are cleaned of dirt and dust using a brush with stiff bristles. The tree is coated with an antiseptic, lapyrimide.

- Izolon is rolled out onto the wall and ceiling with the foil side inward and secured to the wooden wall with a stapler. When the bathhouse is built from blocks or bricks, it is necessary to fill the walls with bars 20–30 mm thick, 1–1.5 m long, in a checkerboard pattern. The insulation will be attached to them. Izolon does not allow moisture to pass through to the wood, so there is no need to use a vapor barrier under it. If you don't have a stapler, use a hammer with small nails.

- The joints are taped with metallized tape. The same applies to places where the material is attached with staples. Untaped joints will not be protected, and moisture will get inside under the insulation. The walls will begin to rot.

- A lathing made of 40x40 mm timber is mounted on top of the insulation, for further finishing with clapboard or other material. The sheathing pitch is no more than 1 m.

The insulation of the steam room is ready, you can begin finishing. You can see how to insulate a steam room in the video:

https://youtube.com/watch?v=1BMehi4cwNU

https://youtube.com/watch?v=1BMehi4cwNU

Izospan A: instructions for use

Group of materials Izospan A - vapor-conducting windproof membranes that do not conduct liquid water. The exception is Izospan A base. This membrane is only wind protection. It does not interfere with the passage of steam and water. Used in the ceiling above a ventilated facade, stuffed from the underground side. Protects mineral wool from blowing and does not interfere with the removal of moisture from the insulation.

| Name | Maximum elongation in transverse/longitudinal direction N/50 mm | Withstands steam density, g/m2*24 h | Withstands water pressure, mm.water.st. | Withstands ultraviolet radiation (without protective coatings) for at least months |

| Izospan AQ proff | 330/220 | 1000 | 1200 | 12 |

| Izospan AQ 150 proff | 270/160 | 880 | 1200 | 12 |

| Izospan AS 130 | 240/130 | 880 | 1200 | 3-4 |

| Izospan AS | 190/110 | 880 | 1200 | 3-4 |

| Izospan AM | 160/100 | 880 | 1200 | 3-4 |

| Izospan A | 190/140 | 2000 | 300 | 3-4 |

| Izospan A base | 170/100 | 1700 | — | 3-4 |

| Izospan AF+ (NG) | 1400/1000 | 800 | 900 | — |

| Izospan A with OZD (RP-1) | 190/140 | 1800 | 300 | 3-4 |

To understand where and how best to use Izospan A, look at the characteristics. Once again: the film is not blown (retains heat), removes steam, and does not allow water to pass through. These properties are needed in the following constructions.

Rules for laying and installing windproof, vapor-permeable membranes

Vapor barrier materials are laid on vertical, inclined and horizontal surfaces. Despite the fact that the designs are different, the installation rules are no different. Here's what to remember:

The basic rule of installation is to make overlaps and carefully glue them

- On pitched roofs and walls, work begins from below. On horizontal roofs - from one of the walls.

- The second layer of material is laid overlapping. That is, one panel overlaps another by no less than:

- 10 cm on walls;

- 15 cm on roofs;

- 15-20 cm in overlaps.

- Vertical joints (if any) have the same dimensions.

- All connections of the canvases are glued using double-sided adhesive tapes.

- The connection to the walls and rafter system is also glued. To adjoin the rafter system, it is recommended to use self-adhesive sealing tape Izospan. For joints - KL, for adjoining the structure KL+.

The task of vapor-permeable waterproofing and windproofing is to allow steam to pass through, but not to allow moisture to enter in a liquid state. Therefore, the strength of the joints is important.

On a pitched roof, on top of insulation

The vapor barrier is laid on top of mineral wool and covered with any roofing material. Let's see how everything works. Here it is necessary that the steam that gets into the insulation from the attic is removed. At the same time, condensation and possible leaks did not enter the insulation. So you need to remove steam and not let water through. This is what Izospan A does.

Application of Izospan A in an insulated pitched roof

The membranes are turned with the logo facing towards you. It is better to lay it not under tension, but with sagging. In this case, condensation, which cannot be avoided on the roof, will flow into the center, and then into the gutter of the drainage system. This way it will dry out faster even in damp times, moisture will be retained less, and there is less chance of it getting into the insulation.

On top of the vapor barrier, slats are placed along the rafters, and then across the sheathing for installation of the roofing material. With this device and the presence of ventilation holes in the roof, the vapor barrier will be blown and dried.

In frame walls on the street side

Typically, indoor humidity is higher than outdoors. And no matter how much we protect the walls, steam leaks into them. These are the laws of physics. And since he hit the wall, he needs to be taken out. So the task here is the same - to let off steam. This can only be done from the street side. So Izospan A in frame walls is also placed on the street side. Here you can use all types of Izospan A, except for the “base”.

Izospan A - instructions for use in a frame wall

When using Izospan A “in its pure form”, it does not matter which side it is laid on. We unfold all other modifications - AS, AQ, AM - so that the logo is facing out.

When insulating walls with mineral wool and for ventilated facades

With external insulation of walls, in ventilated facades, the situation is almost the same as with the frame. Some moisture is seeping into the wall from the room. Then it penetrates into the insulation. Since wet mineral wool is a poor insulator, care must be taken to ensure that this steam is quickly removed. At the same time, it is necessary to protect the cotton wool from getting wet and retain heat as much as possible. That is, the problem is solved by the same vapor-permeable membranes of the Izospan A group.

Application of Izospan A for external wall insulation and in the system of ventilated facades

Any vapor barrier for use in the case of external wall insulation, except Izospan A with OZD, AF+ and base. The installation rule is the same - turn it with the logo facing you. For use in ventilated facade systems, Izospan AF+ is recommended. If a metal structure is used, its strength will ensure that the vapor barrier will not break. If the ventilated facade is covered with wooden blocks, Izospan AM, AS and AQ in any of the options may well be suitable.

Ceiling over a ventilated subfloor

The floor insulated with mineral wool over a ventilated base has its own characteristics. First and most important, for the scheme to work, the subfloor must be ventilated. This means that there must be vents in the foundation. And they must be open even in winter, otherwise you will have wet insulation and cold in the house.

How does this pie work? From the side of the house, moisture and steam seep into the insulation. If you simply line the insulation with mesh or slats, the wind blowing underground will do an excellent job of removing moisture. But at the same time, it will carry away heat and gradually remove mineral wool particles, reducing its thickness. To get rid of heat and insulation from escaping, Izospan A base vapor barrier is used. It allows steam and moisture to pass freely in both directions, but does not allow wind to pass through.

Izospan A: instructions for use in the ceiling above a ventilated subfloor

The following objection may arise. Moisture from the soil will evaporate and enter the insulation. Under certain conditions, it condenses on the membrane, causing the insulation to become wet. Maybe it’s better to use a vapor barrier with waterproofing properties? No. This won't work. If the membrane does not conduct moisture, then the moisture that condenses or gets into the insulation will remain there. Because it will not heat up enough to evaporate and be released as steam. In a couple of years you will have bags of water hanging from the ceiling and completely wet and unusable insulation.

And in order to reduce the evaporation of moisture from the soil, a dense film is placed in the underground, a layer of sand (any kind, but without clay and dust) is poured on it in a layer of 5-10 cm. The film retains most of the moisture, and the sand works as an adsorbent, absorbing fallen condensate. It (the sand) is also dried by the passing wind.

Interfloor and attic floors

In ceilings, steam enters from below and must be discharged from above. Therefore, a vapor barrier is placed at the bottom to protect against moisture, and a vapor-permeable wind barrier is placed at the top. In this case, it also additionally protects against the penetration of mineral wool particles into the room. You need to put Izospan in the same way - the logo should be facing you.

Izospan A for flooring - in interfloor and attic floors

In the interfloor ceiling, to reduce the cost, vapor-permeable Izospan can be replaced with non-woven material (any type of geotextile). Its main function here is to protect against the penetration of small mineral wool particles into the air. But you can do this only if the flooring is sheet material in two layers, with the seams spaced apart. Otherwise, moisture may seep in and then simply the non-woven material will not protect the insulation from getting wet.

In the attic floor, such a replacement is not considered at all - here it is also necessary to protect the heat from weathering. So wind protection is necessary here.

Also note that the vapor barrier is attached to the beams with counterbattens. And the flooring is already laid on them. Counter rails are needed to create a ventilation gap, which is a prerequisite for moisture evaporation. It is important.

Useful video

In the video we will see a typical mistake when installing vapor barrier:

You won’t find a clear answer: which vapor barrier is better and which vapor barrier to choose for a bathhouse. It all depends on the correct installation: you can buy expensive foil, but not get the desired effect if you install it incorrectly; and, conversely, proper vapor barrier with cheap natural materials will perfectly protect the structure from rotting.

(2 ratings, average: 4.50 out of 5) Loading…

Bath ceiling vapor barrier

Hello, dear readers! Today we’ll talk about one important factor, without which your steam room will not have the necessary thermal characteristics...

A truly good bath should not only look beautiful, but also have properties specific to it. One of these properties is the rapid injection and retention of heat indoors.

Properly performed vapor barrier of a bathhouse ceiling solves not only this important problem, but also a number of others.

Which ones? - you ask. More on this below...

Where to buy Izospan FB?

Izospan FB is a building material that is quite widespread and actively used for various types of installation. As a result, there are also many companies that can offer it to you. How to choose “yours”?

Do not rush to immediately respond to the offers of those who offer fabulously low prices for reflective insulation. It’s likely that the cost of the product will be the only thing you really save on. The quality will leave much to be desired.

The need to purchase Izospan is a case when it is much wiser to turn to market leaders, because who, if not them, knows what customers need? One of the famous suppliers is ours. What other benefits can we offer our customers?

- Affordable prices for the Izospan FB brand and other heat-insulating building materials that are presented in our online catalog, for example, Penofol.

- Wide range of products.

- Cooperation with manufacturers whose names are known not only in Russia, but throughout the world.

- Many years of experience and dozens of positive feedback on cooperation. Competent advice from specialists that will be useful not only to those who are buying building materials for their home or bathhouse for the first time, but also to professional builders who may also have difficulties, especially if this or that new product has appeared on the market.

- Consistently fast and timely delivery not only in Moscow and the Moscow region, but throughout Russia.

Concluding the conversation about Izospan FB, let us remind you once again: the most important thing is not the price of the material, but its quality. You can be happy when you buy bath foil for a minimal price, and then be sad when it turns out that the promises made by the manufacturer are not fulfilled. offers only high-quality reflective insulation options!

Advantages and disadvantages of ceiling insulation with penofol

Today the product is very popular due to its versatility and easy installation. Masters also appreciate it for the following qualities:

- The material is lightweight, making it ideal for work performed at heights.

- To lay penofol on the ceiling, no special equipment is needed.

- The metal coating does not allow steam and water to pass through, does not absorb liquid and is not destroyed under its influence, so it is indispensable in damp rooms, for example, in baths. It does not require additional protection with hydro- and vapor barrier membranes.

- The material performs several functions. Once attached to the ceiling, it not only retains heat in the apartment, but also dampens sounds transmitted through the air or through the ceiling. It is often used with other products to increase thermal insulation properties. For example, in saunas it additionally maintains the temperature by reflecting heat.

- When heated, it does not emit harmful substances. In its production, the same polyethylene and foil are used that are used in the food industry.

- After installation, the distance between the floor and the ceiling decreases slightly. A 1 cm thick canvas can be used instead of 8 cm thick mineral wool or 4 cm thick polystyrene foam, so insulation is often used in rooms with low ceilings.

- The sheets are sold rolled up, which makes installation work easier.

- The product does not burn and is often used in fire hazardous areas.

- Rodents don't like him.

Penofol has few disadvantages. Negative factors include the high cost of the material and the need to use other insulation materials to improve the result. It is also glued to the surface to ensure the integrity of the coating, which increases financial costs. The material is soft, so it cannot be used if plastering or wallpapering is planned.

Quality and range: everything to protect your home

In total, the Izospan line of insulating products has an assortment that is conventionally divided into 4 groups:

- windproof waterproofing vapor-permeable membranes;

- waterproof vapor barrier films;

- universal materials that work in several directions at once;

- heat-steam-waterproofing materials with additional energy-saving effects.

Here is an explanatory illustration of how exactly all these materials differ:

A roofing pie with films from Izospan looks like this:

Series A are windproof materials, and series B, C and D are hydro-vapor barrier membranes. If you are afraid of getting confused in abbreviations, remember a simple rule: the first letter means the insulation class, and the second means the modification.

If there is no second letter, then the material is classic, without additional frills:

Plus Izospan produces a special tape designed specifically for this product:

This manufacturer also produces special waterproofing materials for flat inversion roofs. The company itself always boasts that it creates all its products in automated production facilities.

And this is evidence that technical control is constantly being exercised over the quality of products. This cannot be achieved with any kind of handicraft production.