Choosing the right paint

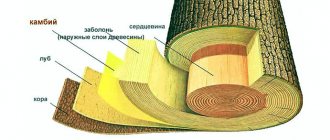

Wood is a building material of natural origin and, unlike man-made brick and concrete, it reacts much more strongly to air humidity, wind, temperature fluctuations and solar radiation. Wood without bark can rot, burn out and become a haven for all kinds of molds and wood-boring beetles.

The factor that determines the service life and external decorative qualities of a log house is the choice of coating. Paints or impregnations for treating wooden façade walls are used to preserve wooden elements and must meet certain requirements:

- Create a surface protective layer that protects the wood from rain, snow and atmospheric moisture. Be frost-resistant (not destroyed by cyclical temperature changes).

- Have UV protection . Direct sunlight causes unprotected wood to change color (tanning effect) and lose its attractiveness.

- Have good adhesion (adhesion to the plane of the facade) and absorbency (important when processing with impregnation; penetration depth is indicated in the instructions for the product).

The type of paint is chosen based on its protective properties and visual appeal Source derevyannyy.com

- Demonstrate lack of moisture absorption .

- Be environmentally friendly . A parameter that is especially relevant for a log bathhouse.

- Don't lose your attractiveness. Varnish and acrylic compositions should not lose their original gloss. Paints must retain their original color .

- Contain fire retardant and antiseptic additives. Modern dyes are capable of maintaining the safety of a wooden structure.

- Be abrasion resistant .

The market offers a wide range of products suitable for painting the facade of timber and log houses. Modern coatings make it possible to preserve and emphasize the naturalness of the facade material or completely hide it under a protective layer. When deciding how to paint the exterior of a log house, owners give preference to proven, certified products. In practice, several types of coatings are used, the characteristics of which are useful to have an idea of.

The use of certified paints is a guarantee of high-quality painting Source fasad.guru

Antiseptic impregnations (waxes, stains) and varnishes

Liquid antiseptic impregnations for wooden surfaces penetrate the wood structure to a depth of 0.5-1 cm and create a barrier to all threats, natural and weather. There are two types of antiseptics on sale:

- Wax . Water-based wax is perfectly absorbed into wood, without creating a continuous film and maintaining its breathable properties. When finishing the exterior of a log house, a colorless or glazing (translucent) composition is used, creating a mother-of-pearl effect or an additional shade on the surface. Gives the facade water-repellent properties, leaving the natural structure visible.

- Wood stain . The composition is a tinting (impregnating) agent that colors the facade and protects it from biological contamination. The coating is short-lived, so a varnish is applied on top, which can extend the life of the stain and enhance its protective properties.

Treatment of wooden elements with fire retardant Source optimal-r.ru

- Varnishes (colorless or colored) are a proven, reliable means of protecting facades. Both options do not hide the natural texture of the wood; colored varnish can highlight its color. Varnishes, glazing impregnations and wax are used for painting not only outside, but also inside homes, where non-toxicity and external decorativeness are especially important.

Acrylic (acrylate) paints

Water-based acrylic paints for treating the external walls of a log house are considered the most acceptable, high-quality option with many advantages:

- contain solvents ;

- dry quickly and form a durable, vapor-permeable film;

- protect the wooden facade from ultraviolet radiation ;

- durable (resistant to weather vagaries);

- They retain their original color and shine for a long time (7-8 years) .

Impeccable appearance of acrylic paint Source materialyinfo.ru

See also: Catalog of companies that specialize in finishing materials.

The construction market offers several types of paints:

- Water-based acrylic paints . It is a water-acrylic emulsion (composition of two immiscible elements). After application to a wooden wall, the water evaporates, leaving a thin film layer with attractive properties on the surface. The paint does not have a strong odor, is flexible enough not to deteriorate under the influence of low temperatures, is vapor permeable (allows the wood to breathe) and at the same time waterproofs the facade.

- Water-based latex paints . They also contain acrylic resins, and therefore they are elastic, do not fade under solar ultraviolet radiation and are resistant to abrasion. Synthetic latex in the paint makes the surface silky in appearance. This paint is used when processing facades, window and door openings, and fences.

Types of decorative impregnation with water-based acrylates Source plantu.ru

- Alkyd compositions . They are produced on the basis of alkyd resins, which remain in the surface layer of wood to form a protective glossy layer. This paint fades quickly, but is resistant to negative temperatures and high humidity; it is often used to paint doors and window frames.

The disadvantage of acrylic dyes is their fairly high price. When painting log walls, they can be replaced with less expensive acrylate paints and aqualacs based on acrylate resins and dispersions, which reduce costs. These compositions have similar characteristics, they are safe and beautiful, but are designed for a shorter service life.

Oil based paint

Oil paint for a log house, used externally, is a familiar and fairly common method of painting. Despite its modest consumer qualities, it continues to be used; more often for painting fences than residential buildings.

Oil paint is a budget way to update a facade Source pkr.grunfest.ru

How to coat a log house after sanding

Question:

Good afternoon, Semenych! Please tell me, in the spring of 2018, a log bathhouse was installed from a winter Siberian forest (diameter 36-48), the lower three crowns are made of larch, the top is pine. The roof and ceiling were done almost immediately after the frame was built. Now we sandblast it.

The question is what to cover after sanding (primer, bioprotection, fire protection), in what order and in how many layers. We want to coat the outside with matte or semi-matte varnish. Which products are better - there are many manufacturers, and prices vary. Please advise.

Best regards, Elvira, Irkutsk.

Answer:

Hello, Elvira from Irkutsk!

In our practice, we most often cover the outer surfaces of log houses with belinka, tecurilla, and penotex.

True, sandblasting is far from the best option. We prefer to grind with conventional angle grinders; they leave less abrasive on the surface of the logs.

However, if after any type of sanding you walk over the logs with brooms, mops or a vacuum cleaner, there will be much less of this abrasive.

Builders do not have a unanimous opinion regarding the order of operations for coating wood with specific compositions.

Some first treat with antiseptics, which include both fire and bio protection, then apply a primer, and only then paint and coat with colorless varnish. Others do not use this order.

There are now a lot of different compounds on the market, I wouldn’t like to advertise them. In each case, you should carefully read the instructions on their labels. In this case, the most important thing is that all subsequent compositions are compatible. Because sometimes this is not the case, and after a year or two, or even a shorter time, the layers begin to separate from each other, crystallization of salts, their peeling, cracking, etc.

As a rule, brands from more well-known manufacturers, preferably imported rather than home-grown ones, have higher quality and longer-lasting characteristics. Although sometimes I had to run into expensive counterfeits of domestic “Kulibin” ones.

As they say, there are no comrades according to taste and color. But choosing colors and shades of dyes is also a difficult decision.

No matter how high-quality the dye is, over time (when after a year or two, when after five, or even ten years) it can still change its color tone. Atmospheric environment - rain, fog, dew, snow, etc. doing their job.

Most often, darker colors (like rosewood) are less susceptible to changes over time compared to lighter colors (pine or Oregon).

But not everyone likes dark colors, too gloomy, lighter ones are much more pleasant.

When you paint it in a light tone, it can darken very quickly and it happens that you can’t look at the logs of such a log without tears.

Just for fun, walk around and look at the wooden houses with different colors. I'm sure you'll notice the differences right away. And only then make a decision.

Varnish finishes are generally the right choice because the varnish fills the pores left after painting and the wood is less affected by the atmosphere.

So read everything I have said and take action. I understand that I’m not giving you definitive recommendations, but what you read shouldn’t make things worse.

In any case - good luck!

The method of applying the compositions is also important. The use of compressor devices for spraying them is productive, but the traditional old method of rubbing in with brushes, although a slower process, is of higher quality.

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurykomfort.ru

Other questions on the topic of log houses:

- All about log houses

- Replacing logs in log houses

- About caulking log houses

Replacing logs in log houses

- Cost of replacing the top rims of a log house

- Replacing a cut-off wall with foam blocks

- Replace half a wall in a log house

- Replacing a rotten wall of a timber house

- Replacement of lower crowns and cracks in logs

- Replacing the lower logs of an already sheathed house

- Rotten places in logs

- Vertical log house made of round timber

- What to do with rotten logs from a log house

- Rotten crowns in the middle of the wall

- Replacing a log frame with a brick or block

- Replacing the lower crowns of a log house

- Replacing rotten crowns with bricks

- How to strengthen a corner in a log house

- When you need a fifth wall in a log house

- Vibrations in the log house

- Remove the three lower crowns of a log house

- Replacing a wall in a log house

- Replacing the lower crown with brick or foam blocks

- Joining logs of different diameters

- Replace the corner of a log frame with sleepers

- Replacing the lower crowns of a log house with a concrete wall

- Rotten log in a log house

- Restoration and cladding of a timber frame

- Reconstruction of an old log house

- Replacing a rotten corner of a house

- Repair of rotten beams in a log house

- Replacing the lower crowns of a log house with blocks

- Replacing rotten logs of a log house

- Replacement of the lower crown of the house

- Replacement of a main wall made of timber

- Transfer of logs in height in a log house

- Alignment and replacement of the lower crown of the log house

- Replacing rotten logs under the window with blocks

- 2 corners rotted at the level of the log house windows

- Cost of work to replace the top rims of a log house

- The log house is rotting next to the vent

- The wall near the log house in the five-wall building has rotted

- Repair of old logs

- Replacing a log house wall with a foam block

- Replacing the lower crown in a wooden house

- Replacing logs in a log house

- Replacing logs eaten by insects

- Replacing the lower crown of a timber frame

- Replacing the lower crowns in the house

- Replacing the top rotted crown of a log house

- Replacement of the lower crowns of the bath

About caulking log houses

- Caulking log corners

- Rules for caulking a log house

- Caulking of an old log house

- Cold corners in a log house

- Caulking and insulation of a log house

- Caulking a log bathhouse over old moss

- How to caulk a log house covered with clapboard

- Should tow for a log house smell?

- How to fix a chopped pediment

- Re-caulking of a log house

- Caulking and log processing

- Re-caulking the bathhouse with moss

- Calculation of the amount of jute for caulking a log house

- Caulking of a log house lined with bricks

- Caulking tight logs

- Dismantling inter-crown insulation

- Log caulking

- Log house for three years in the open air without a roof

- Re-caulking of a log house

- The basics of caulking a log house

- Caulking and sanding of a log house

- Caulk of a log house from the inside

- Do-it-yourself log caulk

- Caulking of a log house made of rounded logs

- Sanding timber

All about log houses

- Log house made of logs or timber?

- Estimate for finishing the log house

- Strengthen the corner of the log frame from the gun carriage

- The wall of the log house is collapsing

- Forced shrinkage of the log house

- How to fix a crooked timber frame

- The lower crowns of the log house are getting wet

- Correction of a 9-year-old log house

- Rot between the crowns of a bathhouse log

- The frame sank and the window jammed

- Led walls made of profiled timber

- The crown of the log house was turned out

- The dovetail insert moves apart

- Construction of a log house in the South of Russia

- Painting the outside of the log house

- Is casing necessary for small log windows?

- What to do to prevent the log house from twisting during shrinkage

- The quality of the log after 5 years of settling

- Protection of the sauna frame

- Rebuilding an old log house

- Strengthening the fifth wall of the log house

- Bathhouse gables made of rounded logs

- The top crown of the frame was torn out

- How to cut large arches in a log house

- Remaking door and window openings in a log house

- The partition made of logs was torn out

- Repair of an old log house

- Finishing the log bathhouse immediately after installation

- Which interventional insulation to choose

- Lining crowns made of logs with natural stone

- How to beautifully seal shrinkage window openings in a log house

- Tiles and laminate for log floors

- Ceramic tile floors in a log house

- Strengthening the log house

- Align the crown for installation of ceilings

- How to coat a log house after sanding

- Editing the geometry of a log house

- How to install profiled timber in a log house

- Installation of crossbars in a timber house

- New doorway in an old log house

- Reconstruction of a log house

- The bottom beam on the plinth gets wet from the inside

- Treatment of the log house before cladding the outside

- The walls of the log house got wet through and through

- The first crown of a log house made of oak

- Insulation of the stone base of a log bathhouse

- Overcut in the house

- Basement and blind area for an old shrunken log house

- Uneven shrinkage of the frame

- Repair of an old 2-story log house

- What kind of foundation for a 6 by 8 log house?

- How long does it take for a log house to shrink on a pile foundation?

- Increase the height of the log house without removing the roof

- Wind protection between the foundation and the log house

- Problems when lifting an old log house

- Insulation of a log house with sawdust and lime

- How to lay a log house from timber of poor geometry

- Pouring a concrete floor in a log house

- Interfloor ceiling in a log house

- Waterproofing the log house from the foundation

- Renovation of an old log house

- Repair of an old brick-lined log house

- How to strengthen a log house

- When to put a roof on a freshly assembled timber frame

- When to cover a log house with natural humidity

- Support under the log and shrinkage of the log house

- Beetles in logs

- Door in the end wall of a log house

- A team for the construction of a log bathhouse

- The cut of the log on the outriggers of the log house darkens

- Rot on the lower crown of a log house

- Vertical log house

- Which finishing plaster for clay to choose

- Mushrooms on a log house

- Log house without frame and floor beams on slab

- Dry rot of the lower crown of a timber house

- The upper corner of the frame has been removed

- Demolition of a log house wall

- Displacement of profiled timber in a log house

- How to build up log extensions of a log house for a veranda

- The log house was mowed down

- Installing a shrinkage compensator in a finished log house

- Twisted the logs of the log house before assembly

- Log house with nails instead of dowels

- How to protect a log house without a roof from rain

- A set of works on the external finishing of a log house made from central fiber boards

- Repair of a log house after a fire

- Is it possible to put a roof on a log house for the next year?

- Warm joint with sealant for log house

- Insulation and cladding of a log house made of corrugated timber

- Insulation of a log house from the inside

- Concrete floors in a log house

- Shrinkage of log walls old and new

- The procedure for finishing a log house

- How to preserve timber from spring to winter

- What comes first: flooring or door casing

- Dismantling half of an old log house

- Types of beam connections

- Sealing the joint between the roof and the frame from OCB

- Cleaning a log house from old paint

- Connection of two log houses

- Support column in a log house on stilts

- The difference in the shrinkage of a log house between winter and summer felling

- Dismantling and moving a house made of profiled timber

- Supporting floor beams in a log house

- Preparing a log house for winter

- Guarantees when cutting a log house on a plot

- Chop into a bowl or warm corner

- How to lower the ceiling in a log house

- The timber turned blue in the rain

- Preservation of the log house in a non-temporary gathering place

- Consultations on a timber house

- Sheathing of a house made of cylinders without insulation

- Scheme of a log house with outlets and a ridge roof

- How to lay a carriage while lying down

- Reinforced concrete slab on a log frame

- How to assemble a log house from twisted timber

- Repair of a cut in a log house

- Installation of a log house on a columnar foundation

- The chopped gables of the log house are shaking

- Fastening beams in a log house

- The top beam in the log house was driven into the screw

- How to cover a timber façade

- Waterproofing the frame of an old house from the foundation

- A log house without nails is being pulled apart

- Sheathing a log house

- Cutting the lower crown in the log house

- Settlement of a log house made of used timber

- The log house rotted in the castles

- The corners of the log house are rotting

- How to strengthen a log house

- Work plan for interior finishing of the log house

- Log processing procedure

- How to lay a log house in the rain

- Cut the lower crowns of the log house

- Sheathing a log house immediately after construction

- Heating and windows in a new log house

- Processing the crown of an already built house

- Painting a timber house

- Blind area and shrinkage of the log house

- How to enlarge a house made of timber

- Connecting a timber house with a brick extension

- Finishing a timber frame with jute rope

- Diameter of a log for a permanent home

- Treating the log house with an antiseptic during assembly

- Reconstruction of a wooden house

- Connecting timber in cuttings

- Protection of the ends of the timber at the corners of the log house

- How to connect two log houses together

- Cutting a balcony doorway in a log house

- When to casing a newly assembled log house

- Insulation of gables made of lining

- Gaps between the logs of the log house pediment

- How to preserve logs before cutting a log house

- Raise the frame to increase the ceiling height

- Methods for joining timber in the walls of a log house

- Raise a log house to increase the underground floor

- Cladding a log house with clapboard before shrinking in winter

- When to remove the compensating jacks of a log house

- Log house for three years in the open air without a roof

- How to make a cut in a log house

- Make a house from an old bathhouse (timber)

- Moving the log house to another location

- Log house hanging on dowels

- The fifth wall in a log house made of smaller timber

- Should I paint the backing board in a log house?

- Remove mats to increase log ceilings

- The log house does not match the foundation

- Ceiling mats in the log house

- Construction from fire monitors

- How to remove bark from an already assembled aspen log house

- Transporting an old log house

- Connecting internal timber walls with external ones

- How to repair cracks in a log

- Gap between log and foundation

- Alignment of the first crown of the log house

- Stages of arrangement of the assembled log house

- Treatment of the log house after installation in the summer

- Processing the ends of the frame from the outside

- The log house floated - the walls moved

- An old wooden house sank

- Leveling the crowns when assembling a log house

- How to close the opening between the log house and the foundation

- How to straighten a log house

- Sheathe a log house with protrusions with corrugated sheets

- How to process the ends of a log house

- Collecting the first crowns of a timber frame

- Riser frame

- Preservation of the log house during assembly in rainy times

- Forgot to waterproof the log house from the foundation

- Installation of log shrinkage compensators

- Interventional gaps in a house made of profiled timber

- Gaps between logs in a house

- Communications and finishing in a timber house

- Precision when cutting log houses

- Which log house will be warmer?

- Log house made of timber 200 by 120

- Old log house - reconstruction or demolition

- Partitions in a log house

- Internal partition in a log house

- Beginning of finishing of shrunken timber frame

- Double timber construction technology

- Processing the log house from the outside

- Log shrinkage process

- The walls of the log house collapse during shrinkage

- Insulation of a log house from the inside

- How to build a house from sleepers

- The logs were kicked out of the log house

- Supports (pillars) instead of crosscuts in a 9x10 house

- Do-it-yourself timber log house without experience

- Preservation of a house made of rounded logs for the winter

- Embed additional beams into the frame

- Backing crown - installation tricks

- Log house on brick walls

- Sequence of work in the log house

- How to make a load-bearing partition in a log house

- The log house got wet during assembly

- How to seal cracks in a log house

- Align the vertical wall of a log house

- Vents in timber on foundation

- Timber 200 by 200 construction nuances

- The log house turned blue, what should I do?

- How to seal cracks in cutouts from the outside

- You can live on the second floor of a log house for shrinkage

- Replace rotten logs with mortar

- A non-load-bearing log has shrunk

- Replacing logs with boards in a house project

- Vertical supports in a log house for shrinkage

- Does a large log house need recutting?

- Metal tiles on a non-shrunken log house

- Permissible gaps between timber crowns

- Gaps in log beams

- Replacing parts of rotten logs in a log house

- The logs of the log house are shaking

- The log house was poorly assembled

- The gap between the log log and the foundation

- Protect an unfinished log house for the winter

- How to save a log house without a roof

- Log finishing service

- Assembling a profiled log house in the rain

- Gaps when fastening profiled timber

- Sealing cracks in a bathhouse

- Processing timber with a blowtorch

- Butt beam - is it reliable?

- The wall of the log house is littered

- How to align protruding ends in a built timber house

- Transferring beams in a log house in height

- The corners of the log house disappear from the timber during assembly

- The log house is wet, what should I do?

- Does a log house need a fifth wall?

- How to assemble a log house 10 by 11

- Restoring a log house after a fire

- Processing of a log house made of rounded logs

- Extension of a log house when replacing the roof

- Sand under the crowns for insulation

- Methods for lifting a bath to replace the crowns

- Impregnation of the log house inside and out

- The façade of the log house leaned

- Log shrinkage - problems

- Treatment of timber against bugs

- The smell in the house is from sleepers

- How to preserve the light color of a fresh log house

- Estimate for a house made of timber 7 to 9

- Treatment of exposed ceiling beams

- Strengthening the corner of a log house

- What is the dowel pitch?

- Protection of the lower crown of the log house

- How to check the diagonals of a log house

- Which timber to choose, square or rectangular?

- Spruce and pine log house

- Sequence of work when finishing a timber house

- Insulate an aspen log house from the outside

- How to install a casing on a log house

- What to put between the crowns

- Should I trim the paws of a log house?

- What is the best way to impregnate a log house?

- Window opening in a log house - how to seal it

- Gaps in the assembled frame

- Support pillars in a timber house

- How to move the 5th wall in a log house

- Ants and the lower crown of the house

- Sanding and processing of the log house after installation

- Barked or planed log for log house

- Repairing the corner of a log house of an old wooden house

- Should window openings in a log house be closed when it is in storage?

- Consultation on the size and shape of the log house

- Questions about construction from profiled timber

- Log house and foam block on a single slab

- Preparing an unfinished log house for winter

- Longitudinal cuts in a log house

- Cracks in the ends of logs

- Should I paint a log house with tikuril?

- Strengthening the corners of the log house

- How to secure a cross beam in a log house

- Ventilation gap between insulation and frame

- Moss or tow for building a log house

- Shrinkage of a timber house

- Fifth wall in the log house

- How to raise a 6 by 6 log house

- Distance from the corner of the frame to the windows or doors

- How to cut off the protrusions of the corners of a log house

- Log house without nails

- How to clean a linden bathhouse from darkening

- Impregnation of a log house with fire-bioprotection

- Velo log house

- Questions about cutting a bathhouse after installation

- Painting a log house

- Blackness between the crowns of the log house

- Types of cutting corners of half beams or carriages

- Attaching beam supports to a log wall

- Strengthening logs in a log house 7 meters long

- How to sort through the log gables of a log house

- The beam was squeezed out of the wall

- Is a matitsa needed in a 3 by 3 m bathhouse?

- Priority work after installing the log house

- Entrance door in a log house

- Maintaining the level when assembling the log house

- The corner of the log house and the lower log have rotted

- The sequence of finishing a timber frame

- Insulation of a settled log house

- Restoring a burnt larch frame

- Quality of a 40-year-old oak log

- Permanent roof on a newly assembled log house

- Cracks in logs

- What time of year is it better to cut a log house for a bathhouse?

- What and how to make partitions inside a log house

- Ceiling beams in a timber frame

- Installation of a metal door in a log house

- The crown molding of a log house

- Questions about assembling a log house at home

- Turnkey log house for a season - is it possible?

- Arrangement of the subfloor in a rounded log house

- Common roof for a new log house and its extension

- Ventilation system in the log house underground

- How much does it cost to change the lower crowns of a house?

- Finishing the log house after shrinkage

- Reinforcement as a dowel for a log house

- What to rest the floor joists on in a log house

- Attaching timber to a log frame

- Cover an old house with a new frame

- Extension made of foam blocks to a house made of timber

- Wet lower rims of a new timber frame

- House made of sleepers

- How to cover a log house on screw piles with bricks

- How to strengthen the motherboard in a log house

- Birch log house

- Sauna log - pine or aspen

- The lower crowns of a larch frame as a plinth

- Adjusting anchors for shrinkage of the log house

- How to properly assemble a log house

- Octagonal timber frame

- Is a fifth wall needed in a log house?

- An alternative to dowels when assembling a log house

- Problems after shrinkage of the log house

- What to make partitions from in a log house

- Tongue-and-groove slabs as walls in a log house

- Insulation of the log house inside

- How to strengthen floor joists in a timber frame

- Log houses in Kolomna

- House made of timber or frame house

- Insulation of a log house from the inside

- Work plan after shrinkage of the log house

- Squeezed logs out of the log house

- Where to start after installing a log bathhouse

- Rounded log with Finnish profile

- The timber frame is spreading

- How to align the geometry of a log house

- Large gaps between logs

- Are dowels needed for profiled timber?

- Is it worth overpaying for profiled timber?

- Repairing the corners of a log house

- How to cover an unfinished log house for the winter

- The beam bends out of the log house

- Construction of a log house in the rain

- Processing and insulation of external walls of a log house made of timber

- How far can the outer ends of the logs be trimmed?

- Ceiling beams 7.5 m in a house made of timber

- How to attach a room attached to a house

- Technology for assembling a log house from timber

- Waterproofing log walls outside

- Replacement of the lower crown of an old house

- Interior finishing of the corners of the log house in the paw

- Dry brown rot in log timber

- Shrinkage of timber frame

- Roof on only installed log house

- How to fill the gaps between the log house and the outbuilding

- When to install a log house for a house

- How far can the ends of logs be trimmed?

- When should a log house be treated with impregnation?

- Cutting the end corners of the log house

- Leveling timber in a log house

- Protection of the log frame from the outside

- Replacing log walls with stone

- How to seal the gaps between the foundation and the log house

- How to cover a timber house

- How and with what to seal the gap between the foundation and the log house

- Bark on logs - to remove or not?

- Sandwich panel or log house?

- Preservation of log wood

- How to change the lower crown

- Settlement of a log house made of laminated veneer lumber

- Log house repair

- What kind of foundation is needed for a log house made of 9 by 12 m timber?

- How much timber is needed for a log house 9 by 12 meters

- Foundation for a log house with chopped gables

- When to put a roof on a log house

- How to seal cracks in a timber frame

- Log house on the spring

- Preparing a log house for winter

- Oak backing for the lower crown of the log house

- Log house repair

- Photo of a chopped log house

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurykomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurykomfort.ru

Construction in Moscow and Moscow region

We work with a guarantee! Wide range of construction services. Foundation, walls, ceilings, roofing, turnkey! +7 (905) 797-20-34

luxurykomfort.ru

Log houses and their maintenance

All questions to Semenych about construction

Semenych (author of materials)

Our site is regularly updated with interesting and unique materials and articles on the topics of lumber, building materials and works, the author's opinion and knowledge of a real coven with more than 15 years of experience are provided. There is a section - funny stories of shabashniks. If you would like to receive information about this, subscribe to our website's newsletter. We guarantee that your address will not be shared with third parties.

Apartment renovation in Moscow and Moscow region

We work with a guarantee!

Wide range of repair work. Professional craftsmen.

+7 (905) 797-20-34

luxurycomfort.ru

| Country house | Bath |

| For the dacha | Tool |

| Materials | Tales |

| Foundation | Log houses |

| Roofs | Insulation |

| Walls | Siding |

| Floors | Cellars |

| Attics | Doors windows |

| Stairs | Extensions |

| Wells | Toilets |

| Balconies | Loggias |

| Condensate | Flooding |

| Fences | Kennels |

| Sidewalk | Birdhouse |

| Adobe | Carts |

| Garages | Barn |

| Greenhouses | Bath |

| Swing | Brazier |

| Shower | Horizontal bar |

Stages of preparing a log house for painting

In order for the paint layer to lay smoothly and beautifully, and for the coating of wooden walls to satisfy the quality throughout the guaranteed service life, it is necessary to consistently prepare the facade, adhering to the technology. Before the exterior of a wooden house is processed, a number of preparatory works are carried out:

- Grinding . It is mandatory even for new buildings (from 1 to 3 passes are performed). The surface is sanded using a power tool (grinder with coarse abrasive). This treatment removes defects left after sawing (or manual processing) - chips and minor cracks. Sanding also opens the pores of the wood, which facilitates deeper penetration of impregnation and paint.

- Polishing . It is carried out with a grinder with a fine-grained nozzle or sandpaper (which significantly delays the process). As a result of processing, a fresh, lighter layer of wood appears; the surface becomes even and smooth, absorbs paint better.

Sanding prepares the surface for painting Source gdeprosto.ru

Why and from what wood needs to be protected

The outer layer of wood, devoid of bark, is completely defenseless both from the destructive effects of wind and sudden fluctuations in humidity, and from insect pests. The risk increases if the house is located in a rural or wooded area. This is explained as follows:

- As a result of complete cleaning of the wood surface from bark, it is easier for wood-boring beetles to access it.

- Under the influence of constantly changing relative humidity levels throughout the year, mold appears on wooden houses over time (usually in inconspicuous places, where it is most difficult to remove).

- Moisture stains remaining on an unprotected surface provoke the development of fungal diseases on the wood.

- With constant weathering, the surface of the building changes its natural color, becoming dull brown, which is why a wooden house loses its aesthetic appearance.

Based on this, when a wooden house is ready, it should be subjected to surface sanding, antiseptic treatment, and then painting.

Painting logs on the outside has a number of advantages:

- paint and varnish materials prevent destruction, dampness and rotting;

- antiseptic treatment protects the log house from pests, fungal mold and corrosion;

- Exterior painting provides an opportunity to create a façade that fits perfectly into the architecture of the house and landscape solutions.

Painting the outside of a log house: stages of the process

Protective and decorative painting of a house made of rounded logs on the outside is the key to its long-term preservation without loss of visual appeal. Typically, processing is divided into several stages:

- Antiseptic . Impregnation of the facade with water- or oil-based antiseptics and fire retardants disinfects the wood and prevents new insects and microorganisms from appearing (1 to 2 passes are performed). It is convenient to apply the antiseptic through a spray bottle, so a respirator and safety glasses at this stage are not superfluous. Further procedures begin after the composition has completely dried.

- Primer . The purpose of the treatment is that the composition prepares the surface for final painting. The primer prevents tree resin from escaping (in knots) and staining the paint.

The paint color is chosen taking into account the style features Source gomabygg.com

- Adhesive primer (acrylic or oil, optional). The impregnating composition improves the adhesion of the base paint to the wooden wall and reduces paint consumption. Avoid getting dirt and dust on the drying primer.

- Cover paint . The main paint for a log house, the final layer that decorates and protects the walls. The ideal option is acrylic paint, applied in a thin layer sequentially in three steps, using a brush or roller.

Preparatory stages

Before applying painting materials to the frame, it should be thoroughly processed. First you need to remove all contaminants from the surface. A brush with soft bristles, a washing vacuum cleaner or an ordinary garden hose are suitable for this. Just be careful not to water the logs abundantly; the tree may become saturated with moisture and will take several weeks to dry.

Grinding

Sanding of the log house cannot be performed immediately after completion of construction work. Wood with high humidity is poorly processed, and any further coating will look unsightly on a poorly polished surface. Therefore, the house must stand for at least a month. It is also recommended to carry out such work at an ambient temperature of no lower than 10–15 °C and no higher than 30 °C. For internal surfaces this circumstance is less critical than for external ones.

Before starting grinding, the log house should be checked for leaks. The result is to caulk possible cracks and gaps left after construction. If this stage is not necessary for houses made of laminated veneer lumber, then log buildings (especially in the crown joints) may have some leaks that must be carefully sealed using acrylic or silicone-based sealants.

Since wood of normal humidity is sanded quite easily, you should not use a massive tool. The optimal power of an angle grinder is 800–1000 W. In this case, the size of the grinding disc must be consistent with the diameter of the rounded log. Preference is given to machines that allow you to adjust the speed of the grinding disc.

When sanding with your own hands, work begins with the back walls and the most even areas: this makes it easier to get used to the tool. When calculating the required time, it is worth remembering that it takes about 5–8 minutes to process one linear meter.

Then you should sand the surfaces of the ends inside and outside the house with sandpaper. This processing stage is quite labor-intensive. The smoother the surface, the easier and faster the protective impregnation of the wood will apply. A grinder with an emery wheel will help speed up the grinding process. To sand wood, you should use two types of sandpaper: coarse and fine grit.

Grinding is performed using circular movements of the disc over all elements of the frame, starting from the top rows. It is not recommended to treat all walls and areas at once - the sanded surface quickly becomes weathered, and therefore requires immediate impregnation with an antiseptic. Therefore, the processing process should be divided into a number of successive stages.

In hard-to-reach places, grinding is done manually - using a chisel.

Antiseptic impregnation

Logs require immediate surface coating with anti-rot compounds, which should be done immediately after sanding. For this purpose the following can be used:

- Bioprotective compounds that protect wood from the harmful effects of ultraviolet radiation and also increase the moisture resistance of wood.

- Fire retardants that provide adequate fire protection for your home. They are carcinogenic substances, so special precautions are required when handling them!

- Combined preparations that combine both fire-resistant and moisture-preserving impregnations. For example, acrylates are substances that, when painting a surface, simultaneously increase its resistance to adverse external factors.

- Antiseptic compounds. Antiseptics for internal and external use are produced separately.

- Compositions that destroy tree pests. For this purpose, fumigation (fumigation with special generators) is used after grinding. To do this, it is better to invite specialists. Also, to combat wood borers, they are treated with ultrasonic fields. In the interior of log houses, you can use a regular microwave oven with the door open, but you should be careful - it is dangerous.

Fire-, bio- and moisture-resistant impregnations are applied in 2 layers and left for 10–14 days for complete absorption and distribution throughout the wood.

In order to save money, you can use the “old-fashioned” secrets of processing a house made of logs. Wax and turpentine have long been used in equal proportions to protect against rodents. The inside of the log house can be treated with starch or laundry soap.

Machine oil can be used as a water-repellent layer on the outside.

Painting the outside of a log house: factors affecting quality

The quality of painting a wooden country house depends mainly on two factors:

- Weather . Ideal weather is dry and windless. Do not paint in the sun (the paint will dry too quickly and unevenly), during or after rain. The permissible temperature is determined by the type of paint (indicated on the label).

- Wood moisture content . It should not exceed 20% during painting, so façade walls made of wood with natural humidity are painted after the frame has shrunk.

A necessary condition for a quality result is ease of use Source projecty-domov.ru

Sanding a log frame made of cylindrical logs

After initial processing, logs always have defects and irregularities that must be eliminated before painting or coating with compounds that prevent rotting and destruction of the wood. For this, a grinding process is used. It is carried out immediately, as soon as the log house dries in natural conditions and sag slightly. You cannot delay this operation, otherwise the logs will darken, harden and become less amenable to processing.

What does sanding a log frame provide?

No matter how durable a wooden house is built, it will be exposed to natural factors all year round. Therefore, it must be reliably prepared to withstand winds, frosts, scorching sun and precipitation. For this purpose, the log building is polished. This operation helps solve a number of important problems, namely:

- stop wood aging;

- prepare log walls for subsequent processing;

- eliminate defects and give the wood a natural structure;

- improve the adhesion of oils, paints and other protective and decorative compounds;

- make a log building aesthetically attractive and noble.

Sanding a log frame made of rounded logs, the cost of which is quite reasonable, allows not only to extend the service life of a wooden structure, but also to give it a beautiful and more luxurious structure. Therefore, it is important that the grinding of a rounded log house is carried out with high quality and in compliance with technology, then it will fully perform both protective and decorative functions.

Prices for services

| Type of work | Cost RUR/m2 |

| Warm seam | from 80 |

| Sandblasting a log frame | from 200 |

| Painting (one layer) | from 50 |

Leave the sanding of the log to the professionals!

The cost of sanding rounded logs depends on the area of the surface being processed and the quality of the initial processing. It is carried out in the presence of protective equipment, consumables and special tools - an angle grinder, a grinder with discs of different grain sizes. This process itself is time-consuming and labor-intensive, and therefore requires practical training.

Mistakes when painting a log house unqualified

If the desire to save on professional services for some reason outweighs the guarantee of the quality of the work performed, then after a while unsightly results such as stripes, stains and simply peeling areas on a recently painted surface are very likely. In such cases, the quality of the paint product is not always to blame. Unprofessional builders, due to inexperience, make basic mistakes that affect the final result:

- The facade is not properly prepared for painting: poor-quality sanding (or lack thereof) leaves the surface rough.

- painting technology (sequence) is violated

- Work is carried out in unsuitable conditions (high humidity or under the scorching sun).

- Newly erected ( naturally damp ) walls are painted.

- Incompatible materials were selected for painting .

Peeling of paint is caused by a violation of technology Source otdelka-expert.ru

Grinding a rounded log frame

A mandatory preparatory measure before painting a log house or treating it with protective agents is preliminary sanding of the log. Using this technology allows you to:

- Refinish walls that have darkened over time.

- Change existing color.

- Prepare wood for base or protective coating.

- Protect timber from fungal diseases.

You can order sanding of a house made of rounded logs in excellent quality at a reasonable price on the website (Moscow) by calling the contact number.

Price from 650,520 rub/m2

Reduced price for painting the inside of a house

During the period from 09/01/2020 to 03/20/2021 (subject to the conclusion of the contract before December 31, 2021)

Benefits of working with us

- More than 12 years of experience in painting houses

- 5 year warranty

- We use German paints

- You choose the color, we do the rest

Our works

Reviews

Home sanding prices

| Service | Price |

| Grinding, rub./m 2 | from 300 rub. |

* minimum volume of work 200 m2

* minimum volume of work 200 m2

Price from 550 rub/m2

For external and internal work

With a volume of 1500 m2 (including work, consumables and paintwork)

Sanding a log frame

Sanding a house made of rounded logs, even using a special tool, requires a lot of labor and time. In addition, the technological process is accompanied by a lot of dust, and, consequently, the need to use respiratory and eye protection.

Experts will solve the problem. They will complete the order in accordance with the client’s requirements, and he will save his health and time.

The technological process proceeds in stages:

- Chernova. Performed with grinders, flap grinding wheels, and 60-80 abrasive.

- Basic. Eccentric machines are used with an abrasive of 100-150. They completely eliminate the smallest irregularities on the surface of the walls.

- Polishing. It is carried out to obtain a perfectly smooth, shiny surface. It is performed using vibrating machines, 150 grit.

Depending on the initial condition of the wall surface, the process may consist of 2-3 passes. If this service is ordered as a preparation before covering walls with paints and protective agents, then tools with an abrasive size of no more than 120-150 are used. As a result, the service life of the finished coating is greatly increased

After the facade, the ends, corner joints, and grooves are processed. An angle grinder or grinder with a thin attachment in the form of a special brush is used. The cost of polishing the end of a log frame made of rounded logs starts from 220 rubles per lin. meter.

Service price

Processing and cleaning a wooden surface is a labor-intensive process that requires accumulated experience and time. The cost of quality work cannot be low, but the costs will be justified by the long-term operation of the house in excellent condition.

The price of sanding a rounded log per square meter depends on the amount of work and the characteristics of the material. On average in Moscow, prices start from 300 rubles per sq. m. meter.

The final cost is influenced by factors such as:

- Working volumes. They are performed on the entire object, or on a separate part of it.

- Is the pediment sanded?

- Type of material.

- Height of work performed.

- Number of passes.

Order rounded log sanding and you will receive a healthy, aesthetically pleasing house for long-term use. For consultation, please call +7 (495) 648-43-92. We work in Moscow and the region.

Services

- Interior painting

- Painting the facade of the house

- Sanding at home

- Wood brushing

- House sealing

- Painting in the workshop

During the period from October 15, 2018 to April 10, 2019

For painting interior walls the price ranges from 490 to 580 rubles. m 2

Painting an old wooden house

Over time, the painted facade begins to lose its attractive appearance - the paint peels off, mold appears, and the south side fades more rapidly. Sooner or later, the external walls of an old country house will require updating. Before repainting, the old coating is cleaned (for example, with a wire brush), and the surface is inspected to identify possible defects.

To ensure that the new layer goes on smoothly and lasts as long as it should, choose the same type of paint that was used originally. A study of the texture of the old coating will help determine what the façade was painted with:

- Acrylate paint . Thin, elastic structure reminiscent of leather; You can roll a piece of peeling paint into a roll.

- Oil paint . It has a matte color and may leave marks on your fingers after touching. You won’t be able to roll the roll—the fragment will crumble.

Old walls need careful preparation Source color-kostroma.ru

An old wooden house is painted in the same way as a new one. The difference is that it is not recommended to paint the old facade with a roller; it does not fill the unevenness that appears after periodic swelling and shrinkage of the fibers with paint. To give the old façade a neat look, painting the log house can be done in three or more layers.

How to sand and paint a log house.

Upon completion of the construction of a wooden house, multiple finishing works are performed, including sanding and painting the frame.

Many people consider the need for resurfacing to be an optional procedure. Experts recommend not to ignore this stage of work. Sanding a log frame is a rather labor-intensive job that requires some knowledge and skills, the availability of special tools and a sufficient amount of time to complete it.

Main goals of grinding:

- Restoration of appearance. Under the influence of external atmospheric phenomena, the surface of the logs begins to darken over time. Sanding returns the original appearance, the wood becomes light (as if it had just been cut down).

- To protect against fungal infections and mold. If the conditions of transportation or storage of wood are violated, fungal or mold damage may occur, and dark spots may appear. They can be removed by sanding.

- When sanding, the grain and texture of the wood becomes more apparent.

- Increased adhesion to paints and varnishes.

- Protection against premature aging of wood.

You can start cleaning the log house only after it has dried thoroughly. The roof must be installed. If you try to sand immediately after assembly, the wet wood will scuff and you won’t be able to get a beautiful smooth surface. Sometimes the logs of a log house may turn blue or darken; in this case, the first priority is treatment with a bleaching antiseptic. After the surface has dried, start sanding. If the sanded surface is not coated with a protective compound, it will darken within a week. When sanding a log house yourself, furrows and holes may appear on the log house - traces of too much pressure; we have a specialized team on staff that professionally performs this work. Particular attention should also be paid to the ends of the frame; it is impossible to make them perfectly smooth, but they need to be sanded - they absorb better, so you have to lubricate more generously.

To grind logs and beams, you can use two types of tools: grinders or grinders with appropriate attachments. For grinding, you need a supply of attachments with different grain sizes. For the initial processing of logs with bark residues and various types of unevenness, you will need sandpaper with a coarser grain, and for the finishing pass - fine-grain sandpaper.

There is another method of polishing a log house - sandblasting facades. This type of treatment eliminates the appearance of pits and furrows, helps to open the pores of the wood, this allows the protective composition to penetrate deeper and create a protective layer. There are various cracks and hidden surfaces on the surface of the logs; first of all, they contain various fungi that cannot be cleaned out with hand tools. Abrasive blasting cleans such areas uniformly, after which they must be protected with an antiseptic. The meaning of this technique is to clean the surface with sand particles under pressure, along with an air flow. Please note that regular sandblasting is not suitable for cleaning a log house. It will damage the surface. The advantages of this cleaning method: high speed of work, the texture is revealed most advantageously, corners and hard-to-reach places are well processed, opening the pores of the wood, no damage to the wood from sanders or grinders. Disadvantages: high cost, need to use equipment.

Our experts advise painting the log house within a maximum of 36-48 hours, after sanding at above-zero air temperatures. External processing of a log house consists of grinding and painting with various compounds; these measures can extend its service life several times.

There are a large number of paint and varnish products that are used to treat a log house after sanding. Please note that not all products are suitable for use in residential premises.

The main function of processing a log frame is protective; the natural texture of the wood is also emphasized and it is tinted.

Means for coating the log house after sanding:

First layer: antiseptics that prevent the appearance of mold and mildew;

Second layer: Painting. Compositions with glazing properties that make the appearance of walls more attractive or covering compositions that paint over the wood texture;

Finishing layer: fire retardants - solutions that increase resistance before fire.

It is better to paint a log house with a brush. This option, when painting, is the most preferable, in our opinion, since the composition is rubbed and penetrates deeper into the wood, and accordingly the protective properties increase.

The compositions are also applied using a spray gun (spray gun).

Coating application is ensured by pneumatic spraying through finely dispersed crushing of the paint composition. This technology applies only to a small area of painting to avoid sagging and overlaps. Sagging and overlaps must be smeared immediately. It is important to maintain the same distance between the wall surface and the spray gun; the speed of movement of the spray gun should also be the same. The use of a spray gun is unacceptable for the use of translucent compositions, but for covering paints, a spray gun can be used, since when the paint is applied opaquely, the overlaps become invisible.

If you paint the walls of a house with a spray gun, to improve adhesion, a person with a brush should follow you, this way it is possible to avoid smudges and the composition will be absorbed deeper.

The main rule for durable wall treatment is the use of high-quality compounds. Saving on materials leads to the fact that the log house will suffer first, since wood is a rather vulnerable material that requires careful care.

We employ qualified craftsmen with many years of experience in sanding and painting log frames. Also, our own department of paint and varnish coatings and tinting equipment provides a wide selection of impregnations for wooden surfaces to suit every taste and budget.

Exterior painting of a log bathhouse

A bathhouse is a building with specific operating conditions; the interior of the log house is exposed to high humidity and temperature. Therefore, the main condition for the external coating is to maintain the vapor permeability of the walls. Otherwise, moisture will linger in the wood for a long time, creating a favorable environment for the development of mold microorganisms. When thinking about how to paint the exterior of a log bathhouse, do not forget about the nuances of processing the loghouse of a bathhouse:

- Logs must be dry and clean .

- In order for the protective layer of the new log house to serve as reliable protection, the lumber is treated with stain before collecting the crowns .

- Before repainting, the structure must be cool and ventilated .

Stages of processing and painting a bath Source do.59.ru

Impregnations are conveniently applied in the following sequence:

- Antiseptic . Products based on natural and synthetic oils are optimal.

- Fire retardant.

- Dye . The best option is acrylic facade paints, non-toxic, durable and vapor-permeable.

When to do it?

Building a high-quality wooden house is never quick. First, the material is delivered to the site, then it is installed and roofing work is performed. All this happens over the course of one season. The drying process of wood lasts 1-2 years, depending on the cutting season, storage conditions of the material and its characteristic features.

During the entire period of drying and shrinking of the wood, sanding is prohibited. According to experts, at this stage there is also no need to use antiseptics, since the structure of the wood will not change significantly throughout the year. During grinding, you will be able to remove darkening, since the procedure involves removing at least 1-2 mm of the top layer of material. Installation of doors and windows is carried out after sanding.