Wood is a living material in which biological processes continue long after the tree is cut down. Including rotting during house construction.

Of course, experienced builders know that a log house requires wood dried to a certain moisture content. But the fact is that a house cannot be built in one day. And during storage at the construction site, logs, beams and other lumber are exposed to various natural influences - heavy rains or thaw, hail and simply hot, humid weather.

All this contributes to the fact that the level of humidity in stored materials increases. Because of this, rotting may begin. Therefore, it is urgently necessary to treat the log house with protection against rotting. Because rotting is caused by fungi feeding on substances contained in the tree, which destroys its structural strength.

In principle, all means for protecting a log house from rotting can be divided into three types. These are impregnations containing wood antiseptics and phytoncides, bleaches and preservatives.

How are they different? The way they act.

Impregnations with antiseptics fill the pores of wood materials with chemicals that make it impossible for wood to be consumed as food - not by fungi, not by algae, not by bugs or ants. As if they poison, slowing down and, subsequently, stopping the development of biocontamination. The most effective impregnation is creosote. Railway sleepers and edged lumber impregnated with it last for 70 years. But it is very toxic to people, so it is best to buy modern products.

In our country, you can treat a log house with products produced under the brands “Prosept” and “Neomid”.

Bleach is a remedy for treating already diseased (damaged) wood. The bleaches most often used in Russia are chlorine, oxygen, oxalic acid-based and combined. Their main purpose is to kill an existing infection or rotting that has begun during the construction of a house. Even if you bought high-quality timber, dried and processed at the factory, it still can get spores of wood-decaying fungi during long-term storage. It is almost impossible to detect this visually. And the destruction of strength will continue after construction is completed. Therefore, professionals advise treating all lumber that is subject to temporary storage with bleach for preventive purposes.

And, preservatives. These are certain impregnations that make wood materials resistant to penetration and saturation with moisture. And if there is no moisture, there is no possibility for fungi to live. Usually, preservatives are applied after the above products. In one case, before painting and sometimes used as a primer, in another - after, and in the third - some coating compositions (glazes, glazes, varnishes, paints) contain preservatives.

But in any case, wood that is being processed for the first time must be impregnated with all means in turn separately.

Materials for processing (impregnation and antiseptic) of a log house

Construction of your own country wooden log house involves not only the direct construction of walls, but also the use of various impregnations of antiseptic agents. This is done in order to extend the life of the future home, protecting it from mold, rot and the effects of fungal formations.

Impregnations and antiseptics for wooden houses

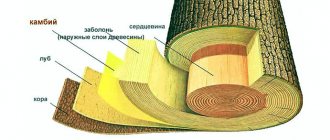

Modern impregnations and antiseptics for the home represent a whole range of safety products, the use of which will allow you to better protect the wood from premature destruction. The principle of operation of such protection is based on the fact that the active substance penetrates deeply into the wood structure, interacts with the microstructure and creates a protective shell. In addition to the protective properties, the main thing you should pay attention to is the chemical composition. The latter is explained by the fact that the protective shell created should not interfere with air circulation, disturb the level of humidity inside the room and adversely affect people's health.

Let's give an example of the main areas of work of protective equipment and find out exactly how they protect a tree from the harmful effects of the environment without having a harmful effect on the human body.

- Saline. They are a clear example of comprehensive protection, since with their help you can protect yourself not only from mold, rot, fungus, bacteria, as well as other influences, but also from fire. For use with external cladding only. Please note that such impregnations are strictly prohibited from being used in combination with roofing (for example, metal tiles), since salt will certainly lead to corrosion.

- Water based . The most common and inexpensive. Completely harmless. Their main purpose is to protect against moisture. Therefore, they are often used in combination with salt products to protect the latter from leaching.

- Solvent based . Easily penetrates the wood structure. They are an indispensable tool in the fight against fungus. They protect wood well from moisture absorption and exposure to ultraviolet radiation.

- Based on linseed oil . It is used extremely rarely in the construction of wooden houses due to the fact that it is necessary to regularly update the impregnation structure, and, therefore, entails corresponding financial costs.

Photo: the log house of a wooden house is treated with fire and bio protective materials against fungi that cause rotting of logs and beams. After treatment with antiseptic protective materials Neomid 440 outside and Neomid 400 inside the wooden frame, the logs and beams are impregnated with the decorative composition Neomid Biocolor Ultra on the outside of the frame. The inside of the log house was left without painting. This log processing technology is recommended by experienced construction experts in the field of wooden log housing construction.

Photo: a log house made of rounded logs is treated with protective materials against rot and destruction by fungi that cause rotting of the wooden structures of a log house. Good, effective treatment of a log house with antiseptics will significantly extend the service life of a wooden house made of rounded logs.

Methods for applying protective compounds

The thick solution must be applied to the logs using a roller.

Depending on what product is used to treat the log house, the method of applying it may be different. There are several methods for applying a protective coating.

The first is to use a roller or large brush. This option is more suitable for thick mixtures that cannot be applied by spraying. This method is more labor-intensive.

Preparations in the form of aqueous solutions are applied to the surface of the wood using spray guns. It is known that most protective drugs (mostly antiseptics) contain toxic substances, so the procedure is carried out in a respirator or a mask and goggles.

The third method is to immerse the wood in special baths containing the working solution. Any worker building a house or bathhouse should know that there is no need to skimp on protective compounds. It is recommended to use only proven products. It is important to remember that the solution must be applied to both the internal and external surfaces.

Advantages of Neomid 400 impregnation

The antiseptic composition Neomid 400 is absolutely safe, because it is made on a water basis. The antiseptic does not contain heavy metal salts. Intended for treating wooden surfaces located indoors only. Both planed and sawn wood can be processed. This impregnation prevents the formation of wood-staining and wood-destroying fungi, mold, and rot. It also prevents the occurrence of wood-boring insects. Neomid 400 provides treated wood with a long period of protection, which is at least 25 years.

The composition of Neomid 400 during processing does not affect the structure of the wooden material, does not change its color and properties. After applying this antiseptic impregnation, the wooden surface can be easily painted or glued. If in the future it is planned to apply glaze decorative impregnation to the wood, then Neomid 400 can serve as a primer.

This antiseptic impregnation is a concentrate. Before using it, dilute the composition with ordinary water, maintaining a ratio of 1 to 5. If the wood will subsequently be located in a damp room, then it is better to dilute it in a ratio of 1 to 3. This concentrated type of impregnation allows you to save money, i.e. when purchasing 1 liter of the composition, the result will be 4 - 6 liters of finished antiseptic.

Bleaching agents

In order to prevent the appearance of fungus, you can use bleaching agents.

You can treat a log house for your home with bleaching agents. This group of drugs is intended to protect the log house from a special fungus that can cause the wood to turn blue. There are a large number of products on the market that have similar properties. The most popular and effective products are Sagus, Neomid 500, Saga and others. Neomid 500 is available in the form of a concentrate, from which it is necessary to prepare a working solution. The ratio of substance to water is 1:1.

Sagus log treatment product gives good results. Like Neomid 500, it whitens the frame and gives it a good appearance. After applying this mixture, it is advisable to treat the log house with the antiseptic Neomid.

One of the newest is the drug League. It allows you to get rid of blackness and blueness. The product gives the tree its original appearance. It is of great importance that wood processing for a house or bathhouse is carried out only after it has completely dried. In most cases, the log house manages to get wet. It will take from six months to one and a half years to dry it completely.

Advantages of Neomid 440 Eco impregnation

The colorless, safe antiseptic composition Neomid 440 Eco is intended to provide protection to wooden materials from the effects of various types of mold and fungi indoors and outdoors. Also to prevent the formation of moss, lichen, algae and the invasion of various wood-boring insects on wood. Antiseptic impregnation Neomid 440 Eco can eliminate existing contamination of the material. This composition provides the treated surface with a long period of protection, which is about 25 years.

Neomid 440 Eco can be used for application to wood located in a room with high air humidity (basement, bathroom, cellar, etc.). After the treatment, the structure of the wooden material does not change. In the future, it can be easily painted, glued, etc.

Preparation for processing

Processing should not be delayed. It must be applied immediately when the log house is ready, even before caulking. If the work is postponed, then the finished log house is covered with a film to protect it from external manifestations - precipitation and other things.

Before treating the exterior of the bath house, you should thoroughly clean it of construction debris. You can even use a vacuum cleaner to do this. Then it is dried and the compositions are applied in this order:

- Impregnation against mold and mildew and for protection against moisture.

- Anti-parasite layer.

- Fire retardant is an important component for wooden buildings.

If everything is done correctly, then subsequent treatments are done no earlier than three years later. Many compositions are good and durable, lasting up to five years.

Wood needs to be processed throughout its existence. Then she will delight her owners for a long time.

Konstantin Shcherbakov

Author of publications on 1Drevo.ru with the topics: Ventilation valves for PVC windows | Round house | Rounded timber | Bathhouse 6 by 4 | Finnish houses | Bathhouse with gazebo | Installation of log house | Pellet boilers | Solid fuel boiler | Electric boiler in the house | Heat pump | Painting laminated timber | Solid timber house | Panel house | Manual felling of a log house | Foundation insulation | House kit made of laminated veneer lumber and others.

Where can I buy these quality products?

Photo: the most popular antiseptic and decorative impregnations of the Neomid brand.

You can buy high-quality wood preservatives for processing wooden log houses, high-quality sealants for wood, from our company, which is the official dealer of effective impregnations Neomid and Prosept.

Call, check the availability and cost of wood protection products for wooden log and timber frame houses.

Process Rules

The first work is carried out before the construction of the house. The logs are immersed in an antiseptic. But basically, the wood is processed during manufacturing. If the cottage will not be built immediately after the lumber is delivered, then proper storage must be ensured. The tree should be stored in a ventilated area where there is no dampness or under a canopy, away from the ground.

Secondary wall treatment is done within 2-3 days upon completion of the work. For this purpose, water-soluble agents are used that do not interfere with the natural shrinkage of lumber. Finishing is carried out at a temperature of at least 5-7 degrees . If a house made of timber is being built in the winter, processing can only be done in the spring.

Once shrinkage is complete, a final coating is applied. The time it takes to complete the work depends on the moisture content of the timber and its type. Kiln-dried lumber can be processed immediately after the construction of the cottage is completed. From profiled timber after 1-1.5 years, when the moisture concentration reaches 20%.

Article on the topic: Is it necessary to sheathe a house made of timber with siding?