Knitting reinforcement is one of the main stages of work to create a reinforcement frame. By connecting the reinforcement, a reinforcing structure is created, thanks to which the concrete receives greater strength in both compression and tension. If the rods are connected incorrectly, the finished monolithic structure will not receive the design strength. In order to avoid this, we will look at how to knit reinforcement correctly, observing all the rules and regulations, and what tool can be used to do the work; this will be useful for novice reinforcement makers and for experienced builders.

Strip foundation in private construction: features and limitations

The basis of the strip foundation is concrete. This material was widely used as a basis for the construction of buildings back in Ancient Rome. And only 200 years ago they figured out how to increase its strength using a frame made of steel rods. A new building material, reinforced concrete, combined the advantageous characteristics of metal and concrete and made it possible to build impressive structures. The process of placing a metal frame in concrete began to be called reinforcement.

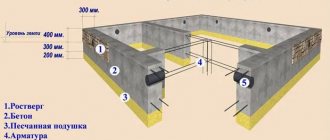

When a country house is being designed, a strip foundation is most often chosen as the basis for it. The preparation of a strip base (like any other) takes 25-30% of the construction cost; the reason for its demand is a successful combination of qualities:

- Simple in design.

- Suitable for projects with basements (unlike the pile-screw analogue) and heavy floors (reinforced concrete, monolithic).

- Does not require the use of special equipment.

Strip foundation in formwork Source profundamenti.ru

Despite its wide distribution, strip foundation also has limitations in use:

- Beneficial only on dry and rocky soils.

- Not suitable for installation on problematic (wet, heaving, peaty) soil; it will have to be poured to great depth, which is unprofitable.

The shape of the strip foundation is determined by the layout; it has a closed shape and is laid along the entire perimeter of the house, under load-bearing walls and internal partitions.

Use of plastic clamps

The main advantages of this method include the speed of work completion, as well as the strength of fixation of structural elements. Using plastic clamps for knitting reinforcement also does not require special knowledge. However, plastic clamps have a certain cost and their purchase can be considered an economic cost. The disadvantages of clamps also include the fact that they can fail at low temperatures.

When analyzing these options, it can be said that the wire binding process will have a greater advantage than the same process using plastic clamps, since in the first case there will be less cost. However, clamps will help create a stronger and more reliable structure, even though it costs more money.

Prerequisites: why reinforcement is needed

The foundation is created in order to withstand the load of the structure; It works best with evenly applied pressure. But in practice, the load is too often uneven and internal stresses arise in the foundation. The reason may be both changes in the soil and design miscalculations (unequal weight of individual parts of the structure).

Design errors will definitely become noticeable Source homeklondike.site

Concrete has excellent resistance to axial compression and weak resistance to tension. Reinforcing bars have natural plasticity and compensate for the lack of concrete. The latter, in turn, protects the metal from corrosion.

During operation, concrete (which resists compression) and metal (tension) are able to most effectively resist multidirectional loads, protecting the structure from destruction. Correctly carried out reinforcement not only increases strength, but is also a means of saving: it allows you to reduce the cost of concrete (reduce the massiveness of the foundation).

Reinforcement requirements

The strip foundation is laid with a margin of safety; it must be resistant to external factors (mechanical and climatic). How to correctly knit reinforcement for a strip foundation is described in the provisions of SNiP 52-01-2003, which contain detailed requirements for design and materials. There are a number of requirements for fittings:

- The placement of the reinforcement cage should not interfere with the correct technological pouring of concrete.

- The reinforcement is installed with a given design step.

Calculation of the spacing of clamps when reinforcing a corner Source ep2nnov.ru

- At frame intersections, floating (movable) connections of rods are not allowed using any connection method.

- It is necessary to create a protective anti-corrosion layer for the structure.

- Replacing the type of load-bearing rods is allowed if the calculated load-bearing capacity remains the same.

See also: Contacts of construction companies that offer foundation repair and design services

Rod diameter

In SNiPs, which define the rules, regulations and requirements for construction stages, the diameter of the reinforcement is calculated based on the geometric dimensions of the foundation. Its amount should be more than 0.1% of the cross-sectional area of the base.

The cross-sectional area is calculated by multiplying the height and width of the rectangular strip. For example, for a base 60 cm high and 30 cm wide, the cross-sectional area is 1800 cm2.

- The area of the metal rod must accordingly be greater than 1.8 cm2, for the example under consideration 2 cm2.

- For a rod with a diameter of 10 mm, the cross-section is 0.78, for 12 cm - 1.13.

- Accordingly, we will need three and two rods with the necessary margin.

- But a thread requires at least four, this will give a margin of safety.

To save on the cost of consumables, it is allowed to use a smaller diameter rod and smooth reinforcement of class A I, but only in non-critical areas: for jumpers, fastening clamps, in the middle of the frame.

Materials and tools used for reinforcement

Since the reinforcement cage increases the stability of the structure by taking on a significant part of the load, its quality becomes fundamental. The frame is formed from interconnected reinforcing bars. Various are used for knitting the frame:

Types of fittings

Manufacturers offer fittings that can be divided into:

- Material of manufacture. Steel reinforcement is a classic, time-tested option; It is divided into 6 strength classes, it can be bent and welded. Composite reinforcement contains carbon, basalt, glass or aramid fibers. It is lighter, cheaper, does not corrode, does not bend and cannot be welded.

Reinforcement with a periodic profile has improved characteristics Source yar-limb.ru

- Profile. Reinforcement with a smooth profile is more often used as connecting jumpers. Reinforcement with a periodic profile has a relief surface, which improves adhesion to concrete.

Connection materials

Knitting of reinforcement for a strip foundation, the pattern of which can change, is done using:

- Knitting wire. Reliable and common knot connection technology. There are different knitting patterns.

- Threaded and crimp couplings (at mechanical joints).

- Metal paper clips. The reinforcement elements are connected without tying a knot.

- Plastic clamps and clips (fasteners). Plastic products provide simple and quick installation and are resistant to corrosion. Their use is not approved by all professionals.

Composite reinforcement bars secured with a clamp Source 1-detective.ru

- Welding. The process is fast, but the welds form a rigid connection, differ in density from the base metal and are susceptible to corrosion. When the load changes, they burst and reduce the strength of the foundation. The method is suitable for connecting rods of large diameters (in industrial facilities); To obtain a high-quality weld, you need a highly qualified welder.

Required wire

When choosing wire, the following factors must be considered:

- Manufacturing accuracy class. The accuracy class is determined by the production method. There is a wire of a higher accuracy class, its deviation of the actual size, diameter, from that declared by the manufacturer along the entire length of the wire is less than that of a wire of a lower accuracy class. However, for knitting reinforcement, the accuracy class is not particularly important.

- Wire rolling method. There are two types of rolled products: cold-rolled and hot-rolled. Cold-rolled steel is rolled out from blanks by presses without heating. With the hot rolling method, rolled steel is rolled out in a heated state, which gives greater strength.

- Which group in terms of tensile strength does the wire belong to (there are the first and second groups);

- Degree of corrosion resistance. On this basis, there is only one difference - whether there is a galvanized coating on the wire or not.

The criterion for choosing a wire is very simple, you need a wire that is called “knitting” . It has a full set of necessary characteristics: sufficient softness with the declared strength, abrasion resistance and reliability when fastened.

Galvanized wire is considered overkill. The optimal diameter of the knitting wire is 1.2-1.4 mm. A wire with a diameter of 1.6-2 mm takes a lot of force, as a result of which construction slows down, and the piece is too weak, it will simply burst.

Care must be taken to ensure that the reinforcement connection remains rigid after tying the knot: the frame must remain motionless during pouring.

This will ensure the reliability of the structure after hardening. You need to check the rigidity of the connection of the reinforcement by touching the rods - if they are rigidly fixed, they will not move, which means everything is in order. You should not test the strength of the knot itself, otherwise there is a risk of loosening the binding. The length of wire recommended for one knitting point is from 30 to 50 cm. The wire itself is extremely cheap - about 50 rubles. for 100 meters. To avoid running out of it at the wrong time due to loss or excessive consumption, it is recommended to buy it with a double supply. 100 rubles for 200 meters is quite inexpensive.

Requirements for reinforcement cage parameters

The rods that make up the structure differ in purpose:

- Working fittings. This is the name given to the longitudinal horizontal rods placed along the foundation strip.

- Clamps. They are divided into transverse horizontal and vertical, connecting the frame into a single whole.

The reinforcement frame of the foundation in private construction often has the following parameters:

- Fittings. Metal or composite, with a cross-section of 11-14 mm (for a small outbuilding), with a periodic profile and a cross-section of 12-18 mm (for reinforcing a strip foundation).

An example of how to knit foundation reinforcement with transverse clamps Source massimo.spb.ru

Average price for work

Approximate prices for assembling and tying a frame from individual rods by professional teams are 3000-3300 rubles/m3. If the facility configuration is complex, the cost of work may increase.

When working with ready-made meshes or laying single-row frames, starting prices for reinforcement of horizontal structures are 150 rubles/m2, for vertical ones – 180.

Renting a professional tying gun costs 800-100 rubles/day, with a deposit of 25,000-30,000 rubles.

Video description

How to properly crochet reinforcement in the video:

Calculation of the amount of consumables for tying reinforcement

The amount of material (in linear meters) is calculated based on:

- Foundation parameters (length, width, depth)

- Reinforcement schemes (number of layers and longitudinal rods in width)

Most often, reinforcement material is sold not by linear meters, but by kilograms. There are special tables for converting values. Plastic fittings are often sold by linear meters.

Scheme of strip foundation reinforcement Source kamtehnopark.ru

Grillage

The external similarity of the grillage to a strip foundation leads to errors in self-reinforcement. The tape experiences tension at the base from the prefabricated loads of the cottage, and at the top from swelling of the soil. Heaving forces never act on the grillage, since it is separated from the ground by a crushable layer of polystyrene foam or an air gap of 10–20 cm. However, here a bending moment arises in the vertical direction in places where the posts are rigidly pinched into the beams.

Important! For a grillage, it is not enough to make a standard frame of longitudinal rods tied with clamps. It is necessary to further strengthen the top row near the columns (piles and pillars), and the entire lower belt.

Diagram of the correct reinforcement of the grillage/pile interface.

Recommendations on how to properly knit reinforcement joints apply only to steel rods. It is not recommended to use composite reinforcement in foundations, which, when tensile forces appear, first elongates and only then begins to absorb loads. This is fraught with the opening of cracks in the base of the upper part of the concrete foundation beams that make up the grillage.

We recommend reading: Reinforcement of the grillage of a pile foundation.

Reinforcement knitting pattern, corner reinforcement

The correct knitting of reinforcement for a strip foundation, optimal in many respects, is a “cage” connection of the reinforcing frame rods. In this case, the rows are secured with wire (or other chosen method) at an angle of 90°. The knitting pattern consists of several sequential operations:

- A fragment 25-30 cm long is cut from a coil of knitting wire (for rods with a cross-section of 8-16 mm).

- The wire is bent in half and placed under the overlap of the rods, placing it diagonally.

- The hook is hooked onto the loop (the place where the wire is bent), the opposite end of the wire is circled over the intersection of the rods and placed above the hook.

- By rotating the hook around the upper end of the wire, a twist of 3-4 turns is created.

- The hook is removed, the ends of the wire are bent inside the structure.

Video description

About the intricacies of reinforcement in the video:

The corners of a strip foundation cannot be reinforced by simply overlapping the rods; This is considered a gross violation of technology. To reinforce the corners and connect adjacent linear elements with them, bent rods are used; the corner fragment is reinforced with L-shaped or U-shaped anchors.

Rods laid at the corners of a building without bending, at right angles, are unable to create a rigid structure. Such sections of the foundation are highly likely to be subject to destruction in the future.

Reinforcement of corners requires compliance with technology Source zen.yandex.ru

Reinforcement technology: execution order and features of the stages

The frame for the future foundation is calculated and installed based on the dimensions of the trench, using working reinforcement and auxiliary wire. Its parameters are calculated in advance, taking into account the expected load; It is convenient to assemble the structure on a long workbench. Installation of fittings takes place in stages:

- Vertical elements (clamps) are assembled. The vertical position of the rods is checked using a plumb line.

- The lower horizontal belt is mounted. The lower belt works to deflect the foundation downwards. It is attached with a knitting wire to vertical clamps.

- The upper horizontal belt is mounted. Its task is to resist the upward bending of the foundation strip.

- Corner elements are mounted. They need to be given special attention because they connect the sides of the foundation. Additional rigidity is provided by additional vertical posts, which are laid twice as often.

- The formwork for the foundation is being prepared.

Installation of a linear fragment of a reinforcing frame Source beton-house.com

- The prepared reinforcing frame is being laid. During the installation process, pipes are laid between the reinforcement bars (the utility and ventilation systems will subsequently be laid through them).

- Concrete is poured. Filling is carried out in several stages, with each layer leveled (manually or with a vibrating platform). This technology ensures uniform distribution of the concrete mixture.

- The foundation is being waterproofed. After the concrete has dried, the foundation strip is covered with bitumen mastic or roofing felt. This operation is an important measure to preserve the foundation.

If the frame is assembled in a trench, rods are first driven into the ground, observing the calculated distances. Transverse jumpers, lower and upper reinforcing belts are fixed to them.

Distance between rods

According to SNiPs, the distance between horizontal threads should not exceed 40 cm; for unloaded bases, 50 cm is allowed.

Important! The edge of the metal reinforcement should not come into contact with the formwork and should not come out of the thickness of the concrete!

The minimum distance to the edge of the foundation tape is 5 cm. If the width of the base is 35 cm, subtract a margin of 10 cm and get a horizontal thread pitch of 25 cm. The value is less than the established one and meets the requirements.

- For shallow foundations up to 80 cm high, two horizontal strips are allowed. We retreat the recommended 5 cm from the bottom and top of the monolith, obtaining a height between the threads of 70 cm.

- The jumpers are installed vertically and horizontally with a minimum pitch of 30 cm.

- When constructing a main wall made of sand-lime brick, a multi-storey building, or locating the structure on moving and heaving soils, the cell pitch is reduced and the number of threads is added.