The blind area is an almost invisible, but important part of any structure. It prevents the soil at the very base of the house from getting wet from precipitation and, at the same time, eroding. But the blind area can only fully perform these functions if it is properly constructed and protected. During the construction process, waterproofing of the blind area will be required, and how it is done is described in detail below.

Some features of blind area waterproofing

The installation of waterproofing of the blind area is an important criterion in ensuring the protection of the foundation of the building and the adjacent area. Waterproofing features:

- Waterproofing measures and the depth of the blind area are done taking into account climatic conditions, annual precipitation, groundwater levels, geological characteristics of the area in which the building is located, and the presence of water supply and sewerage networks.

- Waterproofing of the blind area can be primary and secondary. In the first case, the concrete screed is initially laid taking into account the water-repellent properties and waterproofing measures taken. In the second case, waterproofing measures are additional and waterproofing is used for this.

- To obtain a high-quality blind area, each layer of it and the foundation of the building are treated with bitumen mastic.

- Waterproofing is laid at the bottom of the trench under the blind area. Polypropylene or PVC film is best suited for this purpose. Polyethylene film and roofing felt are also a good option, although they are inferior in characteristics. The sheets of material are laid overlapping and secured to the foundation walls.

- To effectively drain water, a gutter is made around the perimeter of the blind area.

- Materials with high porosity are treated with a special composition that has water-repellent properties.

- The drainage membrane is an alternative to a concrete blind area. It is laid on the ground and covered with a layer of crushed stone and sand. This allows you to make a covering for the blind area from any materials.

We will equip a “protective” strip around the house

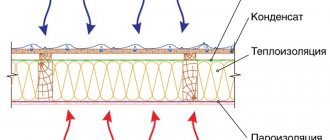

The whole structure resembles a multi-layer cake, where there are materials for both insulation and waterproofing. Therefore, you need to strictly follow a small plan:

- Dig a trench, the depth of which will coincide with the depth of the foundation.

- Clear it of roots and plant seeds, if any. If this stage is ignored soon, the plants will begin to sprout and break through the waterproofing layer.

- The bottom of the trench must be covered with clay. This layer should be 10 cm. The substance is carefully compacted so that the area near the foundation is 2-5 degrees higher than the far part of the blind area. The slope will allow water to flow away from the walls on its own.

- The wall is coated with liquid waterproofing.

- Lay roll protection against moisture. If joints form, they must be sealed with tape. And, of course, don't forget about the whip on the wall.

- Sand should be poured on top of geotextile or other film. The thickness of this layer is about 10 cm. It is also leveled taking into account the slope and compacted. To quickly cope with this task, you can spill a little water on the sand, but the amount of liquid should be minimal.

- Thermal insulation layer. For blind areas this is as important as for walls. The house loses about 20% of its heat through the floor, so by insulating it and the foundation, you can save warm air in the house and not heat the street. It is important to remember the slope.

- Another layer of sand. The thickness is also about 10 cm and must be leveled and compacted while maintaining the slope.

- Waterproofing again. The installation principle is the same as in the first layer of geotextile.

- To fix the waterproofing layer, you need to pour fine crushed stone on top.

- Decoration.

Types of blind areas

The choice of blind area depends on the amount of precipitation. It can be produced in several ways:

- simple bulk made of clay and crushed stone;

- bulk with waterproofing underneath;

- concrete reinforced and unreinforced;

- prefabricated reinforced concrete slabs.

The bulk blind area is lined with two layers: compacted clay 20 cm thick and crushed stone 10 cm thick. In this case, the simplest waterproofing is used. Water is drained from the roof through gutters.

This option is suitable for areas with low average annual precipitation. Walking on this structure is not recommended. It is the most short-lived, since over time the clay layer can erode when wet. Additional waterproofing for the bulk blind area will make it more reliable and suitable for houses with basements. The rolled material spreads over the compacted clay layer, covering the foundation. A mound of crushed stone or pebbles is made on top. To create a dense bulk waterproofed blind area, you can create the following pie:

Cost of raw materials and work in the Russian Federation

The cost of work depends on many factors , including the area of the object, the width of the blind area, the soil, its condition, and the selected material for waterproofing.

If specialists are invited to carry out the work, then after inspecting the site they will draw up a detailed estimate and calculate the approximate cost. When building a structure with your own hands, its price will depend on the material chosen and the purchase of the necessary tools.

On average, prices for waterproofing materials in the Russian Federation are as follows:

- liquid glass - about 500 rubles. for 15 kg;

- rolled materials - about 1,400 rubles per piece;

- hydroconcrete - about 1000 rubles. for 25 kg;

- roofing felt - from 350 rub. per roll;

- PVC film - about 100 rubles. per m.p.

In the Russian Federation, the average price of work is from 500 rubles. per meter

The most important and useful information on the construction of blind areas is collected in this section.

Necessary materials for waterproofing the blind area

When choosing one or another method of waterproofing and materials for arranging the blind area, you need to take into account its design features. This can be done using several materials:

- Bitumen-based mastics. They are the best option for protecting the foundation surface from water. Used when constructing bulk blind areas.

- Roll waterproofing. This includes polypropylene, polyvinyl chloride films and varieties of roofing felt. It is recommended to combine the laying of these materials with the application of bitumen mastic to the foundation to obtain an airtight coating.

- Hydrocement or asphalt concrete. The resulting solid slabs reliably protect the foundation of the house from water.

- Polymer-based penetrating compounds. Applied to surfaces with a porous structure. Penetrating deeply into the material and creating a water-repellent barrier, they reliably protect it. They are resistant to ultraviolet radiation and temperature changes. Prevents the formation of mold.

Requirements

Taking into account the functions performed, the covering of the blind area must meet the following requirements:

- Waterproof and moisture resistant. The coating must provide the necessary tightness.

- Sufficient mechanical strength, ensuring the ability to walk on the blind area and resistance to unexpected falls of various objects (for example, icicles).

- Resistance to temperature changes, sufficient frost resistance and resistance to solar ultraviolet radiation.

- Attractive appearance, in harmony with the interior of the facade.

The current SNiP imposes requirements on the design of the blind area itself . It should not have a flat surface and be adjacent to the foundation wall.

At the same time, a compensation gap must be provided to level out thermal expansion and the influence of soil swelling.

The blind area must have a slope to allow moisture to drain. It is laid in a continuous strip around the entire structure, with the exception of the porch.

In addition, the blind area must be wide enough for passage and installation of stairs. No heat should be lost through this element, which means that the problem of its insulation needs to be solved.

Types of blind area waterproofing

Waterproofing the blind area around the house can be done in several ways, which vary depending on the material used. Waterproofing can be:

- clay;

- roll;

- painting;

- concrete.

Clay

This option is the simplest and most cost-effective way to waterproof a blind area without the help of specialists. You can do the work yourself. First, the top soil layer is removed, after which a layer of clay is filled in and compacted. It is important to provide a slope away from the building. The junction of the clay and the foundation is carefully coated with bitumen mastic. To improve waterproofing qualities, roll waterproofing can be glued to the foundation. The last stage is filling and compacting crushed stone.

Roll

Rolled waterproofing is most often used for houses with basements and ground floors. The work begins with digging a trench and compacting the clay layer. After this, the sheets of waterproofing material are laid overlapping and lifted onto the wall. You can lay two or more layers, coating each with mastic. The finished waterproofing is rolled with a roller weighing at least 70 kg. The final stage is backfilling with soil or crushed stone.

Painting room

Waterproofing by painting involves applying a special water-repellent primer. After it has completely dried, 3 layers of mastic are applied, each up to 2 mm thick. In this case, the next layer should be applied after the previous one has dried.

Concrete

Formwork is installed in the prepared trench, into which concrete is poured. To increase strength, the structure can be reinforced. The finished structure can be left as is, or decorative tiles can be laid on it.

Possible mistakes

The most common mistakes when constructing a drainage system:

- Lack of drainage, which removes excess moisture from the building. To avoid stagnation of water, it is necessary to properly construct the drainage system.

- Gaps between layers of waterproofing material during the construction of the blind area. To avoid this, each layer of waterproofing must be secured or glued.

- Wrong choice of material.

- Before applying waterproofing, the concrete was not treated with a primer (improves the adhesion of the material to the surface). To correct the error you will have to spend a lot of effort and money. To do this, you will need to remove the blind area and carry out the work again.

- Insufficient waterproofing, which causes moisture to seep into the blind area.

Almost all of the above errors require significant costs, because to correct them you need to remove the blind area and carry out the work again.

Insulation

No less important issue than waterproofing in arranging a blind area is insulation. Thanks to insulation, the basement and basement can retain heat and also extend the service life of the structure. Several materials allow you to insulate the blind area:

- Expanded polystyrene. It is characterized by high strength and durability, and has hydrophobic properties. Easy to install thanks to its light weight. Laying can be done in just one layer of material 10 cm thick. Sealing of the joints of the material can be achieved by sealing them with a special film that has water-repellent properties.

- Polyurethane foam. An environmentally friendly material that can withstand frosts down to -60°C without changing its thermal insulation characteristics.

- Styrofoam. The foam structure of this lightweight material provides good heat and sound insulation properties. It has low hygroscopicity and good waterproofing properties. Resistant to temperature changes and fungi.

Video description

About the differences between tiles and paving stones, watch this video:

There are three options: concrete, clinker and natural stone.

Concrete paving slabs

In turn, concrete paving slabs can be made in two ways: casting and pressing. Although in both cases vibration is used to compact the mixture.

The “classics” of concrete paving tiles are still relevant Source vip.picsyou.ru

Vibro-cast tiles are made using classical technology (except for dyes and special additives that accelerate the maturation of concrete stone). This is an ordinary “liquid” cement-sand mixture with high mobility and plasticity of the solution. Thanks to this, the mixture can easily take any shape and be painted, and the surface of the tile is bright and smooth. From a decorative point of view, this is the most attractive material for paving, if not for its low strength. It would seem that this property is not the most important for a blind area (it is rarely walked on), but one must take into account the precipitation flowing from the roof. If the roof does not have an organized drainage system, the paving slab blind area will quickly collapse.

Concrete paving stones can be the main element of landscape design Source kamtehnopark.ru

Adviсe

Advice from the experts will help you make the blind area correctly:

- Waterproofing the foundation must be done immediately after its construction.

- The blind area around the entire perimeter of the house must be done with a slope of at least 3%. At the same time, you must try to make it the same everywhere. The construction level will be an assistant in this.

- When preparing a concrete solution, you must prevent clay from getting into it.

- For insulation, you need to choose durable materials that are resistant to deformation, so that under the weight of the blind area they do not change shape or crack.

- The blind area is a structure that requires maintenance and periodic repairs. This can be done using different sealants and mastics. They treat the damaged surface to prevent further destruction of the structure. If there are deep cracks and chips, they are jointed, that is, expanded, and then filled with concrete. The repaired screed is covered with film and watered once a day to prevent it from drying out quickly.

- The top layer of the blind area is both decorative and protective. You can make a covering of concrete, decorative tiles, or simply cover it with a layer of colored crushed stone. After filling the top layer with soil, you can arrange a lawn around the house or plant flowers.

- It is recommended to use natural crushed stone rather than scrap as a filler for a concrete base, since it tends to contract and expand with temperature changes.

- It is better to choose solutions that are made on the basis of cements with waterproofing additives.

- An important role in ensuring the drainage of water from the foundation of a house is played by the installation of drains from the roof. The blind area should extend beyond the roof eaves line by at least 20 cm.

Is it necessary and why?

The main function of waterproofing is to protect the building from destruction under the influence of moisture.

In addition, she:

- prevents soil erosion;

- protects the foundation from vegetation roots;

- improves the thermal insulation qualities of the building;

- prevents water from penetrating the basement of the building;

- perform a decorative function.

To ensure maximum protection, waterproofing should be laid along the entire perimeter of the blind area, without gaps. If this is not done, the foundation will gradually begin to collapse.

DIY making

You can also make paving slabs yourself to reduce construction costs . The simplest, casting method is carried out as follows.

Molds are made (wooden or metal) that exactly follow the shape of the tile. A solution is poured into them, pre-mixed thoroughly, with a fairly thick consistency. Drying is ensured within 60-70 hours.

Then, the mold with the contents is immersed in heated water for about 30-40 s, which makes it possible to easily remove the workpiece. The tile is placed on a flat, horizontal surface and aged for 23-25 days.

Recommended solution composition:

- cement grade not lower than M400 (20%);

- sifted river sand (55%);

- crushed stone fraction 6-10 mm (22%);

- fiber fiber (4% by weight);

- plasticizer (0.5% by weight);

- dye for concrete (up to 7%).

The water is cleared of all impurities and amounts to 6-7%. For 1 m3 of mixture, 135 liters of water are recommended.

The highest quality and most durable tiles are obtained using the vibration method. However, this requires special equipment. The molds are installed on a vibrating table, which ensures the necessary compaction of the mixture.

Reinforcement of a concrete pad

The concrete base around the building is reinforced with a flat steel mesh with a cell size of 15x15 or 20x20 cm from reinforcement with a diameter of 6-8 mm. The pieces of mesh are laid sequentially in a row with an overlap on each other in 2 cells, fastening the overlaps with knitting wire with your own hands. The plane of the installed reinforcing mesh should be positioned so that after laying the concrete it is under a layer of mortar of at least 3-4 centimeters. The mesh should also not have stressed areas, which, after pouring concrete, will bend outward from it.

Especially on heaving soils: a special cushion and reinforcement are required

Necessary tool

To do the work yourself you will need the following tool:

- shovel and hand tamper for preparing the trench;

- knife and scissors for laying layers;

- a trowel, usually a trowel, for preparing the base for tiles;

- a mallet and rubber hammer for laying tiles, a grinder or a special guillotine for cutting them;

- building level, tape measure, metal ruler, square for measurements and control.

When making the tiles yourself, you will need special equipment, tools and accessories.