The installation of a vapor barrier is an important stage in construction necessary to protect against the effects of water vapor on the insulation. The absence of such a layer during sudden temperature changes contributes to the deterioration of the characteristics of most building materials and a reduction in their service life. Moisture ingress also causes mold to appear on them.

Vapor barrier is installed using a variety of materials both from the outside and from the inside of the house. During installation, compliance with technology is required, as well as rules on which the quality of the finished work directly depends.

The principle of operation of vapor barrier in general

The main task is to create an obstacle to the permeability of vapors. Thanks to this property, the walls are protected from destruction from accumulated moisture (condensation). But the very definition of “vapor barrier” does not mean that the film creates a barrier and completely interferes with the circulation of steam. Modern materials are aimed at providing a slight air flow to eliminate the greenhouse effect in the house itself.

Content

Most modern standard thermal insulation mineral wool materials are capable of fully protecting housing only in a dry state. Therefore, it becomes important to take into account the dew point, and, if necessary, provide additional vapor barrier for the room. The dew point is the point where warm and cold air touch and the result is condensation of water vapor. If condensation occurs inside the insulation, its characteristics will be significantly deteriorated, even to the point of destruction of the material. Therefore, let's take a closer look at how to avoid this, what a vapor barrier is, why it is needed and how to install it.

Where vapor barrier is needed

There is a category of premises where installing a vapor barrier is a mandatory measure. Such cases include the following:

- Premises with high temperatures and high air humidity, in particular baths and basements;

- The use of materials that become wet due to high humidity and lose all the characteristics declared by the manufacturer, deteriorating over time, for example, glass wool and mineral wool;

- In the construction of multilayer walls of frame houses, since condensation is likely to occur between the layers;

- When installing ventilated facades, in this option the vapor barrier makes the air flow weaker, protecting the insulation from excessive load, for example, a brick wall with cotton insulation and sheathed with siding.

Comparison of vapor barrier materials

Let's consider the main operational characteristics of some types of vapor and waterproofing from different manufacturers:

| Name of product | Water vapor flow density, not less | Water resistance, no less | Vapor permeability, g/m2 (24 hours) | Breaking load (front/top) not less | Temperature range of application, ºС | Resistance to UV irradiation, months. |

| Turboizol A | 2,000 g/m² *24 h | 300 mm water. Art. | more than 1,000 | 100 N/70 N | –40 … +80 | 1 |

| Ondutis R 70 Smart | 1,000 g/m² *24 h | more than 1,000 | less than 10 | 150 N/130 N | –40 … +120 | 1,5 |

| FASBOND membrane | — | more than 250 | not less than 3,500 | 38 N/19 N | –60 …+80 | 3-4 |

| Tyvek Solid | — | 2 000 | more than 1,300 | 250 N/210 N | –73 … +100 | 4 |

| D-Folie A 100 | — | not less than 1,000 | 3 500 | 185 N/85 N | –40 …+80 | 3 |

If you have any questions regarding the wind, moisture and vapor barrier materials presented in our catalog, please call +7

, and managers will help you choose the option that best suits you.

Polyethylene

Traditionally available material with a thickness of only 1 mm. It should be fastened with concentration and care to prevent excessive tension, which could damage the film due to temperature changes.

There are several types of film protection:

- Perforated with small vapor-permeable holes;

- Non-perforated.

In the absence of perforation, along with steam, the flow of air is also limited, which affects the acceptable microclimate in the room. Polyethylene is practically not used at present, as there are more modern materials.

Membrane films

The base of the vapor barrier membrane is polypropylene, with fiberglass mesh. The rough surface of the film creates a barrier that does not allow moisture to pass into both the wall and the insulation.

Due to the fact that the membrane is multi-layered, it stops not only the permeability of moisture, but also allows a small amount of air to pass inside.

Advantages:

- Can be used for wooden and frame houses;

- No need to create an air gap;

- Easy installation;

- Strength;

- Resistance to an increase in the number of mold microorganisms on the surface of the walls;

- Resistance to putrefactive processes;

- The material is harmless to humans;

- Extended service life - the film retains the original properties declared by the manufacturers for 50 years;

- Large temperature coverage during operation (from -60 to +80 °C);

- The presence of types of membranes reinforced with a layer of foil, which will reflect the heat coming from the house.

Advantages and disadvantages

Today there are a huge number of varieties of vapor barrier membranes and films. Of course, some have more advantages, others less. However, there are advantages inherent in absolutely every type.

For example, all modern films and membranes are known:

- safety and environmental friendliness;

- functionality and practicality;

- resistance to the harmful effects of climatic factors;

- resisting the destructive effects of chemical influences;

- resistance to the harmful effects of reasonable mechanical actions;

- invulnerability to the negative influence of biological factors;

- simple installation.

The disadvantage is the fear of fire, that is, the material burns.

Thus, dear friends, vapor barrier can solve a number of problems associated with the construction of a particular object, regardless of its properties and purpose.

How to install a vapor barrier on a wall

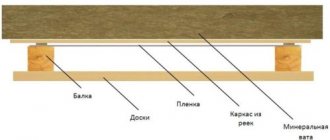

This type of installation is often used if mineral materials are used as thermal insulation. As a result, a multilayer structure appears, consisting of such layers as:

- External cladding;

- Windproofing;

- Insulation;

- Frame;

- Vapor barrier;

- Interior decoration.

Attention! It is strictly forbidden to attach a vapor barrier to both sides of the insulation at once - this leads to the formation of condensation due to a violation of the natural insulation.

The correct order guarantees a long service life of the insulation and the house as a whole. The process consists of several stages:

- Installing the film and securing it to the sheathing;

- Sizing of formed cracks, overlaps and puncture sites;

- Installation of sheathing using beams to provide ventilation;

- Sheathing with finishing materials, such as plasterboard or panels.

Which side to attach the vapor barrier to the insulation

If both surfaces of the material are the same, then it does not matter which side to attach the vapor barrier material - this will not affect the protective function. If one of them is rough, then it should be the one that “faces” the house; thanks to such a surface, droplets of condensation are retained.

The foil membrane fixes the shiny surface inside the room - this helps retain heat in the room.

Film materials - smooth side to the insulation.

Briefly about the main thing

The vapor barrier film is designed to form a monolithic barrier that will prevent the passage of vapors into the protected insulation or structure.

The main materials for the production of canvases are polyethylene (budget options) or polypropylene.

Materials are distinguished according to various criteria: the number and purpose of layers, functions performed, degree of solidity and smoothness.

Laying of the canvases is carried out on the sheathing, maintaining a ventilation gap to remove moisture.

The solidity of the heat-protective layer is ensured by overlapping the edges by 100-15 mm and sealing all junctions and seams.

Ratings 0

How is vapor barrier attached?

Fixation is done in several ways:

- Nails with wide heads;

- Construction stapler;

- A lathing of wooden sticks at a certain distance.

Preparatory work

Before installing the insulating layer, you should select a material taking into account the characteristics of its installation process. For example, when working in a wooden house, all materials must undergo protective treatment with antiseptic agents and fire retardants.

Before attaching the vapor barrier to the insulation layer of the internal walls, dismantling work should be carried out to clean the surfaces from the remnants of previous finishing materials. Cleaned natural wood surfaces are treated with compounds to prevent burning and rotting. Concrete or block buildings should also be treated with a deep penetration antiseptic compound.

When insulating brick walls from the outside, it is recommended to carefully eliminate all cracks and cracks. And after this, treat the surfaces with an antiseptic solution. Only on completely cleaned surfaces can leveling mixtures be applied and a vapor barrier coating system installed.

Ceiling vapor barrier

For the ceiling, you can also use materials with foil surfaces. They are laid with the heat-reflecting side inside the room for better heat retention. Fastenings are made using nails with wide heads, and the joints are additionally insulated with tape.

It is necessary to lay a layer of vapor barrier on the ceiling on laid layers or rolls of insulation, previously laid in the spaces between the joists and rafters. If the thickness of such insulation is equal to the height of the logs, it may be necessary to install a slatted counter-lattice to maintain a constant level of ventilation. In this case, you need to fasten it correctly: with a slight overlap on the walls around the perimeter. Particular attention should be paid to the corners: we fix the film with an overlap and tightly.

Roof vapor barrier

It is better to choose a membrane film for the roof. How to properly install such a vapor barrier? Place the smooth side on the insulation. To prevent steam particles from penetrating through the mounting holes, it is recommended to fasten the insulation directly to the wooden beams with a staple gun. This ensures the tightest possible fit. Therefore, perforated films are not used for vapor barrier of roofs and ceilings.

There are films with an anti-condensation coating that are placed under materials susceptible to rust (galvanized steel, corrugated sheets or metal tiles). This film can protect metal surfaces from moisture droplets. Such materials are laid with the fabric side down at a short distance from the layer of mineral wool or any other insulation. It is possible to lay two layers of film with anti-condensation treatment.

External vapor barrier of the walls of the house is necessary to combat atmospheric moisture, which can destroy the insulating material. It is important to make a double vapor barrier layer of insulation. This will cover all the joints of the sheets and provide more reliable protection from steam and unnecessary moisture.

Vapor barrier of frame structures

A layer of vapor barrier in a frame house may not be needed. This happens when using such insulation - ecowool, polyurethane foam, polystyrene foam, and provided that an effective ventilation system is created.

If the need for installation does arise, then one of the two schemes given below is used. It is chosen based on the expected intensity of use of the premises in a certain season:

1 scheme:

- The vapor barrier is attached to the frame posts;

- The walls are covered with clapboard, plasterboard or other interior finishing materials.

This method is used in buildings for the warm season, without being in them during the cold season. For example, a dacha, a workshop, a summer guest house.

2 scheme:

- Installation of horizontal or vertical sheathing located 30-50 mm from the wall to create an air gap;

- Fastening the membrane under the sheathing side exclusively indoors when using a construction stapler;

- Taping the joints with construction tape.

The scope of application of this method is for buildings with active use in the winter season.

Classification of vapor barrier materials by purpose

The vapor barrier device determines its use. There are certain differences in vapor barrier designs used on the walls, floors, ceilings or roofs of buildings.

Roofing membranes

The main requirements that membranes of this group must meet are: high resistance to UV radiation, sudden temperature changes and significant mechanical strength.

According to their design, they are divided into:

- two-layer film membranes

are cheaper than three-layer ones (there is no one protective layer). Reliability is lower, so the coating will not protect against mechanical damage; - superdiffusion three-layer

– made of several layers, each of which solves its own problem. They do not have holes, which allows them to be used in areas with heavy dust without reducing vapor permeability. They have significant wind protection; - porous

- have interfiber pores for the passage of water vapor. Vapor permeability is determined by the degree of hydrophilicity of the walls of the existing pores and their size. Not recommended for use in areas with significant dust; - perforated

- otherwise called combined fabric or reinforced film. They have punctured holes to allow water vapor to pass through. They are characterized by low vapor permeability. Designed for use on cold-type sloping roofs as under-roof waterproofing.

The film is laid on supporting structures with an overlap (very rarely end-to-end). The seams are connected with adhesive tape. Fastened with a construction stapler, self-tapping screws, dowels or nails. In case of damage to roofing materials, it plays the role of a backup roof.

Ceiling vapor barrier

A very important material for work in unheated attic spaces under a pitched roof. It must be securely separated from the heated part of the house.

The film from below is attached to the floor beams, secured with elements of the rough (optionally, the frame of the finished) ceiling with the formation of a ventilation gap (between the vapor barrier and the finished ceiling). This will prevent moisture from entering the room.

The film is laid between the facing material or insulation.

Wall vapor barrier

Due to the large area of these enclosing structures, the issue of preserving their thermal properties is very relevant. One solution is to lay a vapor barrier, which is installed at the beginning of the renovation work. The optimal type of vapor barrier film for walls is a combined version (universal film). One side is made of polypropylene (for better absorption of moisture vapor), the second side is coated with metallized foil, which reflects thermal energy into the room.

It is possible to use membrane films with low external vapor permeability.

Floor vapor barrier

The optimal solution is to use PE films (without perforation), as well as grades with an aluminum layer. Placed under the frame. The smooth side should be facing the insulation.

Vapor barrier in wooden houses

Wood is a material that requires mandatory vapor protection due to the passage of air and the absorption of excess moisture, which causes its swelling.

Since logs shrink during the first 5 years, when installing a vapor barrier, you must adhere to the following rules:

- Before using laminated veneer lumber, it must be dried as best as possible;

- There should be grooves on the timber so that over time, during drying, the material becomes compacted to minimize the formation of steam.

If shrinkage has occurred for less than 5 years, then membranes of the type “Izospan B”, “Izospan FB”, “Izospan FS” are used.

Vapor barrier installation on the outside of a wooden house

The sequence is:

- The vapor barrier layer is laid directly on the wall;

- A sheathing made of beams or metal profiles is installed;

- Thermal insulation material is placed in the cells of the sheathing;

- Finishing in the form of siding and other types of materials.

This method is suitable for rectangular timber.

Vapor barrier device inside a wooden house

The method of installing a vapor barrier from the inside of a room is suitable for preserving the appearance of a wooden house. Produced in the following sequence:

- Insulation is laid between the wooden beams;

- The vapor barrier film is attached to the sheathing using a special stapler;

- After fastening, seal the membrane joints with mounting tape;

- The interior decoration of the room is installed on the vapor barrier layer.

This technology is used when using cylindrical timber.

General rules for installing a vapor barrier film for a wooden house:

The film is stretched tightly without sagging, overlapping by about 10 cm. To connect them together, adhesive tapes are used.

Adhesive tapes

For the convenience of laying any vapor barrier materials and protecting joints from moisture penetration, construction experts recommend using adhesive tapes. Tapes are used to glue horizontal and vertical overlaps and are used to connect vapor barrier materials to adjacent structural elements, as well as to connect vapor barrier materials to each other. To install vapor barriers, it is recommended to use Izospan adhesive tapes of several types: Izospan KL, Izospan KL+ and Izospan ML proff.

Izospan KL is a double-sided adhesive tape with a spunbond base. A water-dispersed polymer is used as a double-sided adhesive layer without the use of any solvents. The service life of the product is 50 years. Recommended for gluing overlapping sheets of type A.

In addition to Izospan KL, its analogue from another manufacturer is offered - Izobond SL.

Izospan KL+ is a special adhesive tape made on the basis of non-woven material with a double-sided reinforced adhesive base applied. For strength, the base is reinforced with reinforcement. Izospan KL+ is used for gluing individual sheets of vapor barrier membranes to create a reliable vapor barrier on the surface. It has excellent vapor barrier properties and high temperature endurance in the range from -40 to +100 degrees. Excellent for joining polyethylene and polypropylene films, as well as heteroporous, uneven and dissimilar materials. Recommended for gluing overlapping sheets of any type: A, AM, B, C, D.

Izospan ML proff is an adhesive single-sided tape made on the basis of artificial silk using special mesh reinforcing fibers to enhance the basic technical characteristics. Thanks to this, this tape is ideal for gluing the junctions of vapor barriers to all types of surfaces, including concrete, gypsum and plaster, as well as at the junctions of pipes, window openings, plinths, or in places where additional vapor barrier is required. It exhibits all its properties perfectly in the temperature range from -40 to +100 degrees. Can be used for both interior and exterior work.