Materials used in the construction of roofs and arrangement of premises with non-standard temperature and humidity operating conditions are endowed by manufacturers with special properties. They not only easily resist the attacks of steam-saturated hot air, but also create a “thermos” effect, due to which energy consumption for heating is greatly reduced.

These specific products include foil vapor barrier, the installation of which allows you to solve a lot of important problems in the construction of building structures.

Principle of operation

Foil materials are a complex product with a layered structure. The base here is polypropylene fabric, fiberglass, and lavsan. These are components that are resistant to explosive effects, biological and chemical aggression.

The use of a durable non-woven or woven polymer base allows you to create a reliable base for metal foil, which itself cannot boast of particular strength. At the same time, flexibility convenient for installation is maintained. This composition eliminates the possibility of fungal colonies settling and rotting.

Vapor barrier materials on the working side are backed with metallized film. The positive qualities of both aluminum foil and the polymer base are preserved. Vapor barrier with foil copes with three tasks at once:

- Insulation from precipitation and steam. The foil material protects the wall insulation system or roofing pie from steam penetration.

- Reflection of thermal radiation. The metal coating serves as a kind of reflector; it interrupts the flow of heat waves, redirecting the stopped heat within the house.

- Protection from ultraviolet rays and wind. Vapor barrier films are a durable barrier against wind. In the summer, they are able to reflect the sun's rays from the roof if they are installed with the working side facing outwards.

Foil functionality

The foil material has unique properties that set foil apart from other vapor barriers for baths. The material perfectly reflects heat, keeping gases and vapors indoors. This function promotes quick and high-quality heating of the room. In addition, this layer on the walls will prevent the appearance of mold, mildew and pathogenic microorganisms. And the appearance of the walls will become more attractive. It turns out that foil in a bathhouse is not just a whim, but a necessity that will help improve the functioning of the bathhouse.

The most effective way to use foil

Foil vapor barrier for a bathhouse is a necessity, which is the basis for normal heating of the air in the room. By taking into account the features, the effectiveness of this coating can be increased. Foil can be used as an independent layer, but it is better to place it in an insulating “pie” of several parts. This creates a “thermos” effect.

Attention! If aluminum foil is laid on the walls in 1 layer, then the thermal conductivity will be slightly lower. However, there are a lot of other advantages: protection from fire (fire resistance), decorative finishing of the rough surface, protection from moisture and destruction of the walls of the bathhouse.

Methods of application

The structure of foil vapor barrier materials has significantly expanded the scope of application. Now they are actively used in insulated roofs , they are often placed on the inside of the roof pie, and in the south they are usually mounted above the insulation. If the house has an unfurnished attic, then foil protection is installed along with waterproofing.

They are often used as a substrate for floor coverings and underfloor heating systems, and for insulating frame wall structures. A foil vapor barrier is also installed in the form of a screen that reflects heat flows from any heating units.

The system must be installed correctly so that the foil materials can perform their reflex function. Between the ceiling of the steam room, the walls, the inner lining of the attic and the metal covering, you should always leave a non-ventilated air gap, the thickness of which should not be less than 2 cm.

If the material is used as a heat-reflecting screen for an attic or flat roof, then a ventilated gap of 3 cm is left . Here, everything that is reflected from the foil can easily be discharged onto the street along with the penetrated steam and condensate.

The necessary gaps are formed by installing a sheathing made of a metal profile or bar. The laths are installed taking into account the type of roofing, the calculated load on the structure, and the slope of the slopes is also taken into account.

Recommendations for use

If the walls are frozen, this will worsen the microclimate. As for a wooden house made of timber or logs, foil vapor barrier is ideal for internal insulation. It can also be used for unheated loggias, laying it under the finishing floor covering to make it warmer. When glazing open balconies, when the perimeter is supposed to be finished with sandwich panels that do not emit heat, foil vapor barrier allows you to reduce heating costs.

Benefits of use

Insulating materials, where water-repellent material is combined with foil, have many advantages, which is why they are in high demand among craftsmen. These include:

- Minimum thickness. Laying does not affect the thickness of the roof pie. If materials with anti-condensation properties are used, then it is not necessary to install a distance gap.

- Lightness. This installation will not affect the weight of the structure. Therefore, there will be no need to carry out additional actions to strengthen the foundation.

- Flexibility. Installation is easy, even if you have to lay the material on complex forms. You can easily go around concave and convex corners, various rounded surfaces.

- Environmental Safety. Vapor barrier films are made from materials that are not harmful to human health or the environment.

- Manufacturability. The sheets are easy to cut with regular scissors, or you can use a construction knife.

- Zero porosity. Vapor barrier does not absorb moisture. Long-term use, even in a damp room, will not cause the foil to rot.

- Multifunctionality. The same film can be used to protect several adjacent structures, creating a continuous sealed barrier.

Additional nuances

It is worth considering additional nuances that relate to arranging a bathhouse with a vapor barrier. If the room is made of thick timber, then it is not necessary to cover all surfaces of the walls and ceiling with foil - the room will already be warm enough. If desired, the part of the surfaces where the boiler or heating stove is located is finished.

Aerated concrete and brick-concrete structures require complete finishing, since poorly planned vapor barrier of the room leads to slow but inevitable destruction of the walls. In this case, the stone base will not cool down so quickly.

If you make such a layer in the steam room of a bath, you can save fuel (up to 25-30%) and ensure a longer period of operation of the room. You should not save on the construction of such a specific building. Laying a vapor barrier layer is necessary to ensure the normal functioning of the bathhouse at any time.

Laying foil material on the walls of the bathhouse is a mandatory step in the process of finishing the walls. Initially, you need to choose the type of vapor barrier material suitable for the type of walls. Next, you should properly prepare the wall, and then secure the strips in frames made of bars. Installation is usually carried out without any problems and does not take much time. Thanks to this layer, you can avoid many troubles regarding heat conservation, high fuel consumption and damage to the integrity of surfaces.

Installation technology

Most often, vapor barrier materials with foil are used to equip a cold attic and a warm attic. In the first case, the insulation system must be installed along the ceiling, in the second - along the slopes.

To install a vapor barrier correctly , you need to adhere to generally accepted construction rules:

- The vapor barrier of the slopes should be a continuous barrier that prevents the penetration of moisture. To do this, the canvases need to be sealed together with regular tape.

- Strips of vapor barrier material are usually laid strictly horizontally. The first panel is fixed at the ridge girder, the second is placed on top to cover the edge of the installed panel on the side of the room that is being finished.

- The canvas spreads from the attic side onto the wooden floor in strips, extending onto the walls along with vertical ceilings of 20 cm each. It turns out to be a kind of pallet with sides.

- Then the material is rolled out as if the roll was formed by the manufacturer himself. The installation side is indicated on the vapor barrier - it cannot be changed at your discretion.

- On pitched roofs, the material is stapled to the rafters from the inside. If they are fixed with a block, then a counter-lattice must be placed on top under further cladding.

- If you need to put a vapor barrier in a system with open rafters, then it is placed along the outer ribs, then rigid slab insulation is installed. The fabric is secured with a stapler.

- If you are installing a ceiling on the ceiling side, then you need to buy self-adhesive materials.

It is worth noting that accessories for foil insulation must be selected from the same manufacturer as the material. Of course, you can find universal tape on sale that is suitable for joining materials of any kind, but in the case of foil structures, you need to remember about tightness. Therefore, here it is better not to experiment with options for adhesive tape for gluing, but to take it from the same company that produces the foil sheets themselves.

How to protect the ceiling - preparing a “pie”

It is much more difficult to protect the ceiling in a bathhouse, this is due to the fact that hot air vapors rise primarily vertically. So he takes the brunt of the blow. Vapor barrier for a bath can be complex, that is, it includes the use of several materials. This is especially recommended for the ceiling.

A special liquid mixture is prepared, consisting of the same volume of clay, sand and sawdust

Another interesting method is to create a so-called “pie” from various materials, for example, clay, sawdust, etc. This method can be called, to some extent, old-fashioned, but professionals advise paying attention to it. After all, this will allow you to be almost 100% confident in the reliability of the protected structure. This isolation is performed as follows:

- 1. Fiberglass fabric is laid on the rough surface of the ceiling.

- 2. A special liquid mixture is prepared, consisting of the same volume of clay, sand and sawdust.

- 3. The resulting mixture is poured over the fiberglass.

- 4. The last layer is a mixture of vermiculite (three shares) and liquid clay (one share).

All that remains is to wait some time (up to 14 days in summer, up to two months in cold weather) before the resulting “pie” dries completely.

Foil film is a universal polymer material. Used for vapor barrier purposes in industrial and civil construction. For advice, please contact the company. The building material can be presented in different designs, colors and shades, with a holographic coating.

What is foil film used for?

The material is necessary for thermal insulation in cases of large temperature differences between the outside and inside of objects. Suitable for vapor barrier of all surfaces, reliably retains moisture.

The foil vapor barrier film has an auxiliary layer that does not allow condensation to penetrate into the layers of insulation and protects it. High-quality film reduces heat loss and enhances the insulation effect on the construction site. The material helps direct thermal energy to the right place.

Related products for fastening: adhesive tape with a metal element; you can install the film on wood with a construction stapler, on concrete - with mounting tape.

Types of material

Typically, foil insulation film is supplied in the form of rolls or layers of different sizes and densities. The composition includes a base and a reflective layer of film. In various modifications there may be several layers.

Foil film is divided into three types:

- With aluminum coating;

- With a layer of foil;

- With aluminum foil.

The composition of the material is:

- Foam polyethylene, universal insulator (foil can be on one or both sides);

- Foiled polystyrene foam insulation;

- Foil foam insulation;

- With basalt wool;

- Foil insulation with a self-adhesive surface.

Material properties

The texture of the material is continuous and smooth, and during work it guarantees the absence of unevenness, seams, and cracks. Foil vapor barrier film is suitable for finishing houses, baths, gazebos, for heated floors, walls, ventilation systems, roofs, refrigerators. The film can be given any shape, since it contains a flexible, durable structure plus aluminum foil-type coating.

Advantageous qualities of foil film:

- Easily attached to the wall or other surfaces, easy to install;

- Withstands temperatures from -40°C to +100°C;

- Made from environmentally friendly material, it has no harmful effects on the human body at any temperature;

- Not susceptible to mold, repels moisture;

- Has a long service life;

- Can be used in high humidity conditions;

- Resistant to mechanical stress;

- Protects against radiation;

- In addition to all this, it also has soundproofing qualities.

Price

The price of foil film depends on the thickness of the film and the internal filler. Consult a specialist!

Cost of foil insulation

- Thickness 3 mm - from 50 rub. up to 120 rub. per m2;

- Thickness 10 mm - from 110 rub. up to 145 rub. per m2

You can buy foil film from us! offers materials of proven quality at competitive prices.

Materials used in the construction of roofs and arrangement of premises with non-standard temperature and humidity operating conditions are endowed by manufacturers with special properties. They not only easily resist the attacks of steam-saturated hot air, but also create a “thermos” effect, due to which energy consumption for heating is greatly reduced.

These specific products include foil vapor barrier, the installation of which allows you to solve a lot of important problems in the construction of building structures.

Foil materials used in vapor barrier devices are complex products with a layered structure. Their base is made of polypropylene fabric, lavsan, fiberglass and similar options that are resistant to tearing, as well as chemical and biological aggression.

The use of a durable woven or non-woven polymer base allows you to create a reliable base for the naturally fragile metal foil. At the same time, it was possible to provide easy-to-install flexibility. The composition of the thermoplastics used in the manufacture eliminates the possibility of decay and the spread of fungal colonies.

On the working side, vapor barrier materials of this category are backed with a metallized film. Thanks to the method of applying the foil coating, all the positive qualities of both the polymer base and aluminum foil are preserved, which copes “excellently” with three very significant functions, these are:

- Insulation from steam and precipitation. Foil materials ideally protect the insulation of a roofing pie or wall insulation system from the penetration of steam coming from inside the house being furnished, and from atmospheric water tending to penetrate from the outside.

- Reflection of thermal radiation. The metallized coating serves as a reflector, interrupting the flow of heat waves outside the heated room and redirecting the stopped heat in the opposite direction.

- Wind and UV protection. Vapor barrier films with foil act as a strong barrier against wind, tending to remove heat from the cotton insulation. Installed with the working side facing outwards, they reflect the sun's rays from the attic roof in the summer heat.

Using a vapor barrier with foil allows you to significantly save on heating bills and turn on the air conditioner less often.

Scope and methods of application

The structure and properties of foil vapor barrier materials have significantly expanded the scope of application. These materials are used in insulated roofs, in our latitudes they are most often installed on the inside of the roofing pie, in the south they are mounted above the insulation. In houses with an unfurnished attic, foil protection is installed in combination with waterproofing.

In addition to the traditional purpose of protecting ceilings and residential attic spaces from vapor, they are used as a substrate for all types of floor coverings and underfloor heating systems, as well as in insulated frame wall structures. They are installed in the form of a screen that reflects heat flows from heating devices and heating units.

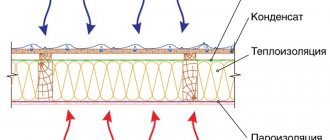

In order for foil materials to perform a reflex function, it is important to properly arrange the system. A non-ventilated air gap 2–3 cm thick should be formed between the inner lining of the attic, the walls, the ceiling of the steam room and the metalized coating.

When using a flat or mansard roof as a heat-reflecting screen, a standard ventilated gap of 3–4 cm is left between the metalized coating turned outward and the roof. The goal here is not to conserve thermal energy. Everything that is reflected from the foil can be freely released into the atmosphere along with condensate and steam that has penetrated into the thermal insulation.

The gaps necessary to ensure ventilation and to maintain a distance between roofing materials of different compositions are formed by installing lathing from a bar or metal profile. Laths are installed in accordance with the type of roofing, the slope of the slopes and the calculated load on the rafter structure.

Benefits of Using Foil Insulation

The undeniable insulation priorities of materials in which water-repellent material is combined with foil are complemented by an impressive list of convincing advantages, these are:

- Lightness. The installation of a vapor barrier does not in any way affect the weight of the structure as a whole and does not force measures to be taken to strengthen the foundation.

- Minimum thickness. Laying a vapor barrier layer does not affect the thickness of the roofing pie at all. When using materials with anti-condensation properties, there is no need to create a distance gap between the vapor barrier and the sheathing.

- Flexibility. The installation of a vapor barrier is easy; there are no problems even when laying it on complex forms. It bends around convex and concave corners and rounded surfaces without any problems.

- Manufacturability. Rolled materials can be easily cut with ordinary sharp scissors or a construction knife.

- Environmental Safety. In the production of vapor barrier films, raw materials are used that do not pose a threat to the environment and the owners of the structures being developed.

Produced in a wide range of vapor barrier options with foil, they do not absorb moisture at all and are characterized by zero porosity. Their long-term operation in damp rooms does not threaten the materials with rotting. An important advantage is its multifunctionality, thanks to which the same film can protect several adjacent structures, creating a continuous sealed barrier.

Foil protection installation technology

Let's look at the most common technological options for using vapor barrier materials with foil. In the format of our website, the situations under consideration include the arrangement of a warm attic and a cold attic. In the first case, the insulation system is installed along the slopes, in the second - along the ceiling.

Since the main purpose of vapor barrier films is to protect the insulation, their place in the system is determined by the position of this particular component of the roofing pie. Those. in attic structures, vapor barrier is installed along the slopes; in houses with a cold attic, it is laid on the attic floor from above or attached from below under the ceiling sheathing.

To properly install a vapor barrier, you should adhere to generally accepted rules:

- The vapor barrier of the slopes should be a continuous moisture-proof carpet that absolutely excludes the penetration of moisture or eliminates the possibility to the maximum extent. For this purpose, the panels of rolled material are hermetically connected with tape.

- Strips of vapor barrier material are laid strictly horizontally. The starting strip is attached to the ridge girder, the next one is placed on it so that the edge of the lower strip overlaps the edge of the already installed strip on the side of the room being finished.

- Vapor barrier material is laid on the wooden floor from the attic side in strips extending onto the walls and vertical coverings by 15 - 20 cm. The result should be something like a pallet with sides.

- The material is rolled out onto the surface to be constructed in the same way as the roll was formed by the manufacturer. The installation side must be indicated on the vapor barrier; it cannot be changed at your own discretion.

- Fastening the material on pitched roofs is done from the inside of the rafters using a stapler, and if necessary, with slats. If fixation involves the use of a block, then a counter-lattice under the sheathing is installed on top of it.

- In systems with open rafters, a vapor barrier is placed along the outer ribs of the rafter legs, then rigid slab insulation is installed. The material is fixed with a stapler.

- In insulation schemes with extruded polystyrene foam when arranging living rooms with traditional operating conditions, i.e. without vaporization and exposure to high temperatures, it is permissible not to use a vapor barrier layer.

To arrange the ceiling from the ceiling side, it is advisable to select self-adhesive materials. In thermal insulation systems for attic floors with backfill insulation, for example, with expanded clay, it is permissible not to glue the vapor barrier strips with tape, because they will be loaded.

When arranging the attic floors of houses with cold attics, a vapor barrier carpet is built over the floor, and waterproofing is placed on the roof slopes. In this scheme, the insulation is washed by air currents created by natural ventilation, therefore any insulating layer above it will only interfere with the removal of moisture.

And further. When using foil insulation, it is important to select accessories from the same company as the material itself. There are, of course, universal adhesive tapes that can connect any type of material, but... systems with increased requirements for tightness are constructed from insulation with foil, it is better not to experiment with options for gluing tapes.

Leading foil products

To install a ceiling or attic, you need to select a suitable and reliable vapor barrier film. Therefore, you should first find out what proven and popular product options are available on the construction markets.

Energy saving film DELTA®-REFLEX

These products have proven themselves well in roof construction and have an impeccable reputation among roofers. The reflective coating on the working side is created by spraying. Then a polyester film is applied over it, which protects the aluminum layer from shedding and damage. The reflection coefficient of this product is about 50%.

At sub-zero temperatures , the film does not lose its flexibility; it is used to provide protection against steam from inside and outside the house. Can be used in different rooms with high humidity. If you find a version of a similar film, but where the word PLUS is added to the marking, then there will be a self-adhesive tape along the edge of such films - it makes the work of installers much easier, which is why it is what is most often purchased, despite the high cost of the product.

Reflective material “Izospan FD”

In terms of price, this is a more humane option, but it is also less resistant to the realities of adversity. This is a two-layer composition made of polypropylene fabric, with an aluminum coating applied on top.

In terms of strength indicators, it is inferior to the first option, but is able to outperform in terms of energy-saving characteristics: the coefficient of thermal reflection is about 90% . It usually attracts installers with its affordable price; in addition, these products are easy to find in many hardware stores. It is worth noting that in the technical data sheet of the film, a separate line indicates the temperature range, which ranges from -60 to +80 degrees.

Foil vapor barrier: scope of application and installation technology

Materials used in the construction of roofs and arrangement of premises with non-standard temperature and humidity operating conditions are endowed by manufacturers with special properties.

They not only easily resist the attacks of steam-saturated hot air, but also create a “thermos” effect, due to which energy consumption for heating is greatly reduced. These specific products include foil vapor barrier, the installation of which allows you to solve a lot of important problems in the construction of building structures.

Specifics of foil vapor barrier: characteristics, conditions of use, installation

To create a fully functional vapor barrier in rooms with unstable temperature and humidity levels, it is necessary to use appropriate materials tailored to specific specifications. Similar conditions are formed in buildings such as bathhouses, attics, unheated cottages and extensions. Considering the features, a good solution would be to install a fabric such as a foil vapor barrier. But in order to ultimately obtain a fully functioning protective layer, many factors should be taken into account.

Why do you need foil vapor barrier ↑

As mentioned above, a vapor barrier layer with a metal aluminum coating is used in special cases and only in certain types of buildings, why is this necessary?

Firstly, the most important function of a foil vapor barrier is the ability to protect structures from excess moisture entering them. But, unlike other films and membranes, analogues with an existing metallized coating still perform the work of a heat reflector. That is, foil layers of vapor barrier are primarily needed where it is worth increasing energy saving.

2 Secondly, in rooms such as baths and saunas, the use of conventional films and membranes is impractical, since high temperatures will quickly render the protective layer unusable. And in conditions of high humidity, a protective layer is simply necessary.

Also, a good solution would be to use a vapor barrier with a layer of foil in the premises of dachas, outbuildings, balconies and attics, which are poorly or not heated at all. This will both protect structures from condensation and reduce the overall heat loss of the room.

The main disadvantages of Penofol

Some consumers refuse to purchase Penofol when they learn about its shortcomings. Among them:

- high penetration;

- inconvenience during installation due to the need to use special adhesives;

- Insulating walls from the outside with Penofol involves using the material only as an additional layer of thermal insulation.

As for high penetration, it will manifest itself even at low pressure; this characteristic is due to the softness of the material.

Types of foil insulation and regulations for their use ↑

In addition to wall materials, the use of vapor barrier is regulated by its type, or more precisely, by the material from which it is made.

The panel has two layers - the base and the actual metallized coating. The vapor barrier base can be of two types:

- Made from kraft paper. Quite a simple and cheap material, but it is subject to mechanical stress and less resistant to moisture. Made from polymer materials. This base is resistant to damage, humidity, and temperatures.

The metal coating of insulating panels also comes in two types:

- Aluminum spraying. The layer thickness can be 0.3 microns or more. However, thin metallized films play the role of a heat reflector much worse. Aluminium foil. Such vapor barrier materials have a metal layer of 10 microns, which makes them resistant to corrosion, and the degree of reflection is about 97%.

You should select foil insulation based on two factors: the type of room, and the types of film itself. Cloths coated with metal foil on a polymer base are best suited for wet bath conditions. And for dry rooms, you can purchase a cheaper option for spraying on paper. Also, the first option, covered with foil, goes well with heated floors.

Waterproofing and vapor barrier: what is the difference?

The main difference between waterproofing and vapor barrier is the vapor permeability of materials. Waterproofing does not allow moisture to pass through, but collects it on the surface. Therefore, this type of material is laid in those places where moisture enters in the form of drops, for example, under corrugated sheeting on the roof. Condensation from the corrugated sheeting in the form of drops of water falls on the waterproofing, flows down it and is discharged outside the roof (that’s why the edges of the waterproofing are wrapped in the form of an envelope).

The task of vapor barrier is different: it should prevent water vapor from penetrating into the insulation. Since the vapors are mostly on the warmer side, membranes or films are often laid on the “warm” side. If we talk about the roof, then vapor barrier materials are placed from the attic side; if we talk about the vapor barrier of the walls of the steam room or other rooms of the bathhouse, then membranes/films are placed behind the decorative cladding.

To summarize: waterproofing does not conduct water (but can conduct steam, releasing the one that has penetrated into the insulation); vapor barrier does not allow steam to pass through.

The difference between vapor barrier and waterproofing is described in detail in the video.

It must be recalled that the dew point, in relation to the premises of a bathhouse or sauna, is often floating.

Advantages of foil vapor barriers ↑

A metallized layer on a vapor barrier base significantly improves the properties of the barrier and gives it tangible advantages over conventional films.

- Low weight. With decent functional properties, foil vapor barrier is lightweight, which does not create large loads on the load-bearing structures of the building. Slight thickness. The layer laid on the attic ceiling or ceiling does not in any way affect the volumes or height of the room due to the minimum thickness of the base and the metallized coating itself. Ease of use. Vapor barriers with foil can be easily installed on curved contours of buildings and in hard-to-reach places. In addition, it is very easy to make a workpiece of any shape by simply cutting the panel with scissors. You also do not need to have specialized tools and skills to install the insulating layer. Temperature stability. The presence of a foil layer makes the vapor barrier less susceptible to high temperatures. And in combination, the film provides maximum protection to structures from high humidity. Cleanliness of materials. The production of such insulation does not require toxic materials and compounds that can be released under the influence of heat. Versatility. Using the same type of panel, you can insulate various building elements adjacent to the installation site.

Manufactured assortments of reflective vapor barrier can be selected for any room based on the price-quality factor. It will equally have vapor barrier protective properties. And long-term use in conditions of even excessive humidity (typical of a bathhouse) will not lead to the formation of mold and mildew.

But, you can get a fully functioning vapor barrier in a room only taking into account its specifics, and most importantly, compliance with the installation rules.

The main advantages of Penofol

Before purchasing Penofol, it is important to pay attention to its advantages, among them the following should be highlighted:

- high environmental friendliness;

- low vapor permeability;

- ease of installation;

- ease of transportation;

- insignificant thickness;

- noise absorption ability;

- high fire safety;

- inaccessibility for rodents.

Features of installation of foil vapor barrier ↑

The main task of a vapor barrier is to protect the insulation and walls from moisture penetration inside. This function is the starting point when installing panels in different rooms.

- When assembling a “cold” roofing pie, metallized strips of material are mounted in the ceiling (recommended for the ceiling), from the inside of the room with the foil down.

- If installation is carried out for a house in the attic, then the foil vapor barrier is laid with the metal side inside the room on top of the laid insulation on the inside of the roof slopes. Fix the film with a stapler and counter-lattice slats. In the bathhouse, foil vapor barrier is installed on all planes, on the floor, walls and ceiling. The foil surface is turned inside the room.

When installing layers, you should adhere to the technological laying rules:

- All wooden parts of rafter systems and other building elements should be carefully inspected for protruding sharp edges or fasteners to avoid damage to the film during installation. Before you begin installing the insulation, you should treat all wooden parts of the structure with an antiseptic. This will extend the life of the material and is guaranteed to eliminate problems such as the formation of fungus and mold. Vapor barrier layers on any planes (roof slopes, walls, interfloor ceilings) must be continuous. The porous structure does not require ventilation gaps. The mounted panels are connected hermetically using foil tape. Laying of vapor barrier is carried out only in a horizontal position, according to the scheme from top to bottom. That is, the first strip is mounted near the ridge, the second lies lower, overlapping the first. When laying sheets of material, releases are made on walls and other nearby areas. The width of such strips should be at least 150-200 mm. Fastening in attics, attics and ceilings is carried out with a stapler. Additional fixation is performed with sheathing slats, which can later be used as a base for the internal cladding. All joints of the panels are taped with foil tape.

Types of vapor barrier materials

Traditionally, during construction, the role of vapor barrier was performed by glassine, roofing felt or roofing felt. Today, the popularity of these materials is falling; they are gradually being replaced by new materials that have better characteristics. In addition, it is better not to use roofing felt and roofing felt for steam rooms: when heated, they emit a specific smell that cannot be called pleasant, and besides, the released substances do not have the best effect on health.

Films made of polyethylene and polypropylene

Polyethylene films are the most affordable, but they have a significant drawback: a short service life. Polyethylene films are either perforated or non-perforated. For vapor barrier, experts recommend using non-perforated materials.

Vapor barrier: polyethylene film

It is not practical to use ordinary polyethylene films for vapor barriers in steam rooms: they quickly lose their properties at high temperatures, but they can be used in washing rooms or changing rooms/dressing rooms.

Any polyethylene films have a significant drawback: they tear easily. Therefore, during installation you need to be careful and careful. The slightest violation of integrity will lead to steam penetrating into the insulation, worsening its properties. Even when using reinforced polyethylene films, which are more durable, there is a significant risk of holes and cracks.

Polypropylene films have much higher strength characteristics. Their prices are slightly higher. Polypropylene films withstand temperature changes better, can also serve as wind protection, tolerate thermal and ultraviolet radiation well, are less likely to crack and are more difficult to tear.

Recently, polypropylene films based on viscose and cellulose have begun to be produced. This layer has a matte, slightly loose surface and can retain significant amounts of moisture, which then evaporates. When using polypropylene with such an anti-condensation layer, be sure to leave a ventilation gap to allow moisture to evaporate.

Vapor barrier: polypropylene film

Membranes

The most modern, but also the most expensive vapor barrier material is diffuse or breathable membranes. They have high vapor permeability, strength and durability. There are single-sided or double-sided membranes. One-sided ones conduct steam only in one direction; when installing them, it is important not to confuse which side to lay the vapor barrier on (all recommendations should be in the instructions for the material).

As a rule, a two-layer polypropylene vapor barrier is mounted on the inside of the insulation with the smooth side close to the insulation. For example, if a vapor barrier is installed in the attic of a bathhouse, then the rough side should be at the bottom.

Double-sided membranes can be laid on either side - they operate in both directions.

Vapor barrier: diffuse membranes

Membranes are also distinguished by the number of layers: there are single-layer and multi-layer. Multi-layered ones can accumulate moisture inside, then gradually release it. There are membranes that simultaneously regulate humidity, temperature, and serve as waterproofing. They are also called “intelligent”. They cost, of course, a lot, but if you consider how much materials they replace, save space (they are small in thickness and do not require a ventilation gap) and installation time, then they are not that expensive.

Foil materials

All of the above materials perform their functions well. But you can’t put them in steam rooms of baths and saunas: they will either melt from high temperatures or release harmful substances when heated, or maybe both at the same time. Special materials are made for steam rooms that can withstand heating up to 120°C and are safe at such temperatures.

There is a whole group of materials with foil glued to one side. It not only prevents steam penetration, but also reduces heat loss: infrared radiation is reflected from the metallized surface back into the steam room. That’s why such a vapor barrier is called reflective.

When laying panels, the joint can be made with a slight overlap and glued with metallized tape, or use double-sided tape, but then one panel must overlap the other by at least 10-15 cm. When installing, be sure to place the foil layer in the room and leave no gap less than 2 cm to the interior finishing layer. This is done by stuffing the sheathing with bars of the appropriate size.

Foil vapor barrier on the ceiling and walls of the steam room

There are several types of such materials:

- Foil on kraft paper (Alumkraft and RufIzol). The material is easier to handle than regular foil and is easy to roll out and attach. Disadvantage: hygroscopicity and low strength of the base, which can be damaged by fungi when wet.

- Lavsan coating on kraft paper (Izospan FB and MEGAFLEX KF). Although the operating temperature range allows these materials to be used in a steam room (up to 140°C), they are not very popular: chemicals in a steam room in any form are not welcome.

- Foil based on fiberglass (Thermofol ALST, Aromofol, Folgoizol). The materials have very high strength: fiberglass is very difficult to tear. The pleasant thing is the fairly high degree of thermal insulation, the unpleasant thing is the price.

There is also a combined material: foil thermal insulation (Isover Sauna, SAUNA BUTTS from ROCKWOOL, Ursa foil). A layer of foil, sometimes metallized lavsan, is applied to the mineral wool mats. This combination allows you to speed up the construction process.

Cheap vapor barrier for baths

If funds are really tight, or you don’t want to use the achievements of civilization, you can soak cardboard with drying oil and use these sheets as a vapor barrier material. Another material that is not the most effective today, but is affordable and does a good job is glassine. It has been used for many years and no harmful fumes have yet been detected.

Liquid (coating) vapor barrier

Another material that can be used for vapor barrier is liquid rubber (also called coating vapor barrier). It is an aqueous solution of polymers that is applied in a liquid state. After drying, a durable film is formed on the surface, completely impermeable to water and steam. This film also has heat and sound insulation properties. Coating vapor barrier is most often used for floor treatment. In bathhouses it can be used to cover concrete or subfloors made of boards. To solve vapor barrier problems, the emulsion consumption is about 1.5 kilograms per 1 m2; for waterproofing, the consumption increases by 2-2.5 times (layer thickness is about 0.7 mm). Liquid rubber is also suitable for vapor barrier of brick walls both inside and outside the room; you can use this kind of mastic in washing rooms or locker rooms, but for steam rooms the composition must be chosen carefully - it must be non-toxic and withstand high temperatures.

Vapor barrier: liquid rubber

Bath lovers and experts recommend using only foil roll materials for vapor barrier of the ceiling and walls of the steam room, which not only serve as a vapor barrier, but also reflect thermal radiation inside, reducing the cost of maintaining the temperature.

Vapor barrier with foil

Heating your home costs more and more every year. Winters are getting colder. Many people have found a solution: installing insulation for walls, ceilings, and floors. But a large difference in air temperature inside and outside leads to the occurrence of condensation precipitation. They, in turn, negatively affect the insulation material. Thus, you most likely will not be able to save money. Either you will pay a lot of money for electricity consumption, or spend money on a new insulation system every year.

The only way out is a vapor barrier. This is an auxiliary layer that prevents condensation precipitation from damaging the insulation layer.

Materials for vapor barrier can be:

- plastic film (not a reliable barrier);

- reinforced polyethylene film (due to its structure it is not a reliable material for vapor barrier);

- fabric for bags (better suited for roof vapor barrier);

- combined spunbond fabric (better suited for roofs);

- foil fabric (great for vapor barrier of all surfaces).

Thanks to its unique properties, practicality, reliability and economy, foil film is the most optimal option for creating a barrier.

The texture of the foil is solid and smooth. These indicators create an ideal barrier.

- About the thickness of Penofol

- FLOORING CONSTRUCTION USING PENOFOL

- More information on the topic:

Varieties of "Penofol"

"Penofol" can be classified by type:

- A.

- IN.

- WITH.

- ALP.

- R and M.

- Super NET.

- AIR.

In the first type, the aluminum layer is applied only from the outside; this material is used in conjunction with polystyrene foam and styrodur. Type B is coated on both sides and is suitable for independent use. Type C is a self-adhesive material in which the outside is covered with foil, while the inside is polyethylene foam with contact adhesive.

ALP is “Penofol”, on top of the aluminum layer of which a polyethylene film is fixed. This material is laminated and can be used for needs in rural areas. One-sided foil embossed material are varieties R and M. But “Super NET” is used for thermal insulation of networks. The latter variety is suitable for air ducts.

Advantages of foil vapor barrier

Foil is a material that creates the maximum barrier, preventing precipitation from entering the insulating material by 100%. This is what is most often used to decorate a bathhouse.

Many people use regular foil, but it is quite fragile and can break under the slightest pressure.

Manufacturers have taken care to eliminate this drawback. They created a two-layer material. It consists of a flexible and durable material and aluminum foil coating. This tandem brings maximum benefit, reducing negative indicators to a minimum.

This type of vapor barrier material can retain over seventy percent of thermal mass. It is easy to attach to the wall or any other surface. It is fixed to a wooden base using a stapler. For concrete and other surfaces, mounting tape is used. This film can be easily divided into the necessary elements. It tolerates very high temperatures well - more than plus one hundred degrees, low temperatures - below forty. Therefore, it is often used for baths.

Advantages and disadvantages of aluminum foil

Before you figure out the need to apply an additional layer to the walls of the bathhouse, it is worth considering several features. Aluminum foil for a bath has certain advantages and disadvantages, we will consider them below in table form.

| pros | Minuses |

| Permits vapors and gases in the smallest amount. Fire resistance – withstands a maximum temperature of 145°C. The reflectance is approximately 93-96%. | Over time, the reflective layer may become cloudy if there is no metallized topcoat layer. |

High resistance to:

| Be sure to have a ventilation hole in the room to prevent overheating of the foil. |

| The material is completely environmentally friendly; microbes cannot multiply on its surface. Does not emit harmful gases during heating and is not destroyed by ultraviolet rays. | It can be difficult to find quality material, since most products are not certified. It is advisable to find it with documents confirming quality. |

Aluminum foil is easy to install and dismantle if necessary. But you need to accurately cut out the parts from the canvas in order to tightly close the walls of the bathhouse.

Disadvantages of this material

Foil film for vapor barrier is divided into three types:

- with a layer of foil;

- with aluminum coating;

- with aluminum foil.

If you choose a film with a layer of ordinary foil, you must be prepared for the occurrence of corrosion processes. Simply put, the foil layer can become rusty.

Film coated with aluminum and aluminum foil are not subject to such processes.

It is important to fill the joints between film elements with an adhesive composition that forms the film. Otherwise, all positive effects will be lost.

It is important to protect material coated with aluminum from overheating. Otherwise, it may damage the finishing layer.

If you buy aluminum-coated film, remember that it does not retain heat well. In general, aluminum foil film is the most useful option.

Vapor barrier in a bathhouse with aluminum foil is shown

Laying process

Most often, foil vapor barrier is used for bathhouses. In this room, more moisture is located inside. Also, the inside is subject to sudden temperature changes. That is why the vapor barrier layer is laid on the inside.

Useful picture for work

Usually the bathhouse is built of wood. And it tends to collapse under the influence of moisture. To prevent this from happening, it is important to use a vapor barrier material. It is this layer that will ensure quick and high-quality heating of the room, with minimal consumption of resources. To be most effective, it is important to follow the instructions exactly when installing the vapor barrier.

Stages of work:

- prepare a layer of insulation;

- for reliable vapor barrier, it is important to make the previous layer as even as possible;

- prepare wooden boards: thin and low;

- divide the foil film into strips;

- fasten strips of material using wooden boards and nails, staples;

- elements of the material must be superimposed on each other, with an overlap of twenty centimeters;

- You can connect the strips together with adhesive or tape with foil elements;

- Tape the joints of the material with the wall, ceiling, floor, and windows with tape.

Important Tips:

- ensure the tightness of the vapor barrier layer;

- leave a gap for air between the vapor barrier layer and the decorative layer, about two centimeters, the height of the boards for fastening will help with this;

- Do not stretch the material; when heated, it will deform; leave a sag of two centimeters.

You can buy vapor barrier film at any hardware store. The price per square meter of such film with aluminum foil starts from twenty-five rubles per square meter. It can withstand about one hundred and forty degrees Celsius with a “+” sign, and is capable of reflecting about ninety percent of heat. Environmentally friendly.

You can buy tape with a metal element in the same store. The price for it ranges from one hundred rubles per fifty meters, fifty-five millimeters wide.

Good luck with your renovation!

We would be grateful if you share this article on social networks with your friends.

How to attach a vapor barrier

The choice of fastening method depends on the type of vapor barrier material used. Polyethylene and polypropylene films are secured with small nails or with staples and a construction stapler.

Construction stapler (mechanical)

In order to minimize damage, it is advisable to use wooden planks that press the film against the guides, and drive staples/nails into the plank. Membranes can be attached in the same way. They are not as torn as films made of polyethylene or polypropylene, and they are easier to work with.

Attaching the vapor barrier

The sheets of rolled materials are laid one on top of the other with an overlap of at least 10-15 cm, gluing the joints with adhesive tape. You can use specialized, foil or regular adhesive tape.

Double-sided adhesive tape UNIBOB based on cotton fabric. An adhesive layer based on synthetic rubber, which ensures high quality gluing of vapor-waterproofing sheets

Foil tape must be used at the joints of foil materials, otherwise most of their effectiveness is lost. When gluing joints of other materials, manufacturers recommend using their own adhesive tape, but they do not explain their differences and advantages.

Please note that during installation the vapor barrier sheets should not be stretched: they tend to stretch/shrink when temperatures change. To avoid ruptures during tension, you need to leave a small margin. It is considered normal for the canvas to “sag” by 1-2 cm during installation. This is especially true when laying a vapor barrier on a roof or in an unheated room.

When installing vapor barriers in places with complex terrain (protrusions, corners, etc.), it is advisable to seal the adjacent surfaces with tape: perfect tightness in such places is difficult to achieve, and this is the main condition for the effectiveness of protection. Therefore, any aids will be useful. It is also necessary to tape the edges of the vapor barrier around the perimeter of door and window openings to ensure a tight seal. In general, tightness is the basis for high-quality vapor barrier of a bathhouse, roof or any other room. Therefore, when carrying out work, pay maximum attention to this aspect.

Foiled penofol for frame housing construction

This article describes the technical characteristics and distinctive features of Penofol insulation. Which can be used for frame house construction, made using wooden house-building technologies or LSTK technologies. Insulation in frame houses is used to insulate the house from external weather conditions. Insulation materials are usually produced in flexible versions, as well as in the form of slabs or rolls. Penofol is available in roll form, which is convenient for insulating corners, roofs and walls of frame structures.

It should be borne in mind that Penofol, due to its small thickness, does not retain heat very well and cannot be used as the only insulation. Penofol is equivalent to stone masonry five centimeters thick.

Penofol - reflective thermal insulation - a new generation of insulation. Unique thermal insulation properties with low thickness.

Penofol is a highly effective vapor and heat insulation based on foamed polyethylene covered with aluminum foil. Penofol - combines the heat-insulating properties of “trapped” air bubbles with the high heat-reflecting ability of pure aluminum (99.4%), thus being a unique product that stops heat in all three ways of its propagation: thermal conductivity, convection and radiation.

Features of "Alufoma" and "Tepofol"

The polyethylene foam base is “Alufom”, which has a one-sided coating of aluminum foil. The operating temperature ranges from -60 to +100 °C. Vapor barrier performs the functions of sound, hydro, steam and heat insulation, and also reliably protects against radon. It can be used for thermal insulation of roofs and floors. The wrinkled texture allows you to bend around curved elements of small radii without tearing the coating.

Foamed polyethylene is the basis of Tepofol, which in different variations has a reflective layer on one or both sides. The temperature effect can vary from -60 to +100 °C. This vapor barrier can be used for thermal insulation of air ducts, roofs and walls, as well as for the installation of heated floors.

Foil vapor barrier for a home must be completely safe, such as Izolon, which is environmentally friendly. The base is foamed polyethylene foam. The vapor barrier is vapor-tight, durable, and is distinguished by the flexibility and softness of the foil layer.

Foil vapor barrier will save your money

Heating your home costs more and more every year. Winters are getting colder. Many people have found a solution: installing insulation for walls, ceilings, and floors. But a large difference in air temperature inside and outside leads to the occurrence of condensation precipitation. They, in turn, negatively affect the insulation material. Thus, you most likely will not be able to save money. Either you will pay a lot of money for electricity consumption, or spend money on a new insulation system every year.

The only way out is a vapor barrier. This is an auxiliary layer that prevents condensation precipitation from damaging the insulation layer.

Materials for vapor barrier can be:

- plastic film (not a reliable barrier);

- reinforced polyethylene film (due to its structure it is not a reliable material for vapor barrier);

- fabric for bags (better suited for roof vapor barrier);

- combined spunbond fabric (better suited for roofs);

- foil fabric (great for vapor barrier of all surfaces).

Thanks to its unique properties, practicality, reliability and economy, foil film is the most optimal option for creating a barrier.

The texture of the foil is solid and smooth. These indicators create an ideal barrier. The absence of seams, cracks, allows you to reliably retain moisture. The reflective effect retains heat by reflecting warm air and bringing it back inside.

Among other things, this material is not susceptible to mold and bloom. They are convenient for covering surfaces. You do not need to use special equipment for this. Affordability is also an advantage of this option. A fairly low price makes it accessible to everyone.

Self-vapor barrier of a bath using aluminum foil

You can cover the walls and ceiling of the bathhouse with a vapor barrier material yourself. To do this, first select the appropriate type of material, then proceed directly to finishing. At the same time, it is worth taking into account a lot of nuances that affect both the quality of the coating and the functioning of the room.

Preparing the walls

To decorate your walls with reflective material, first prepare the surface. To do this, it is necessary to attach beams in the form of lathing to the walls. It is advisable to use the latter with a cross section of 5x5 cm. The distance between the bars should be the same as the width of the foil material. It is better to sand the wooden surfaces of the sheathing immediately. This will help maintain greater integrity of the intermediate material. Only after this can you begin laying the reflective insulation.

How to decorate walls with your own hands

The next step is the installation of the insulation-reflector itself. You can make a vapor barrier with foil in a bathhouse yourself as follows:

- It is necessary to measure the length of each strip of timber sheathing if the width is selected in accordance with the parameters of the foil material.

- Prepare separate strips for each section - cut off a part from the total roll.

- Then you should lay the prepared strips in the sheathing sections. This must be done carefully so as not to damage the thin material.

- To fix the position of each part of the foil element, glue the edges with metal tape.

Attention! Instead of tape, in some cases it is better to use small nails or work out the joints with staples using a construction stapler. Thanks to this tool, fixation is also made along the length of all strips.

Ceiling vapor barrier

Vapor barrier of the ceiling and walls of the bathhouse is carried out in a similar way. But to improve the thermal insulation of the room, it is worth putting 2 layers of foil material or immediately choosing a denser type of foil. This will help retain all the heat generated during the heating process in the steam room, since warm air tends to rise. Vapor barrier of the bathhouse ceiling with foil is carried out in this way:

- Make a sheathing on the ceiling from beams of the same size as on the walls. In this case, the same parameters are observed as on the surface of the walls.

- Place a lengthwise strip of foil material into each pre-prepared cell.

- Attach the strips to the sheathing beams using a staple gun. It is advisable to fix the edges approximately every 5-10 cm, but you can reduce the distance to 3-5 cm.

Do not forget about the overlap, which is necessarily formed to drain condensate. To do this, each strip must be a total of 50 cm longer than the initial parameter. Attaching the canvas to the ceiling is more difficult than to the walls, but these manipulations are necessary.

Final finishing of walls and ceiling

Once the vapor barrier layer has been laid and secured, the final stage of finishing the walls and ceiling can begin. Usually the steam room is “sewn up” with wooden clapboard. When attaching wooden planks, do everything carefully so as not to damage the foil layer. At this stage, finishing is considered complete.

Advantages of foil vapor barrier

Foil is a material that creates the maximum barrier, preventing precipitation from entering the insulating material by 100%. This is what is most often used to decorate a bathhouse.

Many people use regular foil, but it is quite fragile and can break under the slightest pressure.

Manufacturers have taken care to eliminate this drawback. They created a two-layer material. It consists of a flexible and durable material and aluminum foil coating. This tandem brings maximum benefit, reducing negative indicators to a minimum.

This type of vapor barrier material can retain over seventy percent of thermal mass. It is easy to attach to the wall or any other surface. It is fixed to a wooden base using a stapler. For concrete and other surfaces, mounting tape is used. This film can be easily divided into the necessary elements. It tolerates very high temperatures well - more than plus one hundred degrees, low temperatures - below forty. Therefore, it is often used for baths.

Price

in the production of foil insulation on the Russian market :

- Jermaflex;

- Izolon;

- Penofol;

- Tepofol;

- Folgoizol;

- Ecofol.

| Firm | Characteristics | Price |

| Jermaflex | 1.2 m x 8 mm | 80 RUR/m² |

| Izolon | Type A, thickness from 2 to 10 mm, length 1 m | 140-260 RUR/m² |

| Penofol | Type A, thickness from 3 to 20 mm, length 36-12 m (the thicker, the shorter the meter) | 53-278 RUR/roll |

| Tepofol | Type A, thickness from 2 to 10 mm, length 2.5 m | 40-1200 RUR/roll |

| Folgoizol | Type A, thickness 10 mm, length 15 m | 1650 RUR/roll |

| Ecofol | Type A, thickness from 2 to 15 mm, length 25-10 m | 780-1030 RUR/roll |

Disadvantages of this material

Foil film for vapor barrier is divided into three types:

- with a layer of foil;

- with aluminum coating;

- with aluminum foil.

If you choose a film with a layer of ordinary foil, you must be prepared for the occurrence of corrosion processes. Simply put, the foil layer can become rusty.

Film coated with aluminum and aluminum foil are not subject to such processes.

It is important to fill the joints between film elements with an adhesive composition that forms the film. Otherwise, all positive effects will be lost.

It is important to protect material coated with aluminum from overheating. Otherwise, it may damage the finishing layer.

If you buy aluminum-coated film, remember that it does not retain heat well. In general, aluminum foil film is the most useful option.

Vapor barrier in a bathhouse with aluminum foil is shown

Additional solution for the attic: “Ondutis R Termo”

This material is used for thermal insulation of metal and wooden structures. When insulating an attic space or installing a roof in a residential attic, the film allows you to retain heat and reduce heating costs.

The water resistance of this vapor barrier is 1000 mm of water column; as for the minimum vapor permeability, this parameter is less than 10 g/m2 per day. The material easily endures temperature changes ranging from -40 to +120 °C. When considering strength, you should pay attention to the breaking load, which is 150 N along and 130 N across. This indicates that this foil film can support the weight of an adult.