The pace and technology of modern construction imply the use of innovative solutions at all stages, including the improvement of buildings. The key is to insulate the premises from moisture and cold. For this purpose, insulating films are used, available on the market from several brands.

The optimal price-quality ratio is the Izospan vapor barrier. This material is easy to install, has high technical characteristics and attracts buyers at an affordable price. Let's look at the features of Izospan class B film.

Types of Izospan products

Vapor barriers are represented on the construction market in a wide range of models. Each type has its own technical characteristics, which determine the scope of the material. 14 of insulating membranes of this brand . Let's look at 4 main categories. In particular:

- Group A

The film is intended for thermal insulation of premises and protection of wall structures from moisture and condensation. The material is made in the form of a double-sided membrane, one side of which serves as insulation from wind and moisture, the other removes evaporation.

In order for the film to cope with its function, it is mounted on the outside of the insulation.

- Group B

One of the most popular and frequently used categories is “Izospan”. A special feature of this category of material is its absolute vapor permeability. Such characteristics are due to the structure of the insulating membrane.

One side of the film is smooth, the other has pronounced surface roughness. The smooth structure protects the interior from the wind, and the fibers help remove moisture.

- Group C

This product performs identical functions to Group B Izospan, but is more expensive. The material is based on ultra-dense polypropylene fabric, which reliably protects structural elements from any external influences.

The film is suitable for use in regions with cold climates and provides insulation of rooms even if the wall panels or roof elements do not fit tightly.

- Group D

This is a universal film that is suitable for indoor and outdoor use.

The key feature of the material is its high resistance to mechanical damage and neutrality to direct ultraviolet rays.

It is worth noting that there are “A” class films on the market. M" "A. S" "A. Q Proff.” Unlike basic prototypes, these films have a more dense membrane structure (often three-layer) and have greater tensile strength. Of course, improved technical characteristics proportionally increase the cost of the material.

What tasks do insulating films perform?

Izospan is a film or non-woven membrane used in thermal insulation structures to protect insulation from moisture, wooden and metal elements from rotting and corrosion.

Vapor barrier membranes are necessary when arranging multilayer building structures, mainly external ones. These are external insulation systems, pitched roofs, frame housing construction, and the installation of wooden interfloor ceilings.

The main task of the Izospan vapor barrier is to prevent the appearance of a “dew point” in the structure. Warm air tends to leave the room, and cold air tends to get inside. Without a well-equipped barrier, flows of different temperatures will meet in the density of the wall and condense into droplets of moisture. The result is that wet insulation freezes, thermal efficiency decreases, and mold appears inside.

Vapor barrier solves this problem - the membrane allows moist air to escape without being trapped in the thermal insulation layer. The dew point moves - condensation does not fall.

Characteristics of "Izospan B"

If we talk about technical parameters, we can highlight the following characteristics:

| Compound | 100% polypropylene |

| Width | 1.6 m. |

| Square | 70 m2. |

| Density | 70 g/m2. |

| Tensile strength | 130-107 N/5 cm. |

| Vapor tightness | 22.4 g/m2 per day |

| Moisture resistance | 1,000 mm. water Art. |

| UV stability, months | 3-4 |

Suitable for use in temperatures ranging from -60 to +80 degrees Celsius.

Given these features, it is not recommended to store the material in the open air in order to preserve its performance properties.

Features of type B

There are quite a lot of materials of the described brand. At the same time, only a few varieties are very popular, including isospan B. It’s not just about the affordable price. The material has an acceptable combination of cost and performance.

To understand all the benefits, you should get acquainted with the characteristics of isospan B:

- the density of the material is 70 grams per square centimeter;

- isospan B is one hundred percent propylene;

- the material is capable of withstanding a longitudinal tensile load of 128 and a transverse tensile load of 104 newtons;

- water resistance is at least 1000 millimeters of water column;

- The temperature range at which isospan B does not lose its qualities is from minus 60 to plus 80 degrees.

The described type of vapor barrier consists of two layers. The lower part is designed for high-quality “coupling” with the base. The top layer has a fleecy or rough surface. Thanks to this feature, the top side retains moisture well and does not let it in.

Advantages and disadvantages

Izospan insulation belongs to the category of building materials, therefore it has advantages and disadvantages. This feature is typical for any product, however, in the case of the vapor barrier of this brand, there are noticeably more advantages than disadvantages. Let's look at the strengths of the material.

The undeniable advantages include the following characteristics:

- High water repellency.

- Resistant to any external factors and mechanical damage.

- Absolute inertness to the development of pathogenic microflora (wall mold, fungus).

- Environmental Safety.

- Ease of installation.

- Long-term operation – at least 50 years .

Disadvantages include the high cost of some model groups and the lack of fire resistance.

General provisions

- Laying films does not require special skills; it can be done independently, taking into account the individual characteristics of the membrane.

- The set of films comes with instructions; you must act according to its instructions. It is especially important to pay attention to the correct side of the attachment to the insulation.

- The material should fit snugly to the surface with a small gap in the corners (3-4 cm or more, if it depends on the design features). The canvases are overlapped relative to each other (at least 15 cm).

- Fastening to wood is done using a stapler; you should not forget about sealing seams and possible cracks using Izospan tape.

- For heat-insulating films, the metallized part should look inside the room, and the installation work itself is done end-to-end, without overlap. The seams are also sealed with metallized tape.

Where is it used?

This group “B” (B) is considered universal, therefore it has a rather multifaceted scope of application. The only installation limitation is internal installation. Izospan B is not suitable for external insulation; there are other groups for this. For internal insulation, the material is used to insulate the following surfaces:

- Wall structures.

- Internal partitions.

- Interfloor ceilings.

- Floors in rooms with high humidity.

- Underlay for parquet or laminate.

- Roof insulation.

This demand is due to the fact that the thermal insulation pie will not cope with its functions without a vapor barrier film.

Which side should I lay towards the insulation?

According to the official instructions:

- For the roof. Smooth side to insulation.

- For walls. Smooth side to insulation.

- Attic floors. The film is laid between the finishing material of the living room ceiling and the rough ceiling (smooth side towards the rough ceiling).

- Basement ceiling. The rough side is towards the insulation.

Instructions for using vapor barrier Izospan V, C, D

Izospan vapor barrier films are also waterproofing. They do not allow water or steam to pass through. What are the differences between Izospan A and B? The fact is that B does not let steam through, A does. That's it in short.

Made from different materials. There are films, nonwovens and fabrics made of polyethylene and polypropylene. Fabric-based materials have very high strength characteristics. Their use is justified in places where they may be subject to high mechanical loads. Technical characteristics of Izospan vapor barrier films are given in the table.

| Name | Maximum elongation in transverse/longitudinal direction N/50 mm | Vapor permeability | Withstands water pressure, mm.water.st. | Withstands ultraviolet radiation (without protective coatings) for at least months |

| Izospan RS (рс) | 413/168 | No | 1200 | 3-4 |

| Izospan B and B fix | 130/107 | No | 1200 | 3-4 |

| Izospan S | 197/119 | No | 1200 | 3-4 |

| Izospan RM (rm) | 399/172 | No | 1200 | 3-4 |

| Izospan D (D) and D fix | 1068/890 | No | 1200 | 3-4 |

| Izospan DM (DM) | 700/650 | No | 300 | 3-4 |

The main task of these materials is to cut off steam from the insulation as efficiently as possible and at the same time provide protection from moisture. A “side” but important effect is protection against the penetration of mineral wool particles into the indoor air. It is used in the construction of walls, ceilings, roofs, and when constructing concrete floors. Vapor barriers are often part of the “pies” above, simply because they perform other tasks.

Rules for installing vapor barriers

The main task when laying vapor barrier films is to achieve as complete a seal as possible. It is necessary to let as little steam as possible into the insulation. We make all connections reliable using sealing and connecting tapes. The basic rules of vapor barrier do not differ from those described above:

- On the walls and roof we start from the bottom.

- The next canvas overlaps the first by 10-20 cm.

- We make vertical joints with an overlap of at least 20 cm.

Vapor barrier materials are usually installed from the inside of the room - We glue all connections with double-sided tape.

- We make connections to building materials using mounting and connecting tapes.

- When used for flat roofs and ceilings, the vapor barrier is applied to the walls and sealed there.

In addition to gluing the joints of the canvases, it is also important to use even strips-bars for final fastening of the material. They press the material tightly, sealing at the same time the holes that the fasteners invariably pierce.

Pitched roofs - insulated and non-insulated

Pitched roofs can be insulated or cold. In any case, a vapor barrier is installed on the attic side. It does not let steam into the insulation and this is its main task for this case. But Izospan is recommended differently for insulated and non-insulated roofs:

- for insulated roofing it is better to use RS, B or B fix, they differ in strength (RS is stronger);

- for non-insulated - D or D fix, DM (DM is stronger than just D).

Application of Izospan vapor barrier for roofing

Izospan RS and B films have one rough side and the other smooth. So, Izospan V and RS should be turned with the rough side into the room. We unfold the smooth one towards the insulation or roofing material.

Flat insulated roofs

When insulating a flat roof, a vapor barrier is laid on the ceiling under the insulation. The purpose of this layer is twofold. On the one hand, do not let steam into the insulation, on the other, cut off moisture from the ceiling in the event of a leak.

How to use Izospan when insulating a flat roof

In this case, it is recommended to use Izospan D and RM, RS. They have sufficient strength to withstand the loads that will certainly arise when laying insulation.

Izospan B: instructions for use for walls

In frame walls, Izospan V vapor barrier is installed on the side of the room. The task of vapor barrier is to let as little steam into the insulation as possible. Whatever gets into it (and it will definitely get in) will come out, since there is a vapor-permeable Izospan A film on the outside. But the less moisture there is, the better.

Izospan A and B - instructions for use for frame walls

In this case, Izospan RS (RS) and B are recommended for use. The strength of RS will be required only if you are planning a break in work and the cladding will be mounted on the walls after some time. The smooth side of Izospan B goes to the insulation, the rough side is directed into the room. This is the basic rule.

Please note that in the diagram Izospan B is nailed to the racks with strips, and sheet wall covering material is mounted on the sheathing strips. This option is good because it allows you to use a strip to isolate the holes made by the fasteners. There is another option - you can attach the film to the stands using a stapler and staples with wide backs. The inconvenience is that the rack will not be visible and it is unclear where to attach the sheet material. But the option is possible, although not ideal.

Attic and interfloor ceilings

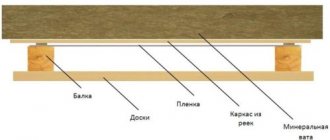

A vapor barrier in a wooden floor pie is needed from the lower room. If you look from bottom to top, the sequence goes like this:

- ceiling filing;

- vapor barrier (Izospan V);

- rough ceiling;

- insulation between beams;

- vapor-permeable film (Izospan A);

- floor laid on a counter-batten.

Which Izospan should be laid on the ceiling side in the attic and interfloor ceilings

? How does the vapor barrier work in this pie? It does not allow vaporous moisture to pass from the room into the insulation. If there is a leak from above, it will also retain moisture, but this is an emergency and the water will not hold for long.

Which side should Izospan B be placed in this case? The rough side goes into the room, the smooth side goes up. When installing, try to damage the panel as little as possible. If a hole has formed somewhere, seal it with tape. Branded is better, but you can also just use a good one, with a high-quality sticky layer.

Basement ceiling

The basement floor is built according to a completely different logic. Here steam will flow from top to bottom. From a warm room with humid air to a cooler and drier underground. And so that moisture penetrates into the insulation as little as possible, we put a vapor barrier on it (the thermal insulation). The steam that gets into the insulation will either fall on the ground in the form of drops, or will be carried away by the wind in a vaporous state.

Vapor barrier Izospan B and RS in the basement

Izospan B and RS are recommended for use. When laying, we turn the rough side towards the insulation, the smooth side faces the room. The films are laid on beams and secured with slats - counter-battens. The flooring is already being laid on them.

For better heat conservation, you can use vapor barrier materials with a metallized layer: RF, FS, FD, FX. In this case, the thickness of the counter rails is at least 35 mm. This is the minimum gap that ensures effective heat reflection.

Screed on concrete base

If it is necessary to level a concrete slab, a screed is often used. To prevent water from the solution from leaking into the ceiling, it is advisable to use waterproofing. This can be a coating or rolled material. The cheapest is film. But you will have to walk on it and it is unlikely to remain intact. Especially if the screed is reinforced. Is it possible to pour screed without film? If you are not afraid of flooding your neighbors below, then you can. Or if you use coating waterproofing. Without it, most likely, the screed will not have the required strength. A certain amount of moisture is required for the formation of cement stone. And it will partially go into the slab, and partially seep through the cracks. What the result will be is unknown. Accordingly, it is advisable to use film.

Application of waterproofing in floors on a concrete base

It is recommended to install Izospan D (D) or Izospan RM (RM) vapor barrier under the screed on a concrete base. These are waterproofing materials of increased strength. It doesn’t matter which side these materials are laid on. But Izospan D has very high strength and it makes sense to use it only if reinforcement will be laid. For a screed without reinforcement, RM is quite sufficient.

If there are significant depressions in the base, it is better to seal them; it makes sense to cut off humps that are too protruding. This will not only increase the chances of preserving the film, but will also make the screed thinner. And this is a significant saving.

Manufacturer company

All categories of Izospan are manufactured by Izospan, which has its own production facility in the Tver region. The company produces various membrane films with vapor barrier, moisture-repellent and energy-saving properties.

Products undergo strict quality control at all stages of production and have international certificates of conformity. Thanks to these features, the products are in consistently high demand in the domestic and European markets.

Vapor barrier of non-insulated pitched roof

Roofing arrangement:

- Roof covering

- Vapor barrier Izospan D, DM

- Lathing

- Rafters

- Counterrail

Izospan D (or DM) is laid with the smooth side facing the roofing. When installing them, to organize the ventilation flow, it is necessary to make a ventilation cut along the ridge.

Izospan D (DM) is rolled out and cut directly onto the roof rafters. Installation is carried out with horizontal panels overlapping, starting from the bottom of the roof. The overlap of panels at horizontal and vertical joints is at least 15 cm. The joints are glued with Izospan KL, KL+ or Izospan SL tape. The stretched material is fixed to the rafters with vertical wooden counter-battens 4x5 cm, treated with antiseptics, on nails or screws with a slight sag, but not more than 2 cm.

Lathing or continuous plank flooring is installed along the counter-tracks, depending on the type of roofing. At low roof slope angles, Izospan D (DM) is recommended to be installed on a plank flooring to prevent large sagging of the material.

Prices

Prices for polymer film depend on the type to which it belongs and the manufacturer that represents it on the market. Izospan is sold in rolls with the waterproofing side inward, the area of one roll is 70 sq.m.

The price for one roll of types A and B, which are suitable for use on the ceiling, can range from 1000 to 2000 rubles.

Self-adhesive Izospan tape is available for sale, which is used in different qualities. It costs about 500 rubles. per piece, it contains about 30 m.

Often, unscrupulous manufacturers want to pass off their products as isospan, so when purchasing, you should ask about the presence of a quality certificate and compliance with production standards. To calculate the amount of product, there are special online calculation calculators on the websites of special construction companies or intermediary stores.

By the way, you can buy good eurolining on the company’s website RealWood.ru. Good quality and reasonable prices.

Vapor barrier for frame walls

On the outside the insulation is protected with hydro-wind protection, and on the inside with vapor barrier. Therefore, for work you will need two types of membranes:

- Izospan A (or AS, AQ Profi, AM);

- Izospan B or RS.

General scheme of a wall pie:

- External cladding.

- Cottrogrid.

- Hydro-wind barrier – Izospan A.

- Thermal insulation layer.

- Vapor barrier – Izospan V.

- Internal finishing.

Izospan A is mounted on the frame on top of the insulation, the side of placement is not important. If the brands AS, AQ Profi, AM are used, then the white side faces the heat insulator. The panels are placed from top to bottom, horizontally with an overlap of 10 cm at the joints. They are fixed to the frame with a construction stapler.

Vertical slats are attached on top of the hydro-windproofing film - the basis for the outer cladding. The lower edge of the membrane is fixed to the drainage drain of the base.

Instructions for use of Izospan B:

- Installation of the canvas from inside the room, on top of the insulation. Fixation to the supporting beams of the frame.

- The order of installation is from below, with an overlap of horizontal panels of 15 cm.

- Izospan B is placed with the smooth side facing the heat-insulating layer, the panels are fastened with connecting tape.

- The interior decoration is mounted on a slatted frame (lining, plywood) or galvanized profiles (plasterboard) - a ventilation gap of 4-5 cm should be obtained.