The bathhouse is a place for relaxation and restoration of health. Therefore, finishing the dressing room with block house and stone is becoming increasingly popular. This is due, first of all, to the environmental friendliness and safety of the material for the health of vacationers. Bath finishing technology has its own characteristics. To perform high-quality installation with your own hands, you should familiarize yourself with it.

An example of a classic interior decoration of a timber dressing room

What is the dressing room used for?

A properly equipped dressing room can become a full-fledged functional room in any bathhouse. As a rule, it is located between the steam room and the sink, so it is used:

- for protection from cold and drafts penetrating indoors;

- for relaxation after procedures before visiting the washing room or swimming pool;

- for a change of linen and clothes that you can hang comfortably and not worry about them getting wet;

- for leisure time in a warm, friendly atmosphere.

If the finished bathhouse is not equipped with a dressing room, then you can expand the structure quickly and economically. Considering in more detail the question of how to make a dressing room, it is recommended to choose a frame construction method.

The main advantages of the method are:

- ease of erecting a frame with minimal foundation costs;

- speed of construction;

- a wide selection of materials for interior and exterior design;

- high heat capacity of the structure.

Styling

When performing interior wood finishing, you can choose interior options that are similar in spirit:

- Russian - curtains with embroidery, carved wooden furniture, bagels and a samovar - a tribute to roots and traditions. On the walls there are oak and birch brooms, wooden spoons, painted mugs, and they create a unique atmosphere and coziness.

- The interior is like in a fairy tale - pieces of furniture made of driftwood, forest gifts in the form of grass bunches and berries help create the illusion of the house of Baba Yaga or Leshy. Even children will enjoy relaxing in the bathhouse.

- Ship style - wood can be complemented with chrome and metallized elements, red fur and carpet, as well as yacht paraphernalia. All this helps to feel the atmosphere of a trip around the world.

Sharing a sauna with loved ones is a special event. For this reason, the choice of style for the dressing room is an extremely important point, which is based on individual preferences.

Construction of the foundation for the dressing room

Before the start of construction work, a working scheme is selected and the size of the waiting room is determined. The area of the room is calculated according to the following principle: 1.35 sq. m for 1 person. The width of the dressing room must be at least 100 cm, the length is arbitrary.

For a frame structure, a lightweight foundation is suitable - pile or shallow.

How to build a shallow foundation? The work is performed as follows:

- They draw up plans for construction.

- Prepare a trench with the required parameters: depth 55 cm, width 35 cm.

- The foundation base is filled with fine sand, compacted, and wetted.

- Formwork is made from boards according to the dimensions of the foundation.

- Install a reinforcing base under the foundation.

- Fill the formwork with concrete mixture.

- The concrete base is dried and protected with a waterproofing layer of roofing felt.

External cladding

Functions of external cladding:

- Decoration of the building;

- Extending the service life of enclosing structures.

Boards

Pine and spruce lumber are used for the exterior cladding.

A frame wall can be easily recognized by the horizontal arrangement of the boards: this way they ensure the rigidity of the entire building, maintaining the correct geometry of each wall.

Before finishing a bathhouse made of timber, finishing a log bathhouse, the boards are connected over a windproof membrane:

- Butt;

- Overlapping;

- At a quarter;

- Tongue and groove connection.

The fastening of the sheathing to the frame posts is 60 mm nails.

Information. Before purchasing a cladding board, measure the area of the walls to be covered, add 15–20% to the resulting figure and obtain the calculated cladding area.

Sheathing boards are protected by impregnation with fire retardants, antiseptic, and painted.

Plaster

You can plaster not only stone, but also frame-cladding exterior walls. Then the frame is reinforced with jibs, and oblique lining made of chipped boards is stuffed onto it - this will ensure the rigidity of the frames. The lining is filled with plaster shingles (“shingles”, “shingles”, “drazga”, “splints”, “cod” - thin, plucked strips of wood).

The plaster is placed on the outside and on insulation - mineral wool of suitable strength, capable of absorbing the load from the plaster layer.

Non-asbestos slate, cement particle boards

Fiber cement sheets are flat slates that do not contain asbestos. A concrete sheet reinforced with fiberglass mesh is called an “aquapanel”.

Fiber cement sheets are dense, have a uniform structure, are not hygroscopic, and are good for external cladding of a frame house for tiling.

Non-asbestos slate and DSP are attached to the frame with galvanized self-tapping screws.

The joints of the sheets are secured with sickle tape using tile adhesive, the edges (at the corners of the bathhouse, in the openings) are reinforced with a painting profile.

The adhesion of cement products is increased with a penetrating primer.

Panels, slabs, sheets are installed strictly vertically on the bathhouse frame, otherwise the casing risks “collapsing”.

Ceramic surface

Mineral products for outdoor use:

- Facing brick, facing ceramic stones;

- Large-size ceramic slabs, glazed or unglazed;

- Facade ceramic tiles;

- Carpets made from façade ceramic tiles (up to 1.15 m2 in area) are small tiles or tiles glued to wrapping paper with bone glue.

Brick facing is created during or after the construction of the walls and rests on the foundation. Ceramic slabs have a thickness of about a centimeter, are produced in square, rectangular shapes with side lengths close to a meter, half a meter and multiples of the traditional frame strut spacing - 0.6 m.

Frost resistance of large-size facade ceramics is 50 cycles, water absorption is not higher than 1%.

Ceramic tiles for external cladding have 15 standard sizes, divided into 2 groups:

- Facade (water absorption 2–9%, frost resistance of at least 40 cycles);

- Basement (2–5%, 50).

Both wall panels and blocks are covered with tiles. In unheated, damp rooms they are also used to decorate the internal surfaces of walls.

Block house outside

If you line the bathhouse with a block house from the outside, the building will resemble a log house: a block, frame bathhouse will harmoniously fit into the system of buildings made of rounded logs or calibrated timber.

Unlike traditional lining, the block house is available in different widths - from 11 to 19 cm. Installation of wooden products on the sheathing is more durable: the gap will create conditions for ventilation of the wall and cladding. Impregnation with anti-rot compounds and fire retardants will extend the service life of the cladding board. Sheathing and lining the outside of the bathhouse, competent finishing of rooms with different operating conditions is the key to safe, long-term and efficient operation of the bathhouse.

Construction of frame structure

Before installing a wooden structure, all elements are carefully treated with protective and antiseptic compounds for wood.

Assembly is performed in the following sequence:

- Installation of the bottom trim from bars with a cross-section of 10 × 10 cm.

- Installation of corner posts, checking the correct installation of each element using a level.

- Installation of intermediate racks in 80 cm increments.

- Making the top trim from bars with a section of 8 × 8 cm.

- Installation of bracing strips in the outer corners to increase the rigidity of the finished structure.

- Fixing floor joists from unedged boards.

- Installation of elements under openings for doors and windows.

- The internal lining of the finished structure is made of membrane material, which provides protection from the penetration of wind and moisture.

- External wall cladding.

How to properly insulate a door

Door insulation technology

Large heat losses occur through door cracks, so you must take care of the thermal insulation of the wooden or iron door leading to the bathhouse.

Felt, basalt wool, and foil insulation can be used as insulation. There are several ways to insulate a door; below we present the most common:

- A frame of 15x20 mm slats is mounted around the perimeter of the door, which should be 10 cm away from the edge of the door leaf.

- A piece of hardboard is placed inside the frame and stapled.

- Felt or other material is pulled over the top of the frame and secured with nails, which should be 5 cm larger than the frame itself.

Installation of a ventilation system in the dressing room

Ventilation in the dressing room is an important element that will ensure the necessary inflow and outflow of air in the room. This is required to maintain a favorable climate inside the bathhouse and maintain optimal heat transfer conditions.

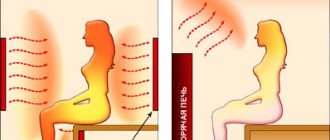

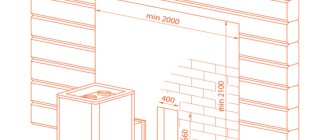

The ventilation ducts for the dressing room are arranged as follows:

- At a distance of 55 cm from the stove firebox we make a small hole measuring 16 × 21 cm.

- We prepare a wooden damper of the required size and attach a bar with a handle to the front side.

- On the side opposite the ventilation duct, we make another hole of the same size at a height of 200 cm from the floor level.

- We equip the second hole with a similar damper.

The dampers for ventilation ducts must always be closed.

How to insulate a dressing room correctly in order to maintain the required temperature between the steam room and other functional rooms? In this case, all surfaces are subject to insulation: walls, ceiling and floor.

Requirements

Before building a dressing room, you need to study the requirements that the room must meet:

- There should be enough space in the room. One person needs 1.5 meters of free space.

- If the bathhouse will be used in winter, the rest room should be heated to make it comfortable to be inside.

- A high-quality ventilation system must be installed inside - natural or forced.

- The room should have furniture installed for a comfortable stay.

- The light in the recreation area should not be too dim or bright.

Often the furnace channel with the firebox is discharged into the dressing room. In this case, the area around the firebox door must be fenced off. This space should not be subtracted from the free space.

Features of floor insulation

A functional bathhouse with a warm dressing room is equipped with a base that is resistant to high humidity.

To make a warm wooden floor, it is enough to install expensive heating systems - water or electric. An affordable option is to use inert floor insulation materials - cotton wool and extruded foam.

Work on thermal insulation of the floor is carried out according to the following algorithm:

- We install beams for the rough foundation on wooden logs.

- We cover the beams with a membrane for vapor barrier.

- We lay insulating material under the joists and secure it tightly to the frame.

- We overlap the waterproofing and secure it with construction staples using a stapler. We protect the connecting joints with metallized tape.

The wooden base under the floor is treated with antiseptic compounds to prevent possible rotting and destruction of the wood.

How to choose?

But the choice of insulation material cannot be uniform for the entire bathhouse as a whole. There are too many differences between individual rooms. In addition to the washing and steam rooms, you also need to place a locker room and a dressing room inside (often these rooms are combined into one if there is not enough space). The air in the vestibule is always cooler than in other compartments.

Paints and plasters, which manufacturers proudly call heat-protective, do not provide a high enough level of thermal insulation, and can only be an auxiliary element in it.

Bulk material is used mainly for roofing and flooring. It is much more difficult to lay it inside the walls, and for this you definitely need a well masonry. Brick dressing rooms are mainly insulated with foam plastic due to its ideal compliance with the required parameters and affordable price.

Frame fastening of insulation on a wooden beam is carried out for finishing:

- clapboard;

- plastic panels;

- boards;

- corrugated sheets and siding.

The installation pitch of the frame is determined by the width of the cladding being created. Considering the inevitable crumbling of foam when cutting, a certain supply of material should be reserved.

If the air humidity in the sauna waiting room is relatively low, it is permissible to use mineral wool. They attach it in the same way as polystyrene foam. If the spaces between the racks are occupied by communications, a layer of unedged board is placed above the frame, and thermal protection is mounted on it.

Given the insignificant thickness, such a coating will allow the most efficient use of useful areas. Where heating devices are attached, penofol should be left unfinished. It can also be used as part of underfloor heating. When placed under pipes or electrical cables, penofol increases heating efficiency.

When forming a slab foundation, the dressing room is insulated using wooden logs. The timber is connected to the slab using self-tapping screws; the gaps must be filled 100%.

In the case of a pile foundation, installation of all structures is carried out on beams made of steel or wood. They are treated, respectively, with antiseptics or anti-corrosion mixtures. The insulating layer must be covered with a vapor barrier in the form of a membrane that stops the condensation of steam inside the thermal protection.

The requirements for thermal insulation in a steam room will be significantly higher, but the following will help reduce the need for it:

- installation of solid double-glazed windows;

- formation of a high threshold with a low door;

- purchasing not a simple stove, but a heater;

- carefully thought out bathhouse configuration;

- high-quality ventilation.

Waterproofing material for a steam room should easily withstand even very intense heat. Kraft paper copes well with this task. The walls of the steam rooms are insulated with sphagnum (placed in the gaps of the crowns) and tow (bridging the cracks). Actually, insulation is achieved using building moss, extruded polystyrene foam, polystyrene foam and penoplex.

The advantages of synthetic materials are:

- resistance to mechanical destruction;

- long period of work;

- excellent heat retention.

It is chosen both because of its excellent practical qualities and because of its low cost. Expanded clay is also inexpensive, but it will have to be poured at least 30 cm inside the walls, which significantly complicates the work.

Ceilings can be insulated with clay; if they are filled with sawdust, soil must be placed on top of the insulation layer to ensure fire safety. Among modern solutions, experts recommend basalite, isospan, or overlapping layers of simple foil.

Specifics of ceiling insulation

An insulated ceiling reduces heat loss and provides a comfortable indoor microclimate. Basalt wool is used to insulate the surface. Additionally, work is being carried out to vapor barrier the ceiling.

The insulation process is carried out as follows:

- A layer of insulating basalt wool is laid between the ceiling beams.

- Polyethylene on a foil base is overlapped over the insulation. Thin strips are used for fixing to the beams.

- The connecting joints are covered with tape.

If the attic space is not used during the operation of the bathhouse, then the ceiling surface in the dressing room can be covered with flooring. Sawdust, clay or expanded clay chips are suitable as a thermal insulation base.

Furniture

What kind of furniture is needed in a bathhouse? You certainly won’t be able to do without a bench and a hanger; this is the bare minimum. But this does not mean that nothing else is needed in the waiting room. A small chest of drawers or whatnot , where you can put clean clothes, towels, tablecloths and other necessary things, would be quite Of course, if possible, then in the dressing room you can place not only a chair and benches for relaxation, but also a refrigerator or even a TV.

If you want to place a sofa in the dressing room, then choose upholstery made of leather or leatherette; due to high humidity, textiles will quickly become unusable. If you don’t like sitting down on your skin after a steam room, then buy a blanket made of natural fabric . All textiles in the dressing room should be easy to wash and dry quickly. For long service life of furniture and decorative elements in the dressing room, you need to ensure that vapor barrier and insulation are done according to all the rules.

Choose the design you like or come up with your own. Each dressing room looks different and bears the imprint of the owner’s character. You can see interesting ideas in the selection of photos.

Subtleties of wall insulation

For internal insulation of the walls of a log dressing room, foil foam or mineral wool is used.

All work on internal wall insulation is carried out in the following sequence:

- Installation of membrane vapor barrier on wall structures.

- Installation of wooden sheathing from bars with a cross-section of 5 × 5 cm, observing a step of 55 cm. Before installation, all elements of the sheathing are carefully treated with antiseptic compounds.

- Mineral wool flooring between the sheathing elements.

- Laying polystyrene foam on a foil base and fixing it to the sheathing using staples and a construction stapler.

The next stage is connecting communications and laying electrical wiring in a plastic corrugation.

After completing the insulation work, you can begin interior decoration of the room. The traditional interior of the dressing room involves the use of natural materials - wooden lining or tongue and groove boards. Do not forget that the design of the dressing room should be combined with the general design style of other bath rooms.

Details

Types of finishing materials

If the bathhouse is built of logs, then its finishing will be damaged. The brick facade can be insulated even from the outside, but the inside is left unchanged. The only thing that can be used is to cover it with a protective composition against fire and mold. The use of paints and varnishes is contraindicated. Due to the high temperature, they release harmful components into the atmosphere of the dressing room and steam room. Bath decoration must meet the following parameters:

Environmental friendliness - at elevated temperatures there should be no release of harmful odors into the room.- Practicality - easy to clean, ventilate and repair.

- Thermal capacity - during operation, the finish must maintain an ideal temperature regime.

- Fire-resistant properties - extremely important for walls that are adjacent to the steam room.

- Aesthetics - not just the body, but also the soul should rest, and because of this, the interior is far from the last factor for an excellent rest.

If we consider the most well-known finishing materials, we can highlight several main ones:

- Wood is the most popular option. Can be used on walls, floors or ceilings. Finishing the dressing room with wood will meet all the properties that are listed. Fire-fighting qualities are added through the use of specialized protective liquids. Block house, lining must be mounted on the frame, which makes it possible to insulate even the dressing room. If a similar finishing of the dressing room, made with your own hands earlier, has lost its original appearance, then it can be returned by sanding the surface and again covering it with protective compounds.

- Stone helps to impart rigor and elegance, and special color can be achieved by combining stone and wood. Its use for a wall structure adjacent to the steam room is more than justified. When heated, the stone will accumulate heat in the dressing room for a long time, which will create an optimal microclimate for comfortable relaxation.

- Tiles - a system of heated floors with ceramic finishing is a guarantee of comfort. In addition, tiled finishing is excellent waterproofing. With such floor coverings, the additional condensate source from the underground space will disappear. Often the wall adjacent to the steam room is also decorated with ceramics. The heat transfer effect will be lower than that of stone, but all fire safety rules will be observed.

Bath decoration using all of the above methods makes it possible to create a healthy microclimate and comfort, which is so important for proper rest and recuperation. The best option would be to finish the ceiling, fix wood on the wall surface, lay ceramic tiles or wood with a heated floor system adjacent to the steam room - with stone or tiles.

Floor finishing

Taking into account the fact that people often run out of the steam room barefoot, the floor in the dressing room should be warm. The following basic methods for arranging floor coverings can be identified: wood and tiles.

Ceramic coating in the dressing room. For such finishing it is necessary to install a heated floor system. Otherwise, your feet will begin to freeze after leaving the steam room, because the tiles do not have high thermal capacity. The tiles can be laid on the concrete surface, and for this you need to carry out a number of preparation works, depending on how ready the rough base is.

- Earth - first, this surface needs to be leveled and compacted, and then a cushion of sand (from 0.4 to 0.5 meters) is poured, which needs to be compacted on top. To do this, it is important to lay waterproofing and insulation (that is, polystyrene foam) on top. New layer - installation of reinforcing mesh and pouring concrete screed. The last layer will be laying electric mats for the heated floor system. To finish with tiles, the base will be ready; it needs to be made according to the height of the base.

- Joists - waterproofing must be laid on the subfloor surface. Insulation material is placed between the joists, i.e. Styrofoam. Afterwards, boards are installed with a thickness of 2.54 cm. A waterproofing layer is laid on top, and then the DSP boards are fixed. Everything needs to be covered with film, a concrete screed should be poured and a warm floor should be installed.

The base in the prepared type can be finished with tiles.

Wood floor

This is the most common option for covering the floor of a waiting room. But here it is important to take into account the high degree of humidity indoors. For this reason, this decoration of the relaxation room and bathhouse will include the following layers:

- Waterproofing - laid on a clay or sand cushion.

- Treating logs with a special agent against rot and mold. Along the overall length, blocks are nailed onto which subfloors are laid. You can also use croaker, but it needs to be coated with a rot-protective agent.

- Finished floors (planks). It is recommended to leave gaps between the insulation and the finishing coating for ventilation.

It is important to choose coniferous wood. The fact is that its resins have natural antiseptic properties, and essential oils will have a beneficial effect on human health. It is also recommended to use hard wood varieties for flooring – larch, oak. But this is a completely different price category. Finished floors are not coated with varnish. When heated, it is capable of releasing harmful aromas into the microclimate of the room.

Wall decoration

Finishing a dressing room in a bathhouse with your own hands is not difficult, and for the installation of all types of coatings it is recommended to provide insulation, waterproofing and, if necessary, a gap for ventilation.

Finishing with clapboard and block house

This type of cladding material requires the construction of a bath frame, which makes it possible to easily waterproof and insulate wall surfaces. It should be noted that the lining is usually installed vertically, and the block house only horizontally. For this reason, the guides for the first finishing material are attached horizontally (perpendicular to the installation), and for the second type only vertically.

The process itself can be divided into the following stages:

- Laying vapor membrane insulation.

- Installation of guides - most often wood beams are used.

- Laying insulating material – mineral wool sheets.

- The sheathing is made with a foil reflector, and the joints are fastened with metallized tape.

- Installation of bars - guides for final finishing.

- Final cladding.

This technology is aimed at retaining heat to the maximum, and the ventilation gap makes it possible to ventilate the finish. There should be no difficulties when covering with clapboard. It is installed using hidden nails or clamps. Materials for fastening are chosen with an anti-corrosion coating. For forcing, elements such as skirting boards, corners, and also strips for connection are produced. Wood can be used, as well as conifers, in contrast to the steam room. When installing a block house, difficulties may arise with corner joints. They need to be cut at an angle of 45 degrees, and the internal finishing of this type, according to the fixing method, is similar to the finishing of lining, and the appearance is strongly reminiscent of rounded logs. We do not recommend covering indoor walls with protective compounds, especially those that border the steam room.

Finishing with natural stone or tiles

If the bathhouse is made of timber or logs, then it is necessary to cover the walls with sheets of plasterboard in advance, which will make it possible to insulate and waterproof them. The technology is as follows:

Laying membrane-type vapor insulation.- Installation of guide profile/beam.

- Installation of insulation into a frame, which is covered with a foil reflector.

- Sheathing with plasterboard.

- Putty.

- Tile finishing – clinker tiles imitating natural stone are often used.

This type of finish is more suitable for walls adjacent to the steam room. When heated, it will distribute heat evenly and for a long time to the rest room. The finishing of the dressing room with stone and block house looks interesting. The simplicity and roughness of the lines will make the interior especially cozy. If the building is brick, it is necessary to insulate the walls from the outside using a ventilated facade system. The inside needs to be waterproofed as best as possible before sheathing it with wood. Such measures greatly reduce heat losses during operation and also protect against damage due to moisture.

Sheathing the ceiling

The most suitable option is clapboard finishing. Technology for arranging suspended ceilings with the finishing process of walls using wood. Maintaining a technical clearance for ventilation of the finish will increase its service life. The ceiling is the weakest point when decorating the inside of the dressing room with your own hands. The fact is that moist warm air from the steam room and temperature changes are the cause of condensation. For this reason, waterproofing must be mandatory, and thermal insulation materials, or more precisely, mineral wool, are recommended. A video with instructions for finishing the ceiling is presented below.

Decorative floor finishing

The next stage in arranging the dressing room is tiling the floor. Moisture-resistant wood species such as larch, oak and cedar are suitable for finishing. Before starting work, all materials are treated with antiseptic impregnation to prevent rotting and destruction of wood fibers.

The work is performed in the following order:

- Lathing bars are mounted on the waterproofing layer, observing a step of 40 cm.

- The lining is treated with fire retardant compounds for wood.

- The board is installed on the sheathing using the “tenon and groove” type and secured with self-tapping screws near the walls.

- A protective rubber coating is laid on top of the lining.

What to do if you need to paint the floor in the dressing room, which is lined with wooden paneling? In this case, colorless varnishes and stains are used, which protect the coating from premature wear and damage.

Characteristics of wood

Linden. This type is familiar to practically everyone. Its positive qualities were already familiar to our ancestors, who made many household items from linden, etc. This wood does not absorb moisture, has a pleasant aroma and light color. Linden is one of the most popular materials and copes with the task perfectly. Does not swell or deform during use.

Aspen. Most consumers prefer aspen. It is durable, does not rot, and does not change its appearance for a long time. Does not contain resins or other substances harmful to health. Often used for interior decoration of saunas and other places with high humidity.

Pine. For rooms with a stable temperature, pine is used. Dressing rooms and rest rooms are lined with it. This wood does not crack, is durable with a pleasant aroma. Many people consider pine to be a harmful material because of the resins it produces. But that's not true.

Interesting to see:

Oak. Of course, this white wood is a more suitable option for interior decoration of baths. But not everyone can afford it. In the operational environment it has proven itself to have a long service life, high strength, and resistance to rotting. It has virtually no disadvantages. At high temperatures, they release favorable odors and substances that improve human health.

The variety of cladding materials opens up enormous possibilities for the consumer. Wood is easy to work with. It is quite easy to cut and performs health-improving functions well. Having chosen the right product, the steam room will have a fairly high attendance, having a great impact on the health of clients. Only natural substances are placed in these rooms.

Types of extensions to the bathhouse

Construction of an extension to a bathhouse will cost less than construction of a separate building, due to the presence of a common foundation and roof. There are several types of buildings that can be erected to an existing bathhouse.

Gazebos

The gazebo is a structure of various geometric shapes - circle, square, rectangle and polyhedron - which can be equipped with a stove, barbecue and barbecue.

Depending on the design features of the gazebo for the bathhouse, they can be represented by the following types:

- Open. The bathhouse roof forms a special canopy for protection from precipitation. The structure has no walls and is equipped with support posts, a canopy, and openwork or wicker railings.

- Half open. Structures with one- or two-sided walls and a curtain roof.

- Closed. They are represented by pavilions equipped with panoramic windows with an open or semi-open frame design. Can be used as a living room or relaxation room.

- Transformers. Functional structures, the walls of which are erected from sliding aluminum profiles.

Verandas

Structurally, the veranda resembles a gazebo, since it is a semicircular, triangular, square and oval shaped room. The veranda attached to the bathhouse will become not just an original architectural addition, but also a functional area for comfortable relaxation for visitors.

Verandas are of the following types:

- Open. Structures with support pillars instead of walls and a roof overhang. An excellent option for a lean-to bathhouse.

- Half open. The structures require the construction of walls and a foundation and can be built under or without a canopy.

- Closed. Pavilions with walls and roof. Panoramic windows turn the extension into an open or semi-open area.

Terraces

The terrace is an open, unglazed area, decorated with a low fence around the entire perimeter. Such an extension can be built under the same roof as the bathhouse, which will provide additional protection from precipitation.

Depending on the location, bath terraces have several design options:

- Construction in front of the entrance group. This is a traditional option for arranging a terrace, which involves dividing the building into functional zones: a terrace for relaxation, a dressing room for storing things, a steam room and a washing room for wellness treatments. The extension can be small (up to 7 sq. m) and spacious (up to 13 sq. m).

- Construction of a free-standing structure. A similar type of terrace is installed next to the bathhouse near an artificial or natural reservoir.

- Construction around the perimeter of the building. The structure has a common roof with the bathhouse, and the railings serve as a protective fence.

- Construction on the second floor. A more complex version of the site, which can serve as a balcony or veranda. Requires additional waterproofing and floor insulation. It is better to build baths above the technical premises.

Restroom

The relaxation room is designed for restorative treatments, healing massages and complete relaxation.

Ready-made bathhouse projects provide for the arrangement of a relaxation room next to the steam room; in most cases, a similar function is performed by a dressing room.

When constructing a small-sized bathhouse and in order to save usable space, the room can be attached to the outside of the building. In this case, the addition of a recreation room will require the construction of a solid foundation and a reliable roof structure.

An alternative solution is to arrange a relaxation room in a closed gazebo or veranda.

Rain canopy

The most affordable and practical option for adding a bathhouse. It can be represented by the following types:

- Porch canopy. Provides reliable protection of the entrance group from the negative effects of precipitation. The hanging structure is made of polycarbonate and metal sheets mounted on a frame. It is designed in the same style as the main building.

- Garden shed. A stationary or removable structure that is erected near the bathhouse and serves as an open gazebo. Does not require the construction of a foundation or side walls.

- Carport. The design is suitable for sauna houses that are used in the summer or on weekends. An attached open box near the bathhouse will provide additional protection for the car from precipitation.

Each plane has its own finishing coating

Traditionally, a bathhouse has three rooms - a steam room, a washing room, and a relaxation room. In each room it is necessary to definitely finish the walls, floor and ceiling.

The steam room welcomes ceramic or wood flooring. The advantage of such floors is their naturalness and roughness. True, for the floor you will have to select wood that does not slip and does not rot. Therefore, oak and birch are immediately crossed out.

Decorating the inside of a bathhouse with clapboards with your own hands has an analogue option - covering the walls with standard boards. As for the ceiling, it must be hemmed.

The washing room allows the use of lining and boards for wall cladding. But the floors and ceiling can be organized using porcelain tiles and a suspended ceiling, respectively. If the latter hits your pocket, then you can limit yourself to plasterboard sheets.

The rest room does not have any special requirements for decoration (although the walls, floors and ceiling should continue the general idea of a wooden bathhouse).

Lighting

The lighting in the waiting room should not be too dim or too bright. You need to create a comfortable atmosphere by choosing a neutral type of lighting. At the same time, in conditions of high humidity it is undesirable to use open-type lamps. The selected options must have an optimal water protection class.

The type of lamp must correspond to the chosen design style. Moreover, it must be combined with other lighting devices installed in the bathhouse. Most often, there is no window in the dressing room, which reduces the level of illumination.

In small baths, small lamps are installed. These can be spots, spotlights. The best options would be wall-mounted lamps (models without pendants). They need to be positioned in such a way that the room is illuminated equally along the entire perimeter. The presence of dark corners will make the waiting room uncomfortable.

If the dressing room is small, one lamp is enough. In a spacious room, you can install several identical lamps, placing them along the ceiling beams or linearly. In addition, they can create a specific light composition, emphasizing a specific area of the room.

The body of the selected device must have a high resistance to high temperatures and humidity. Water or steam must not enter the lamp. The maximum permissible power of purchased lamps should not exceed 75 W. If it is larger, the light sources will quickly burn out.

Frame material

Main raw materials:

- beam;

- metal profile.

Let's look at the pros and cons of using each material for the frame.

Wooden beam

It is often used as a raw material for the frame of houses, verandas, and baths.

The thickness (section) of the beam is selected in accordance with the load-bearing capacity of the structure, the type of heat-insulating material.

Wood raw materials are purchased, impregnated at the factory, or treated with antiseptics independently before installation. The costs in both cases are almost the same. But if you buy ready-made timber, you will save time.

The frame consists of an upper and lower frame.

Advantages of a wooden frame:

- convenience and ease of material processing and installation;

- affordable price;

- environmental friendliness of the material;

- attractive look.

The main disadvantage is the limited service life and the need for periodic maintenance of the wood. In addition, we must not forget about the high probability of shrinkage.

Metallic profile

Masters call such structures LSTK - light steel thin-walled structures.

The raw materials are profile pipes, channels, angles (optional).

The metal frame is compatible with any type of foundation. It is not used so often for arranging baths.

The key factor that affects the cost of the structure is the profile section. The larger the cross-section, the more difficult it is for the pipe to bend, so the cost of the work increases.

For the outer cladding of the frame, corrugated sheeting, siding, and PVC panels are suitable.

Among the advantages of a metal frame structure:

- Quick installation.

- Possibility to assemble the building at any time of the year. Metal is not afraid of temperature changes, while a bathhouse made of brick or aerated concrete needs to be laid out only at above-zero temperatures, otherwise the masonry mortar will lose its properties.

- Does not shrink throughout the entire period of use.

- Provided high-quality anti-corrosion treatment has a long service life.

- Light weight simplifies the process of transportation and installation.

- Low price compared to stone and brick baths.

The downside is the need for high-quality anti-corrosion treatment of the metal. Otherwise, the metal will begin to rust.

What it is?

The dressing room is a room for undressing, located in front of the sink and steam room. Today it is not only an obligatory element of the building and a undressing area. A modern dressing room is characterized by maximum functionality.

Depending on the size and layout of the bathhouse, it can be not only a undressing area, but also a place of rest, storage of equipment, and arrangement of the furnace room. An alternative concept of a dressing room implies a small room designed to retain heat from the steam room and prevent the return of cold. In such a room they store steam room caps, essential oils, and wooden containers that cannot be kept in the steam room all the time.

A dressing room is needed to restore the user’s body temperature before going outside. This space is almost always separated from the shower, toilet, or room with a swimming pool. Its arrangement is related to the assigned functionality.