The vast majority of our compatriots are confident that there is only one carriage - a structure used for mounting artillery pieces. But the Norwegians do not agree with this statement, and call the beams processed using a special technology, which are used specifically for the construction of buildings and structures, as a carriage. The second meaning of the word carriage seems to us more pleasant and correct.

Lafet - what is it?

What is a carriage

Initially, a carriage was called a log, from which a “slab” was cut off from two parallel sides - the bark and part of the trunk. The result was a material that was much more convenient to work with than an ordinary log, because the same width of the carriages made it possible to make even walls from them. Gradually, the carriage began to be called not only cut logs, but also some types of profiled timber assembled into a “Norwegian castle”, a special type of connection in which a complex-shaped hole is cut out in the upper and lower timber. The Norwegian lock is a further development of the laying of log cabins, but adapted to new materials, therefore it uses all the best solutions, such as joining in a clasp and an okhryap, moreover, fixation with the help of such a lock increases as it shrinks.

The connection in oblo (from the Old Slavonic “obly”, that is, round) involves cutting or cutting out a bowl in the upper log, the size and shape of which corresponds to the lower log. Thus, each upper crown keeps the crown underneath it from spreading. The connection in the okhryap involves the creation of identical, but 90° rotated locks in the upper and lower beams. The width of the lock is equal to half the diameter of the log, and the depth is equal to a quarter of the diameter.

Pros and cons of carriage houses

In most cases, the carriage is made from logs of natural or high humidity, so the material itself is cheaper than any type of timber, with the exception of double. Read about what double timber is in the article (Houses made of double timber - features of construction technology). Due to the fact that the carriage has high humidity, after the start of shrinkage, cracks begin to cover the saw cut, which are a distinctive feature of houses made of rounded logs or timber with natural moisture. If, under the name of a carriage, you are offered a profiled beam with a connection in a Norwegian lock, then the cracks on it will look very ugly and even alien, so it is difficult to call such a beam a carriage. However, many companies call profiled timber of varying humidity, assembled into a Norwegian castle, a carriage, so we will stick to this so as not to cause confusion.

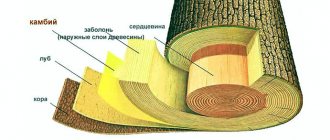

Compared to a log, a carriage, like all types of timber, is less resistant to rot and mold, because a layer of sapwood is cut from its ends, which is highly resistant to these damaging factors. Therefore, the carriage requires more serious protective and aseptic treatment than a peeled or unbarked log. But the main advantage of the carriage is the Norwegian lock, which has one unique quality. The more the wood dries out, the tighter the joint.

Because of this, houses made of gun carriages, such as those in the photo, are very popular, despite the fact that the Norwegian castle is very complex to make and requires great skill. A house assembled into a Norwegian castle is much stronger than any other wooden structure that has to be reinforced with dowels. Therefore, the number of dowels that go into making a house from a gun carriage is always less than what goes into a frame made of logs or sawn timber.

Useful video

In this video you will learn how to assemble a mansard roof:

The attic is that room in your home that can carry a wide variety of functional loads: from a workshop and office, to a bedroom and living room. Arranging an attic will cost you much less than a full second floor. And the technology for its construction is more accessible. In this article we will look at the types of attics, as well as the stages of constructing an attic with your own hands.

The attic is a room limited from below by an interfloor ceiling, and from above and on the sides by roof slopes. Depending on the shape of the attic slopes, there can be:

- single-level symmetrical with a gable roof (a, b);

- single-level symmetrical with a sloping roof (c);

- single-level asymmetrical (g);

- two-level asymmetrical (d).

Cost of building a house from a gun carriage (photos of projects)

The price of building any wooden house consists of the cost:

- lumber preparation;

- lock cutting;

- delivery and storage;

- installation

Preparing lumber for a real carriage is inexpensive, since it is enough to trim the log on both sides to ensure the same thickness and remove the bark. A carriage in the shape of a beam is a little more expensive. These materials do not need to be thoroughly dried because the Norwegian lock compensates for the effects of drying. A decorative carriage in the form of a profiled beam will cost much more, because it will have to be dried to a humidity of 12–14%, otherwise cracks will ruin the appearance of the house (see photo). Therefore, the cost of preparing materials depends on what kind of carriage you are interested in.

Cutting locks, if carried out on site, is very expensive, because the Norwegian lock, in terms of complexity of execution, surpasses any other connections, including such as “claw” and “dovetail”. If the house kit is prepared at an enterprise, then in the conditions of a woodworking shop there is no difference in the complexity of the lock. Modern equipment can easily cut a lock of any shape, complexity and size. Therefore, the cost of cutting locks directly depends on where this operation will be performed.

The cost of delivering a carriage does not differ from the price of the same operation for any other type of timber, but storage is cheaper because the carriage is not afraid of dampness, unlike profiled or laminated timber. Therefore, the cost of delivery and storage of the carriage is comparable to that of a log or sawn timber with natural humidity.

The cost of installation directly depends on where the locks will be cut. If the assembly is carried out using a ready-made house kit, then highly qualified workers are not required for this, which means the operation will cost much less. If the house is assembled from sawn timber or logs, which are processed on site, then the services of a specialist who can independently mark and cut the Norwegian lock are very expensive due to the high complexity of the work.

Concept

So, the gun carriage. What it is? These are logs that differ from the traditional log house familiar to the Russian population in their square shape with rounded corners. This technology for processing logs appeared during the search for options to reduce the cost of building a wooden house. Once on the territory of Russia and other post-Soviet countries, the carriage became a very strong competitor to a conventional log house, since its cost is much lower, and its thermal insulation qualities are in no way inferior to the usual round logs. This innovation confidently competed with traditional solutions and is successfully used to this day.

Lafet, timber or log?

A house made from a gun carriage does not have any serious advantages or disadvantages compared to houses made from rounded logs or sawn timber with natural moisture. In appearance, it is inferior to a house made of double, profiled or laminated timber, although some, on the contrary, like “antique” cracks. Therefore, a house made from a gun carriage is chosen by those who are not embarrassed by its shortcomings and are satisfied with the low price when using a house kit. If you have to make the carriage or cut the locks on the spot, then the house made from the carriage loses its main advantage - its low price.

One of the people I talked to on YouTube prompted me to open this topic. This work is certainly not an easy one, but I don’t think it’s too difficult, the main thing is to be able to work with a saw, and most of all with your head. The only downside to this procedure, if you don’t do it yourself, is the price.