A good-quality frame bathhouse is not just a room for washing. A well-thought-out structure looks harmonious inside and out, pleases with its atmosphere and consistent style, and matches the landscape. Detailed modern designs for frame baths allow you to build a reliable, durable structure that will last for many years. If you dream of taking a steam bath in the near future, having a pleasant rest and recharging your energy, the technology for constructing frame baths opens up all these possibilities for you. In a short time, with an affordable budget and excellent results.

Features of a panel bath

The correct name for such buildings is a frame-panel bathhouse. The production process of such baths is quite complex and requires money. The main element in baths of this type is the SIP panel.

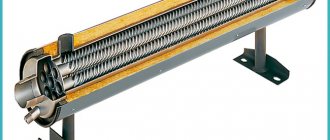

Its structure resembles a sandwich. Inside two sheets, which are made from high-quality wood, there is insulation. It is able to retain heat even at low temperatures.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Attention! High-quality structurally insulated bath panels are made from oriented strand boards. There must be only polystyrene foam inside them. Other heat insulators are not suitable for this.

All layers of the panel are connected using an adhesive composition, which is applied by cold pressing. After gluing, all surfaces must be treated to prevent possible moisture from entering the structure. During assembly, all panels are fastened using a wooden beam using a standard tongue-and-groove lock.

The supporting frame must be made of high-quality wood and must be treated against fungus and pests.

The bars in high-quality baths are laid horizontally and vertically to obtain good rigidity and support for the entire structure. Frame-panel baths are usually decorated with siding or block house.

Attention! During assembly, be sure to pay attention to whether all seams and joints are sealed. They need to be well filled with polyurethane foam.

Walls

An equal distance between the axes should be maintained, approximately 60 cm if there is no connection with other walls, as well as if there are no door or window openings in the wall.

If you plan to join walls or openings, the distance between the posts is 40 cm. An additional rib is placed next to the frame. Installation proceeds from the corners, starting from the wall communicating with the harness. Sheathing is done after the frame is completely assembled.

Advantages

Despite the high cost of the structure, if they have a budget, many are happy to choose frame-panel baths.

This is explained by the large number of advantages of such buildings:

- the cost of frame-panel baths is half that of log baths;

- quick construction that does not require the use of special equipment;

- the low weight of the entire structure together with the roof allows you to save on the construction of the foundation;

- after completion of construction there is practically no shrinkage, which allows you to immediately finish the baths to your liking;

- the ability to erect structures of increased complexity in any climatic conditions;

- due to the light weight of the entire structure, the bathhouse can be built on any type of soil;

- due to low thermal conductivity, the room heats up very quickly and cools down slowly;

- low thermal conductivity reduces the consumption of heating materials several times;

- external panels are absolutely fireproof, as they are treated with anti-foam;

- all materials, including the adhesive composition, are absolutely safe even with strong heating;

- all walls are smooth, do not require leveling and can withstand any finishing materials;

- baths are not afraid of temperature changes, the material does not deform or rot;

- Such structures can be erected at any time of the year; fungus and mold do not form on them due to antiseptic impregnation.

It is a rare developer who is able to offer a client an individual project for a frame-panel bathhouse. As a rule, only standard ones are built, which is due to the characteristics of SIP panels.

Waiting room

A frame one-story house with a bathhouse, like a multi-story building, requires the organization of a dressing room in the appropriate room. This room is a changing room. It is advisable to install benches here for the convenience of changing clothes, and put lockers or nail hooks for clothes.

To build a frame house with a steam room, you need to become familiar with construction techniques. The work can be done with your own hands, but it is recommended to invite professionals to arrange some communications. This will require additional costs, but will guarantee quality work.

Flaws

Despite the large number of advantages of such structures, the negative aspects of such baths should also be taken into account.

These include the following:

- the maximum service life is 50 years, but only subject to high-quality assembly;

- It is imperative to ensure the integrity of the seams and joints; if the thermal insulation layer heats up above 125 degrees, it may catch fire or become deformed;

- externally, without additional cladding, panel baths are not very aesthetic and of the same type;

- if the installation technology is violated, the strength of the entire structure is greatly lost and thermal conductivity increases;

- during external and internal finishing it is recommended to use only non-combustible materials;

- If the seams are poorly sealed, the likelihood of large heat loss and rats and mice getting inside the panels also increases.

Attention! During repairs, care should be taken to ensure good insulation of the connection points of sockets and switches. Even a small spark can cause internal material to burn.

Step-by-step technology

When all the materials have been purchased, and the tools have been collected in a pile and humbly waiting in the wings, it’s time to move on to practical actions. And it’s worth starting with the project. You should build a frame bath only after you have decided on the layout . If you want to arrange, for example, a bathhouse with a veranda and a barbecue under one roof, then reflect this desire in your working design.

- What size plot do you have?

- Do you want to separate the steam room and sink?

- Are you ready to sacrifice a rest room for the sake of extra meters in the dressing room and vestibule?

Find the answers to all these questions - and then it will be easier for you to decide on the design of your frame bathhouse. In addition, the Internet is now full of ready-made projects and drawings . All that remains is to adjust the scale and take the tools into your own hands. However, do not forget that you are based on the size of the area at your disposal. And it goes without saying that for complete comfort you should take care of a certain usable area around the building. And in case of frequent use of the bathhouse during the winter season, you should even ask about the veranda .

Work on the foundation

- we drive pegs around the perimeter of the proposed frame bath and make a ditch approximately 0.6 meters deep, the width can be determined in each individual case, but not less than 0.4 meters;

- fill the vacated space with sand to approximately 1/3 of the entire depth and fill it with water on top, after which we compact it thoroughly;

- we fill in the prepared gravel, and on top - a layer of sand, which is then leveled with soil using a building level;

- we make formwork from reinforcement and fill everything with concrete;

- The final touch is insulation with roofing felt; a thin layer of it is enough.

Leave your foundation for at least a week - during this period it will settle well and “gain strength”.

Walling

- dry the lumber prepared for the construction of the walls of the frame bath; it is best to choose linden or aspen, since these species have an excellent ability to retain heat;

- after erecting the wooden frame, treat the inside of the boards used with any antiseptic, and the outside with varnish, and it is advisable to use at least 2 layers of it;

- make a harness from timber and fix it from below;

- secure the beams in each corner with regular nails and support them with metal posts so that they do not disturb their balance;

- fill the base posts with concrete;

- mount intermediate support posts; the same material that you use for the basic structure is suitable for them;

- decorate the floor by laying out timber, give preference to a section of 0.15 meters.

Erection of the roof

- select eight ceiling beams cut at a certain angle;

- align the outer rafters, and then fasten a few more directly in the center;

- arrange the remaining ones through the ridge, fixing them to the capital structure from different sides;

- the next step is to install vertical posts to improve the strength of the base;

- if the frame bathhouse you make with your own hands has an attic, then think about an exit for it in advance;

- those rafters that protrude beyond the edges are sequentially processed - we cut out the beams with our own hands, and then we nail the boards and fix the battens.

We insulate the walls, floor, ceiling

- one of the best options is mineral wool, but roofing felt should be abandoned, since during operation it can release harmful substances into the air and cause a nasty odor;

- we place roll-type insulation between the vertical posts, and then secure it with slats;

- We have already protected the floor from moisture with timber, and now we use expanded clay - it is cheap and retains heat well;

- To insulate the ceiling with your own hands, you can use polystyrene foam, but you should protect it with a vapor barrier film - this way you will avoid an unpleasant odor and can extend the life of your frame bathhouse.

We design windows and doors

If your project includes openings for windows and doors, now is the time to fill them. Don't forget that both windows and doors must be securely sealed. During breaks between using a frame bath, the room should be ventilated as thoroughly as possible.

Interior decoration

The logical final touch is the pleasant interior decoration of the frame bath. Making it yourself will not be difficult. Moreover, the key to comfort is not only a reliable design and high-quality materials. It is also important to carry out competent finishing work so that every person feels as comfortable as possible in the bathhouse and can fully relax. That's why:

- the ceiling can be finished with pine upholstery - this not only looks impressive, but also reliably protects the materials from the harmful effects of high temperatures;

- the stove is finished with red ceramic brick or its fireclay version - this way the heat will be retained much longer, and the air in the steam room will be more humid and pleasant;

- the walls are finished with clapboard - it’s inexpensive, but very practical and, by the way, quite nice. You can use different types of lining, or better yet, its spectacular European version.

Important points before purchasing

After deciding to purchase and build a frame-panel bathhouse, several points need to be taken into account in order for the structure to be as strong and durable as possible:

- all panels must be smooth, without bumps or streaks;

- there should also be nothing superfluous or deformed in the internal section;

- it is desirable that the heat insulator be of an even shade without interspersing other materials;

- SIP boards should not emit a sharp or unpleasant odor;

- when purchasing a turnkey panel bathhouse or with a rough finish, all seams must be foamed, the places of sockets, switches and light bulbs must be well insulated;

- you should definitely pay attention to the window frames, the connecting joints should also be well foamed and hidden;

- the minimum width of the plinth beam cannot be less than 20 cm;

- all panels must be treated with antiseptic and anti-foam, these points can be checked in quality certificates;

- the minimum cross-section of timber for the construction of a vertical frame cannot be less than 10 cm;

- for the longevity of the bathhouse, it is better that the roof is gable, especially in areas with snowy winters, and does not weigh down the frame;

- you should not buy structures covered with metal tiles; it is better to buy buildings with sheet or roll roofs;

- There should be a vapor barrier material between the inner and outer skins, and ideally there should also be water and wind insulation.

If possible, during construction you should invite a third-party specialist who can evaluate all technological aspects and errors.

Frame steam room 6 by 4

Project of a medium-sized 6x4 frame bathhouse for a large family and for guests. There are also three rooms inside, but their area is much larger. Their sizes allow you to visit the steam room comfortably.

Two layout options for a 6 by 4 bath.

The frame bathhouse in the 4x6 design is equipped with a spacious shower and a comfortable lounge with a sofa, armchair and table for tea drinking. Room sizes:

- Steam room – 2x2.1 m with two shelves. This space is quite enough for 5 people to visit.

- Shower room – 2x1.9 m – there is a shower stall installed here, so you can change clothes and leave things inside.

- The rest room – 4x4 m – is a spacious room in which you can relax, have a tea party or even spend the night.

The project also includes a porch with steps. The construction materials are the same as in the 3x4 project. The above do-it-yourself frame bathhouse project is carried out without much effort during the step-by-step construction of the bathhouse.

Questions and Answer

Why should a bathhouse be built only from panels with polystyrene foam insulation and OSB boards?

They are resistant to moisture and perfectly maintain indoor temperature. Other panels can quickly become deformed, especially if poorly assembled.

Is it possible to hang storage cabinets, hooks and shelves in the dressing room on the panel?

Can. SIP panels are very strong and can withstand even heavy hanging furniture.

How to care for SIP panels so that they last longer?

There is no special care for the material. You should constantly check the integrity of the joints and avoid problems with the wiring.

What type of finishing is better to choose when ordering a panel bath?

If the bathhouse is ordered turnkey, the manufacturer will do all the necessary finishing at the factory, but it is so difficult to assess the quality of the entire structure. With a rough finish or without it at all, it is easier to consider the quality of the build, but the walls will have to be covered on site.

Which foundation is better to choose for a frame-panel bathhouse?

It’s better to go with a tape or shallow-recessed one.

With your own hands: how realistic is it?

You can build a frame-panel bathhouse yourself. But you will only get a truly high-quality structure if you purchase a ready-made set of panels, manufactured in a factory, and assemble it according to the manufacturer’s instructions (if you still want to do everything yourself, it is better to opt for the frame method, not the frame-panel method. Study the technology of building the facility .

Photo: ]Ekodomstroy (Moscow)[/anchor]

ATTENTION ! Panels cannot be cut or sawed!

The presence of panels of various shapes will make it easy to assemble the object.

Types of panels:

- wall (the external wall and the partition wall are different in thickness);

- window;

- door;

- corner;

- floor panels;

- roofing

IMPORTANT ! Buy quality products from a good seller. BEWARE ! Unscrupulous manufacturers use low-quality glue and gluing using artisanal methods, which leads to loss of strength.

Perform all stages of work sequentially. Comply with construction standards and technology.

A worthy alternative to frame-panel baths are buildings made of foam blocks.