The bathhouse has become a desirable attribute for residents of cottages and dachas. A simple wooden structure gives people health and unique sensations. For those who cannot afford to build a bathhouse from logs, there is an alternative option - a frame-panel bathhouse.

This design consists of a frame made of wooden beams, covered with insulated panels. This type of construction is different:

- low cost of materials;

- short period of construction of a bathhouse;

- rapid heating and low thermal conductivity of the material;

- minimal shrinkage;

- ease of doing the job.

The disadvantage of the design is the joints between the panels, which must be carefully sealed using mineral insulation and vapor barrier.

Project

Bathhouse layout

A small do-it-yourself panel bathhouse includes three rooms: a washing room, a steam room and a relaxation room. This is an optional arrangement; the number of rooms can be increased or decreased as desired. You can make a room design yourself or use a ready-made one. On the drawing it is necessary to note the location of windows, doors, stoves, communications.

Recommendations for planning a bath

First of all, consider the optimal building area . For one person, 5 m2 is provisionally provided. That is, if you want to accommodate four visitors in a steam room, start from a total area of 20 m2 (at least). Below we offer a list of which rooms should be included in the bath complex:

- steam room;

- shower and font;

- restroom;

- dressing room;

- toilet.

Sketch out a few diagrams and drawings for yourself:

- general plan of the building;

- separate drawing for each room;

- schematic structure of the foundation;

- plan for fastening and laying out timber;

- floor and ceiling arrangement plan;

- installation diagram of a sauna stove with the removal of its design features.

Foundation

Columnar foundation from the inside

On the site chosen for the construction of a bathhouse, markings for the foundation are carried out using pegs and twine. For light frame construction, a pile base made of asbestos-cement pipes is most often used. These supports will last a long time, they are durable and do not collapse under the influence of moisture. The work does not require special skills or the use of special equipment.

The underground part of the pillars is buried below the depth to which the soil freezes in winter in your region. Their diameter is chosen taking into account the weight of the planned building; for a bathhouse, pillars of 20 cm will be required. Asbestos-cement piles are placed in each corner of the building and at the intersections of walls. All places for pillars are marked with pegs.

Pillar

Pits for pipes are dug from 1 to 1.5 m, a sand cushion of 20 cm is placed at the bottom. The pillars are leveled, and if there is groundwater, they are coated with mastic for waterproofing. The base of the pipes is filled with concrete. The outer side is wrapped with roofing felt and covered with sand. 2-3 iron rods are placed inside the pillars and concrete is poured. After it hardens, construction of the frame begins. A columnar foundation will make it possible to place a drain and provide floor ventilation. Instead of asbestos-cement pipes, reinforced concrete blocks can be installed.

Important Rules

It is useful for novice builders to learn a number of rules, thanks to which the bathhouse will last for many years:

- do not build a steam room too close to a pond to eliminate the risk of flooding, or near a road;

- decide on the location - a separate building or an extension to the house;

- ventilation and wastewater disposal are important tasks that should be solved at the design stage;

- the building must be located taking into account the cardinal directions and wind direction, preferably in the southern part of the site, protected from the wind, with access to the west;

- a very careful attitude should be taken to fire safety, especially if the bathhouse is adjacent to the house;

- To maintain normal relations with neighbors, consider the size and location of the bathhouse so that the owners of the neighboring property do not experience discomfort and do not make complaints.

Base trim

A layer of roofing material must be laid on the installed pillars as waterproofing. Next, the base piping is installed. To do this, take a 120x120 mm beam and soak it with an antiseptic. It is better to use softwood such as pine or cedar. The beam is laid around the entire perimeter and fastened using the “half-log” method - half of one beam is sawn off from the top, and from the second from the bottom. When connected, a flat plane is formed. The piping, checked using a level, is attached to the pipes with anchors.

Advantages and disadvantages

Advantages of using sandwich panels for bathhouse construction:

- Light weight of the material, which eliminates serious load on the foundation.

- Ease of transportation, installation and storage, which is important for small-sized construction.

- Good thermal insulation, thanks to which the desired temperature will always be maintained in the bathhouse.

- Possibility of choosing decorative panels of different colors to match the surrounding landscape.

- Fire resistance. A bathhouse is a building with a high level of fire hazard, so it must be built from non-combustible materials, which include sandwich panels.

- High level of sound insulation. In a sauna made of sandwich panels it is always quiet and comfortable, which allows you to completely relax and unwind.

- Hygiene. Mold and mildew do not grow in the panels, despite the fact that the humidity level in the room is always high.

A sauna made from sandwich panels is not without its drawbacks , including:

- Simplicity of design. The panels are not suitable for creating complex architectural structures.

- Difficulty in calculating the required number of sheets. With little experience in construction work, it is almost impossible to do it yourself, which leads to loss of money.

- Difficult installation.

Owner reviews

People who built bathhouses from sandwich panels are satisfied with their choice.

They note that objects heat up very quickly and retain heat for a long time. This design is inexpensive, cheaper than brick. However, you have to spend money on high-quality insulation. At the same time, many users note the safety in terms of non-flammability of materials .

The main disadvantage of this design is their unnatural composition. People are used to steaming in wooden saunas, but they are wary of sandwich panels. Difficulties in performing calculations are also noted.

Reviews of saunas made of sandwich panels can be found here and here.

Frame making

The supporting racks are made of timber 12 cm thick. They are installed in the corners of the bathhouse and where partitions are built. The racks are attached to the bottom frame with steel corners. The beams must be installed strictly vertically, using a plumb line and level for control. Before completing the top trim, the racks are fixed with temporary struts.

If there are long walls, the installation of additional racks is required. For them, timber with a smaller diameter is used. The spacing of the racks is 50 cm; 1 meter is left for the doorway. You can install the beams by cutting out the base beam, but in order not to weaken it, it is better to use steel corners.

The top trim is made in the same way as the base trim. Its horizontal position is set according to the level, and the beam is attached to the racks with metal corners. Ceiling beams are laid on the frame.

Devices for work

Before starting any work, pay due attention to preparing the necessary supplies. It is better to spend time collecting them before construction begins than to be distracted later.

You will need the following equipment:

- Circular Saw;

- jigsaw;

- level;

- hammer;

- square;

- electric screwdriver;

- nail puller;

- mites;

- hacksaw;

- yardstick;

- axe;

- all kinds of fasteners;

- insulating materials;

- construction panels;

- timber for arranging the frame.

Roof

Construction of the roof

The frame of the bathhouse is ready, all that remains is to cover it with a roof. The roof structure is chosen taking into account the amount of precipitation; if there is a large snow cover, it is better to install a gable roof. The roofing material should not weigh down the structure of the bathhouse, because it has a light foundation. It is better not to use natural tiles, but to choose rolled roofing. To construct the roof, hanging rafters are installed, to which horizontal sheathing is attached. Its pitch depends on the choice of roofing material. A waterproofing membrane must be installed under the roof.

The interior of the bathhouse ceiling is finished with clapboard. For insulation, mineral wool is laid between the beams, a layer of vapor barrier is lined underneath, and waterproofing is placed on top. When sewing up the ceiling, the outlet of the chimney is arranged.

Design Features

Sandwich panels are ready for use immediately after purchase.

With their help, frame baths are erected. Thanks to simple installation and the presence of insulation, the building will be ready in the shortest possible time. Main design features :

- If OSB-based panels have been selected, they should not be installed on a slab foundation. Only a pile or column support is suitable. Otherwise, after 6 months the base and floor will become unusable.

- A bathhouse made of sandwich panels needs finishing. If you ignore this stage, the slabs will delaminate under the influence of dampness and frosty air. They are plastered and finished with log siding or other materials. Such buildings look no worse than brick or wooden ones. This applies to OSB building material.

- Be sure to think through both natural and forced ventilation systems. This will avoid the greenhouse effect under the roof.

- The boards must be connected tightly. Failure to comply with this rule will result in freezing of the building.

Frame covering

In order for the bathhouse to retain heat well at any time of the year, you need to properly insulate the walls. Mineral wool can be used as insulation, but polystyrene foam, which does not absorb moisture at all, is more reliable and durable. The material is placed tightly between the frame posts, the polystyrene foam boards are glued together with construction tape. Waterproofing is stretched from the outside of the insulation; for this you can use polyethylene film. On the inside, a vapor barrier is attached. Isolon is a suitable material; its foil layer is directed inside the bathhouse, the joints are glued with special tape.

Shield size

For external wall cladding, boards or OSB boards are used. You can decorate a bathhouse with siding or a block house. Boards of deciduous trees are used as internal cladding: alder, linden, aspen. Lining made from coniferous trees (pine or spruce) is cheaper, it is perfect for a rest room and washing room.

The final finishing of the bath requires the installation of partitions between rooms, windows and doors, flooring and a stove.

The construction of a frame-panel bathhouse does not take much time and does not involve significant financial costs. Before starting work, you can watch a video describing the stages of work.

We recommend reading:

- do-it-yourself sauna stove made of metal;

- how to make shelves in a bathhouse dimensions;

- do-it-yourself concrete font for a bath.

Straight to the point: don’t confuse technologies!

If you think that a frame-panel bathhouse is the same as a frame bathhouse, just a more detailed and longer name, then carefully read the following sentences. A frame-panel building is built from ready-made panels, which are purchased from companies that professionally deal with them. A frame building can be built by any home craftsman with minimal construction skills and tools. The frame is erected, filled with insulation, sheathed and finishing work carried out. If you need such a frame bath, then go to the appropriate section. If you are still sure that you need information on panel buildings, then read on.

Photo: VIVA HAUS company

Frame

The supporting structure is a wooden frame onto which all building elements are attached. The bathhouse is installed on the site without the use of equipment. This is 100% handmade. It is possible without the involvement of specialists.- When designing a frame bath, any customer requests are taken into account. The only restrictions are regulations.

- Quick commissioning of the facility.

- Frame baths, including mobile ones, have the most affordable price . The cost can increase: a) increasing the size of the bath; b) type of foundation; c) expensive materials for interior and exterior decoration; d) type of insulation; there are recommendations for insulating the roof, walls, floor and ceiling of the bathhouse; e) independent work or with the involvement of specialists; f) engineering additions...

- They are durable and reliable . A large number of stiffeners prevent the structure from deforming.

Frame-panel

1) The production of frame-panel baths is a complex, expensive process . The main structural element is SIP.

The design of SIP (structural insulated panel) is similar to a sandwich. Between two sheets of wood-based material there is a thermal insulation layer.

There is a wide variety of SIPs on the market. But, since you are interested in a bathhouse, then look for a sandwich where the outside is oriented strand boards with the abbreviation OSB, and the inside is polystyrene foam.

The middle layer binds the entire structure together using a special high-pressure adhesive (cold pressing). The wood leaves are strictly parallel. Waterproof treatment of slabs is carried out during their manufacture.

Individual design is not possible. Always a ready-made standard design solution.

2) This bathhouse is assembled quickly (2-3 days) . All blocks and elements are clearly adjusted to each other at the factory. 3) The cost of frame-panel technology is growing due to:

- expensive production;

- attraction of lifting equipment;

- possible increase in the number of construction crews.

4) The panels are attached to each other using a wooden beam, the selection of which requires special attention, according to the “tongue and groove” principle.

The joints are sealed with polyurethane foam. Vertical and horizontal bars provide additional rigidity and stability.

5) Panels can last more than 50 years.

Flaws

The increased fire hazard of frame buildings has already been written about. And this is the main disadvantage of houses built using this technology. Therefore, it is advisable to treat all materials with fire retardants (agents that reduce the flammability of materials).

The flammability of walls leads to the fact that all electrical wiring must be laid in metal boxes or special non-flammable corrugated sleeves. For this reason, electrical installation work becomes more complicated and more expensive - the cost of casings and corrugated hoses is added.

A frame bath has additional disadvantages: high humidity makes its own adjustments. You will have to pay increased attention to the vapor barrier of the walls. When using mineral wool, you will need to protect the insulation from moisture very carefully: when wet, it loses its properties. Moreover, when dried, it restores them only partially. If it freezes wet, it simply crumbles. Therefore, we choose a high-quality and reliable vapor barrier (not “hydro”, but “steam”). When laying, we follow the technology down to the smallest detail (overlaps, gluing joints and fastening points, etc.).

Advantages of frame buildings

The frame building is a skeleton made of timber, sheathed on both sides with finishing materials. A vapor barrier and insulation are laid between them. It immediately becomes clear that, if necessary, construction can be low-budget. After all, it is possible to use inexpensive thermal insulation materials (straw, sawdust, etc.) which, despite their availability, retain heat well.

It is clear that the weight of the walls with this technology is very small. And this leads to the fact that the foundation can be made lighter. When building baths, they are most often made using piles, piles and grillages, or strips. But a monolithic slab or block foundation is also suitable.

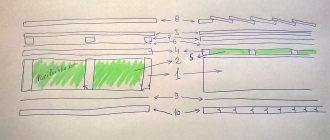

This is how the walls of buildings erected using frame technology look schematically

A lightweight foundation means lower costs for materials and construction, because the foundation sometimes costs half the cost of the entire construction. And in this option the costs will be relatively small.

To build a frame house, no sophisticated equipment is required. All you need is a saw, a hammer, nails, screws, a screwdriver, a plumb line and a level to check the verticality of the walls. If there is another technique, use it for your health, but this is the minimum you can get by with.

An important advantage is that you can work alone, only occasionally inviting assistants for some operations. A striking example is presented in the video: the woman herself, with her clearly unathletic hands, has almost completed the construction of a small two-story house using frame technology.