By visiting a heating equipment store, you can choose a model that is intended not only for heating rooms for various purposes, but also for cooking. The range is also complemented by sauna stoves, which are compact in size and are also complemented with stones, allowing you to obtain noble steam for a Russian steam room. An example is the Chenille stove, which can operate in one of two modes, the first is intense combustion, the second is slow.

In the first case, fuel combustion occurs at a high temperature, this allows you to heat the room and cook food in a short time. If you set the equipment to the second mode, when the gas generator system is activated, with one setting a comfortable temperature can be ensured for a period of 8 to 12 hours. The main type of fuel for such devices is firewood, which is publicly available and not so expensive.

Why should you buy Chenille?

The Chenille stove is equipment that is suitable for a summer house and a bathhouse. A long-burning device can replace a large Russian-style brick stove, which releases a large amount of heat into the house. However, the devices described in the article take up little space and consume fuel economically. Sometimes such units are compared to potbelly stoves, which guarantee quick heating of walls, houses and rooms, and can also be used for cooking. If you are interested in units with the mentioned functions, then you should pay attention to several models of the manufacturer, which will be discussed below. Characteristics, review and their features will allow you to make the right choice.

FREE transfer to transport companies: business lines, ratek, energy

The "NVU - 50/100" furnace is a unique invention made by energy engineers in Russia.

This stove is ideal for our winter. Please read these instructions carefully and use the oven correctly. 1. DESCRIPTION AND PURPOSE

The Tulinka oven is intended for heating domestic and industrial premises, cottages, garages, greenhouses, workshops, construction sites, as well as for drying mushrooms, fruits, grain, lumber, etc. With cooking function. The "NVU - 50/100" stove is an all-welded steel structure coated with heat-resistant paint (during the first firing, it polymerizes, which is accompanied by a characteristic odor). The furnace consists of two combustion chambers: the lower chamber – the gasification chamber and the upper chamber – the gas afterburning chamber. In the front part there are afterburner injectors. If you experience smoke coming from these pipes, your chimney is either not the right height or is clogged. The stove is equipped with two regulators: on the door (power regulator) and on the chimney pipe at the back of the stove (gasifier regulator). The efficiency of the Tulinka Furnace is up to 80%.

2. TECHNICAL DATA

| Technical data | NVU – 50 | NVU – 100 |

| Height, cm | 45 | 56 |

| Width, cm | 36 | 46 |

| Depth, cm | 53 | 69 |

| Weight, kg | 28 | 55 |

| power, kWt | 3,8 | 6,7 |

| Room volume, cubic meters | 50 | 100 |

| Weight of one fuel load, kg | 4 | 6 |

| Chimney diameter, cm | 12 | 12 |

Fuel. The Tulinka stove operates on all types of solid fuel: wood, wood waste, cardboard, peat briquettes, except coal. It is best to use large round logs the length of the stove itself (no need to chop wood). In all cases, one must strive to fill the entire volume of the lower combustion chamber - only under this condition can a period of continuous operation on one load of fuel be achieved for 8 - 12 hours.

3. INSTALLATION OF NVU OVEN – 50/100, “Tulinka”

The installation of the stove and the installation of the chimney must be carried out in compliance with the requirements of this manual, current fire safety standards and regulations.

INSTALLATION

It is recommended to install the stove no closer than 1 meter from walls and combustible surfaces (wood, wallpaper, etc.), at a minimum distance from the existing chimney (if any), and the free distance in front of the firebox should be at least 1.25 m. Distance to combustible surfaces can be reduced to 200 mm if combustible materials are covered with 25 mm thick plaster. or a metal sheet over a layer of thermal insulation material.

FOUNDATION

For better air circulation through the pipe system, raise the oven by at least 200 mm. from the floor level and install on a base made of bricks or slabs. stone or other non-combustible material. To ensure fire safety, there must be a metal sheet measuring 500x700 mm in front of the firebox, with the wide side facing the stove.

CHIMNEY Chimneys can be made of metal pipes with a wall thickness of at least 1 mm. ATTENTION! The pipe of your chimney should be higher than the ridge of the roof of your house. If the roof is flat, the pipe should rise 0.5 m above it. The recommended chimney height is at least 4 m.

4. OPERATION OF THE OVEN.

After installing the stove, make sure that the smoke duct joints are tight and that there is draft. To do this, hold a strip of thin paper or a candle flame to the open firebox door. Their deviation towards the firebox indicates the presence of draft.

KINDLING. Before ignition, set the power regulator and gasifier regulator to the fully open position. Then use paper and wood chips to light the stove.

ADJUSTMENT. After the fire has started, you add the main fuel, trying to fill the volume of the lower chamber as much as possible. After the main fuel has ignited and the chimney pipe has warmed up (15 - 20 minutes), you must close the gasifier regulator at least 45 degrees from its longitudinal position. Thus, you switch the oven to gasification mode. The position of the gasifier regulator, which ensures the best gasification process, is individual for each chimney height.

5. DELIVERY SET.

1. Gas generator furnace “Tulinka” “NVU – 50” or “NVU – 100” 2. This manual

6. MANUFACTURER WARRANTY

The manufacturer guarantees that the quality of the product meets the requirements of technical specifications TU 4858-002-57205680-2003, and undertakes to eliminate all manufacturing defects discovered by the owner within 24 months from the date of sale free of charge. The warranty on the stove is valid subject to compliance with the rules of storage, transportation, installation and operation in accordance with this “Operation Manual” and the requirements of SNiP 2.04.05-86, GOST 9817, “Rules for the performance of work, repair of stoves and smoke ducts”, VDPO, 1991 Guaranteed shelf life (without re-preservation) in consumer warehouses is 1 year.

Review of heating and cooking stoves from: model “C50”

The Chenille sauna stove is manufactured in Moscow, so its cost is reasonable and amounts to 9,800 rubles. It is a long-burning equipment with convection heating of air. You can use not only firewood as fuel, but also peat briquettes, as well as wood waste. However, coal should be avoided. The combustion chamber is divided into two parts, the upper one is called the afterburning chamber, while the lower one is called the main combustion chamber.

The fuel door is as tight as possible and has an adjustable blower. When the equipment operates in gas generation mode, gaseous products are formed in the furnace, which burn out in the afterburner due to oxygen entering through the holes in the injectors; they are also called afterburners.

Such a Chenille oven has a steel casing on the outside, which is separated from the device by an air gap; powerful convection currents arise in it, which heat the room. The casing plays a protective role against infrared radiation that comes from hot metal. There is a cooking stove on the top of the structure, covered with a lid that closes when the stove is not in use.

Preparation for use

For safe operation of the Chenille, you need to make sure that it is connected to the smoke channel, which must be without ledges and predominantly vertical. In total, the height of the channel must be more than 5 m . The elevation of the chimney above the roof depends on the structure of the roof and the location of neighboring houses. The head of the smoke exhaust duct must be protected from precipitation, and if the roof is made of flammable materials, then a spark arrester must be installed on it.

Before starting operation, you must make sure that all elements of the “Chinele” are securely and hermetically connected to each other. You should also check the presence of draft by holding a burning candle or a piece of thin paper to the open firebox door. The deflection of a candle flame or a strip of paper towards the firebox confirms the presence of draft. The tightness of the joints of the component parts can be assessed by the absence of soot on the surface of the seams when paper or wood chips are ignited in the firebox.

Reviews of the heating and cooking stove brand “S-100”

The Chenille sauna stove, reviews of which you can read below, is long-burning equipment. Consumers like that the device can be installed in any room; it can be not only a garage or a private house, but also a greenhouse or a country house. An important advantage is the ability to use at any time of the year. In winter, you can use the unit for efficient heating, while in summer, the stove is perfect for maintaining warmth on a cold evening, because the user will have the opportunity to adjust the temperature.

This long-burning stove “Chenel” also attracts buyers with the ability to install it in the smoldering wood mode, which is a new operating mode for such a stove. At the same time, the user will have the opportunity to save not only fuel, but also time and effort. It should be borne in mind that the heat will not come from the walls of the oven. The design consists of two cylinders that are located inside each other, this allows air to circulate between them. This technology provides efficient heating in smoldering mode.

Oven operation and safety standards

In order to remove the protective coating from the surface of the stove and get rid of volatile residues of the paint and varnish composition, it is necessary to heat it in medium mode for 2 hours in a well-ventilated area. The system should be installed on a stainless steel sheet away from flammable materials. Coarse gravel is used as stones in the “Chenille” bathhouse, filled to two-thirds of the volume, which allows maintaining the desired temperature for a long time.

For safe use of the oven, it is prohibited:

- melt it with flammable liquids;

- use something other than firewood as fuel;

- cover the oven body;

- independently change the design of the system;

- use “Chenelle” if any malfunctions are detected.

Only if these rules are observed, reliable and safe operation of the stove is guaranteed.

Technical characteristics of the heating and cooking furnace brand “S-200”

This heating stove “Chenelle” also has the ability to heat food, with its help you can prepare any dish. The weight of the equipment is 68 kg, and the height, width and depth are 673 x 560 x 785 mm. The chimney diameter is equivalent to 140 mm, and the equipment power is 11 kW. Thus, you can install the device in a room whose volume varies from 200 to 300 m3. You will have to pay 17,000 rubles for this equipment.

Advantages and disadvantages

Chenille stoves are usually used as gas generating equipment, when fuel smoldering in the chamber, carbon monoxide is released. The main advantage of the series under consideration is the presence of an afterburner chamber in which residual gases are completely processed. If you adhere to safety standards, this design minimizes the possibility of carbon monoxide damage.

What does a Chenille stove look like?

Another strong point of the Chenille long-burning stove is the ability to fully service large premises with its own small dimensions. The equipment helps maintain a comfortable microclimate for up to 12 hours. Sauna systems quickly restore the required temperature conditions literally after adding a few logs.

A significant drawback of the model range is the need to use pipes with a diameter of 140 mm when installing (they are quite expensive and are not publicly available). The manufacturer offers variations with pipes of a different diameter; with smaller parameters they are significantly cheaper. It is not always convenient for owners of sauna stoves to use tanks with a small volume; in this case, it is worth introducing additional capacity.

Prices for sauna stoves brand "Chenel"

If you are interested in the Chenille sauna stove, then you should pay attention to the characteristics and cost. For example, if we are talking about the “C35-1.3” model, then consumers speak of this equipment as a not too expensive stove, because you will have to pay 22,500 rubles for this option. The device is designed for a volume of up to 22 m3.

If you want the equipment to be supplemented with a tank, then you should pay attention to the “C35-2.3” model, the cost of which is 26,500 rubles. According to consumers, if a steam room is limited in free space, then it is worth choosing equipment with a tank on the side, an example would be the “C35-3.3” model, the price of which is 28,500 rubles. The volume of the room reaches 22 m3. If necessary, you can purchase a model with two tanks, in this case we are talking about the “S35-9.3” stove. However, according to buyers, its cost is quite high, amounting to 33,000-34,500 rubles.

Specifics of operation

Chenille ovens are filled with coarse gravel to approximately 2/3 of the total volume. Thanks to this, the resulting temperature is maintained for quite a long time. In addition, this ensures a sufficient amount of steam, without which a Russian bathhouse is simply impossible to imagine. The evaporation scheme resembles the Finnish one: water evaporates from one tank. This creates a wet steam room.

Installation of Chenille stoves

This design quickly heats the air and creates the required amount of steam. Just 30-50 minutes - and the steam room, with a volume of about 20 cubic meters, already warms up to 70 degrees, and the water in a 40-liter stainless steel tank warms up to 80 degrees.

There are special screens on three walls of the oven that effectively protect against burns. And if desired, it is quite possible to install an additional tank in which water will be heated, providing the required level of steam and intended for washing.

By and large, Chenille is the same Buleryan, only with a simplified design. The differences are lower efficiency and a less convenient flame power control system.

Positive reviews about sauna stoves of the Chenille brand

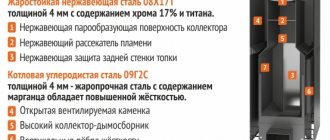

If you want to choose a truly durable model of a sauna stove, then you should consider the option that is designated by the supplier as number 50. In this case, the design uses 4 mm and 8 mm steel, the latter of which is included in the base of the combustion chamber. According to buyers, such a double metal jacket increases the rigidity of the product compared to analogues and increases service life.

The body is an all-welded structure. According to buyers, the presence of stones will allow for good temperature retention, and the room will be filled with real Russian steam. If we are talking about the standard model, then its power is 67 kW, and the weight is only 100 kg; this, as lovers of the Russian bath emphasize, is relatively low in weight, and there is no need to make a foundation.

Design features

Chenille stoves have a simple design - they look like an all-welded body equipped with four legs, it comes complete with an ash pan, protective screens and a chimney. The body contains a combustion chamber, closed by a door. At the bottom of the firebox there is a window with a cast-iron grate; under it there is an ash box (it also serves as an ash pan).

Chenille sauna stoves allow you to heat the room to 100°C within an hour. For the manufacture of the structure, sheet steel with a thickness of 4-8 mm is used. The firebox is equipped with double walls, which protects it from deformation at high temperatures. The basic variation produces dry steam for a sauna; the improved model is complemented by a tank located on the side, which produces wet steam for a Russian bath. Any configuration includes the possibility of installing an external firebox.

Protective screens near or around the oven

Screens are shields made of brick or metal that protect walls from intense thermal radiation. Similar protection is used when installing metal stoves.

- Metal screens are made from steel or cast iron sheets, these

casings surround the heat source with a distance of 3-5cm.

Additional frontal or front shielding, which is located on the walls depending on the location of the stove, will not hurt. The protection guarantees the wood from overheating, reducing the temperature by 100 degrees or more, and provides the opportunity to save space in the steam room. A stove protected by a casing can be installed at a distance of 50-55cm from the wall.

Installation of screens is simple. The casing, equipped with legs, is secured to the floor by side or front screens - with galvanized nails or self-tapping screws.

- Brick screens are masonry used to cover the stove with

on all sides, the same casing, only made of brick. Another method is to lay half a brick between the firebox and a wall made of solid fireclay bricks laid on a solution of clay and cement. The width of the wall should be 120mm, although there is an opinion that it is permissible to put 60mm in a quarter of a brick, but it should be remembered that in this case the thermal insulation value is reduced by exactly half. It is recommended to raise the height of the masonry 20-30 cm above the surface of the firebox, but if you raise it to the ceiling, it will not be worse.

We suggest you familiarize yourself with Protecting the wall from a gas stove

The screen should be placed at a distance of 10-15cm from the wall, 5-15cm from the stove, that is, the space saving is 30-40cm

Protective screens are effective; they reduce the temperature to a level acceptable when using high-temperature fuel units. The same function is performed by wall cladding made of non-combustible materials.

Such a system will need to be implemented when installing a potbelly stove in the corner of the room. You can mount or lay out several screens from brick, installed at a short distance from each other. In this case:

- The first screen protects a person from touching the iron stove and getting burned. It is usually made of refractory or fireclay bricks;

- To protect walls made of flammable material, a second layer of protection is provided. It can be made of brick or covered with a barrier made of sheet steel with a mirror-like front surface. In this case, heat waves will be reflected from the mirror and spread faster throughout the room;

- if the foundation is insufficient in size or it is impossible to manufacture it, it will be necessary to lay a protective screen made of durable fire-resistant material on the wooden floor. This can be a sheet of steel or a decorative layer of heat-resistant clinker tiles or porcelain stoneware. The surface will first have to be covered with a layer of thermal insulation.

Screens are shields made of brick or metal that protect walls from intense thermal radiation. Similar protection is used when installing metal stoves.

- Metal screens are made from steel or cast iron sheets, these

casings surround the heat source with a distance of 3-5cm.

Advice! When purchasing a metal sauna stove, you should give preference to a model equipped with a metal casing. Its cost is not much higher, but the issues of wall insulation are eliminated.

Installation of screens is simple. The casing, equipped with legs, is secured to the floor by side or front screens - with galvanized nails or self-tapping screws.

- Brick screens are masonry used to cover the stove with

on all sides, the same casing, only made of brick. Another method is to lay half a brick between the firebox and a wall made of solid fireclay bricks laid on a solution of clay and cement. The width of the wall should be 120mm, although there is an opinion that it is permissible to put 60mm in a quarter of a brick, but it should be remembered that in this case the thermal insulation value is reduced by exactly half. It is recommended to raise the height of the masonry 20-30 cm above the surface of the firebox, but if you raise it to the ceiling, it will not be worse.

The screen should be placed at a distance of 10-15cm from the wall, 5-15cm from the stove, that is, the space saving is 30-40cm

Important! Functional openings for heat exchange should be made in the lower part of the masonry. Protective screens are effective, they reduce the temperature to a level acceptable when using high-temperature fuel units

The same function is performed by wall cladding made of non-combustible materials.

Protective screens are effective; they reduce the temperature to a level acceptable when using high-temperature fuel units. The same function is performed by wall cladding made of non-combustible materials.