Design and principle of operation of "Buleryan"

This heating unit was developed specifically for mobile teams of Canadian lumberjacks who roam from place to place during the season (winter). Therefore, from the very beginning, high demands were placed on safety and efficiency: the oven must heat the room in a matter of minutes. At the same time, there is no complicated setup or adjustment, the possibility of getting burned should be kept to a minimum, and carbon monoxide should not be allowed to enter the room. On top of that, it's light weight. Here is such a set. And it must be said that “Buler” (one of the names of this design) fully corresponds to them, for which Canadian heating engineers need to say a huge “thank you”.

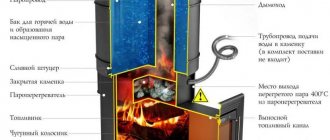

The design of the Buleryan stove - many interesting and effective solutions

The furnace body has the shape of a cylinder in less powerful models and teardrop-shaped (in cross section) in units for large heated areas. Sinusoidally curved pipes are built into the housing. They are mostly located inside the body, protruding only 1/3 from it. This is done for optimal heat transfer: cold air is sucked into the lower pipes, moving through the pipes it heats up and comes out hot. In the active combustion phase, the output temperature may be 120°C or slightly higher. From 4 to 6 cubic meters are pumped per minute, so the room heats up really quickly.

The firebox is divided into 3 parts. The top and bottom are separated by ¼: at the bottom there are grates made of cast iron or a grate made of thick structural steel (at least 4 mm thick). The upper quarter of the firebox is separated by a steel sheet with holes that occupy about 7% of its area. This partition is installed horizontally and does not reach the door by about ¼ of the length. In this secondary chamber, partial combustion of the gases released during the combustion of wood occurs. The air for this process comes from the firebox through holes in the partition. Therefore, fuel combustion is incomplete (yet). But not the entire process takes place in the furnace; the remaining part of the gases burns out in the pipe.

Cold air is sucked into the pipes from below, which is heated as it moves through the pipe.

The door is wide-format, the fit is sealed, there is a pipe on it with a built-in rotary throttle, which plays the role of a blower. By adjusting its position, the intensity of combustion is changed. Some manufacturers provide this throttle with a scale marked in degrees.

But that's not all the features. The main one is that part of the combustion products of wood occurs in the chimney. From the top of the firebox, unburned gases exit into a horizontal section of the chimney, up to 1 meter long. This section is mandatory for the Buleryans; the combustion of gases slows down a little and they cool down a little. The chimney then turns upward. And here the original Bulerjans have an economizer - a device that completes the process of afterburning pyrolysis gases. With it, the efficiency of the stove is around 80%, and without it - about 60%, which is also not bad, but... In a section of the chimney pipe 15-30 cm long, secondary burnout of gases occurs. The combustion is not constant, but periodic: it flares up and then dies out.

Branded Blerjan with economizer. It is installed at the factory and gives detailed recommendations on how to install the chimney, so you don’t need to invent anything.

To achieve this effect, the pipe is carefully insulated. For this, heat insulators that can withstand high temperatures are used (basalt wool, mineral cardboard, etc., a layer of 3-5 cm, depending on the characteristics of the material). Gases that have not completely cooled down in the horizontal section of the pipe enter this section, where, due to good thermal insulation, a large amount of thermal energy accumulates. The temperature of the gases rises, they flare up again. The flared gas increases in volume, but due to the limited volume, it clogs the lumen of the pipe. A plug of gases forms. All gases burn out, cool and dissolve. Then the process is repeated. Its intensity and frequency depend on the quality of the wood and the throttle position. “Buleryan” itself adapts to these parameters without additional adjustments.

Gate valve at the furnace outlet

A slide valve is installed at the exit from the furnace to regulate the draft intensity. The diameter of the damper is approximately 10-20% smaller than the diameter of the chimney. A sector approximately a quarter of a circle in size is cut out of the damper disk. This plug is welded to a metal rod, with the help of which it is movably attached to the pipe. It is with this gate and throttle on the door that the combustion mode is set. How often the stove “puffs” depends on the fuel and their position.

It is worth agreeing that the Buleryanov device is original and expedient in everything. Very interesting and unusual solutions made these stoves very popular. Moreover, even without the last afterburning in the pipe, they use the device and do not complain: its efficiency is much higher than air heaters of other designs. Added to this is high safety: even leaving the door open, it is impossible to get caught. The same as getting burned on a hot body: in normal operating mode its temperature is only 50-60°C, which is clearly not enough for a burn.

Conclusion

The Buleryan stove is very convenient and useful if you use it correctly. It does not accumulate heat near itself, but distributes it throughout the room. Such boilers can be used in a home, garage, industrial premises or greenhouse. All the tips presented in the article are most useful for people who use the stove all winter.

When choosing a stove, pay attention to the fact that Buleryan has a number of useful advantages - easy installation, cost-effectiveness, long service life, good heating (it is easy to maintain a comfortable temperature). To heat several rooms at once, it is necessary to lay additional pipes. But don’t forget that the Buleryan stove does not run on coal, only on wood fuel.

Combustion depends on many factors - outside temperature, fuel quality, wood moisture content, chimney height, so there cannot be exact instructions for heating. The main thing is to follow the instructions exactly so as not to harm people in the room and not damage the boiler.

Useful operating tips can be found in user reviews, but do not trust them 100% if they are completely at odds with fire safety rules and do not comply with the instructions.

At the present stage of development of society, the issue of space heating is very acute. From year to year, this kind of pleasure becomes more and more expensive. However, there is a great option that can help you save a lot of money. Buleryan – accessible heat. The device, which can rightfully be called a brilliant discovery, was created in Canada. This is a stove, which is also called a heater. It is made in such a way that the atmosphere is heated by the air itself. The operating instructions for Buleryan are not particularly complicated.

How to heat properly

The main operating mode of “Buleryan” is smoldering mode (firewood, pellets, wood chips, briquettes). Intensive combustion - only for the first time to quickly heat the room. If combustion is constantly active, the metal will quickly burn out: it was not created for such a regime.

First you need to light the oven. For these purposes, you can use paper, cardboard, pellets, dry wood chips, etc. the main requirement is dry fuel that burns at a high speed. The volume of the bookmark is for 20-30 minutes of burning. Here you need to get used to it: the fuel should turn into coals at a time when the room is almost completely warmed up.

First, add dry, fast-burning fuel.

The fire is lit with the damper and throttle open, and the door is closed. The fuel burns actively and the room heats up quickly: at this time, from 4 to 6 cubic meters of air passes through four pipes per minute, and the outlet temperature is around 140°C. So even a decent room won’t take much time.

You need to observe the process: through the glass in the door or through an open throttle, however, the second method is very inconvenient. When the fuel turns into coals, coarsely chopped firewood is added to the firebox. You can use whole logs of wood, just push them through... You can put in briquettes. What you can't use is coal. The oven is not designed for such temperatures. Bulleryans are a purely wood-burning stove.

Now set the throttle to the mode required (you can go to the extreme position up to the limiter), the damper to the “closed” position (¼ of the chimney cross-section remains open). In this situation, the fuel smolders, and the process proceeds in stages. Air heated to 60-70°C comes out of the pipes, and the furnace body has a temperature of about 50°C.

How not to heat: There is no need to “accelerate” the stove to super high temperatures. And it’s not just that the metal will burn out. It’s just that with this design, most of the heat cannot be transferred to the air through the heating pipes: its thermal conductivity is limited. And all the excess will simply fly away through the chimney into the street. Therefore, the manufacturer categorically does not recommend using coal or coke: it is a waste of money, and besides, the equipment will quickly break down, and the plant will not accept complaints - the operating conditions are violated.

Briefly about the main advantages

A small stove of this type can easily heat 100 m2, and a little larger in power and 200–400 m2, while the period between fillings can be about 8–12 hours. You only need to add firewood several times a day and the stove will maintain a constant comfortable temperature .

The rate of firewood combustion depends on the set power, and in many ways also on the type of wood. The room heats up very quickly - in 3 hours the air will be heated to an acceptable temperature. For large areas, several Buleryans are installed or a larger unit is purchased.

This stove is truly very convenient and versatile; it pleases the new owners with big dividends:

- heats a large area;

- uniform heating;

- absence of soot and smoke in the room;

- compact size;

- quick heating of the living area;

- saving firewood;

- easy-to-use door for storing firewood.

Installation "Buleryan"

When installing, you must maintain the distances to the walls that are recommended by the fire department. Examples of wall protection and distance to the stove depending on the material:

- wooden unplastered - at least 1000 mm;

- layer of heat insulator 7 mm, and metal on top 1 mm - distance 500 mm;

- non-combustible plaster with a layer of 25 mm and ceramic tiles - 700 mm;

- single brickwork (55 mm) - 500 mm;

- double brickwork (110 mm) - 300 mm;

- a shield made of two sheets of metal 1 mm thick, assembled using non-flammable inserts, the distance between the sheets is 30 mm; The structure is mounted on a wall protected by a layer of thermal insulation - the distance to the walls is 300 mm.

The Bulerjan stove must be installed on a non-combustible base. This could be four rows of bricks laid flat. A clay mixture is used as a solution. The dimensions of the base are 30 cm larger than the parameters of the stove in any direction. To save bricks, you can leave voids in the two bottom rows. Another type of non-flammable base is a metal stand for “Buleryan” made of pipes. Its height is 150-300 mm. For any installation method, a metal sheet must be placed on the combustible floor in front of the stove; its dimensions are: width 500 mm, length 700 mm.

Rules for installing Buleryanov on a flammable floor

When installing the Buleryan stove with your own hands, it is important to make the chimney correctly. They are subject to general requirements (except that it must all be insulated, but this is not a requirement of firefighters, but technological nuances). The chimney pipe can be:

- Brick. Wall thickness 120 mm.

- Concrete with a wall of 60 mm.

- Metal (including sandwich).

The chimney parameters depend on the model. For Buleryan stoves of types 00 and 01, the minimum height is 4 m, cross-section is 120 mm; for models type 02, 03 and 04 - above 5 m, with a cross-section of 150 mm. The chimney must be made airtight, and the joints must be sealed with heat-resistant sealant.

Both types of chimney outlet are allowed: through the roof or into the wall

Both methods of exhausting the chimney are allowed - through the wall and the ceiling. Output to the wall is easier to implement, especially if there are several floors. When exiting through the ceiling, it is necessary to equip a passage unit through the ceiling and roof in compliance with all fire safety measures. The height of the chimney above the ridge is at least 0.5 m.

As you can see, there are no excessive requirements for the installation: you have prepared the place, built a sealed insulated chimney, and you can carry out the first fire. So installing a Buleryan stove with your own hands is possible.

Tips for use

You will be satisfied with the purchased buleryan if you are careful when using it.

Although sellers in advertising talk about this stove as a universal solid fuel boiler, this is not entirely true. The best fuel in this case is wood. It is best to heat it with non-resinous woods such as acacia, poplar or birch. Briquettes and pellets that you can buy also work well. However, it is better to melt with logs, using briquettes during the combustion process. Never use flammable substances to light the stove.

Before stacking, it is best to dry the firewood on top of the stove, then it will burn more efficiently. A burning period of 8–12 hours is possible only when the firebox is fully loaded.

Never make the chimney pipe shorter than recommended. For successful combustion you need good draft, which is possible with a total chimney height of 5 meters . It is also recommended to assemble the chimney pipe not in the direction of gas movement, but against the movement. This will rid your flooring of resins that leak from the stove openings. If you install the chimney wisely, these resins will return and burn again.

The smoker needs to be checked and cleaned 2 times a year, then you will not have any problems with Buleryan.

Models

Buleryan heating stoves are produced by different factories in different countries. There is a plant in Ukraine. They produce heating “Bullers” and sauna stoves; there are also heat accumulators compatible with some models.

Ukrainian version. "Bullers"

The technical characteristics of Buleryan convection ovens manufacturer are summarized in the table.

Technical characteristics of Ukrainian-made Buleryanov (click to enlarge picture)

Thermal accumulators are used mostly in greenhouses, where there are almost no walls that accumulate heat in conventional buildings. The hinged panels are made of painted steel plates and completely follow the shape of the stove, so each modification has its own heat accumulator. The device is hung on the tops of the heat exchange pipes and rests on their lower ends. They can be filled with any solid heat-intensive material: broken brick, large crushed stone, pebbles, etc.

Canadian Bulerjan. Models of different power

Canadian Buleryan stoves are also represented in Russia. Their characteristics are summarized in the table. As you can see, the design is different, but the characteristics are the same.

Canadian Bulerjan. Technical specifications (click to enlarge image size)

First steps

First, we need to make the frame of our entire Buleryan stove - it is an interweaving of curved pipes that form an air heater and the future firebox. Use a pipe bender and bend them to a radius of 225 mm. The length of each pipe is 120 cm - this is more than enough. The pipes are welded together with metal strips to create a stable base for our stove. There should be no holes on the sides, otherwise smoke will penetrate into the heated rooms.

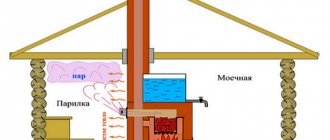

How to heat several rooms

Long-burning boilers "Buleryan" can be used to heat several rooms. To do this, it is not necessary to somehow alter or modernize the unit. You can assemble air ducts and a thermal chamber. Such an air heating system is no less effective than a water heating system, and requires much less money and time to organize.

Assemble the thermal chamber as shown in the figure. You can use galvanized drywall profiles and galvanized sheets. Assemble the frame from the profile. In galvanized sheets, cut holes for the grilles and inspection door, then attach them to the frame. Cover the galvanized surface with thermal insulation (mineral wool mats). Next, the camera can be decorated or not - as desired.

The thermal chamber will allow you to accumulate heat from the stove. From it you can already route air ducts between rooms

Air ducts are connected to the upper outlets for heated air. They can be made of plasterboard, or you can use metal pipes of the appropriate diameter or square ones, as in standard air ducts.

This solution is much more effective than putting corrugation on heat exchange pipes. In the heat chamber you collect all the heat from the furnace and then distribute it through the air ducts. In general, when designing or planning a system, keep in mind that the shorter the ducts, the more efficient the heating will be.

There is one caveat: some people really want to adapt this stove for water heating. Breneran and some other manufacturers of similar stoves even have “Aqua” options. But the operating principle itself is poorly suited for heating water: it has a greater heat capacity than air. The efficiency of such units will not be great. If you want water heating, buy a regular hot water boiler, long-burning or pyrolysis. It will be more efficient.

Making a chimney

If you think that the chimney for the Buleryan stove, assembled with your own hands, is a piece of pipe, then you are completely wrong. We will make a T-shaped chimney with a slide damper for our stove.

Unlike a throttle, the gap here is not completely blocked, but only 3/4 of the maximum diameter of the chimney - this is exactly the damper that will need to be cut out and installed in the outlet (horizontal) pipe.

We weld a vertical section to the horizontal chimney pipe of the Buleryan stove. Smoke will escape through its upper part, and condensation will accumulate in the lower part (it will definitely happen). To make getting rid of it more convenient, weld a ball valve to the bottom. Just one movement of the hand - and all the accumulated condensate will drain into a previously placed container, as we promised earlier.

Reviews about "Buleryan"

With reviews, everything is very simple: everyone who uses the stove is satisfied, very satisfied or “nightmarishly satisfied” (the last saying is a quote from one message). The only thing that people are actively discussing is an effective heat distribution scheme for heating a large number of rooms. What they encounter during operation: the accumulation of soot in chimneys, which needs to be cleaned from time to time. Another thing worth remembering (again, from operating experience): you cannot narrow the chimney, then adjusting the Buleryan will be either very difficult or impossible (this is to adjust the position of the damper and throttle for stable combustion and high efficiency).

Determining the size of the buleryana stove

The size of the stove is of great importance. In the shortest, smallest buleryan (length - 455 mm, width - 620 mm, height - 555 mm), the firebox is correspondingly small, so not much firewood can be stored.

The fuel burns in such a miniature boiler from two to six hours. It depends on the type of wood, the quality of the firewood, and the thickness of the cutting. Accordingly, the area of the heated room will be small - this must be taken into account when choosing the size of the future buleryan.

Of course, for rooms with an area of more than twenty square meters, long-burning stoves with larger dimensions are designed. The average dimensions of a buleryan are: length – 835 mm, width – 436 mm, height – 640 mm. A large stove has the following parameters: 950 mm by 676 mm with a height of 1505 mm.

Frame of a homemade stove Buleryan

Where to buy high-quality oven equipment?

- Prompt delivery throughout Russia. Shipping to remote regions is carried out 1-2 days after payment for the equipment.

- Low prices. We work directly with suppliers, eliminating markups from intermediaries, which allows us to make the best offer on the market.

- Warranty from 2 years.

- Quality control and compliance of equipment with domestic and foreign standards.

To buy a Buleryan stove or get advice, contact the company’s managers by phone or leave a request for a call back.

The manufacturer that produces long-burning stoves, Breneran, has accumulated impressive experience in the production of such equipment. These products have decent demand on the Russian market. The company gives a 2.5 year guarantee for the reliability and safety of its products.

The production company Laotherm has been present on the Russian market since 1993. Previously it produced equipment under the Buleryan brand. Since 2005, the products received a modern brand name - Breneran. This company also produces more budget models - Buran stoves. They are in no way inferior to their predecessor.

Classic stove design

In order to make a homemade unit, you should carefully understand its design and understand the principle of operation. An all-metal product consists of a minimum number of elements. The basis of the furnace is a cylindrical firebox with curved metal tubes tightly adjacent to its walls. On the front side there is a door for loading fuel and a device that allows you to regulate power and set different combustion modes. In the firebox itself there is a secondary combustion chamber and an outlet pipe to which the chimney is connected.

To increase the efficiency of such a furnace, it is imperative to ensure high-quality thermal insulation of the smoke channel. Ordinary mineral wool is perfect for this (a layer of ≥ 3 mm is sufficient). Do not forget that to supply air to the combustion site, you should install a ash pit. It would be useful to install a small ash pan. The double rear wall also improves the efficiency of the device. A number of models have a two-layer oven body.

Bullers without pipes

Professor Innokenty Nikolaevich Butakov (not to be confused with Alexander Vladimirovich Butakov, also a professor, but a lawyer) actually invented the Buleryan back in the 20s of the last century, attaching an afterburner to the top of a potbelly stove with a heat shield. Nowadays, stoves such as “Butakov”, “Professor Butakov”, “Student” in modern design (see figure) successfully compete with Buleryans on the domestic market. Their technical characteristics and principle of operation are similar, like identical twins, but making “Butakov” yourself is much easier, as can be seen from the figure.

Convection oven Butakov

Checking the welding machine

The main tool in the manufacture of a furnace is a welding machine. First you need to make sure it is working properly. If you have minimal experience in such work, we recommend that you first practice on training seams. At the final stage of assembling the stove, you will have to scald it around the entire perimeter. You need to be prepared for this. In addition, do not forget to check the metal and pipes for weldability. Materials may need to be replaced.

Should I do it myself?

Properly made homemade buller

Before moving on to the features of installing and operating bulleryans, their improvements and varieties, you need to dwell on the question: is it worth making a buller with your own hands? The reason is primarily the selling price of ready-made factory ones. Bullers are very technologically advanced: the zero cycle of their production comes down to the manufacture of a couple of bending templates and welding jigs. The material of the product is even scrap metal.

A very good 10-15 kW Buleryan can be purchased for $200-250. At the same time, equipment that is usual for a camp repair shop is not kept at home, in a garage or on a summer cottage, if only because of the lack of suitable space. And ordering piece-by-piece rather large parts made of thick metal will cost much more.

Perhaps the only exception is if a self-made master works at a remote provincial factory, where most of the technological equipment is still idle. And the “Soviet-style” management will allow him to use the machine park in his free time, and will even allow him to rummage through the landfill and pick up workpieces. Although at current prices for scrap metal this is unlikely.

In this case, we will give advice: do not be tempted by narrow water pipes for batteries. The minimum diameter of air ducts is 60 mm; it is determined by the ratio of heat capacity and viscosity of air. A buller with a “picket fence” is unlikely to be more economical than any other slow-burning stove, but it is more difficult to make. A drawing of a design that is unsuccessful in this regard is shown in Fig. below, and an example of a correctly executed homemade buller is in Fig. on the right at the beginning of the section.

Drawing of an erroneously designed buller

Video: review of homemade buleryan

Flaws

- When loading wet firewood, resins will form as it burns, so you should only use completely dry fuel.

- When selecting wood for fuel, you need to choose species that do not emit resins.

- In the second furnace in Buleryan, only 70% of the generator gases are burned.

- If the chimney was not insulated before the Breneran sauna stove was installed, then condensation may be released, which will reduce the performance of the device.

- Due to the metal body of the device, in addition to the additional protective coating and sheathing of the surrounding walls with basalt insulation, a distance from the walls of at least half a meter will also be required, which is not always convenient in small spaces.

- Due to dust getting into the pipe opening, an unpleasant odor may occur when the oven heats up.

- The rooms in which the stove is located require daily cleaning and ventilation, since during its operation charged ions are formed that can have a negative effect on the human body.