Probably every stove owner eventually has a question about changing the type of fuel. This happens for various reasons. For example, someone used to use wood before, but now wants to try coal or peat to fire the stove, since these types of fuel provide more heat. Or maybe buying firewood is more expensive for someone than buying coal. But be that as it may, you still need to know how to properly heat a stove with coal. Although not all stoves are suitable for this type of fuel. For example, you cannot put coal into a Russian stove; a Dutch stove is not suitable for it, since large soot deposits and significant overheating are contraindicated for it. But coal is suitable for potbelly stoves, steel, cast iron and other heating structures.

Coal and its types

At first glance, all coals are the same. But this is far from true. Coal contains carbon and some non-combustible impurities. As a result of the combustion of these substances, a lot of heat is released and ash is formed.

Different regions produce coal with different amounts of impurities. Fuel types are determined by specific criteria. Thus, depending on age, the presence of humidity and impurities, as well as the specific heat of combustion, the following are distinguished:

- lignite coal, which is characterized by a loose structure. It is used less in everyday life, and is more often used to ensure the functioning of power plants and other large enterprises. It refers to young coals (specific heat of combustion (SHC) less than 3 thousand kcal/kg);

- brown coal, which is also called subbituminous coal or black lignite. It is, as it were, a transition phase between lignite and coal. It is usually used in small or private boiler houses. It is a good quality raw material for the chemical industry (TCV from 3.1 to 5.1 thousand kcal/kg);

- hard coal, which is a hard, combustible, mineral resource, occupying an intermediate place between brown coal analogues and anthracite (UTS from 5 to 5.6 thousand kcal/kg);

- anthracite is the oldest and best of all varieties, which is characterized by black color, shine, and high specific heat of combustion (from 7 to 9 thousand kcal/kg). The rooms, heated with anthracite, are incredibly warm and cozy.

What is produced when burning wood

Now we can answer the main question of the article.

Regardless of the size of the flame and the surrounding conditions, wood always turns to charcoal first. If at this moment the flame goes out for some reason, then coals will remain in place of the fire. When the fire burns out to the end, by this time the coals have time to become ash, which remains when the wood is burned. There is an opinion that you can get ash immediately by burning wood, bypassing the stage with coals, but this is not so. The procedure for the appearance and decay of the latter can be done as quickly as possible if there is a high temperature and enough oxygen around, but it cannot be avoided.

Whether ash or coals remain at the site where the wood was burned depends solely on the moment when the flame goes out. If the fire is extinguished early, then instead of firewood there will be coals; if you let it burn to the end, constantly maintaining the flame, only ash will remain. The latter can no longer be used as fuel, so further maintenance of the fire becomes impossible.

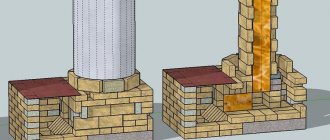

In which ovens can you burn coal?

Since, as a result of combustion, coal produces a higher temperature than wood fuel, stoves for combustible stone (black gold) are slightly different from wood-burning designs.

Although, you can burn with coal using an ordinary brick oven, but only with thickened walls and a 2-row grate. Plus, such a heating structure must be equipped with an additional hood that would not be connected to other channels.

There are designs with two water boilers in the furnace, with the help of which not only the room is heated, but also the brickwork is significantly cooled. Such devices require special supervision, since they must constantly contain water.

Plus, the dimensions of the grate and ash pan must be identical, otherwise there may be significant heat losses.

It will be interesting! Instructions on how to make a bell-type stove.

Coal storage

Coal for heating WPC is easy to place on the site and store. Coal can be placed outdoors. It does not get wet and is not afraid of precipitation. Coal is quite heavy, several tons of coal takes up very little space. I dumped the coal in the area and covered it with a tarp to make it easier to get it out from under the snow. Coal is available both in bulk and in bags. In bags it is more expensive, but it is already prepared for burning, chopped into pieces the size of a nut. But unloading these bags can be a problem, whereas bulk coal can be emptied from a dump truck in 2 minutes. In loose coal there are large pieces that then have to be chopped. I chose this option. It’s even fun for me to go out into the frost in the morning and chop coal. I stab him with a cleaver (a kind of sledgehammer, one side of which is made in the form of a wedge)

A set of measures before starting the fire

For the normal passage of the entire combustion process, it is necessary:

- carefully inspect the stove structure, starting from the firebox door of the stove and ending with the chimney. If cracks are found in the brickwork or chimney pipe, they must be sealed with a sand-clay mixture. Otherwise, the room will instantly fill with smoke, a large amount of carbon monoxide may appear, and small cracks will turn into large cracks and can actually damage the masonry;

- whitewash the pipe if you have not used the stove for a year or more;

- clean the chimney structure, including chimney channels, pipes from soot (if you have not used the stove for 3-4 months);

- clean slag and ash from the furnace. To avoid the appearance of dust in the room, combustion waste must first be filled with water, then raked out and taken outside;

- check for traction. To do this, insert a newspaper folded lengthwise into the firebox, set it on fire, and if smoke goes up the chimney, then everything is fine;

- use a dry cloth to wipe the outer part of the heating structure, otherwise an unpleasant odor will appear during the fire;

- Heat a little at a time 2-3 times a day, if the unit has not been heated for a long time, to prevent overheating of the stove.

*

Owners' opinions

Below are some reviews from stove consumers.

“We purchased a stove for the Rus bathhouse with a fireplace door. It looks great and very presentable. And it works even better - a couple of clutches, and the steam room is already 110°C. Comfortable warmth without the feeling of suffocation. Economical fuel consumption coupled with a stylish design and an affordable price - Teplodar with both hands!”

Zarina Radina, Sverdlovsk region.

“The most affordable option for our home was the opportunity to buy a Teplodar gas stove. We doubted for a long time whether this would be an effective solution. But in reality everything turned out to be very simple and functional. The latest design of the stove allows you to steam comfortably after just 30 minutes of intense heating. No worse than wood heating. Thanks to the manufacturer, we were satisfied."

Sergey, Moscow.

“Based on feedback from friends, I decided to purchase a Rus stove from the manufacturer Teplodar. Outwardly, it is presentable; I was attracted by the increased manufacturer’s warranty of up to five years. Well constructed - thick, good steel. It’s a pity I didn’t immediately buy a tank for heating water; then I had to run around looking for a suitable one. I haven’t found any complaints in operation yet.”

Mikhail Badin, St. Petersburg.

“Our bathhouse is small, we only have enough money for it, so an electric stove is enough for us. We purchased a very inexpensive and practical option from the Teplodar company. We steam with pleasure, just like in a real Russian bathhouse. Installation is simple and consumes little electricity. Considering that we use the bathhouse once a week, the operating costs are quite reasonable. Overall, the result exceeded all expectations.”

Peter, Ekaterinburg.

Price

You can buy sauna stoves in many dealer stores, as well as on the website of the manufacturer Teplodar. The table shows the price of equipment without taking into account the cost of additional installation of a gas burner.

| Name | Dimensions (WxHxD), mm | Steam room volume, m3 | Price, rubles |

| Blast furnace 25 LC | 615x995x705 | 10-25 | 26000 |

| Cascade 18 LP Panorama | 380x920x770 | 10-18 | 20500 |

| Kuban 20 L | 500x865x700 | 10-20 | 19900 |

| Laguna 12 TK | 855x330x690 | 6-12 | 15000 |

| Teplodar Rus 18 LNZP Profi | 335x810x790 | 10-18 | 22600 |

| Rus Panorama 27 LNZP | 440x930x800 | 18-27 | 30800 |

| New Rus' 18 L (2004) | 395x815x805 | 10-18 | 13800 |

| Sahara 16 LRK | 785x380x755 | 8-16 | 17500 |

| Siberian cliff 20 health care facility | 835x565x730 | 10-20 | 26500 |

| Siberia 20 LRK Panorama | 785x375x750 | 10-20 | 23200 |

| Taiginka 10 TU | 405x330x705 | 4-10 | 8500 |

| Electric heater SteamFit 3 | 560x400x240 | 12 | 16700 |

| SteamGross 3 oven | 580x530x643 | 26 | 41000 |

What not to do?

When burning coal in a stove, the following is prohibited:

- use pieces of bitumen, plastic, construction and household waste as kindling material;

- leave the vent and combustion door open at the same time;

- When lighting, use gasoline, kerosene, alcohol, and other flammable substances.

It should be remembered that adults should constantly monitor the combustion process and under no circumstances transfer this function to children.

To ensure maximum heat transfer, it is necessary that the coal be in the form of not too large pieces. It is not recommended to use excessively wet fuel, since during combustion a lot of steam will be released from its surface, which will significantly reduce the efficiency of the combustion process.

Conclusion

Coal is the most common type of fuel. Its heat transfer is significantly higher than that of firewood, briquettes and pellets. Not all types of stoves can be heated with this product. To use it, you need a special firebox made of fireclay bricks or dense steel.

The process of laying, igniting and burning a corner will not require much effort if you follow the basic rules. But it will not be possible to heat the room with this type of fuel alone, since additional materials are required for ignition: paper, wood chips, small logs.

Coal combustion process

Let us remind those who have forgotten, we will teach those who do not know how to light a stove with coal. The following stages of firing a furnace with coal can be distinguished:

Advice! Do not rush to part with coal dust, as it is an excellent fuel.

- Prepare coal.

- Take crumpled newspaper or other paper and place it in the firebox. Ignition can also be accomplished using wood shavings.

- Place 10-12 wood chips, for example pine or birch, on top in the shape of a well or hut. It is necessary to ensure that air can circulate freely between the firewood and the paper, which will promote more efficient combustion.

- Set the newspaper on fire.

- Close the door and at the same time open the ash pan, with which you can regulate the combustion process.

- After the wood has burned, pour fine coal on top with a layer thickness of approximately 12-15 cm.

- After the fuel burns strongly, you can continue to use fine coal, or you can pour larger coal into the firebox in a layer 20-25 cm thick (depending on the dimensions of the combustion chamber).

Important! Until the coal begins to burn well, it needs to be stirred a little from time to time to improve air circulation and prevent the formation of a homogeneous sintered mass.

* To prevent smoke from entering the room, during the next addition of fuel, you should close the ash pan with the door open.

Advice! If the metal stove is equipped with burners, then it is better to pour coal through them.

Why might there be smoke?

Even if the stove is heated correctly, plumes of smoke may form and enter the home. More often, this is caused by low quality coal. However, the causes of problems are:

- Clogged chimney or ducts.

- The appearance of cracks and holes in the masonry. The draft and smoke temperature are significantly reduced.

- Destruction of internal masonry or well.

If ignition is carried out in a cold firebox, smoke may appear. Soot will begin to form if several heating devices are connected to the chimney. To prevent carbon monoxide, smoke dampers must be installed.

Possible problems and solutions

It happens that the stove seemed to light up normally, but other problems appeared during the fire. What to do, what measures to take to eliminate them? Here are the main problems and ways to get rid of them:

- The stove structure heats up unevenly, the temperature inside the stove for burning coal is low. There may be several reasons: low quality coal, a poorly closed fire door, the presence of cracks. To improve the quality of the fuel, it must be slightly moistened with water.

- A partial burst of flame is observed. This happens in two cases: they forgot to open the smoke damper or the natural draft decreases due to strong wind.

- The presence of a white flame and a hum in the firebox indicates too much draft. To fix the problem, you need to cover the vent a little.

- Smoke returns to the room. This is evidence of cracks in the heating system. Another reason is a large accumulation of soot in the chimney, due to which smoke cannot escape outside normally.

When burning coal, you must adhere to operating and fire safety rules. It is not difficult. And if you heat it correctly, the stove will bring warmth, homeliness, joy and comfort to your family. Enjoy this family hearth for many years to come!

Advice! Do not rush to part with coal dust, as it is an excellent fuel.

Principle of operation

Due to the draft of the chimney, air enters the firebox and the fuel burns.

The resulting gases heat the walls of the firebox and transfer heat to the water circulating in the heat exchanger system. The heated coolant is supplied to the pipes, heats the house, and returns to the boiler. The gases then enter the chimney, where they maintain the temperature necessary to create draft. The most common coolant is water, but sometimes mixtures with antifreeze and antifreeze liquids are used. The smoke removal system includes thermally insulated pipes, which are sometimes supplemented with a forced ventilation unit.

Attention! It is forbidden to fire a regular wood-burning boiler with coal, since this type of fuel produces 2-3 times more heat than wood. Based on functionality, the equipment is divided into 2 groups:

Based on functionality, the equipment is divided into 2 groups:

- with one circuit - for heating the room;

- with two - for heating and organizing hot water supply.

Photo 1. Appearance and diagram with the operating principle of a coal-fired heating boiler.

There are classic (single-chamber) and pyrolysis boiler models. In the first case, traditional combustion of fuel in a chamber is implied, the efficiency of which is 70%. In pyrolysis models, coal and gases released during combustion burn in different chambers. The efficiency of such improved models reaches 92%. The fuel in them burns more efficiently with less soot and smoke.

Coal boilers are made of steel and cast iron. Steel models are most often bottom-burning devices and consist of welded elements. Cast iron - cast, characterized by high efficiency, less susceptible to corrosion and contamination. Long-burning devices have a vertical firebox, the fuel gradually burns from above, due to which they operate without additional loading for several days.

Important points

Today, several types of this solid fuel are known:

A well-built stove is designed for a specific operating temperature. It is not advisable to deviate from this value. To maintain such indicators, you need to heat the stove only with a certain type of fuel: wood or “local” coal.

Standard brick devices can operate on almost any fuel. There are no problems with this.

When firing a furnace with coking coal, you must not miss the moment of its coking. To avoid getting burned, you need to fully open the ashpit and use the poker more often.