A frame bath is the best budget solution for arranging a steam room. This is also a great option to try out frame construction technology with your own hands. To carry out construction work, you will need a frame bathhouse design and a set of building materials, which can be purchased at a good price.

Let's look at the example of turnkey frame bathhouse projects with prices. What is the difference between different projects, what should be in their text and graphic parts. And what to consider when choosing design documents?

- Benefits of technology

3x4 frame bath project

Considering turnkey frame bath projects, a 3x4 structure is the simplest option for a future steam room. It is small in size and intended for family use. The 3x4 frame bath project consists of text and graphic parts. The graphic part shows a section of the house, from which it can be seen that there are three separate rooms inside:

- Room for rest and changing clothes.

- Shower room.

- Steam room.

Construction scheme 3 by 4.

The area and dimensions of the internal premises are also shown in the drawing. There are 4 square meters per steam room - its dimensions are 2x2 m, per room at the entrance - 6 square meters. m. - its dimensions are 2x3 m, and for the shower room 2 sq. m. - 1x2 m. The entrance to the steam room is equipped from the shower room. Inside the steam room there is a stove and shelves. There are windows in the changing and rest room, as well as a small window in the shower room.

Projects and drawings of a frame bath provide visual information about the location of rooms, partitions, window and door openings. In addition to the graphic part, the project contains text descriptions and specifications - tables with a list of building materials and fasteners.

Steam room arrangement.

The specification of building materials contains the following list:

- Foundation blocks for a columnar foundation.

- Wooden beams - for joists and frame floor beams.

- Clapboard boards for interior walls and boards for shelves in a steam room made of aspen.

- Corrugated sheeting – for roofing.

- Rockwool mineral wool insulation and Izospan A vapor barrier.

- Screen for the wall next to the stove.

- Bricks for lining the stove.

The presence of a specification with a list of building materials is a mandatory part of the project. It is necessary for purchasing materials. It also prevents waste on unnecessary materials. And it ensures the reliability of the structure - the specification regulates the dimensions of the supports and floor joists sufficient for a strong frame and walls.

Finishing

Finishing the premises inside and outside the walls can begin after covering the roof frame with a roof and installing subfloors.

Internal

The inside of the bathhouses should be decorated with clapboard. The most important thing is not to stuff it too tightly. The tree needs distance to dry out freely.

The lining must first be coated with special antiseptics, which will protect the wood from the destructive effects of moisture.

External

For exterior decoration you can use different materials:

- block house;

- metal or plastic siding;

- different types of plaster;

- clinker tiles;

- decorative brick.

The choice of decorative material depends on the wishes of the bathhouse owner and his financial capabilities.

Frame buildings are present in every modern cottage cooperative. This is due to the increasing popularity of this technology. To build a high-quality frame bathhouse, you need to understand how to build it correctly and prepare the necessary set of materials and tools.

Frame steam room 6 by 4

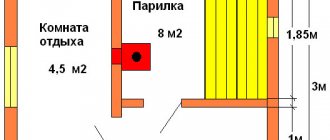

Project of a medium-sized 6x4 frame bathhouse for a large family and for guests. There are also three rooms inside, but their area is much larger. Their sizes allow you to visit the steam room comfortably.

Two layout options for a 6 by 4 bath.

The frame bathhouse in the 4x6 design is equipped with a spacious shower and a comfortable lounge with a sofa, armchair and table for tea drinking. Room sizes:

- Steam room – 2x2.1 m with two shelves. This space is quite enough for 5 people to visit.

- Shower room – 2x1.9 m – there is a shower stall installed here, so you can change clothes and leave things inside.

- The rest room – 4x4 m – is a spacious room in which you can relax, have a tea party or even spend the night.

The project also includes a porch with steps. The construction materials are the same as in the 3x4 project. The above do-it-yourself frame bathhouse project is carried out without much effort during the step-by-step construction of the bathhouse.

Frame bathhouse with terrace

A building with a terrace and external wall dimensions of 6x4 is a structure in which the interior spaces are made in small sizes, namely:

- Steam room – 2x2 m.

- Shower room – 2x2 m.

- Rest room – 2x4 m.

Reducing the area of the interior spaces made it possible to place a terrace under the roof. Its dimensions are 2x4 m.

Frame building with terrace.

Despite the small rooms, the interior arrangement of the 6x4 m building is quite comfortable. The combustion chamber opens into the relaxation room, which allows you to relax after the steam room near the fireplace. The shower room is large enough to be used as a changing room. Inside the steam room there is a stove and two shelves.

The project of a frame bathhouse with a terrace makes it possible to relax outside after visiting the steam room, which is really important in the warm season. You can also use the terrace as a summer dining room.

Base trim

A layer of roofing material must be laid on the installed pillars as waterproofing. Next, the base piping is installed. To do this, take a 120x120 mm beam and soak it with an antiseptic. It is better to use softwood such as pine or cedar. The beam is laid around the entire perimeter and fastened using the “half-log” method - half of one beam is sawn off from the top, and from the second from the bottom. When connected, a flat plane is formed. The piping, checked using a level, is attached to the pipes with anchors.

Frame bathhouse with attic

A fairly large building with two floors, in which the second floor is occupied by a spacious lounge with a bed. If you wish, you can arrange the upper room differently - put a sofa and billiards.

Frame building with attic.

On the ground floor there is a steam room, a shower room, a small relaxation room with a staircase to the second floor and an open veranda. The dimensions of the external walls of the building are 5x7 m. Dimensions of the internal rooms:

- Steam room – 2.5x2.5 m.

- Shower room – 2.5x2.5 m.

- The room on the first floor is 5x4.5 m.

- The room on the second floor is 5x5 m.

- The dimensions of the veranda are 2x4 m.

The design of a frame bathhouse with an attic provides for a reinforced frame, compared to single-story frame walls. For this purpose, the number of frame supports has been increased while maintaining their dimensions of 150x50 mm. The above projects can be used both for doing the work yourself and for ordering a turnkey frame bathhouse from a construction company.

Foundation

Columnar foundation from the inside

On the site chosen for the construction of a bathhouse, markings for the foundation are carried out using pegs and twine. For light frame construction, a pile base made of asbestos-cement pipes is most often used. These supports will last a long time, they are durable and do not collapse under the influence of moisture. The work does not require special skills or the use of special equipment.

The underground part of the pillars is buried below the depth to which the soil freezes in winter in your region. Their diameter is chosen taking into account the weight of the planned building; for a bathhouse, pillars of 20 cm will be required. Asbestos-cement piles are placed in each corner of the building and at the intersections of walls. All places for pillars are marked with pegs.

Pillar

Pits for pipes are dug from 1 to 1.5 m, a sand cushion of 20 cm is placed at the bottom. The pillars are leveled, and if there is groundwater, they are coated with mastic for waterproofing. The base of the pipes is filled with concrete. The outer side is wrapped with roofing felt and covered with sand. 2-3 iron rods are placed inside the pillars and concrete is poured. After it hardens, construction of the frame begins. A columnar foundation will make it possible to place a drain and provide floor ventilation. Instead of asbestos-cement pipes, reinforced concrete blocks can be installed.

Frame-panel bathhouse projects

Frame-panel construction differs from step-by-step construction of a frame bathhouse . Panel walls are assembled from ready-made panel blocks with window and door openings. This block is a large panel. It is manufactured at the factory, delivered to the construction site on special transport and installed in place using a crane.

Frame-panel bathhouse.

This creates some inconvenience and requires money, and also does not correspond to the concept of reducing the cost of construction. Therefore, panel baths have not gained much popularity in Russia. At the same time, panel buildings are very popular in the West.

Frame-panel bath projects have the main advantage of simplifying the construction process. Assembling a panel house is reminiscent of playing with a children's construction set. A small building can be assembled from four wall panels, which are installed on the foundation and secured to the sides.

On a note

It is difficult to download projects of frame baths of panel construction. Due to low popularity and special specifics, there are few such projects. To implement them, it is not enough to receive drawings. Special panels are required, which are manufactured at the factory to fit the dimensions of the project.

Traditionally, panel buildings are built from SIP panels using OSB boards. This material is not suitable for the construction of steam rooms. It is adhesive and does not withstand work in conditions of increased dampness. It also contains harmful synthetic substances. When working at elevated temperatures, they will actively evaporate into the steam room space.

Stage three: floors and their installation

Floors in a panel bath are extremely easy to install:

• Take bars with a cross-section of 5x5 cm and attach them to the bottom of the joist. • A subfloor is laid on top of the timber. • The subfloor is insulated with roofing felt, a 10 cm layer of mineral wool or slabs of the same insulation. • A vapor barrier film or parchment is additionally installed on the insulation, after which a board is laid for the finished floor.

Advice! It is recommended to lay exhaust pipes under the floors of the bathhouse, which will remove excess moisture and prevent the formation of condensation.

Construction process

A do-it-yourself frame bathhouse project with a photo allows you to assemble a steam room, sink, and rest room,

but the construction of a bathhouse always begins with the construction of a reliable foundation.

Foundation for construction

Since a frame structure is a lightweight structure, it is often built on the basis of a prefabricated columnar foundation. It costs a small amount of money and takes a few days to set up.

Columnar foundation.

Ready-made concrete supports or brickwork are used as pillars. The pillars can also be cast from concrete on site. To do this, concrete is poured into formwork, which is placed in a hole dug in the ground. Be sure to strengthen the columnar foundation with metal reinforcement.

Walls

The assembly of the walls of a frame bath is carried out on a ready-made foundation and a pre-assembled frame. The frame is assembled directly on the foundation and then the wall cladding panels are mounted on it. The outer cladding forms the surface of the outer walls, the inner cladding forms the surface of the inner wall.

Insulation

The insulation of the bath room is performed with mineral wool. It is not recommended to insulate the steam room with foam plastic, due to the content of harmful substances in it and their possible evaporation into the steam room space.

We insulate the bathhouse.

Mineral wool insulation retains its heat-saving properties under one condition - if it is dry. Therefore, in the walls of baths and steam rooms, mineral wool must be covered with a vapor barrier film and a special membrane to prevent it from becoming damp and losing its heat-saving properties. In the area where the stove is located, the insulation inside the wall is additionally covered with foil.

On a note

The frame bath project in the photo shows the protection of the walls next to the stove with a metal screen. The foil layer inside the wall is not visible, but it is there.

Roof

Since the frame of the building is a light structure on a shallow foundation, the materials for arranging its roof must also be light. More often than others, they use profiled metal sheets (corrugated sheets) or ondulin - flexible lightweight bitumen shingles. Both of these roofing materials are decorative; the roof is bright and attractive.

Interior decoration

The resulting free frame bath project does not always contain a list of materials for interior decoration. Therefore, we will indicate the main thing that needs to be taken into account when choosing a material for interior walls.

Wooden frame baths are sheathed on the inside with wood - clapboard, profiled timber or block house. This is the only material that can be used to decorate the walls, floor and ceiling inside the steam room. No other analogues or wood-containing substitutes are suitable for damp and hot rooms. They do not satisfy the main criterion of a steam room - health benefits.

Frame steam room.

The choice of material for the interior lining of a bathhouse often comes down to softwood lining, except for the steam room. Pine lining is a source of resinous odor, which is good for health. The resin content of wood is also necessary to increase moisture resistance. Pine lining is one of the most affordable finishing materials at cost.

As for the shelf and steam room, they are often made from aspen. In addition, the floor is made of larch, but these are design techniques that are not taken into account when building budget frame baths with your own hands.

Necessary materials.

A building built on a frame consists of the following elements:

- timber frame;

- cladding from finishing materials on the inside and outside;

- laying insulation, vapor barriers between parts of the sheathing;

- foundation of any type. The most commonly used are shallow belt or pile ones. Depending on the project, other types may be used.

Each element can reduce the cost or, on the contrary, make the final product more expensive, due to the selected materials.

To assemble the frame and floor joist rafter system, timber from high-quality tree species with parameters of 100*150 mm is used. The stability of the structure can be increased by using 150*150 mm bars. Modern technologies offer laminated veneer lumber. For the remaining elements, smaller beams are selected. Any lumber or plywood is suitable for sheathing.

The following can be used as roofing material:

- roofing felt;

- corrugated sheeting;

- folded covering;

- metal tiles;

- Euro slate.

Ceramic tiles are very heavy and will create additional stress on the foundation.

Apart from the joists, the floor has a rough covering. It can be plywood, any type of board, special boards. Materials that imitate natural logs have worked well as external cladding. Various types of lining can be used inside.

All wooden elements must be treated with fire retardants and antibacterial mixtures.

Insulation materials are selected that are resistant to rotting and burning. These are mainly mineral wools. The insulation layer is determined by the climate of the region where construction is taking place. If other types are chosen, you must read the instructions so that they are resistant to high temperatures and do not support combustion.

Additionally, mounting materials and interior finishing are purchased. Principle of choice: lightweight, moisture-resistant, fireproof.

Prices for frame baths

The cost of frame buildings is less than brick, aerated concrete, and log buildings. Cheaper than frame technology - only adobe buildings. You can build a 3x4 frame bathhouse in 2 weeks, spending about 160 thousand rubles on construction. For comparison, the cost of a bathhouse of the same size made of logs will be more than 300 thousand rubles.

Frame building in projection.

Projects and prices for frame baths can vary by several tens of thousands of rubles. This depends on the choice of insulation thickness, roofing, and foundation. It also depends on the size of the future building - the number of rooms, the presence of superstructures, floors, attics.

Benefits of technology

In addition to the budget cost, frame baths have other advantages, namely:

- Fast construction - all work, from laying out the foundation to the complete completion of the walls, roof, installation of windows and doors, can be completed within 2-3 weeks.

- You can build a frame bathhouse at any time of the year, if you have a ready-made foundation, then even in winter.

- Comparative ease of construction, the ability to make a frame bathhouse with your own hands.

These advantages make frame buildings popular. Almost all the work can be done independently, except for one thing - designing the frame, walls and roof of the room. To build a frame bathhouse with your own hands, you need a suitable project adapted to your site.

Frame making

The supporting racks are made of timber 12 cm thick. They are installed in the corners of the bathhouse and where partitions are built. The racks are attached to the bottom frame with steel corners. The beams must be installed strictly vertically, using a plumb line and level for control. Before completing the top trim, the racks are fixed with temporary struts.

If there are long walls, the installation of additional racks is required. For them, timber with a smaller diameter is used. The spacing of the racks is 50 cm; 1 meter is left for the doorway. You can install the beams by cutting out the base beam, but in order not to weaken it, it is better to use steel corners.

The top trim is made in the same way as the base trim. Its horizontal position is set according to the level, and the beam is attached to the racks with metal corners. Ceiling beams are laid on the frame.