Did we do the right thing, many of us ask ourselves, by ordering or purchasing a ready-made log house? Of course yes! There is no better wooden bathhouse, and there never will be. No matter what modern materials are invented, there is no alternative to real wood.

The only thing that can really be a little concerning is the capriciousness of this very wood in terms of processing and operation. But if everything is done correctly, then there will be no problems with this. Now we will consider one of the aspects of the proper construction of a bathhouse, namely the laying of the first crown of the log house.

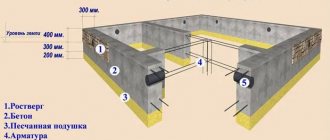

Laying the first crown of the log house on the foundation

Did we do the right thing, many of us ask ourselves, by ordering or purchasing a ready-made log house? Of course yes! There is no better wooden bathhouse, and there never will be. No matter what modern materials are invented, there is no alternative to real wood.

The only thing that can really be a little concerning is the capriciousness of this very wood in terms of processing and operation. But if everything is done correctly, then there will be no problems with this. Now we will consider one of the aspects of the proper construction of a bathhouse, namely the laying of the first crown of the log house.

How to lay the first crown of a house made of timber: all the subtleties and tricks

In the old days, laying the first crown was considered a very significant event; builders had their own rituals that accompanied this work. Various objects were placed under the first crown, symbolizing prosperity and a happy life in the new home. All this is in the deep past, however, even today these works are considered a very significant event. Let's look at how the first crown of a house made of timber is laid.

In past centuries, not everyone built a foundation for a wooden house. Clay was poured under the first crown, which was most often made of oak.

Currently, log houses are built on foundations. The reliability of the installation of the trim is very important for the further construction of the house and the correct installation of the roof. Therefore, let me give you some tips on how to correctly lay the first crown of a house made of timber.

Preparation

Many people have probably heard that in the old days the framed (first) crown was often laid directly on the ground, wrapped only in birch bark. Now no one will dare to do this, and rightly so: a good foundation is one of the keys to the durability of a future building. Therefore, before assembling the log house on site, the support for the bathhouse must be completely ready.

We will begin the construction of walls by laying two “embedded” logs. Before assembly, they (and the others too) had to be marked accordingly. They can also be easily identified by diameter and length. Thicker round timber is always chosen as the basis of a log house, and if they are going to lay the foundation for a cold dressing room, then they are made much longer than the rest of the logs of the log house. Well, another sign of the constituent elements of the first row is the connection of the logs in the corners into the so-called “paw”. This, however, applies only to logs chopped “into a bowl.”

So, these logs have been selected, you can start working directly. And we will start with laying waterproofing. You can use the familiar roofing material as it, or better if it is possible to treat the foundation with bitumen.

How to replace a crown at home:

As you probably already understood, crowns are quite strongly influenced by rain, snow and temperature fluctuations. Therefore, after some time, even the highest quality wood begins to deteriorate and rot. In this case, people have no choice but to replace the damaged beams. We will tell you how to do this correctly below.

Ways to replace rotten logs:

Restoration

We carefully cut out the damaged part of the wood, and put an undamaged piece in its place. This manipulation can only be carried out if small areas are damaged.

Complete dismantling of the building

A rather labor-intensive process, as it involves the demolition of a house. The old structure is completely disassembled and then reassembled.

Backing board: to be or not to be

When constructing log houses, some builders practice laying a backing board or plank on the foundation. Their task is to separate the first row of logs from the cold stone, and accordingly, increase the durability of the wood.

Many, of course, consider this point controversial, because in their opinion this will in no way extend the service life of the log house. If engineering communications are carried out incorrectly or are absent altogether, then no lining will save the tree from damage. If the board rots, the crown molding will also rot.

In general, this is food for thought, but if you still think this is a necessary element, then treat the board several times with an antiseptic. Its thickness must be at least 40mm.

Construction of wooden houses

Not only how long a log house will last, but also its correct geometric shape depends on the strength of the foundation and on compliance with the technology when creating it. But not only the foundation itself deserves attention, but also the methods of installing a log house on it.

Building codes suggest two methods for installing a log house on a foundation:

- Use rigid fixation of the log house to the foundation;

- There is no rigid fixation; the log house is simply placed on the foundation.

Rigid fixation

In this case, a collapsible or non-demountable connection between the grillage and the log is used. The immobility of the lower crown in this case occurs due to mechanical fastening using bolts and clamps.

This option provides a reliable connection and guarantees the immobility of the log house. However, in this case, repairing the first crown is very difficult, the cost of construction work increases, construction time is extended and the need arises to use a large number of consumables.

Overlay option

In this case, there is no need to talk about the complete immobility of the house, since there is no rigid attachment of the log house to the foundation. But at the same time, this option is often used, since it is simpler to implement. In addition, if necessary, there is free access to the first crown of a log house, whereas with rigid fastening, replacing the frame crown is very difficult and sometimes technically impossible.

The reliability of this method is ensured by the large weight of the logs. Practice has shown that the significant weight of log walls helps to obtain almost complete immobility of the frame crown. And it gives the same guarantees as the fastening technologies of the first option.

Installation of a log house on strip or slab foundations

Rigid attachment of a log house to strip or slab foundations requires preparation. Preparation is carried out during construction (when pouring the grillage) or after the foundation is completed.

Strong bolts are mounted into the grillage of the slab or tape, to which the frame crown logs will then be attached using pins - holes must be made in the logs for these purposes. Rigid fixation is achieved thanks to locknuts that are threaded onto the stud. A tight connection between the grillage and logs is achieved through a threaded pair.

Technological details

- After the foundation is poured, bolts are placed in the last layer of concrete. The distance between the hardware is about half a meter. In this case, each log must be secured with two or more bolts.

- At the same time, the logs are prepared by drilling holes in them for fastening.

- It is necessary to check the horizontality of the grillage by removing convexities (they are cut off) and concavities (they are filled with cement). As soon as a flat surface is obtained, a waterproofing roll material is laid on it (most often it is roofing felt).

- Logs are mounted on roofing felt, connecting them with pins. The corner joints of the crown are sometimes reinforced with metal corners on self-tapping screws.

- Finally, strong washers and locknuts are threaded onto the studs. Important! To avoid distortion, the nuts must be tightened at the same time, slowly tightening them.

Installation of a log house on strip or slab foundations without rigid fastening (overhead option) is also carried out. Only then do not install the bolts into the grillage.

Work order

Regardless of whether you laid the board or not, before laying the mortgages, their lower part must be cut off. This is necessary in order to ensure their stability on the foundation. They do this with a chainsaw, cutting off the top of the log. The edge size should be at least 12-15cm. The horizontal positioning is checked by a level.

Next, the transverse (small) logs of the first crown are found and placed in their places, while aligning the marks made on them with the markings applied to the embedded logs. This is done in order to avoid distortion of the log house. If they are missing or you need to make sure that the correct shape of the cell is maintained, an additional diagonal is set.

A gap is formed between the transverse logs and the foundation, slightly smaller than the diameter of the log. It needs to be sealed, of course. This is a very interesting point; if you do the work incorrectly, you can later become the owner of a cold bath.

There are two ways to solve the problem:

1) A subcut is a piece of log equal in length to the resulting gap. They are prepared in advance from the same forest that was cut down. By removing the required layer of wood from the bottom and top sides, the log is adjusted to the desired size.

Having tried it on and made sure that it fits freely, but with minimal gaps, in its place, we put it in place.

Having removed the small logs, we carefully caulk the places where the undercuts adjoin the mortgages. Then we lay a layer of moss or other inter-crown insulation on top. After which we put the transverse logs in place.

In some cases, the roll-offs are installed after the frame has been completely assembled. This, of course, is also possible, but it will not be possible to insulate this place well, and as a result, air leaks may occur later.

2) Recently, the practice of filling the resulting space with cement mortar has become increasingly common. This is done after the construction of the walls is completed.

The process is carried out as follows: in these places, formwork is built on the outer and inner sides of the foundation, reaching a height up to the middle of the lower log. Then the first crown is wrapped in roofing felt and filled with mortar.

Which of the considered options to prefer is up to you to choose. Both have their pros and cons, but choosing one over the other will likely depend on which is easier to accomplish.

Replacement of the lower crowns of the bath

If things have reached such a state that it is urgently necessary to replace the lower rims of the bathhouse, then you will have to work hard:

- prepare the logs, fit them to each other. Or assemble the log house if 2-3 crowns will be replaced along the entire perimeter

- dismantle the sauna stove pipe

Nests are cut out in rotten logs for jacks

cut nests (holes) for jacks in those logs that will be replaced

- place four (or more, depending on the size of the log house) jacks in these sockets

- raise the frame using jacks

- place logs next to the jacks and lower the frame onto them, thereby removing the jacks

- Now you can remove the rotten logs completely

- if necessary, build support pillars from bricks

- you need to bring the new crown on one side, where there are no stops and which seems to hang in the air

- well, continue in the same spirit...

In each case, the entire process of replacing the lower crowns of the bathhouse will be individual. controversial argumentative essay topics

Laying the first crown on the foundation

The entire future “fate” of the structure depends on how accurately the first (or frame) crown of a log house or half-timbered frame is assembled and installed, and how well the foundation, for example, made of concrete blocks, is qualitatively insulated from moisture penetration. They say that in ancient times, log houses were built with their own hands without a foundation, and the frame crown was wrapped in several layers of birch bark and laid on the ground. The technology is very questionable, because it has long been known that a reliable foundation is the key to the strength and longevity of any building.

Lower crown

Features of operation

As can be seen in the photo, it is the lower or frame crown that is in contact with the structures of the plinth or foundation.

After the foundation is ready and completely settled and hardened, the first logs or beams of the future log house begin to be laid on it. It is this part of the building that takes on the maximum load from the gravity of the entire building, and also the lower frame is closer to the ground than others and is in contact with concrete or brick.

Rainwater, under the influence of the Earth's gravity, flows down and accumulates, again, in this area. In addition, there is capillary suction of moisture from concrete and brick, which are in direct contact with the wood of the casing.

No less dangerous is the moisture that is released by the bathhouse itself during its operation. There is space between the floor and the ground where this moisture can settle and accumulate. If there is no good ventilation of the underground space, then the problem of rotting of the lower ceiling, beams and floor boards, as well as lower logs is guaranteed.

As a rule, in Russia, pine is used for the construction of log houses and timber houses, which is quite affordable and of sufficient quality.

However, even pine is not able to withstand constant moisture, as it carries the following dangers to wood:

- Water dissolves most chemicals, changing the composition and structure of materials;

- Salts and other compounds dissolved in water can react with wood components, thereby causing chemical corrosion;

- Water is a necessary condition for the development of life, and this is its main danger: with water it brings fungal spores and insect larvae, as well as plant seeds. As a result, wood becomes the object of culinary interest for a number of organisms, such as fungi, bacteria, wood-boring insects, etc.;

- Under the influence of bacteria, a process such as rotting or decomposition of organic compounds occurs. Wood is a completely organic material, so bacteria can destroy it completely;

- Wood is a common nutrient substrate for a number of molds and other types of fungi. Over time, the mycelium completely permeates the structure of the wooden part, gradually digesting it from the inside with the help of special enzymes that it releases during digestion. As a result, the wood itself turns into useless dust.

Cover crown in frame construction

Frame or half-timbered houses came to us from Europe and immediately proved themselves to be the best. The walls of the building consist of a frame and filler, which is used as aerated concrete, any light blocks, glass, brick and anything else. But for the frame, laminated veneer lumber is best suited. It is stronger than natural wood timber and is not subject to rotting or deformation.

Laying the first row of timber

The first crown of timber is constructed in a certain sequence:

- the top of the base is leveled to a level, then roofing material is spread in at least two layers on bitumen mastic; for greater confidence, it is necessary to lay at least one layer of glass insulation;

- further, a substrate of boards or slats of small thickness impregnated with an antiseptic composition is laid over the waterproofing; this procedure is performed to additionally protect the walls, and it also prevents the lower beam from coming into contact with the foundation;

- checking horizontality with a building level;

- preparing timber for the installation of the first crown of the foundation: cutting according to the longitudinal and transverse dimensions of the base, coating the space between the beams with diluted bitumen mastic to protect against rotting and fungus;

- The timber is installed around the perimeter of the foundation with strict adherence to horizontal level.

Installations of a log bathhouse

Working with a log house for a bathhouse

The answer to the question of how to install a log bathhouse on a foundation begins with identifying and installing the foundation itself. A column foundation for a wooden bathhouse will cost much less than a strip foundation. At the same time, the basic principle of its construction boils down to the fact that pits for support pillars are dug in the center of the walls.

In addition to asbestos-cement pipes, the optimal solution may be to choose rubble concrete as a material for support pillars. It is also common to use cinder blocks for these purposes. Such a foundation is less labor-intensive, so even a beginner can build it correctly.

When constructing a column-type base, you should remember that tubular columns are poured in layers, and not at once. Each new layer should not exceed 40 cm. Using a conventional hammer drill, you can provide the concrete with the necessary vibration compaction. In cases where it is planned to lay a wooden support beam under the frame walls on top of the pillars, a reinforcing rod with a thread for a nut at the end must be concreted into the pipe. This way the beam will be provided with high-quality fastening.

In order to reduce the amount of work with the ground, a mixed foundation is used - columnar and strip. With this combination, you can not be afraid of even serious ground movements that are observed with the change of seasons.

Installation of a log house for a bath

The stages of installing a log house come down to the construction of a log house on the site from prepared and processed logs. Logs and beams are installed alternately. In accordance with the project, the rafter system is assembled and the lathing is made. A roofing covering, mainly roofing felt, is laid on the roof. The floor in the bathhouse is laid with tongue-and-groove boards, which are at least 40 cm thick. Most often, the gables and ceilings are sheathed with clapboard. This work can be done by a specialized construction team. But, if desired, each developer can raise a log bathhouse on a prepared foundation with his own hands.

Installation methods for the first row

There are several ways to lay the bottom row of timber. The angles must be exactly 90°. This strict requirement must be observed throughout the entire building construction process.

- Without attaching the timber to the foundation. It is believed that the structure will stand securely under its own weight. In this case, corner joints are made without locking connections. The calculation is that any lower beam, if necessary, can be easily replaced. Such a decision may raise some doubts about its correctness, especially in the presence of seismic manifestations.

- With fastening to the foundation and to each other. The bars can be connected in two ways; they are called “into a bowl” or “into a paw”. Dowels or strong nails are used as fastening elements. The timber is attached to the foundation with special elements.

The cracks or gaps between the timber and the foundation cannot be left open; they must be filled with foam or some other sealing agent. There is another way to minimize such gaps - to build a foundation from blocks with opposite walls of different heights to match the height of the beam. You will have to tinker with a foundation made of blocks, but there is an obvious saving in sealing materials.

When installing the first crown, the more often the horizontality of the latter is verified, the better the overall result will be and there will be no problems during the further construction of walls.

How can I secure the logs to the foundation?

If you do not attach the logs to the base - the foundation, but simply lay them on top without fixing them, then as a result of the operation of the house, the logs may shift.

This will lead to the destruction of the entire wall, the formation and enlargement of inter-crown cracks and as a result of large heat loss. Some irresponsible builders use nails or ordinary metal pins to fasten logs to the foundation, which after some time leads to the appearance of rust on them, deterioration of strength and tearing of the log from its place. They are not intended for such purposes. And besides, rust can cause rotting processes in the logs themselves. And to ensure the fixation of logs to the foundation, various fastening elements are made. Complex elements of them, by design, are: angles, washers, couplings and supports. And the simpler ones are: screws, staples and anchors. Subsequent crowns of the log house after the first crown are connected using wooden dowels and dowels.

To connect wooden supports, racks with the foundation in the field of wooden home construction, embedded support for timber is very common. The support is highly durable and is made of carbon galvanized steel. In addition to the strength of the structure, this element also helps prevent direct contact of the wood with the concrete base, which will significantly extend its service life and, most importantly, protect it from irreversible rotting processes.

Anchors are most suitable for attaching logs to the foundation. There are many types of them, but it is recommended to purchase foundation anchors specifically for working with a concrete base. They are widely used not only in wood, but also in other types of construction. They are a pin with threads on both sides. There is a nut on one side of the anchor, and a steel square on the other.

When purchasing these fasteners, you must pay attention to their manufacturers. Russian ones have the highest quality, but one can seriously doubt the reliability of Chinese anchors and supports. In large cities of Russia, where there are factories for the production of these fasteners and their prices are lower, but in small towns the cost will be higher, thanks to a number of outbids.

half-timbered house

It is these buildings that have absorbed the best qualities and technologies of residential and commercial construction. When building a frame house, the consumption of basic and auxiliary building materials is reduced. New materials have also become widely used, for example, aerated concrete and laminated veneer lumber.

half-timbered house

In addition, building a half-timbered house with aerated concrete core is much cheaper than, say, a brick or block house. And in terms of construction time, a house with aerated concrete filler benefits. It is noteworthy that such a structure can be easily disassembled and can be moved quite simply from one place to another.

Only the foundation remains stationary. Frame buildings made of laminated veneer lumber and fillings made of aerated concrete, glass, blocks and other materials are resistant to precipitation, rot and fungi, and do not get wet. They are not subject to shrinkage, cracking, and are warm in themselves. And if the filling between the posts, cross members and braces is made of aerated concrete, then the house turns out to be relatively light in weight and does not require a powerful foundation of blocks.

If you wish, you can build such a house with aerated concrete core with your own hands. You just need to stock up on materials, tools and carefully study the project and technology.

Internal walls and partitions in a frame house can be made of aerated concrete - a lightweight, durable and warm material.

Advantages of using fasteners

There are many advantages of using fasteners for attaching timber and logs to the foundation:

- They are available in various sizes and types. This diversity allows them to be used in small houses and in fairly large designer construction.

- They are easy to fix. And to attach them you do not need to have any special skills or tools.

- The fasteners are of high quality and will last for decades.

- With the use of fasteners, there is no need to significantly damage the wooden material, cut out anything in its structure, etc. This allows you to maintain the strength and other characteristics of the wood intact.

- The main thing is that they are low cost and accessible. They can be purchased at any hardware store either individually or in large quantities. And it is clear that the more fasteners purchased, the lower their price. And the cost also depends on the size of the products. All this also applies to wooden dowels, for subsequent fastening of logs and beams to each other.

Thanks to fastening elements - anchors and dowels, wooden walls will firmly adhere to the main foundation of any house - the foundation. Also, the wood will not be afraid of excess moisture, which is provided by direct contact with the foundation and can lead to rotting of the lower crown of the log house. Thanks to these two important advantages, it is worth purchasing and using fastening elements such as anchors and supports.

Construction of the first crown of a log house

For the construction of the first row of a wooden log house, rounded logs from hard wood are usually chosen. Such as, for example, larch or oak, which are less susceptible to rotting and fungal attack than others. Close and scrupulous attention to the design of the first crown is not in vain because the bottom row is primarily and most susceptible to moisture due to its proximity to the soil. In addition, the entire further process of building a house depends on the accuracy of the installation of the first crown.

Preparatory work for the start of construction of a log structure is the same as for a frame structure. This means that it is necessary first of all to align the upper surface of the foundation and level it.

The level and plumb line must accompany the entire process of building a house, from the foundation to the roof. In order for a house to serve its owner for a long time and reliably, its walls must be strictly vertical, and right angles are equal to 90 degrees, and not 89 or 91.

Waterproofing all sides of the base also needs to be approached responsibly and done correctly: thoroughly coat the side walls with bitumen mastic and lay the required number of rows of roofing felt and glass insulation on top.

Insulating roll materials should never be laid dry. The use of bitumen mastic is mandatory. This is both fastening and additional protection from external influences at the same time. The process of constructing a log house is notable for the fact that you cannot place just any kind of logs in the crown. Here, each log must “know its place,” and for this purpose they are all marked, including those intended for the first crown. It is very important that such marks must coincide when the logs come into contact.

Watch the video of how the initial crowns of a wooden house are laid.

Protection of the lower crown during installation

How to protect the lower crown of a log house from high humidity and precipitation? To do this, you will need to organize proper waterproofing and take care of treating the wood with special protective substances.

Waterproofing must be installed on any foundation: these are several layers of roofing material or bitumen mastic, designed to protect the structure from water. In addition, it is necessary to treat the logs or beams themselves with antiseptics to prevent rotting.

The frame of a log frame can be laid in two main ways:

- The lower part of the log is trimmed a few centimeters to create a flat surface necessary for a tight fit to the foundation. Before laying, a layer of inter-crown insulation is sometimes placed on the waterproofing material to prevent heat loss and additionally protect the wood from freezing.

The logs of the lower crown are stacked using the “bowl” method. The main disadvantage is that there remains a gap between the logs and the foundation; it is covered with bars, log halves, etc. The gap must be lined with insulation.

- There is another way: the first two logs are cut exactly halfway, the next two are cut a few centimeters. This allows you to ensure the most even fit to the foundation; there will be no gaps, which means heat loss is reduced. All lower surfaces of the log must be coated with an antiseptic several times, this will help significantly slow down the rotting process.

The casing crown suffers not only because of the proximity of the ground. It will constantly receive slanting rain, snow will accumulate near it in winter, and rainwater will flow down the wall.

The lower crown of a bathhouse frame needs increased protection: constant humidity makes the building much more susceptible to rotting, and this is especially true for the lower crown.

Sometimes a backing board is used in construction: it is placed between the foundation and the lower crown and must be lined with insulation.

The advantage is that the flashing board is much easier to change than the lower crown itself: if rotting processes begin, the building is lifted with the help of jacks, and the boards are replaced with new ones.

Common mistakes when laying the lower crown

Often the lower crown has to be changed very quickly, since gross errors were made at the very beginning of construction. If the protection is insufficient, the wood will quickly begin to rot, and very soon the building will require major repairs. First of all, this applies to log baths, since they suffer much more from changes in temperature and humidity.

The most common causes of premature wood decay:

- If the building has a columnar foundation, it is not recommended to fill it with backfill. The material will settle unevenly, which will ultimately lead to the formation of cracks into which water will begin to enter. The logs will freeze, and after thawing, rotting processes will inevitably begin.

- On heaving soils, the strip foundation constantly suffers due to soil movements. It can be pushed upward unevenly, which leads to the appearance of cracks at the points of contact with the wall. Even small gaps get atmospheric moisture, which is why the logs can begin to rot.

- The condition of the log house can be negatively affected by insufficient treatment with antiseptic compounds, insufficient ventilation of the subfloor, too weak a layer of waterproofing and other common mistakes. The bottom crown will always suffer more than any other wall elements, so it will wear out faster in any case.

Work order

In some cases, in order to protect the first row of wood from the cold concrete of the foundation, you can lay beds (backing slats). Whether to do this or not is a controversial issue and each builder decides it individually. But if it is decided to lay it, then both the logs and the logs must be carefully treated with an antiseptic and protected from moisture penetration.

The next stage is laying the embedded (longitudinal) logs of the first row. To ensure stability, the lower part is cut off. Next, the transverse logs are installed, the markings of which must exactly match the marks on the longitudinal ones. Only if these requirements are met will the log house be smooth. During the installation of the first row, the dimensions of the building perimeter and the correctness of the diagonals are checked.

The next task that definitely needs to be solved is to seal the gap between the foundation and the first row. Craftsmen often use for this purpose small trunks of trees of the same species that were used for the first crown. They are adjusted to the dimensions of the gap and sealed with insulation specially designed for this purpose. Sizing is done by cutting off excess wood from the top and bottom of the log.

We recommend watching a video on how to process log corner notches.

The procedure is very important, since it determines whether the house will be warm and dry or not. Therefore, if during the process of sealing cracks there is no access to all the necessary places, then the transverse logs are dismantled. Eliminate all cracks and gaps between the logs in the longitudinal direction, then return the cross members to their places. In some cases, ordinary cement mortar or polyurethane foam is also used to seal cracks instead of tow or moss.

How to properly install a log bathhouse on a prepared foundation

How to properly install a log house on an existing foundation? Installing a bathhouse on a prepared foundation has its own tricks, the implementation of which guarantees the strength and reliability of the constructed building. Watch the video on how to install a log bathhouse.

There is an opinion that when installing a log house, for reliability, the backing boards should be fastened with anchor bolts to the foundation with the fasteners deepened. If after some time you need to replace the rotted lining boards of the log house, it will be impossible to do this; you will need to disassemble the entire log house. The boards will be securely pressed by the weight of the erected massive structure, so anchors for fastening are not needed.

The logs of the lower crown are laid out on pads of oak boards laid on the foundation, laying insulation: hemp, moss, tow. The insulation should fill the entire space between the gasket and the first crown - the more carefully the insulation is laid, the better the heat will be retained, the less the threat of dampness and mold. The lower crown is fixed to the spacer boards, the logs of one row are fastened together.

Installation of a log house

The next rows of logs are laid in accordance with the assembly diagram, which includes row markings. Each log has a special marking, which indicates in which row a particular log should be placed. Installation of logs is impossible without the formation of gaps between adjacent rows. When assembling a log house, sealing the joints is of great importance.

Foundation waterproofing

High-quality foundation waterproofing well protects the walls of the house and its interior from moisture penetration. Waterproofing must be correct and selected depending on the groundwater level in a particular area.

If the level is high, then when laying the foundation it makes sense to lay a drainage system to drain water. Drainage can be made from a perforated pipe laid in the ground just below the foundation with a slope around the perimeter and drainage of water into a storm well.

Watch the video on how to properly waterproof the lower logs of a house.

The vertical walls of the base (cast or made of blocks) are coated with several layers of bitumen mastic, which is diluted with diesel fuel or waste oil. Horizontal waterproofing most often consists of two or three layers of roofing felt on bitumen and one layer of glass insulation.

These works can be easily done with your own hands, without involving specialists. But first you need to check the horizontality of the upper surface of the base, and, if necessary, level it with cement mortar or boards. Waterproofing should be arranged in such a way that it is wider than the foundation, to prevent moisture from entering the walls, as well as to better protect the foundation.

The more carefully and correctly the preparatory work is completed, the fewer problems will arise with the accurate installation of the first crown, on which the quality of all further work depends.

Replacing a damaged crown

If something irreparable does happen and the material deteriorates, it is better to know how to replace the lower rims of the bathhouse.

There are several ways to do this:

- They dismantle the walls, replace the crown with a new one, and lay the frame again. This is an excellent preventative measure for old buildings, since at the same time a number of other shortcomings can be eliminated. But the procedure is very labor-intensive and time-consuming;

- The upper rows of the plinth or foundation are dismantled, and the rotted material is replaced with a new timber, processed according to all the rules. The house is supported by a special structure or supports. The method is also difficult and tedious;

- They cut holes in the rotted row for inserting jacks, raise the bathhouse, replace the beams and put it in place. The most rational method, provided that the frame is of high quality, the corner joints are not damaged, and changes in geometry are not dangerous.

Advice! Before you replace damaged timber, remember about larch. This tree only becomes harder from moisture and is able to stand for centuries in salt water, like the supporting pillars of Venetian houses.

The frame is lifted with a jack and replaced.

Depending on the size of the bathhouse, lifting it may require from two to four jacks on each wall. In the top of the rotten rows, holes are made with a chainsaw about 30 cm in size and the width of the row in height. There are from 2 to 4 holes in each wall, according to the number of jacks.

Then a jack is inserted into the hole and gradually, in turn, each jack is raised a few millimeters. So they carefully lift one wall and install additional supports for safety. They can be made from logs or large timber.

Replacing the lower crown is a labor-intensive process

The old log is removed, the old roofing felt is removed, everything is thoroughly cleaned and treated with antiseptics, then a new lining of euroroofing felt is laid and a new timber is laid, pre-treated according to all the rules.

The bottom row of logs in a log house is a weak point due to objective reasons. That is why special attention should be paid to its installation in order to avoid time-consuming and expensive replacement and repairs. The video in this article illustrates everything that has been said well, so we recommend watching it.

How to properly lay a log frame on a foundation

The condition of a wooden house is assessed by the three lower crowns of the frame: if the wood is different in color, we can say with confidence that the house was not built correctly. Upon closer examination, a black mold coating will be found on the surface of the timber. The cause of these problems must be sought in the mistakes made during the construction of a wooden house. Professionals believe: only a correctly laid crown molding will ensure a long and trouble-free “life” of the building, and the owners will have comfortable living conditions.

Among the troubles that can arise as a result of improper laying of a log frame on a foundation are the following:

- The lower corners of the log house freeze, the floors in the house are cold in winter;

- There is high humidity in the underground space, condensation forms;

- Wetting of the lower crowns of the log house, the appearance of fungus and mold;

- Skewed structure.

All these troubles can be avoided or minimized by following the rules for laying the casing; this operation is called tying the foundation, and the casing is called strapping. The frame is the load-bearing base for the walls of the building; logs for the floor and for internal partitions are cut into this structure. For buildings erected on columnar or pile supports, the flashing crown can be used as a grillage. In this case, a double harness is needed.

How to correctly lay the lower or embedded crown of a log house

The lower crown of the log house requires special attention, since it will be in close proximity to the ground and in contact with the foundation. Because of this, it suffers most from high humidity and fails very quickly. Very often it has to be replaced when the rest of the frame shows no significant signs of wear. The first crown of a log house (also called the frame) requires careful waterproofing of the base, and the strongest and thickest lumber is always chosen for it.

Preparing the foundation for the casing

A layer of roll waterproofing on a bitumen basis is applied to the basement - upper surface of the strip foundation. The material is laid in 2-3 layers and filled with bitumen mastic. A thermal insulation layer is laid on the hardened waterproofing. Jute tape or construction felt is used as a heat insulator. It is best to place the waterproofing material on a dry base and carry out the work in dry weather. Before installation, it is recommended to dry the surface of the plinth with a gas burner.

When installing a pile foundation, the places where the grillage is laid on the racks are subject to waterproofing. The secrets and tricks of experienced craftsmen include the use of backing boards to minimize the consequences of seasonal movements of the structure. A hardwood board 40-50 mm thick is laid on the waterproofing layer. The bottom and side parts of the board are treated with bitumen mastic, and a heat-insulating lining is laid on top of the board.

Tools and materials used for applying waterproofing:

- Ruberoid or rolled bitumen-polymer membrane;

- Bitumen-latex mastics for hot and cold use with antiseptic and herbicide additives;

- Gas-burner;

- A brush with metal bristles, a corrugated metal spatula, a construction knife.

Crown installation techniques

During the design process, the problem of how to correctly install a log bathhouse on a strip foundation can be solved in 2 ways: by installing a crown with additional leveling pads or by pouring the base with level transitions on the base (step).

Before installing crown logs on a concrete foundation, it is necessary to carefully carry out preparatory operations in the upper part of the monolith. First, the base must be plastered with 2–3 mm of cement mortar, followed by ironing of the entire surface. The laid layer of plaster mortar is leveled in a horizontal plane.

The procedure for leveling the base surface mechanically is shown in the photo:

The foundation with the step is preparing to receive the crown

The height of the base should ensure that the wooden floor is protected from water from the surface of the ground. The minimum rise above the zero mark of the upper edge of the support is 0.2 m.

For a special-purpose building (for example, a bathhouse), the optimal height will be determined by suitable technological communications, the dimensions of the manhole for inspection and cleaning of the underground space. With this device, the rise will be at least 0.5 m.

Selection of material for strapping

For strapping, it is best to use timber made from hardwood; the additional costs for purchasing it are minimal; such a batch will amount to less than 5% of the total volume of lumber. If this is not possible, lumber blanks without visible defects with a smooth surface are selected from the entire batch; if necessary, the lower and upper sides are additionally planed.

When building a log house from corrugated timber, the casing crown is made from solid timber. The lower part of the first timber laid on the flashing is planed before the profile is removed.

Why did you choose a log house?

Wooden baths are no longer a simple tribute to our traditions. At a dacha, a wooden building will decorate the area; in a private house, a bathhouse will become a highlight and a place where you can relax from the noisy city and dust. The heat capacity of wood and its durability, proven over the years, have made the material indispensable for the construction of a log bathhouse.

It is necessary to choose only high-quality, non-rotten logs for the log house.

When building a log bathhouse, logs of the same diameter from 20 cm are taken. It is important that the log is even along its entire length; narrowing will cause difficulties during installation and the structure will be aesthetically unattractive. Of course, if we are not talking about designer baths, where different logs can be used, for example, as in the photo:

An unusual bathhouse made of logs of different diameters.

When choosing logs, pay attention to their surface. The material must be free of knots, smooth and free from rot or mold. Sellers often claim that blued wood can be easily bleached with special preparations. You should not take such material, darkening is the first sign of the development of microorganisms inside: fungus or mold. Such a bathhouse will not last long and you will regret the wasted effort and time.

How to lay a crown beam on a foundation

The strapping is cut using the half-tree method, the connection in the corners is made “in the paw”. This method of laying corner joints is the most reliable and can withstand multidirectional loads. The laying of corners and the connection of beams in subsequent crowns can be done in any way.

When laying the tying crown on a strip foundation, you may encounter unevenness on the base, reaching 10-15 mm. Such irregularities are eliminated by increasing the thickness of the mastic layer of waterproofing. The best solution for laying the first crown of timber on the foundation is an even and horizontal grillage.

Attaching a crown made of timber to a plinth is done in various ways:

- In strip foundations and concrete grillages, anchors with a diameter of 12-16 mm are poured every 1.5-2.0 m; the crown is attached to the strip base with an anchor bolt with a nut;

- Square plates are welded onto metal piles, the grillage and frame row of timber are fastened to the plate with a through bolted connection, the nut is located in the lower part of the fastening.

Holes are drilled for the fasteners with a margin of 3-4 mm, and flax tow is stuffed into the gap.

The next crowns of the log house are attached to dowels, the dowels are installed vertically with tension in specially drilled holes, the edges of the dowels are recessed and do not protrude above the surface.

Professionals recommend paying attention to the leveling of the casing; when setting the horizon, the height is adjusted with wooden wedges between the plinth and the first beam, and the resulting voids are sealed. The operation is performed using a building level. After leveling is completed, the nuts on the anchor fastening are tightened and fixed.

How to properly build a foundation for a log bathhouse

Photo of a bathhouse on a slope by the river.

There are no special requirements or restrictions for placing a bathhouse on the site, but a natural slope to the south, or, in extreme cases, to the west or east, would be preferable. A site near a river would be ideal: in this case, there is a slope, a natural reservoir is within easy reach, and there is no need to build a swimming pool.

But if there is no natural reservoir, the question of building a pool may arise - in this case, a study of the level of groundwater will definitely be required, since if they turn out to be surface water, this idea will have to be abandoned.

What factors does the choice of foundation depend on?

Map of average soil freezing depths.

How to build a foundation for a log bathhouse depends on many reasons.

In addition to the economic component, you should pay attention to the following points:

- type of soil and degree of its homogeneity;

- freezing depth;

- groundwater level;

- the nature of soil swelling and its strength.

All this research can be done independently or you can turn to professionals. It is especially important to contact specialists to determine the level of groundwater, since this indicator can subsequently have a significant impact on the strength and reliability of not only the foundation, especially the strip type, but also the entire structure as a whole.

The freezing index is also related to the level of groundwater and the type of soil; data on this is contained in special reference books, but the following factors must be taken into account:

- denser soil freezes deeper;

- soil moisture also affects the speed and depth of freezing;

- average depth of snow cover - the higher it is, the less soil freezing.

Although there is a rule according to which a strip-type foundation is installed on average 10-20 cm below the freezing level, in some cases, especially when the groundwater level is high, it is possible to make a shallow foundation that will fully withstand the log house of a bathhouse.

This will avoid the negative impact of the natural process of soil swelling, the strength of which is also directly related to its type, humidity and groundwater level.

How to choose the right type of foundation

Once the site for construction has been determined, you can start making a design for a bathhouse from rounded logs and choose the most optimal and correct method for constructing its foundation.

As a rule, the frame of a bathhouse on the foundation of a bathhouse should be placed, first of all, taking into account the type of soil - for any of them there is the most optimal option, which allows you to achieve the strength of the base itself and the reliability of the entire structure as a whole, which, naturally, affects the service life of the structure .

- strip foundation, prefabricated or monolithic, suitable for swampy, clay and loamy soils;

- for construction on heaving soils and in cases where the structure is located on a steep slope, on rocks, the best option is a pile-screw design. It should also be given preference when building on sand or peat bogs;

- columnar foundation methods should be used on soils consisting of fine gravel, sand, and clay;

- slab foundation, which is of the floating type, can be built on sandy soils, peat bogs or used for wetlands; it can ensure reliability of a structure that is being built on so-called soft soils.

Installation of basement drip sill

The gap formed at the place where the casing is laid on the waterproofing layer poses a serious danger to the entire structure; atmospheric moisture stagnates in this part. This drawback is eliminated by installing metal ebbs around the perimeter of the log house. On a strip of iron 20-25 mm wide, a bend is made at an angle of 120 degrees, the structure is fastened with self-tapping screws, and the area adjacent to the beam is treated with sealant. For the manufacture and installation of the drip sill, all the tools are available in the household.

The lower crown of the bath

The lower crown of the bathhouse is most susceptible to moisture. Therefore, it often rots very quickly. The entire frame is still in excellent condition, but it has to be replaced. What to do?

First, let's determine why the lower crown of the bathhouse rots very quickly. The causes of rotting must be determined in order to take a number of protective measures even when assembling a new log house.

The healthy condition of the lower crown is influenced by the following constructive measures when building a wooden house or bathhouse, which must be done without errors:

- a waterproofing layer of roofing felt on the surface of the concrete foundation in front of the brickwork of the base. This layer of waterproofing prevents moisture from rising from below and absorbing it into the brick material. Wet brick is not the best basis for the lower log of a log house.

- the second waterproofing layer of roofing felt is placed on the upper level of the brickwork of the base. It is the roofing felt that comes into contact with the wood of the lower crown of the log house. This contact must be made correctly.

- vents in a brick base or concrete foundation in order to provide natural ventilation in the underground.

- to prevent rainwater from getting in and stagnating on the roofing felt (see point 2), it is necessary to make a protective flashing. Its design can be different depending on the chosen material. You can simply cover the joint with a flashing board around the perimeter of the log house. You can make a drain from galvanized steel or buy it ready-made and install it so that it covers the joint and, at the same time, protects the basement part of the bathhouse from rain due to a slight offset from the outer edge of the brickwork. You can make a screed with a slope from cement-sand mortar along the upper edge of the base and stick soft tiles along it.

- Treat the lower rims with protective compounds in several layers

The absence of any of the above measures leads to rapid rotting of the casing.

The best way to avoid replacing the lower crowns is to make them from larch. Larch has the ability to harden (turn to stone) even more in the presence of moisture. It is not susceptible to fungi.

If it is not possible to get larch logs and in your region only pine is used for log houses, then you can compromise and find at least a larch board. By placing it under the lower crown, you can solve the problem of replacing the lower crowns in the same way if there were a pair of lower logs made of larch. The option is quite generous in monetary terms.

If you can’t get larch boards, then oak grows everywhere. Oak boards are a good alternative to deciduous boards. In addition, it is easier to replace the board than the lower crown.

Regarding the second point of protective measures: since the waterproofing from the roofing felt layer has a horizontal surface on which the lower log is laid, it is natural that water can stand here in puddles. Therefore, it is necessary to ensure that the surface of the roofing material is not horizontal, but has a slight slope to the outer sides to allow water to flow to the ground.

It's very easy to do:

- cut narrow strips of roofing felt approximately 5 cm wide

- put them 3-4 pieces together

- lay these roofing felt strips in the middle of the width of the plinth (or foundation)

- on top of them, place a layer of roofing felt slightly wider than the width of the plinth. (Usually a meter-wide roll of roofing felt is cut in half, resulting in a width of 500 mm, which is quite enough for waterproofing along the plinth (or foundation).

These additional soft “pads” will give you the following benefits:

- a soft “lining” will close the gaps that have formed between the log and the surface of the plinth due to unevenness of the lower surface of the log itself. In a normal situation, they are either left uncovered and the floor is raised above this joint so that it ends up underground. Or they are plugged with tow, but always from the outside; the joint is sealed with some kind of elastic sealant to prevent the tow from getting wet. This option is not entirely reliable. Better tightness is achieved through a soft “gasket”

- since in the middle it will be higher due to 5 layers of roofing material (4 narrow strips and 1 layer of a wide main strip), then the surface of the waterproofing layer will have a slope for water to drain from its surface.

Even with this design of roofing felt waterproofing, it is necessary to cover the lower crown and the upper part of the base with a galvanized or painted steel drain to prevent any moisture from getting under the lower log (see paragraph 4 of protective measures).

Assembling a log house

The assembly of the log house is carried out according to the crowns. The crowns can be made from one log, if the structure is small, or from several logs spliced in a certain way. Let us consider in detail the procedure for assembling a log house from logs.

Everyone knows that a tree grows in thickness unevenly. To the south - more than to the north. And the width of the annual rings is correspondingly smaller from the north, and larger from the south. The lower the density of the wood, the better its thermal protection. Therefore, if the log is flat, then it is laid so that the denser side, the northern one, is on the outside of the frame; this part of the log is less susceptible to cracking. But there is usually not much timber; all trees have a certain curvature. Slightly curved logs are laid regardless of the location of the annual rings, with the hump facing down or up. If there are a lot of curved logs or all of them are the same, then when laying with a “hump” outward, it is almost impossible to notice the curvature of the finished wall.

When laying the crowns of a log house, a compacting layer is laid between the logs. Traditionally this is forest moss. Jute fiber is often used as an inter-crown sealant.

Assembling a log house for a bathhouse. Part 1

- Foundation and embedded logs

- Prepare the logs and lay out the moss

- Features of laying crowns

More than once I had to participate in the construction of a real Russian bathhouse from solid logs, and each time it turned out to be special and unlike the others, this is the difference between handmade work and ready-made standard projects.

Hand felling is still not uncommon in cities, but in villages it is still practically the only one. Only it is closest in spirit to the original traditional bathhouse. Is it difficult to build? Yes, it’s not easy on your own, there are a lot of subtleties in this matter, it requires a special approach, which is why people experienced in this matter are invited both for felling and for its construction.

A bathhouse is the same as a house, only small, which is why its construction must be taken with full responsibility

Foundation and embedded logs

The modern approach to building baths requires a design, assessment of soil conditions and choice of location, but the realities of village life are far from all this (and we are building it there), so we skip this preparatory stage and immediately get to work.

The bathhouse, as usual, although small, but, like any other serious building, cannot do without a foundation. In our case, it is already ready, because it is being built on the site of the old one, and if the soil is normal, the most ordinary strip will do just fine.

We begin the construction of a log house by waterproofing the foundation - we roll out a layer of roofing felt over its entire surface. Then we proceed directly to assembling the walls. Long logs, or as they are also called “mortgages,” are laid first. Let us immediately note that in different regions and even neighboring areas, parts of the log house are usually called differently.

In order for the base of the structure to be stable, the underside of these logs needs to be leveled; to do this, we cut off part of the tree with a chainsaw.

Usually they are placed directly on the foundation, thoroughly soaked with an antiseptic, but in this case it was decided to first lay a board (40mm), and then install embedded logs on it, this will allow them to last longer.

Between the mortgages you need to install the so-called “roll-ups” - special logs that cover the empty space in front of the first crown, but they were not prepared in advance, for this reason they will be laid only after the walls are completely assembled.

Then we begin to assemble the first row (crown) of the frame. To do this, we select the necessary ones from a pile of logs; this is not difficult to do, because each of them is marked in two places - on the log itself and on its end.

After completing the cutting of the bathhouse, all its walls are marked so that the disassembled log house can be easily reassembled in the future - each log should lie in its designated place. The markings are done in different ways; in this version, each log was marked with a marker: a number corresponding to the row and a letter indicating the side of the log house. For example 3 - PR - log of the third row on the right side.

In the old days there was no paint or special graphite pencils, so the numbers were cut out with an ax.

What to do if the finished log house is not marked or the markings are difficult to understand, read this article.

Prepare the logs and lay out the moss

The required logs from the inside, from cup to cup, starting from the groove and ending with the light strip (remains from the top row, since this part was closed from the sun while drying the log house) are planed manually with an electric planer.

At the same time, the tree becomes smooth and even more beautiful.

It was decided to leave the outer side as is for now; in the future it will be sanded with a grinder with flap wheels (KLT) and covered with a tinted antiseptic.

Simultaneously with the preparation of the logs, insulation is laid out on the bottom row of the first crown. We use traditional material - sphagnum moss. In this area, no one uses cuckoo flax due to its absence, and naturally no one will buy it either. The moss was dried and was harvested in the middle of summer.

If the weather is not windy, then laying it out is not difficult: we lay it in a layer of medium thickness along the entire log. We only pay special attention to the cups; here you need to distribute it correctly so that the subsequent log does not “cut off” the moss and does not hang due to the too thick layer of insulation. We lay the prepared log across, next to the bowls and align it along the groove.

Features of laying crowns

You can’t put wood on the edge of a bowl; you can break it; for the same reason, you should never step on it or knock on it. If necessary, the log moves with the help of an inserted ax

Then we lift one side and drop it into the bowl, and do the same with the other end. If necessary, we adjust until we achieve alignment of the groove in the bowl with the top of the log. This is a very important point, it determines how evenly and tightly the bathhouse is formed, and this, in turn, will affect whether it will be warm in the future or not.

After laying each subsequent row, the grooves outside and inside are additionally caulked, thus filling the inter-crown voids. We again pay special attention to the joints of the logs.

This is the order in which the construction of the walls continues. From the outside, everything seems quite simple, but of course everything is not like that, the process is quite slow, taking into account that the logs are pre-planed, and there is no need to rush here, everything must be verified.

On the first day, it is usually possible to fold about half of the log house - 5-6 rows.

The next day, weather permitting, we continue construction. It is becoming difficult to lift the logs, so a deck is built outside and inside.

Work continues until the moment when the penultimate crown is laid, consisting of the following logs: two “skull” logs and two “purlin” logs. Then we temporarily stop the construction of the log house; it’s time to do the ceiling.

Only after its installation will it be possible to complete the assembly of the log house.

Read the continuation in the next article - here.

Rules for assembling a log house

- Laying logs in crowns. There are two ways of laying - butt to top and butt to butt (top to top). But if it is necessary to make horizontal alignment in a row, this rule can be changed.

- To obtain the required rigidity in the log structure, they are fixed in vertical planes using dowels - wooden parts machined in the form of a round or square rod. Dowels pass two or three logs at once into drilled holes; such fastening is done in each crown. Holes are drilled using wood drills with a length of 450 mm and a diameter of 25 mm. The distance between the holes is selected from 80 to 150 cm. There should be at least 100 mm from the edges of the openings and bowls. The pins are driven into the holes with a hammer, into a “tightness”. The use of metal pins instead of wooden dowels for a log house is unacceptable. Firstly, the metal condenses moisture from the air, and wood rotting in the inter-crown seals inside the walls becomes possible. Secondly, when driving pointed pins, free shrinkage of the logs is impossible; during the shrinkage process, the logs “hang” on the pins, the log house does not shrink, and the gaps between the crowns increase.

- After the log house is assembled, the protruding parts of the logs at the corners are cut to the mark, but not less than 200 mm from the corners to the ends. The ends of the logs are cut along vertical markings. Exposed grain ends dry faster than the middle portions of logs and may develop deep cracks. To avoid this, use acrylic varnish or PVA glue to cover the ends. Historically, clay and lime mortar were used for this purpose.

- To create window and door openings, they do not always leave holes in the frame or make them deliberately smaller. Be sure to leave only an opening for entry into the log house. After the frame shrinks, the openings for windows and doors are cut to the required dimensions, taking into account the connection to the landing tenon.

Features of the arrangement of openings

No building is without openings, doors or windows, even a bathhouse. So I had to think about how to make them while still chopping. The fact is that each beam will shrink differently during the drying process and the openings may squint.

It was possible, of course, to install the entire frame of the bathhouse without windows and doors, and after drying it for a year, cut out the openings where necessary with a chainsaw. But in this case, there would be a lot of wood waste, and in my case, every piece of timber counted. The construction of openings during the construction of the log house would provide significant savings.

In order to “feed both the wolves and save the sheep,” I decided to leave a through beam in the openings every 3-4 rows, cutting out the rest. In this case, the shrinkage of the log house will be uniform.

Construction of the lower frame of a log house

The crown molding is closest to the ground; it receives more moisture from rain and snow. Therefore, it requires special attention. Waterproofing of the lower crown is made from rolled bitumen materials in two or three layers. The waterproofing layer is laid along the upper edge of the foundation under the lower crown, and should prevent the frame from getting wet from the foundation.

To make the frame crown, the thickest logs are taken. It is best to use wood species that are resistant to decay - oak or larch.

The logs in the crowns are at different horizontal levels, the difference is 0.5 of the log diameter. There are two ways to arrange the bottom crown.

The first method of installing the lower crown

Two logs are placed on the foundation, hewn at the bottom by 50 mm, so that the logs fit more tightly to the foundation. Under the logs, a sealing material is laid for waterproofing, the same as that which will be used for all subsequent crowns. The most commonly used fibers are jute fiber and tow. Traditionally – moss.

This installation method has a drawback - a large gap between the foundation and the logs located at the top of the crown. This gap is sealed with wood in the form of timber or halves of logs, or with bricks. It is possible when constructing the foundation formwork to make its opposite sides at different elevations, then there will be no gaps under the lower crown.

But this method has a significant advantage, since the logs are laid in one piece. And whole logs are the most durable.

The second method of arranging the lower crown

With this method of laying, there is no gap between the crown and the foundation, since the lower logs are hewn to the middle, and the upper ones - by 50 mm for a tight fit on the foundation.

In the corners, the logs of the frame crown are connected with corner notches, which are called “in the okhryap”.

Since the logs are being processed, measures must be taken to prevent rotting of the lower hewn sides adjacent to the foundation waterproofing. An antiseptic is needed here; it is applied in 4-5 layers with a brush or roller. Sometimes a board is laid under the crown molding. That’s what they call it – a flashing board. Replacing this board if it rots is much easier than crown logs. Using jacks, they lift the frame and replace the old board with a new one. The lining board has a width of 250-300 mm and a thickness of 50 - 80 mm. For its production, wood species that are resistant to decay are used - oak or larch. A thorough antiseptic treatment is carried out, or, as an option, it is kept in used motor oil (exhaustion). It is impossible to antisepticize wood, especially undried wood, using bitumen and mastics. Due to the capillary structure of wood, it rots very quickly if the capillaries are clogged with resins or bitumen. Wrapping it in rolled waterproofing material gives the same effect.

The laying of the boundary sealant must be done both under the first crown between it and the covering board, and between the foundation waterproofing and the covering board, that is, everywhere.

As a result of atmospheric influences, the trim crown is in a wet state for most of the year, that is, almost constantly. Therefore, to increase the durability of the lower logs, it is practical to install canopies or overhangs over them, for example, made of galvanized steel.

Replacing the lower crowns of a log house: technology and important nuances.

The lower crown is the most vulnerable place of the log house. Unlike other structural elements of a wooden house/bath, it is most susceptible to the harmful effects of moisture. But the worst thing is that, easily rotting, it immediately begins to spread rot to the upper logs, which invariably leads to the destruction of the entire structure. To prevent such a development of the situation, it is necessary to immediately, at the first signs of rotting, replace the lower crown either partially or completely. Partial replacement of the lower crowns. If you immediately respond to the situation, you can save yourself from unnecessary financial and labor costs and replace only some damaged parts of the lower crown. Replacement technology. The essence of this procedure is to remove the rotten area and install in its place a “patch” made of wood, brick or other materials. The outer skin is separated from the area affected by rot; Determine the boundaries of rotten wood, marking them with a chisel or knife; To prevent damage to the entire structure, when removing rotten wood, screeds are installed at a distance of 40 cm from the intended boundaries. Screeds are bars 2-3 crowns high and 40 cm thick. A total of 4 bars are used, attaching them to the sides of the rotten area on both sides of the wall. You need to use ties if a large section of the crown is removed, but if a small area is damaged, you don’t need to use ties; The damaged part of the log is removed with an electric or chainsaw. To do this, you first need to make a through cut on both sides. The sawed area must be removed; In the resulting space you need to place an insert. To ensure that it is firmly fixed, notches are made along the edges of the resulting opening (width 20 cm); The lower part of the second crown is cleaned and leveled with a chisel until it is flat. In order to protect the wood from insects, moisture, mold, rot and fire, treat the side walls of the resulting opening and the lower part of the second crown with an antiseptic; The foundation is covered with roofing felt in 2-3 layers or glass roofing felt in 1 layer. An insert is made. A piece of exactly the same diameter as the damaged logs is cut out of the log. The length of the insert should be 1-2 cm less than the size of the opening. It is treated with an antiseptic - vk.com/wall-72891995_1080, and then installed in the opening. If you have problems with this, you can use a sledgehammer. To make the insert, you can use bricks instead of wooden blocks. To do this, in the opening formed after cutting out the rotten part, bricks are laid on concrete mortar. Thus, brickwork will replace the entire lower crown; The gaps between the insert and the frame are covered with fibrous materials such as tow and jute. Replacement of the entire lower crown can be carried out according to the above scheme. This will require a lot of time and effort, since you will need to gradually cut off all the damaged areas, replacing them with new ones. But there is also a big advantage - you will no longer need to lift the frame with jacks. It will be much stronger if the new lower crown is made not from pieces, but from whole logs. To do this, you need to move the entire structure of the log house, lifting it with the help of jacks. Replacement technology. 1. Preparatory stage: To prevent windows and doors from cracking, they are removed while raising the frame; The log house must remain empty, and therefore all heavy objects must be removed from the bathhouse; The floor joists embedded in the lower crown need to be disassembled. The logs laid above the lower crown are not disassembled; To avoid damage to the ceilings and roofing by the heavy chimney pipe, it must be separated; The undamaged crowns of the log house must be fixed. This is done like this: on the inner and outer sides of each wall, at a distance of 0.5 meters from the corners of the log house, boards or bars (4 cm thick) are nailed vertically. Their lower edges should end exactly in the same place as the logs of the crown that cannot be replaced (second from the bottom), and the upper edges should be attached to the logs of the topmost crown. To fix undamaged areas, 16 boards are used, which must be secured at the bottom and top with through dowels. This is done so that when the log house is raised on jacks, its walls do not move.

Once all of the above work is completed, you can begin the procedure for repairing the lower crown of the log house. 2. Basic work The process of replacing the lower crown of a log house depends on the type of foundation. Strip foundation. A log frame consists of a top and bottom log that are joined and tied at a corner. It is very important to accurately determine which logs in the rotten crown are the top ones, since it is under them that the jacks will be installed; In the crown of the log house being replaced, at a distance of 0.7-1 m from the corner of the house, an opening 0.4 m wide is knocked out in the foundation. A part is cut out of the log of the lower crown, located opposite the resulting opening, so that the total height of the niche allows placing a jack there. According to this scheme, exactly the same niches are made on two opposite walls. The distance from the corners should be the same; Now you need to install jacks (2-4 pieces). A very important point is the choice of jacks. To do this, you need to select a mechanism with a load capacity of at least 10 tons. Depending on the size of the house, the lifting capacity of the jack can reach 25 tons. An error at this stage can lead to distortions and broken logs. The number of jacks depends on how the frame will be lifted: all at once or each wall separately. But if you raise the walls one by one, this can lead to distortions, so the best option would be to raise the entire frame together. To do this, you need to install 2 jacks under opposite walls so that they rest against the upper logs of the crown bandaging; Using jacks, raise the frame by 7-10 cm and remove the lower logs of the dressing; Reliable temporary supports, such as bricks, concrete blocks, logs, boards, bars, are placed under the lower logs of the second crown. The main thing is that they can withstand the weight of the entire log house; The jacks, along with the upper logs of the crown being repaired, are lowered, and instead of them, new ones are immediately installed and pressed with jacks. All supports installed under the lower logs of the second crown are taken away. The upper logs of the dressing are placed on the lower ones, and the lower logs are laid on the foundation. The jack is lowered very slowly and synchronously; At the last stage, caulking is carried out - the cracks formed when connecting new logs with the second crown of the log house are sealed. To do this, fibrous materials (tow, moss and jute) are used, which are hammered into the resulting seams. Columnar foundation. Replacing the crowns of a log house on this type of foundation is quite simple. It is necessary to install 4 jacks between the foundation columns, which are connected to the upper logs of the lower crown trim. Place 2 of them on each wall. It is necessary to install these jacks on a very solid base, such as a board made of boards measuring 50x50 cm. The head of the jack rod should rest against the log only through a metal plate; The jacks are raised synchronously. Further actions are exactly the same as when replacing the lower crown of a strip foundation frame. The difference between replacing rotten crowns of a log house with a strip and column foundation is only in the process of installing jacks. The first option is more labor-intensive, since the foundation must be partially destroyed. There is no need to do this for a columnar foundation, since there is a lot of space in its structure for installing jacks. How to protect the lower crowns from rotting? The process of replacing damaged logs can take forever, repeating itself every 2-3 years. The reason for this lies in improperly carried out waterproofing. Protective measures: The lower crowns of the log house must be made from tree species that are difficult to rot - oak or larch. It is not necessary to take whole logs; larch boards that need to be placed under the lower crown are quite suitable for these purposes. Thus, a protective layer is formed between the foundation and the crown, which is not affected by fungi; To protect logs from rotting, they need to be fired and/or covered with fire-bioprotection. It is also possible to carry out “machine processing”, but in this case a pungent odor will be felt for a long period; The base of the house also needs to be covered with a water repellent; Between the crown and the foundation, waterproofing must be used to waterproof the joint; The lower crowns must be protected from external moisture with canopies made of galvanized strips.

Geometric correctness of masonry

Our conversation about how to lay the first crown of a house made of timber is coming to an end. There are some last but still important tips left. During work, do not forget to check the geometric correctness of the masonry. All angles must strictly correspond to 900, the lengths of opposite sides and diagonals must be the same.