Our portal has many useful articles on how to insulate the roofs of houses outside and inside, how to insulate an attic, and which insulation is more suitable for these purposes. In principle, you can work with almost any material, if only you know its installation technology and follow all safety rules, but in the construction industry there is such a complex object as the Russian steam room.

Its roof cannot be insulated with the same approach as a simple residential building or garage, if your life is dear to you. And now we’ll tell you what and how! So, we will talk about how to insulate the roof of a bathhouse - safely and reliably!

Nuances of insulating a sauna roof

At first glance, how to insulate the roof of a modern bathhouse does not seem complicated. Indeed, to the inexperienced eye, the process itself is no different from ordinary house construction. For example, this is how a gable roof of a steam room is insulated:

And flat like this, often using foam plastic:

But there are even special standards that are responsible for regulating the design of a bathhouse roof - these are SNiP II-26-76. And the thermal insulation of any roof must be as fireproof as prescribed by clause 5.21 of SNiP 01/21/97.

Why are we talking about this? The fact is that burning bathhouses are not uncommon. Somewhere the stove was insulated incorrectly from the walls, somewhere the thermal insulation for the chimney when passing through the ceiling was of poor quality, or the system itself was not installed professionally. In addition, over time, any wooden building dries out, and sparks often fall from the chimney. But the most vulnerable in this regard is the roofing insulation. Consider this issue more carefully!

Selection of materials

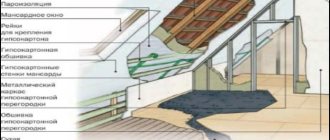

Regardless of whether the attic space will be used, it must be vapor-insulated. Click on photo to enlarge.

If the attic space of the bathhouse is not used in any way, special insulation of the roof will not be required. It will be enough to provide steam and heat insulation of the bathhouse ceiling and attic floor.

If you want to use the attic as a place to relax, or dry clothes and store bath equipment, you will need major insulation.

Almost any insulating material is suitable for insulating the roof of a bathhouse - polystyrene foam, glass wool, mineral wool, synthetic insulation materials such as "Ursa".

It would be good to use mineral wool with a foil side.

When choosing how to insulate the roof of a bathhouse, pay attention to materials that are resistant to high temperatures and high humidity

Steam and waterproofing

Before starting insulation work, all roof elements must be treated with antiseptics and fire retardants.

Membrane coatings are usually used as waterproofing materials.

The waterproofing film is laid on the rafters before installing the sheathing. The film, which serves as a vapor barrier, is installed between the lining and the ceiling insulation.

The film is laid loosely, without tension, with an overlap of strips of 10-15 cm. The seams and joints are taped to seal and prevent stretching and tearing in the event of deformation of the film due to temperature.

Flammability of insulation: debunking myths

Let's dwell separately on such a point as the flammability of insulation. If the seller tells you or the manufacturer claims that this roof insulation is non-flammable, this does not mean that it will not burn at all in a fire. And you will be surprised to learn how many cases of fire in private homes are due to incorrectly installed and insulated electrical wiring passing through the “non-flammable” insulation. So what's the problem?

Non-flammable = does not burn?

The fact is that non-flammable materials are those that can withstand exposure to an open flame for a certain time without ignition. And then, when the desired critical temperature is reached, they will still light up. But in reality, many have seen the following picture: the floor is on fire, the walls are on fire, but the insulation is still intact. But a few minutes pass, and the insulation also deteriorates. And after the fire, in the ashes you will not find bright slabs safe and sound, like some icons. Everything will burn.

Therefore, after insulating the roof of the bathhouse, be sure to insulate all hot pipes and wires:

But depending on how much the insulation can withstand open fire, there is a whole gradation of fire safety of materials. For example, mineral wool is considered the safest in this regard, as it cannot contain hidden sources of decay.

Ecowool, a new generation of insulation, has been declared still safe in terms of fire:

And we will call dry sawdust the most unsafe insulation. Yes, indeed, to this day sawdust is often used to insulate roofs, but only with old, rotted sawdust, which cannot even be set on fire, and only those who understand nothing about construction indulge in dry sawdust.

Toxicity of insulation during combustion

And now - about the other side of the coin of the concept of flammability. Agree that in the event of a fire, the most important thing is to save people’s lives, and this fact depends on how quickly the frame of the building itself is destroyed in the fire: walls, ceiling, floor beams. And you will be amazed that this period of time directly depends on the insulation!

Let's just compare two cases: the roof of the house is insulated with foam plastic and basalt wool. And imagine that a hot metal pipe from the chimney of a sauna stove passes through this roof, and the place where the pipe passes through the attic floor was not properly insulated. So, the fire safety rules were violated; during the first lighting of the bathhouse, the wood near the chimney was charred, and during the second, it flared up! Meanwhile, people are relaxing in the steam room, and they don’t suspect anything about what’s happening.

Case one: because the roof is insulated with polystyrene foam (or polystyrene foam, that doesn’t matter), then due to the flammability of this material it flares up like a match. It burns quickly, which in itself is bad - but what’s even worse is that the foam melts and destroys the entire roof frame with its high temperature - even the metal. As a result, in just a few minutes, the ceiling of the steam room will fall right on top of the entire calm group, who did not smell the smoke in the smells of fresh brooms and did not notice the flames on the ceiling because of the couple of flames on the ceiling. Unfortunately, this happens. Although it happens, of course, that they notice something is wrong in time and even manage to jump out, wearing what the mother gave birth to - but is the risk justified? Not to mention the residential attic of such a bathhouse, where they can play billiards at the same time - before all the players start going downstairs, half of them will definitely get poisoned from the extremely poisonous burning foam. But it's cheap.

Case two: the roof is insulated with basalt wool. Now, if the flames reach the insulation, the binding component will first begin to melt. But at the same time it will still protect the stone fibers, which do not even melt on their own until the fire temperature reaches 1000°C! You remember that basalt wool is made from stone, and stone does not burn even at the throat of a volcano. Such insulation will prevent the spread of flame as much as possible and delay the destruction of the roof structure so much that it can actually be extinguished with a hose from a well.

That is why it is important to choose the right material for insulating the roof of a bathhouse.

General information

Types of roofs

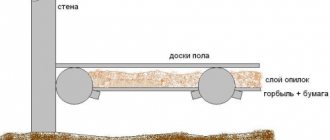

The ceiling itself can also be of two types - suspended and laid. The latter is extremely simple - it does not have beams, there are only boards that stretch from one wall to the second. This ceiling is fragile, it cannot bear excess weight, and even walking on it is dangerous, and the weight of the thermal insulation should be moderate.

The false ceiling has a stronger base - beams. Using skull blocks, you need to attach flooring boards to the beams (across the beams). This overlap can become a durable floor on the second floor. We will tell you in more detail below when we talk about thermal insulation technology. Insulated roofs are usually done either in order to actively use the attic space as a living space, or as a warehouse for necessary and not-so-necessary things. In any case, they do insulation there using the rafter system.

Ceiling pie for a bathhouse with a cool roof

A good option for insulation would be either expanded clay or foamed vermiculite. Naturally, these are fairly light insulation materials, but it is still worth consulting with professionals about the strength of the boards, foundation and walls, because the floor ceiling is made in the most inexpensive projects, and this means it is possible that the load-bearing characteristics of the walls and foundation are reduced. It should be assumed that the expanded clay or vermiculite layer can be from 0.15 to 0.3 meters thick. Roughly speaking, a square meter of such backfill area is 1/6 or 1/3 of the total weight of a cubic meter of both the first and second material. But their fractions are very different - larger ones can weigh less (a cubic meter of vermiculite, for example, weighs 65-350 kg). The weight of the specific fraction purchased should be checked with the seller.

Please note that for greater backfill density, coarse and fine fractions are usually mixed. This will complicate the calculations, and therefore it is possible to make calculations with a “reserve” for the heaviest fraction. Or you can do this as the arithmetic average of the weights from all fractions. For an even backfill, it is recommended to divide the floor ceiling from the attic side using boards of the required width into “paths” the same way a swimming pool is divided. It turns out that you put the boards on edge and attach them to the ceiling, and then you will get long “containers”, and you need to fill the thermal insulator into them - it will be more convenient. Just don’t forget about waterproofing and vapor barrier from below, and also cover with something on top. The pie itself in a bathhouse with a cool roof is very simple:

- Insulation.

- Waterproofing and vapor barrier.

- Flooring board.

Next about the attic.

Insulation technology with various insulation materials

There are many suitable options! Let's start with the fact that it is possible like this:

Expanded clay: absolute safety

To insulate the roof of a steam room, you can’t think of anything better: expanded clay, which is obtained from baked clay, does not burn, does not cake, does not put pressure on the structure and is absolutely environmentally friendly. Look, it’s quite simple to insulate the roof of a bathhouse with it:

And the best part is that expanded clay prevents the appearance of condensation on the roofing. This is a valuable property, because a real Russian bathhouse is famous for its amount of steam, which always rises.

Sawdust: unique technology

Rotten sawdust cannot be ignited at all, which is why they are often used to insulate the roof of a bathhouse. Here are instructions on how to do this:

- Step 1. Treat the subfloor and beams with an antiseptic.

- Step 2. Place construction parchment on the subfloor.

- Step 3. Next - foam plastic slabs, layer - 10 cm.

- Step 4. We seal the gaps between the slabs with foam so that air from under the ceiling does not pass through at all.

- Step 5. Fill with sawdust and tamp until the layer reaches its limit (in winter the sawdust will settle a little, and this must be taken into account). To prevent mice from getting into this insulation later, add a little ash.

- Step 6. Now waterproof and cover with boards.

As you can see, it couldn’t be simpler! The only important thing when choosing sawdust for such a mixture is not to take it with fine dust after cutting the boards - it will interfere, and the thermal insulation qualities will be much worse.

Unusual methods: ingenuity is in fashion!

Here, for example, is one of the most popular types of sauna roof insulation among craftsmen:

Mineral and basalt wool: the main thing is density!

For the manufacture of such insulation, the starting materials can be rocks, glass, concrete and metallurgical slag. From the melt of all this, during the production process, glassy fiber is extracted, which is tied in the form of cotton wool.

This group of materials is classified as fireproof - non-flammable. Moreover, they also have high vapor permeability - the ability to conduct excess water vapor through themselves without any damage.

Thus, among modern materials, Paroc slabs, in which the density of the fiber structure is increased, are recognized as fireproof. Here is a step-by-step master class on their installation:

Other brands of fiberglass and high-quality mineral wool also do not flare up and have relatively good strength. You can handle these insulation yourself:

You can also insulate the roof of a bathhouse with mineral wool from the inside, if it is important to thermally insulate only the ceiling:

Ecowool: fireproof treatment

This recycled cellulose has already conquered the modern market. Thanks to special processing, ecowool practically does not burn, which is important for a bath, but at the same time it has excellent vapor permeability. And ecowool is especially valuable in that it can easily fill the spaces between gaps and the most difficult to reach corners.

You can work with ecowool yourself if you need to insulate a small flat roof:

Or order such a service. Typically, construction companies that deal with ecowool insulation complete this order within a week or a week and a half. And all because working with such material is quite labor-intensive: you need a lift that can deliver up to 10 blocks of ecowool to the roof, you need at least two workers and special tubular pumps for insulation.

The process of insulating ecowool itself looks like this: on the inside of the roof, right in the stretched vapor barrier film, round holes are made for the hose to enter. Moreover, the higher these holes are made, the better. The hose, in turn connected to the pump, blows ecowool directly under the film. Using a special pump, workers regulate the pressure, and this already affects how dense the ecowool blowing will be. And this is an indicator of the flammability of the final insulation! The standard thickness of ecowool roof insulation is 35 cm and 32 cm for its gable.

As soon as a certain cavity is filled, the hose is removed and the hole is sealed with adhesive tape so as not to lose the seal of the insulation.

And finally, advice: if you are insulating the roof of a bathhouse, which is not separated from the steam room by an attic ceiling, then use an aluminum vapor barrier - this way you will retain heat:

Thermal insulation of deck ceiling

The flooring method allows you to erect a ceiling without the use of beams. In such a situation, the flooring of the boards is carried out on the strapping or on the upper crowns. Great for steam rooms with attic space.

The most budget-friendly and easiest ceiling option to install yourself. With this method, the insulation on the roof side is not covered, so it will not be possible to use the attic in the future. In addition, any repair work related to the ceiling will require replacing the insulation, which is not entirely convenient.

Direct thermal insulation work begins with the fact that a rather thick layer of clay is first laid on the ceiling boards. Next, you need to wait until the clay is completely dry, lay the selected insulation on top and cover it with a layer of loose vapor barrier. Before starting work, you need to place a box around the perimeter of the attic, which will serve as a fence for loose thermal insulation.

Insulation can be done using wood chips mixed with cement. This material will allow you to fill all hard-to-reach places and obtain thermal insulation of maximum quality.

Insulating a barrel sauna: a step-by-step master class!

The barrel sauna is a brilliant invention: it is compact, does not require a foundation and is not at all expensive to build. Everything about it is good, except for one thing: it cannot be used in the cold season. At least, that's what most bath attendants think. Still putting up with this shortcoming? Would you like to insulate the acquired know-how, but don’t know which way to approach it? After all, there is no separate roof on such a bathhouse...

It's simple! Study the master class we prepared on the internal and external insulation of a barrel bath:

Of course, it is better to insulate a barrel sauna from the outside, so as not to steal valuable internal space:

As you can see, the principle is the same - the main thing is to choose the right insulation materials and take care of fire safety!

How to insulate an attic? Methods

There are several ways to sheathe an attic.

Installation of thermal insulation material between rafters

This option has the advantage that there is no need to create a ventilation gap between the roof and the thermal insulation layer. But in this case, an additional requirement is imposed on the material: it must be as thick as rafters.

Installation of thermal insulation material between rafters

Installation of thermal insulation material above the rafters

In this case, the area of the room will not be reduced due to the thermal insulation material, and the beams can be used as a decorative element. But it will be necessary to make high-quality hydro- and vapor barrier.

Installation of thermal insulation material above the rafters