We go to the bathhouse not only to take a steam bath, but also to wash ourselves. After the steam room, it’s good to splash yourself with ice water, but you want to wash yourself in hot water. Therefore, it is important to take a hot shower in the bathhouse. In this article we will look at various ways to make it yourself.

[toc]

The easiest way to make a hot shower in a bathhouse is to install a dousing device (bucket) and supply water to it. Such a bucket shower for a bath can be bought in a specialized store. There are models into which water is poured from a regular bucket, and there are those into which water is supplied from a tap. Turning on and off the water supply is controlled by a float (a device similar to that found in waste tanks).

Bucket shower for a bath

Heating a bathhouse from the home heating system

If the central heating system of the house has sufficient power, the auxiliary rooms of the bathhouse can be heated using it.

To do this, heat-insulated pipes are laid from the home heating system to the bathhouse, to which heating radiators for the auxiliary rooms of the bathhouse are connected. In this case, the stove-heater can only be used to heat the steam or washing section of the bath, if necessary. If the distance from the water heating boiler of a residential building to the bathhouse is small, then heat loss with such a heating system can be minimal. In addition, the presence of an independent external heating system will allow you to maintain the optimal temperature in the bathhouse during the winter. This is required to prevent freezing of water supply and sewerage pipes, as well as the bathhouse itself. The combination of heating systems of a residential building and a bathhouse in this case can be of an auxiliary, backup nature.

How to heat water in a bathhouse from a stove

You can organize heating of water in a bathhouse with a brick stove using a cast-iron stove above it. The hot water tank is installed directly on the stove itself, it can be round or square, with water supplied to fill the tank from the incoming water pipe and hot water drawn through the tap.

You can heat water without connecting water pipes to it. In this case, for each heating of the steam room, reserves of cold water should be made in the dressing room, and the water tank should be filled manually before lighting the stove.

This method of heating water is quite simple, but it has significant disadvantages:

- labor intensity of preparation;

- increased humidity from boiling during prolonged heating;

- risk of getting burned on the heated walls of the oven and tank.

You can heat water from the stove in different ways. This depends on the type of stove itself, the presence of water pipes connected to the bathhouse, the financial capabilities of the owner and his desire to make certain efforts.

Heating water in a bathhouse through a heat exchanger

The best option for heating water in a bathhouse is the heating method using a heat exchanger. There are several ways to make a structure for heating through a heat exchanger.

In a brick oven, the heat exchanger can be a multi-section cast iron battery or a register welded from a thick-walled steel pipe. The heat exchanger is mounted in a special furnace cavity with separate inlet and outlet valves. When the stove heats up, the water in the exchanger becomes hot and is dispensed through the water tap as needed.

In the case of a metal stove, everything is much simpler. In order to heat water with such a furnace, several types of heat exchangers are used:

- external heat exchanger (located in close proximity to the firebox or above it);

- internal heat exchanger (located in the firebox itself);

- heat exchanger on the flue pipe (located on the chimney pipe above the tank with stones).

Advice! The water tank with heat exchanger and the hanging tank can be used simultaneously. This combination makes it possible to heat an almost unlimited amount of hot water.

Water heater for a bath on a pipe

To heat the water in the bathhouse, tanks located on the pipe are used. They can have a rectangular, square or cylindrical shape and are rigidly mounted on the stove chimney pipe. Pipe water heaters are universal; they are used in wood stoves and gas boilers. The water tanks on the pipe are small (optimally up to 80 liters) and can fit even into a small bathhouse.

The tanks on the chimney pipe are located high enough above the stove, so there is no need to pump up hot water - it simply flows by gravity. The water tank can occupy the entire length of the pipe, from the heater itself to the ceiling. This increases the hot water production area and the efficiency of the heat exchanger.

The design of the water tank on the pipe must have reinforced fastening to the stove and the exhaust chimney on the ceiling, since a tank filled with hot water is heavy. The usual soft fastening of the chimney in the ceiling area is not suitable here, so for fastening it is best to use special chimney brackets.

Built-in or attached water tank to the stove

Another option for heating water is a water tank built into the stove structure or located on the side of it.

A built-in tank is a rather complex structure that must be thought out before laying a brick oven. The optimal solution here could be a special niche or recess in the furnace to accommodate a water tank with inlet and outlet valves and hot water intakes. It should be noted that for such a design the tank must be durable (preferably made of stainless steel), with thick walls and double welded seams. Otherwise, if a leak is detected, the entire structure of the furnace will need to be disassembled.

A water tank attached to the side of the stove is a less energy-intensive way to heat water. It is often used in bathhouses with metal stoves, which are supplied with water tanks. Since the steel or cast iron body of the furnace has good thermal conductivity, the water in the tank heats up quickly, and if necessary, the tank can be easily refilled (centrally or manually).

Hot water in the bathhouse from the stove (the layout of the water tank is shown below) is a simple task for a good owner.

System Features

When installing a heated water floor in a bathhouse powered by a wood-burning stove, there is no need to install a boiler. However, a heat exchanger needs to be built above the firebox. Any stainless steel tank that is not prone to corrosion is suitable for this. A circuit extends from it into the room where the heated floor will be installed.

To return the waste liquid to the tank, you will need to install a small pump. Without it, the design will only work when the stove is located below the level of the floor covering. The diameter of the pipe with this scheme should be taken equal to 16 mm; the usual 24 mm ones will not work.

The main feature of the stove floor design is the inability to adjust the temperature level. The recommended temperature of heated floors in the bathhouse is 40 degrees, but the heat carrier from the stove will heat up to boiling water.

Video

Therefore, it is necessary to make a mixing block in which hot water will be mixed with already used water, thereby reaching the desired temperature level.

Since it is not possible to install a large container in the furnace, you can place a battery tank near it and stretch steel pipes from it to the heat exchanger.

What makes this type of floor heating system unique?

Thermal energy tends to the top, so in the bathhouse the air is distributed in layers - cold at the bottom, hot at the ceiling, most comfortable in the center. Therefore, the floor in the bathhouse is always cold, which cannot but cause discomfort. This problem is especially relevant for baths with ceramic tiles on the floor. This finishing material is beautiful, but has a cold surface. But there is a way out - to mount the system in the floor, the coolant in which will be heated by the stove.

Instead of a boiler, the heating unit will be a furnace, so a heat exchanger is installed above the firebox - a tank made of stainless steel or other metal that is not subject to corrosion. The pipeline from the heat exchanger is carried out to the premises where the “warm floor” will be installed.

Sauna stove with heat exchanger

To return cooled water back to the tank, you need to install a circulation pump. It is impossible to refuse it, since the stove is not installed below floor level. It is recommended to choose a pipe diameter of 24, while for installation of “warm floors” in residential premises, contours of 16 diameter are chosen. The main feature of a water system powered by a furnace is that the temperature of the coolant inside cannot be adjusted.

For a “warm floor” system, a comfortable coolant temperature is 40 degrees. Very hot water, almost boiling water, will be supplied to the system from the stove, which is unacceptable. Therefore, it will be necessary to install a mixing unit, where the cooled coolant will flow into the hot water. It is advisable to install a “warm floor” from the stove in all rooms of the bathhouse.

Cake of water “warm floor”

The easiest way

Manufacturers make sauna stoves with ready-made water tanks. This option is the simplest for installation and further operation. Relevant for buildings that do not have gas and water supply communications; a limit on the use of electricity has been determined.

Hot water tanks can be installed in two ways:

Placing such a tank inside the steam room is considered a disadvantage due to the large release of water vapor. For bathhouses located in the country, this is one of the few available ways to heat water that does not require any effort in winter arrangement. A current option for a classic Russian bath. It is not recommended to equip a sauna with such a tank.

Installation of a water floor from a sauna stove

Initially, water heated floors were not intended for installation in a bathhouse. Therefore, when laying such a “pie” in a bathhouse, it is required to equip it with additional elements.

The installation of a water heated floor from a sauna stove includes several components:

The heated floor contour is the main working element, which is laid evenly across the entire floor of the room with a certain pitch, filled with a concrete-cement mixture screed. You should choose the right pipe model; in this situation, not every one will be suitable. It is best to use copper, metal-plastic or stainless steel corrugations. However, many people prefer cross-linked polyethylene pipes with increased heat resistance, with a service life of at least 30 years, or polypropylene pipes, with a warranty period of at least 50 years.

The mixing unit is an important part of the system, since the stove is not capable of heating the coolant to the required level. It heats the water almost to the boiling stage; in this state it cannot be supplied to the circuit. Therefore, a mixing unit is needed, in which boiling water will be mixed with the waste coolant to the required 40 degrees, and in this form it will be sent into the pipeline. It is used to regulate, configure and automatically maintain the temperature level of the heated floor in the desired mode.

Heat exchanger - a container, coil or register located above the firebox, where the liquid from the furnace is heated. When using antifreeze as a coolant, you will need to equip a separate heat exchanger, then the antifreeze will not be able to get into the washing water.

A circulation pump is necessary to ensure that the coolant is evenly distributed and moves through the pipeline. Without it, a warm water floor cannot function, as it provides the circuit with additional pressure for fluid circulation. When selecting the pump power yourself, you need to take into account the area of the heated room; the larger it is, the higher its performance should be.

To reduce the load on the pump, it is recommended to divide the pipeline into several parts of equal length.

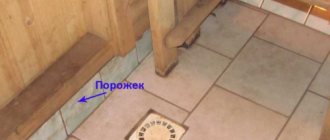

Drainage is necessary to remove excess liquid from the steam room and washing room of the bathhouse. You can equip it with your own hands, taking into account the following two points: by constructing a water outlet - a drainage hole, through which the water will flow into the pipe and be discharged into the sewer pit; fill the screed with a slope in the direction of the drain hole - then all the water will flow towards the slope.

Shower stall and drain

There are many options for a shower stall: from the simplest pipe built into the walls, along which a waterproof curtain “rides” on rings, to a super-modern (or not super) shower stall. From experience we can say that if a cabin is installed in a bathhouse, then it is the most primitive one - walls, a door and a tray, and in principle nothing more is needed. This is an option for those who do not want to bother with waterproofing adjacent walls and like quick solutions.

Bath shower with titanium

In general, if the layout does not provide for a separate small room for the shower, you can fence off part of the washing compartment where the drainage system should be organized. If there is no drain, you will have to arrange one.

If you plan to install a pan, it requires a separate concrete base with a connected drain pipe. The base is needed so that the plastic of the tray does not “walk” under the weight of a person, since most bath showers contain plastic products - they are inexpensive and, if installed correctly, are quite durable, and the plastic bends under the weight of even a not very large person.

If a tray is not provided and the floor is wooden, you need to protect it from water. To do this, galvanized metal is laid in the area where the shower stall will be installed, and the joints of the sheets are carefully sealed with silicone sealant (for example, Ceresit CS 25). Screed reinforcement is laid on the metal with a slope towards the drain, everything is filled with cement mortar. Floor tiles are laid on the fresh mortar (while maintaining the slope), and its joints are also well coated with silicone. Instead of galvanized metal, you can use modern films for waterproofing. In this case they must be reinforced.

Shower drain

If the walls in the shower stall are wooden, they need protection from water. You can protect them with ceramic tiles, plastic panels, or simply lay sheets of plastic of a suitable size, sealing the joints with the same silicone. Under any type of finish, it is also advisable to lay a layer of waterproofing. In the simplest case, it is a plastic film that is attached to the walls using staples from a construction stapler or strips and nails, and it is advisable to seal the resulting holes with reinforced tape.

Plastic shower panels

Plastic shower panels are a budget option for protecting walls in a shower stall; anyone can handle the installation. At the first stage, metal profiles are attached to the walls, from which the frame-sheathing of the walls is assembled. Plastic panels are attached to the profiles with self-tapping screws with a wide head, which are connected to one another using a lock. The connection is sealed (you just need to be careful not to damage the rather fragile edges of the locks). In the external and internal corners, special corners are used, which are sold in the same place as the panels; baseboards are reinforced at the top and bottom. Indeed, there is nothing complicated, but the appearance is like that of a monolithic wall and the protection from water is almost 100%.

Source of water supply

A water source is rarely constructed exclusively for a bathhouse. In the absence of a centralized water supply system, a water supply system is needed primarily for residential buildings and household needs. Therefore, as a rule, a bath water supply system is built into an existing private water supply system. For this purpose, a collector distribution line is installed, where the pipe is routed to the bathhouse building.

The most common source of water is a well. It most often reaches the second aquifer, and its depth is 10-30 m, depending on the depth of the groundwater. If the task is specifically to make water in a bathhouse of a wooden or other structure, then the potable degree of purification is not necessary, which means that it is enough to open the uppermost water carrier at a depth of 5-10 m. Such water should not be used for cooking, but for It's quite suitable for swimming.

Water supply diagram from a well

The depth of the well shaft is important for choosing the type of pumping equipment. The fact is that when lifting from depths of up to 12-15 m, you can safely use conventional centrifugal, surface pumps. With a deeper fence, you will have to lower the deep, submersible installation, which is somewhat more expensive and more difficult to operate.

Another option for a water source is a well. Its depth is 30-50 m, which makes it possible to reach the lower artesian layers, which provide especially pure water, and most importantly, a large and stable volume of liquid for a long time. It is the inextricability of the well source that is considered its main advantage, because wells tend to dry up periodically. The lifting of water from the well is ensured only by deep pumps.

In principle, a third option is also possible - pumping water from a natural reservoir. However, such a system is used quite rarely, and most often unofficially, because requires approval from the relevant authorities. The most important thing is that in this case you will have to solve the problem of installing a rather complex treatment plant.

Electric heater

Special electric heaters for bath needs are traditionally divided into two classes: storage-type boilers and units with flow-through action. When choosing a type suitable for given conditions, it is recommended to proceed from the following considerations.

In areas where there are frequent power outages, a storage tank is more suitable for installation in a bathhouse; in the simplest case, it is a container with a useful volume of 30 to 200 liters. A heating element and a special heat-sensitive sensor are installed in its internal space, which is responsible for maintaining the water temperature at a given level.

Among the advantages of such heaters it should be noted:

- increased level of electrical protection;

- the ability to use heated water for some time even in the absence of electricity;

- availability of several designs (vertical and horizontal);

- efficiency.

For areas with a reliable power supply, less common flow-through heaters that operate on approximately the same principle as a gas water heater may also be suitable.

The disadvantages of units of this type include significant energy consumption and the need for equipment in a bath with powerful electrical wiring. In addition, in order to maintain a fixed level of water heating in this case, it will be necessary to ensure the stability of its supply.

How to choose the right system?

When choosing a water heating system, consider the following parameters.

If you are choosing equipment for a small room, opt for a compact unit. Modern manufacturers offer mini-equipment that boasts high technical performance. Another important parameter is the speed of water heating. Some options quickly heat water to the desired temperature, others work more slowly, but have their own positive characteristics. If you don’t have a lot of time to warm up the steam room, choose the first equipment option. The most important characteristic when choosing equipment is consumables. In this case, you need to consider cost and capabilities. For some users, it is not profitable to use gas for the reason that it is not installed in a specific area. Many people are accustomed to heating with wood and continue to use the natural resource. Before making a choice in favor of a specific option, it is necessary to compare the advantages and disadvantages of all types of heating equipment

Pay attention to the cost of the unit. One model may have different prices depending on the store.

Chimney installation

Some users who are well versed in the intricacies of heat exchange processes manage to install a container for heating water directly in the chimney.

Note! To implement this solution, it is most convenient to use a ready-made opening in the wooden ceiling of the bathhouse, prepared when laying the chimney pipes.

In this case, simultaneously with the arrangement of the heating container, two related issues are resolved at once. First of all, the problem of fire-proof furnace cutting in the bathhouse is eliminated, and, secondly, the required water pressure is ensured in the shower room located under the tank.

Existing types of sauna stoves

Currently, there are a large number of varieties of furnaces with heat exchangers and water tanks.

Their diversity is due to the fact that there are factory-made ovens and home-made devices.

There are two types of factory devices:

- with built-in heat exchanger;

- with an external tank for heating water (usually installed on the chimney pipe).

In various designs of stoves with a heat exchanger, there are options for connecting a water system to provide hot water for the shower, or a heating system so that it constantly works in the bathhouse.

Reference. Homemade devices most often have a tank installed on the chimney pipe for heating water.

With pipe water tank

This design is the simplest version of the unit, since the water tank is installed directly on the chimney pipe, which requires virtually no additional labor costs.

Water is heated by the hot walls of the water tank body.

The general diagram of such a stove is as follows:

- blower;

- firebox;

- chimney;

- a water tank installed on the chimney.

The main feature of this design should be considered that there is no direct contact with the heat source in this stove - the water used as a coolant in devices of this kind is heated from the walls of the tank itself, located on the chimney.

Photo 1. A stove for a bath with a pipe-mounted water tank. The liquid is heated from the walls of the tank itself.

The dimensions of the structure can vary from 80 to 150 cm in height, and also from 30 to 60 cm in width, depending on the total volume of the steam room; with an installed water tank, the size of the structure can reach 200 cm in height (excluding the size of the chimney).

With a heat exchanger, how it works

A device with a heat exchanger is a more complex structure in which the coolant (water) circulates through the system due to the difference in temperature and the resulting difference in pressure.

The diagram looks like this:

- blower;

- firebox;

- chimney.

Important! In such a furnace, the heat exchanger is installed in the firebox body, but in a special way to avoid its direct contact with an open flame. The heat exchanger is connected to the water tank using two fittings, which allow for water circulation and uniform heating of the coolant

The heat exchanger is connected to the water tank using two fittings, which allow for water circulation and uniform heating of the coolant.

Since the heat exchanger is installed in the stove itself, its height, as a rule, does not exceed 120-150 cm, the width ranges from 30 to 60 cm. The height of the chimney is not included in the overall height of the structure.

Power calculation

The correct choice of heat exchanger should take into account the performance of the main heating device. The volume and power of the sauna stove are taken into account here.

To select the optimal equipment and components, you need to consider the following rules:

- The sauna stove transfers part of its energy to the heat exchanger. It is not rational to use large containers so that a larger volume of water can be heated. Such an approach can significantly reduce the comfort of staying in the steam room, increase fuel consumption and create an unfavorable microclimate. The water tank should not absorb more than 10% of the total energy generated;

- heating radiators and a heat exchanger are connected to each other by pipes. If the bathhouse does not have a water pump to maintain proper circulation, the length of the pipes should not exceed 3 meters. This takes into account the diameter of the pipelines and the rational slope, which ensures gravity. Using a pump makes it possible to increase the length of the pipeline and not adhere to slopes;

- It is important to create a balance between fast and slow heating of the fluid in the system. Do not allow water to constantly boil. If a small tank is used for the heat exchanger, boiling will occur after 2 hours and will produce a large amount of low-quality steam. When installing a volumetric heat exchanger, heating will not occur on time, and the process will drag on for several hours. Conditions should be created so that the water is hot 2 hours after lighting the sauna stove.

Now let's talk about the optimal dimensions of the heat exchanger. It must have a power reserve, which will allow it to maintain thermal conditions after the heating device has died out. Of course, the water begins to cool quickly, so it is important to create the right unit that allows you to maintain the temperature for as long as possible.

Let's look at an example of power calculation

. First you need to determine the power of the equipment that can provide heating to the room. For example, we will operate with 5 kW, capable of maintaining a microclimate.

The heat exchanger must be taken with a reserve. We assume its area is 1 square meter, capable of operating at a power of 10 kW.

Explanation

. When making calculations, you need to take into account the proportion - we equate 10 kW to 1 square meter. To take into account all heat losses, the values are adjusted. The formula takes on the following form – 1 sq. m. = 10 kW – 3 kW.

Using this approach, you can achieve the desired room temperature by heating the stove once or twice.

Drain system

How to drain water in a bathhouse? This is a primary issue, without which it is impossible to equip your own water supply system. All water from bathhouses must be removed outside the building and collected in special containers. First of all, in the steam room and washing room, drain holes with a ladder are installed on the floor, and the floor itself has a slope for gravity flow of waste water to these holes. A liquid drainage system in the form of pipes or trays is installed under the floor.

The question of how to drain water in a bathhouse also involves solving the problem of its disposal. Wastewater must not be discharged into the ground without treatment. To ensure this, special filtering septic tanks are constructed in which mechanical, chemical and biological purification of the liquid occurs. As a rule, a septic tank system consists of 2-3 wells with filters, after which the water can be discharged into the ground. The drainage is provided by gravity, for which the pipes are laid with the required slope.

Scheme for draining water from a bathhouse These are sealed containers of the required volume in which water drained from the bathhouse is accumulated. When they are filled, the liquid is pumped out and removed.

When arranging a sewage system, it is important to remember that it must function in winter, therefore, it is necessary to use the same methods as when installing a water supply system - burial below the freezing level, thermal insulation of pipes, insulation of septic tanks

Water supply to a bathhouse in the absence of a centralized water supply is a rather complex, but completely solvable problem. When installing such a system, technical recommendations and sanitary requirements should be followed. When using electric heating or gas devices, we must not forget about fire safety.

Storage, instantaneous water heaters

In addition to the methods described above, it is proposed to place gas water heaters, instantaneous or storage, inside the bathhouse. This can be done if gas communications are connected. A significant drawback is the complex process of installing the entire structure and approving the installation project.

For a gas boiler in a room, it is imperative to provide an exhaust system that removes gas combustion products to the outside. The wall on which the device is supposed to be placed must be protected with fireproof materials in accordance with fire safety rules. Drawing up and agreeing on the project will take some time. The advantage of a gas appliance, for which you can spend time and effort, is the low cost of gas (3-4 times cheaper than electricity).

Electric water heating devices are more often installed inside a bathhouse building due to the reasonable cost of the equipment and the absence of the question of how to connect the system. To choose the type of electric boiler, you should determine the frequency of visits, the number of people, and the time of year of operation.

Thus, a flow-through device can be used in the summer for a small number of people. In winter, cold water does not have time to warm up. For the winter period, it is advisable to use an electric storage device: there is a choice of tank capacity and power consumption.

At the same time, it must be remembered that

- The sauna structure may warm up before the liquid inside the water heater. Therefore, it should be turned on 1-2 hours before the start of heating the room, which is not always convenient in country conditions;

- If there is a limitation on electricity consumption, the power of the device must be correlated with the existing limit, the number of household electrical appliances used;

- Many storage water heaters are not designed for operation at temperatures below +5⁰ C. Violation of this condition automatically voids the manufacturer's warranty.

We heat for heating

Frost creates additional requirements for how we heat a bathhouse in winter.

How to drown

The rooms become cold, approaching the temperature of the environment. In this case, heating immediately causes the appearance of condensation - water vapor from the air strives to instantly settle on something colder than the air itself.

The process of kindling in such conditions becomes an art. Of course, what type and fuel you use is also of great importance. It is difficult to cope with a brick stove; an iron stove is simpler in this regard.

There was a video on the Internet, the author of which shares his experience of lighting a Feringer stove at sub-zero temperatures:

But this is not so much about art, but about whether a small stove can bring a steam room out of the red in an hour. The author clearly shows that he can.

We want to say that you can’t break time records with a brick, but if it happens in winter, and the bathhouse has cooled down to sub-zero temperatures, then you need to be more careful with the stove.

After a cold period, the brick oven is first slowly heated and the moisture is allowed to evaporate.

The video below shows the process of heating a brick stove in a house, and this is somewhat different, because in the house the stove is not overcooled, it does not need to be gradually turned into positive mode, besides, it has a different operating mode - it is heated only in cold weather and constantly, and the bathhouse is heated for procedures at any time of the year. But so far no one has made a video about how you can heat a bathhouse in winter with a brick stove.

How can I heat it?

The question “how to heat a bathhouse in winter” can be answered in two ways - talk about what kind of firewood is best suited for winter heating. Or how to achieve a comfortable temperature for a person in rooms other than a steam room. Above, we have already talked about alternative methods for heating a bath without heating in winter.

Therefore, here we will only say that the only fuel whose quality depends on us is firewood. And you should know that this quality determines how well your stove will work. Specifically, how long will your chimney last without cleaning?

This is influenced by the presence of resin in the firewood - firewood made from coniferous wood is, of course, the cheapest, but it also creates the most problems. Because during combustion, more soot is formed, which settles in the chimney pipe.

Hardwood is much better in the firebox. But they also differ in the heat of combustion. Unfortunately, valuable hardwood species have the highest combustion heat - oak, hornbeam, and ash are good for burning. But, on the other hand, not all of their wood is suitable for processing and turning into building materials, furniture or something else.

Fruit trees (cherry, apple, etc.) are suitable for heating; they are only slightly inferior in heat of combustion to the species mentioned above.

Next come deciduous trees, but not so rare - birch, alder, etc. It is better to use them than conifers.

Another important characteristic of firewood is its moisture content. The damper the wood, the worse it burns, everyone knows this. Therefore, the woodpile should be located in a dry place, protected from precipitation, and you can also dry the wood next to the stove, using its heat to drive out excess moisture from the wood, which will then go into the firebox.

Drying the bath

There are two components to quickly drying wet rooms: heating and ventilation. They should not be considered separately, because together they work most effectively. You just need to combine them in a specific case.

How to dry: ventilation methods

The ventilation system is laid at the stage of construction of the bathhouse (see here about the diagrams and design of the bathhouse ventilation). Therefore, if something is forgotten, it may be too late to redo everything.

For example, vents are usually made in the foundation - these are through holes lined with sewer (most often) pipes that lead to the underground space. They have plugs on the outside that allow you to open and close them at the right time.

For more details about the scheme, see

Such vents are opened only after procedures. And they serve for better ventilation and drying of the bath.

Also, another through hole is usually made in the wall of the steam room under the shelves, leading to the street. On the inside it has an adjustable plug. This hole is also used to speed up the drying of the steam room.

You can dry the bathhouse in winter with the help of ventilation by opening the windows and doors wide - after all, the air inside is much more saturated with water vapor. But you shouldn’t think that all the moisture will leave the bathhouse only thanks to open doors and windows.

In addition to ways to create a draft simply by opening holes, there is also a method where ventilation actively cooperates with heating and works when the stove is on - this is bastu, which you can read about.

Well, don’t forget that even if natural ventilation is not installed correctly or its power is not enough to ventilate the bathhouse, you can always install fans in the air ducts. Forced ventilation, although noisy, is still effective.

BY THE WAY! Heat guns can help here too.

For those who believe that heating alone is enough, and ventilation becomes optional, we recommend watching the video by Konstantin Bely:

After washing: methods of heating

Heating is just as necessary for drying as ventilation. You understand the mechanism: by heating water molecules, you make them more mobile, transform the water into a gaseous state (steam), and it is easily carried away by the breeze. What will the breeze do if the water is cold? Nothing. And if there is no breeze, the steam will cool over time and calmly settle as condensation.

So, the easiest way to dry a bathhouse after washing in winter is to put one or two logs in the firebox and let them burn out. All ventilation openings must be open.

This is for an iron stove. A brick stove is a heat-storage stove, so its heat is enough to dry the bathhouse after the procedures (together with open ventilation).

***

Well, as you can see, you have to invest some money and make an effort in order to use a large bathhouse in the winter. The smaller it is, the easier it is to warm it up even in cold weather. The power of the sauna stove is calculated for the steam room; it is difficult to fit other things into its responsibilities, because there is summer when all this is not needed. So it is better to use autonomous heaters.

Self-production

Some users prefer to make wood-burning boilers with their own hands, which is only possible if you have the necessary tools and practical skills.

When assembling a heating unit yourself, be sure to consider the most labor-intensive design option, which you have to deal with in the absence of a plumbing system.

In this situation, you will need a device capable of accumulating (accumulating) liquid under a certain pressure. The function of such an accumulator can be performed by a container placed on an elevated place, from which a pipe with a pre-calculated diameter is drawn.

The heating unit itself must be installed on a well-leveled and sufficiently rigid platform to ensure a stable position. For its installation, a pre-concrete patch within the bathhouse that has a suitable size is best suited.