Creating ceiling insulation from sawdust

There is nothing particularly difficult about how to insulate a ceiling in a private house with sawdust.

After completing the preparation of the ceiling surface, they begin laying thermal insulation in small layers, leveling and compacting each of them. The height of the insulation should be level with the top of the ceiling. A thin layer of ash is poured on top of the mixture of sawdust and additives. It will protect the insulation from pests and fungus. A couple of weeks after completing the insulation of the ceiling with sawdust in a private house, when the mixture is completely dry, a vapor barrier layer is laid on top of it. It is necessary to prevent wood waste from becoming saturated with moisture present in the air.

Vapor barrier material, usually polyethylene film, is attached to the floor beams using a mounting stapler. The result of the work done will be a thermal insulation layer covered on both sides with a vapor barrier.

Insulation using a mixture of sawdust and clay

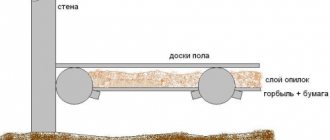

The floor surface is covered with a waterproofing material - even ordinary polyvinyl chloride film is acceptable. You can first place cardboard underneath it as another layer of insulation, but remember that this is a flammable material and does not help reduce the fire hazard.

- A solution is prepared: for this, about five buckets of clay are poured into a barrel and filled with water. The material must be mixed well with water to form a mixture with the consistency of liquid sour cream. Two buckets of the mixture are placed in a concrete mixer, then sawdust is loaded into it: the resulting mass should be quite thick. You can knead the solution with your own hands, but this will require more time and effort.

- The mixture is applied in a uniform layer 10 cm thick over the entire floor surface. The insulation is dried for several days - from 3 to 7. The surface of the clay-sawdust coating may crack. In this case, it is recommended to fill the cracks with ordinary clay.

- The attic can be covered with wooden boards. How to insulate a ceiling using clay sawdust is described in more detail in the video.

Cement can be used instead of clay. To do this, sawdust - 10 parts, mixed with cement - 1-2 parts, and filled with water. Here it is allowed to use wet sawdust. The mixture is then distributed over the floor surface up to 200 mm thick. The advantage of this method is strength, durability and low sensitivity to moisture. The disadvantage is the long drying period, since cement requires at least a month to achieve proper strength.

It is recommended to insulate the ceiling in this way in the spring so that the material reaches the required properties over the summer.

How to insulate a ceiling in a private house

Insulating a bathhouse ceiling with clay and sawdust or straw

If the bathhouse has an attic space, you can significantly reduce heat loss through the ceiling using a mixture of clay and straw (sawdust, sand). A vapor barrier (glassine, roofing felt, etc.) is laid on the plank floor of the attic. The strips are laid with an “overlap” of 5-10 cm. A mixture of clay and straw (sawdust) is laid on top.

A mixture of clay and straw (or sawdust) has good thermal insulation characteristics.

A mixture of clay and straw (sawdust) is applied in a layer of 5 to 10 cm, leveled and left to dry. Drying time depends on temperature and humidity and can take up to 30 days. Cracks appear in the dried clay, which will need to be repaired with a similar composition. Sometimes you have to seal the cracks twice.

We invite you to familiarize yourself with: Blind area with membrane and insulation

To make heat loss through the ceiling even less, a layer of sawdust or wood chips is poured on top of the clay layer (the total thickness of such a “pie” should not exceed 20 cm). To prevent the movement of sawdust and increase the “shelf life” of thermal insulation, another layer of clay can be applied on top of the sawdust, but its thickness should not exceed 2 cm.

There is another option for insulating the ceiling in a bathhouse using clay. The same composition is used, but in this case the layer thickness is about 2-3 cm. After drying and sealing the cracks, sawdust, shavings, and dry oak leaves are poured over the clay (they have antibacterial properties). 5 cm of dry soil is poured on top of this “carpet”. This method is not the cleanest and is quite troublesome, but it requires minimal investment.

Insulation with clay and sawdust is often used. This has the following benefits:

- such material is characterized by its low cost;

- holds heat well indoors;

- allows the room to “breathe”.

Insulation for the ceiling in a bathhouse: which material is best suited

Previously, it was customary to use natural raw materials such as moss, clay, sawdust, straw or earth.

Now people have begun to use the most effective coatings. They make all the work easier, even if you are not a professional builder. For example, it is widely used:

- basalt wool;

- expanded clay;

- penoizol;

- ecowool and others.

You can also use polystyrene foam and glass wool. But when heated, the former emits harmful gases and can ignite. A good protective suit is recommended for working with fiberglass.

The question is whether or not to insulate the entire building only inside or on both sides. There are many opinions on this matter, but the truth is in the middle. There are many additional factors you need to know:

- this is a Russian bath or sauna;

- what material is the bathhouse built from?

- what kind of stove does it cost?

To keep the steam inside and not escape outside, you need to achieve a “thermos” effect. Insulation must be both inside and outside the building. To achieve this effect, you will need insulation for the ceiling in the bathhouse. There are different options:

- waterproofing film;

- expanded clay;

- mineral wool or others.

Waterproofing works

The clay mixture is placed on the flooring wet. Therefore, it is necessary to somehow protect the base from moisture. Usually a simple film is used for this. It is laid on top of the ceiling and attached to it with staples or some other way. The same film will protect the insulation from fumes from the room, for example, if clay is used in a bathhouse.

It is not recommended to use various impregnations and chemicals. Moreover, varnish or paint. Especially in a bathhouse or in a room with a stove. When heated, chemicals begin to emit harmful fumes, and varnish and paint can melt, “cry” and also evaporate toxic substances.

Article on the topic: How to build a fence from metal tiles

Ceiling insulation: features

Air has the maximum thermal insulating effect. A barrier in the form of two sheets of material with an air gap between them serves as a much better insulator than the same two sheets connected together. This principle is very widely used: double-glazed windows with air or gas filling, door vestibules, and all modern insulation materials. The latter are a kind of porous or fibrous structure. Moreover, the more pores it contains, the better the insulator the material is.

Thermal insulation of the ceiling in a private house is based on the use of the same method: creating an air gap between two insulating layers. In this case, the roof acts as one layer, and the floor in the attic acts as the second layer.

The roof, especially when covered with snow, retains heat well, and the air in the attic serves as a heat-insulating layer. In order for the floor to serve as an insulator, it is covered with one of the types of bulk materials depending on the nature of the floor - wood or concrete. As a result, the entire insulated attic serves as a thermal insulator for the ceiling in the house.

A prerequisite is a cold attic. If it is turned into an attic, the proposed method is not suitable.

Sawdust is one of the most ancient materials used for insulation. Its undoubted advantage is its lightness and preservation of the heat and sound insulation properties inherent to wood: with the most careful compaction, air is retained in the sawdust layer. The cost of the material is very affordable, and in some cases, if there is a woodworking plant nearby, sawdust can be obtained for free, according to reviews.

The disadvantage is flammability, so the material is used only in mixtures - with clay, cement, sand and gypsum. Before insulating the ceiling, you should check the quality of the sawdust - it should be well dried and crunchy when compressed.

Advice from professionals

- It is better to hem the beams with tongue and groove floor boards. The material with the selected quarter will also work. The boards must be smooth and well dried.

- Nails should not be driven straight into the board, but at a slight slope, the direction of which should be different for adjacent nails.

- All wooden structural elements must be pre-treated with specialized solutions that will increase the fire safety level of the material and protect it from insect attacks and mold development.

- The outer side of the ceiling in an unused attic is covered with dried sawdust, the layer thickness of which should be from 15 to 20 centimeters. Either a vapor-tight material is installed on top, or a layer of ash or waste slag is backfilled. This layer will serve as a replacement for film. For thermal insulation of the ceiling in a bathhouse, this option is one of the most recommended.

- The ideal option would be to install an insulating layer during the construction of a bathhouse or residential building. If at this stage it was not possible to carry out these measures, you can always take up insulation during the operation of the building.

- If the ceiling is built on the basis of wooden logs, you can resort to thermal insulation using bulk materials that are light in weight. One such material is sawdust. When using them, you need to take into account an important nuance - they cannot be used to insulate buildings with residential or attics used for storing things.

We invite you to familiarize yourself with a bathhouse made of gun carriage, polystyrene concrete, polycarbonate, and tongue-and-groove boards

For the proper functioning of the bath, it is very important to maintain the temperature regime, to create which it is necessary to provide high-quality thermal insulation of the room. In this case, insulating the bathhouse ceiling with your own hands plays an important and special role, since it is poor thermal insulation of the ceiling that causes the loss of precious heat

Bathhouse with a self-insulated ceiling

And cold walls will become hotbeds of steam condensation, which can lead to the development of pathogens and negatively affect human health. In this article we will try to explain in as much detail as possible how to avoid these problems and competently carry out the process of insulating the ceiling surface of a bathhouse, and in conclusion we will watch the video in this article.

High-quality insulation of the ceiling in a bathhouse depends on the roof structure itself, which can be divided into two types: buildings with an attic ceiling and those without an attic. Thus, a feature of the attic ceiling is the fact that the heat-insulating material is installed in it during the construction process, and the air flow will be obstructed by a fairly thick ceiling covering.

Methods

The easiest way to insulate with clay begins with covering the ceiling with boards.

Their minimum thickness should be 4 cm, but it is better if it is 6 cm. Before carrying out work, the boards must be thoroughly dried. In no case should you paint or varnish boards, because many paints and varnishes are simply not adapted to high temperatures and, under its influence, can begin to release toxic resins and polyesters into the space. After completing the sheathing, you must carefully and carefully cover the gaps between the boards with clay and wait for it to dry completely.

The next stage begins with preparing a mixture of sand and clay, which should be quite thick. All boards laid on the ceiling are covered with this mixture. The thickness of the layer should be at least 5-7 cm. Next, you should wait until the layer is completely dry, and this can take quite a lot of time. A thick layer of sand is laid on the dried clay.

Then the ceiling is impregnated first with liquid steam and then with dry steam. The clay, accordingly, first gets wet, and then finally dries and acquires the ability to retain the heat of your bath for many years.

Another method is insulation with several layers of clay with intermediate layers of sawdust or expanded clay. In order to prepare the clay, it is slightly moistened and thoroughly mixed with straw until smooth. The straw is pre-chopped. The final consistency should be similar to soft plasticine or mortar, which is used in laying brick walls.

The clay layer will again be 5-8 cm. After application, it must be carefully smoothed. Seal the perimeter of the ceiling requires special care. The clay will dry in 20-30 days, provided that the outside temperature is above zero. After drying, cracks may appear. This is normal. You can apply another thinner clay layer to the cracks, and cover it with sawdust, expanded clay or wood chips on top.

And this article talks about a columnar foundation for a bathhouse.

Features of using sawdust and lime as insulation

First, sawdust is thoroughly mixed with other ingredients, then applied to areas that require insulation and compacted. The result is a block of wood that is resistant to rotting and destruction. The sawdust must be treated with an antiseptic, and then thoroughly dried, and then mixed with lime, which protects the surface from various rodents.

In areas where it is difficult to get to, sawdust without any kind of impurities is used. Clean sawdust, without treatment with a special agent, has disadvantages: it is flammable, and rodents can grow in such materials. With proper processing and addition of impurities, these problems can be avoided.

Sawdust processing

In order for a homemade heat insulator to meet standards, the first step is to prepare sawdust. They should be cleaned of any impurities (sifted, washed and dried), if any.

Next, you need to impregnate the sawdust with special agents in order to increase their fire-resistant qualities and protect them from rotting processes and the effects of pests.

As you know, each type of wood has its own characteristics. Oak sawdust is highly resistant to bacteria and is practically not susceptible to rotting; its size and density do not change under the influence of moisture.

Softwood sawdust contains a large percentage of essential oils - a natural antiseptic that will protect walls from mold.

Types of roofs for baths, their advantages and disadvantages

The design of a bathhouse roof usually includes one or two slopes.

A bathhouse with a pitched roof is a simple and budget option. Typically, this type of roof is chosen for a summer or small bathhouse. The main advantage of a pitched roof is the low cost of construction.

A gable roof is the most common type of roof. It is chosen if the bath area is more than 12 square meters. This roof looks more aesthetically pleasing and has high functionality.

If the bathhouse is an extension to the house, then the best choice is a pitched roof. If you want to make a spacious attic or additional living space, then choose a gable roof.

Below are photos of bathhouse roof projects:

How are ceiling insulation and bathhouse roof construction related?

Studying the options for planning a bathhouse, you can come to the conclusion that it can be built either with or without an attic.

Many people think that the attic only serves as a storage area for unnecessary things and abandon it for fear that mice may live there. This is not an entirely correct opinion, because the attic allows for more serious insulation. In a bathhouse with an attic, there is already natural insulation in the form of a layer of air. It prevents hot steam penetrating through the cracks in the ceiling from escaping. Also, when equipping an attic, the layer between the attic floor and the bathhouse ceiling is usually insulated. Thus, in the end, such a building already has three thresholds of protection against heat loss:

- attic floor insulation;

- attic air gap;

- roof roof.

In a bathhouse where there is no attic space, the initial thermal insulation is not so strong, however, even in this case, heat loss can be avoided with the help of additional finishing work. In any case, with or without an attic bathhouse, additional insulation of the ceiling must be carried out.

If there is no attic, it is necessary to insulate the roof of the bathhouse

Nuances of insulating ceilings in a wooden house

There are a number of nuances regarding how to insulate a ceiling with sawdust in a wooden house. Thermal insulation of floors in this case can only be done from the top side, if the raw materials are not pressed into slabs or mixed with clay.

When using sawdust to insulate wooden floors, you need to make sure that they are dry. Such chips, unlike wet ones, will crunch and crumble when squeezed into a lump by hand.

All cracks on the wooden surface are filled with polyurethane foam. Sheets of cardboard are laid on the ceiling and nailed with a stapler. Then, when insulating the ceiling in a wooden house, the first layer about 10 centimeters thick is filled with sawdust. Larger shavings are also suitable for this. After completing the installation, the sawdust must be compacted by walking on it.

Next, a second layer of the same thickness as the first is poured onto the compacted material. Fine sawdust is used for it. They are compacted again.

Clay insulation

There are several options for clay mixtures: with sand, with sawdust or with straw. The principle of operation in them is usually similar. But it also has its own characteristics. A very important point is the correct preparation of the working mixture. The quality of the insulation, its durability (if the proportions are not met, the material may crumble or break), and the ability to retain heat depend on this.

Sand and clay

Any repair begins with the preparation of a working solution. Sand and clay are loaded into a concrete mixer and water is added. You can mix them yourself, but this is a very long and labor-intensive process, because you need to achieve a uniform consistency, like thick sour cream.

The resulting solution is coated with the boards. The layer should also be uniform, approximately 5-7 cm. The mixture is allowed to dry for at least 2 weeks. Then sand is poured over the clay; the layer should be thick, at least 2-3 cm. This will not only protect the mixture from sudden temperature changes. Over time, cracks may appear in the clay. Sand will fill the voids as necessary. Thermal insulation will not deteriorate.

The process of laying the clay layer is completed by treatment with liquid steam and then dry. It turns out that the material first gets a little wet, and then, as it were, hardens.

Clay with sawdust

Clay with sawdust

This is the most common insulation option. Any sawdust will do. You can get them almost free of charge at any carpentry workshop. The mixture is prepared as follows: first soak the clay so that it becomes liquid. To do this, 5 buckets of clay are filled with 2 buckets of water. Allow to absorb a little moisture and stir until smooth. Then 2 buckets of the resulting liquid clay are poured into a concrete mixer and sawdust is added to the bowl. The finished solution will resemble a concrete screed in its consistency. It is poured onto boards and leveled. It is advisable to compact the layer a little when insulating the ceiling with clay and sawdust in order to get rid of excess voids. The thickness of the layer should be at least 10 cm. It is left to dry for 1-2 weeks. If cracks appear after drying, they are covered with a thin layer of clay.

Clay with straw

The clay is moistened and mixed with chopped straw. The result should be a thick mass similar to liquid plasticine. It is applied to the floor boards in a layer 8-10 cm thick. After drying, expanded clay, sawdust, wood chips or a mixture of these materials are poured on top. After drying, cracks may appear on the surface; repairing them is easy: just cover the top with a thin layer of clay.

If wood waste is used, it is advisable to treat it against rodents and pests by adding a tenth of lime to the mixture. You can mix sawdust and wood chips with special antiseptics and repellents.

The repair is completed by covering the insulation with boards or wood boards. Then the ceiling will look complete.

Article on the topic: Sulfur baths Tbilisi where to go

It is not difficult to insulate your house or bathhouse with clay. But repairs will take a lot of time, because this material takes a long time to dry. On the other hand, it has excellent thermal insulation properties and does not burn, which is so important for houses with stove heating.

Types and nuances of vapor barrier

Regardless of the type of bathhouse chosen - a sauna or a wood-burning Russian bathhouse - the room will be constantly exposed to high humidity and temperature. Installing waterproofing in the ceiling area will help maintain a healthy microclimate in the room and will also minimize the likelihood of moisture condensation. If polystyrene foam or polystyrene foam is used as insulation, you can skip this step, since such materials are moisture resistant.

Types of vapor barrier

The simplest and most obvious option is to use film. Budget materials can be either rough or smooth; more expensive ones include reinforcement.

- Membrane material. Its woven surface retains moisture and eliminates the formation of condensation.

- Foil is one of the best options for use in a bathhouse. The material not only provides a vapor barrier, but is also an excellent thermal insulator.

- Izospan is a combined material with high vapor barrier properties. Enjoys increased popularity.

How to properly install a vapor barrier?

First of all, you need to decide on the choice of the base material, and then proceed with the installation of the vapor barrier layer of the bath ceiling. A correctly installed ceiling of a steam room looks like a layer cake, with the following layers:

- The top finishing layer is often linden lining.

- The lathing, which serves as a support for the finishing, also serves as an additional ventilation duct.

- Vapor barrier laid over the entire area of the ceiling and extending onto the surface of the walls.

- The ceiling itself and the logs are made of wood.

- Vapor barrier film.

- Insulating material of the selected type - clay with sawdust, mineral wool, polystyrene foam, expanded clay, etc. The minimum layer is 10 centimeters.

- If the attic is needed for storing household items. equipment, installing flooring.

- In the case when the attic space is not used, it is enough to simply cover the insulating material with film. This is necessary in order to protect the insulator from possible heat loss, as well as accidental ingress of moisture and condensation.

Criterias of choice

It is possible to provide high-quality thermal insulation for a room if you choose the right insulation materials. Clay resembles ordinary plasticine - it is plastic. For construction work, it is best to use red clay: it is more pliable, hardens faster, and absorbs less liquid. If such material is not available, you can use other varieties (for example, white). This will not affect the final result, but the finished surface will subsequently have to be looked after more carefully.

Red clay is best suited for insulation work because it has high plasticity and minimally absorbs moisture Source kamtehnopark.ru

Ceiling insulation technology

You need to start work on insulating the ceiling of a private house or bathhouse with expanded clay by laying vapor and waterproofing. To do this, a layer of vapor barrier material is placed on the finished wooden ceiling, which also contributes to waterproofing.

It is better to use modern materials - such as Izospan series B or C, or analogues. If funds are limited, then you can take plastic film, aluminum foil or roofing felt for this purpose. A roll of material is rolled out on the floor and cut into strips, the width of which is 10 cm greater than the distance between the ceiling beams.

Laying over a large area

If the ceiling area of a house or bathhouse is large, then individual sheets of material are laid with an overlap of 10-12 cm.

When using a material like “Izospan”, to improve the properties of the coating, the seams should be glued with a special tape, roofing felt with rubber bitumen mastic, foil with aluminum foil tape, and films with ordinary tape.

The rafters and, if any, the chimney pipe should also be covered with a vapor barrier.

The level of vapor barrier attachment should be higher than the expanded clay backfill layer. You can secure the canvas using masking tape or a construction stapler.

In this case, it is better to use two types of fractions: large and small particles. The use of this method increases the density of expanded clay, reduces the subsidence of granules along the thickness of the layer and thereby contributes to a more uniform filling of the material over the entire area of the insulated room.

To prevent damage to the insulating layer, a cement-sand screed must be applied over the expanded clay.

The final operation is laying the floor. The simplest option is flooring made of boards (leaving a gap of 2-3 cm between them), which are laid across the beams. You can also use plywood, laminate, chipboard, etc. for the floor.

Ceiling preparation

Of course, only prepared floors can be insulated. There are several ways how this can be done:

- hemming with bars 50x50 mm;

- use of edged boards;

- hemming with tongue and groove boards.

The use of bars is considered the cheapest option, since they are not sewn up completely, but with a gap of 20 mm. These cracks will then be filled with a clay mixture. They are joined lengthwise on beams. It is important to securely and correctly fasten the bars. To do this, you can use nails no shorter than 10 cm or wood screws no less than 9 cm long.

A shield is attached to the reverse side. It is needed so that the clay mixture does not spill through the cracks between the bars when they are filled. When work with 1 section is completed, the shield is moved further or a new one is installed.

Hemming with boards takes much less time and saves effort, but in financial terms it turns out to be noticeably more expensive, especially if a tongue-and-groove planed board is used. On the other hand, if the flooring is immediately leveled, then the ceiling in the room will be smooth and beautiful. Additional work with it is no longer required. This is usually how the ceiling of a bathhouse is insulated with clay.

Comparison of materials

The industry offers various insulation materials suitable for floor insulation, but the most popular of them are:

- sheet foam;

- granulated polystyrene;

- sprayed polyurethane foam;

- mineral wool;

- foamed polyethylene.

Each of the materials has slightly better thermal insulation properties, which makes it possible to reduce the thickness of the insulation by 10–20%.

However, the cost of insulation is several times higher, so insulation with sawdust, even with the installation of deepening gutters, is noticeably cheaper.

In addition, only mineral wool and polystyrene granules allow air and steam to pass through, making them suitable for use on wood floors with unventilated subfloors.

The use of other materials will lead to the formation of condensation and rapid destruction of the log wood.

Any materials can be used on concrete floors, but unlike sawdust and lime, they are very attractive to rodents, so if your neighbors have mice, you will soon have mice too. After all, mice and rats are constantly looking for new warm places to live, and modern insulation materials meet all their requirements.

When using mineral wool, another difficulty arises - in order to cut a piece of the required length with smooth edges, you have to suffer.

In addition, the pieces have to be cut with a small margin and then inserted with force, which increases the requirements for the lining. After all, if you cut off the wool without reserve, then there is a high probability of cracks appearing, which will lead to the formation of cold bridges and reduce the effectiveness of insulation.

The same problem arises when using any sheet materials - if they fall into place without serious effort, then cold air penetrates through the cracks, reducing the effectiveness of insulation.

Sprayed polyurethane does not have these disadvantages, however, it completely blocks the movement of air and steam, which is why it can only be used on concrete floors, because wood structures, deprived of air movement, soon begin to rot.

All this allows us to draw an unambiguous conclusion - modern insulation materials do not have any undeniable advantages over sawdust.

In some ways they are slightly superior to sawdust, but in terms of a combination of factors they are noticeably inferior to them.

In addition, given that the Russian building materials market is filled with fake and counterfeit products, there is a high risk of purchasing material that will pose a health hazard, while sawdust, lime and clay are environmentally friendly products.

Choosing material

When purchasing a construction gasket, take into account the technical properties of the raw materials and look at the integrity and quality of the block itself. There are a number of mandatory and additional criteria.

Sawdust of medium fraction

Wood sawdust is best suited for thermal insulation of the ceiling. They are obtained from already dried wood and do not require further drying. In addition, they suffer less from rot.

If sawdust is obtained from sawing wood with natural moisture, it will have to be dried. To do this, they are laid out on a flat, dry surface in a place with good ventilation. An outdoor canopy is perfect. In dry weather, sawdust is dried in several months; if it rains and air humidity is high, you will have to add another week.

If you have a choice of wood species, conifers are best. They contain a lot of resinous substances that repel insects.

If sawdust contains debris or other foreign inclusions, they should be carefully sifted through a construction sieve.

Before you start mixing the solution, you need to make sure that the following requirements are met:

- middle fraction;

- humidity below 10%;

- no mold.

Installation of thermal insulation

Sawdust prices

sawdust

How to make sawdust

Here, as in the case of a private house, the ceiling needs to be covered with wide boards. To install a chimney pipe, you need to make a ceiling cut - this can be purchased ready-made or made with your own hands (cut a sheet of stainless steel that completely covers the hole, cut a circle in the middle for the passage of the chimney, seal the edges of the cutout in the ceiling with basalt wool, and on top lastly fill the strips of metal;

Step 1: First, take care of the vapor barrier layer in the attic. Do not use roofing material, because at high temperatures it will soften, begin to emit unpleasant odors, or even catch fire. As for PVC film, it is also unacceptable here.

Step 2. Lay the sawdust mixture, prepared according to one of the recipes described above, in layers, thoroughly leveling and compacting each layer. If you plan to use the sauna only in summer, then the thickness of the insulating layer can be 5 centimeters, while for winter use you will need at least 15 centimeters.

Insulating the ceiling in a bathhouse with sawdust

Step 3. Upon completion of installation, wait until the insulation layer dries. If cracks appear on the surface after this, seal them with the same mixture. By the way, to keep the number of cracks to a minimum, add salt to the solution before installation (5-6 tablespoons per 10 liters of water).

Step 4. Once the mixture has dried (which can take up to a month), pour a thin layer of lime on top of it and lay a vapor barrier. Then, if desired, you can cover the surface with boards.

In addition, both methods of insulation can be used for both horizontal and vertical surfaces

But in any case, special attention should be paid to the insulation of electrical wiring. Hide all the wires in high-quality metal corrugated hoses, and seal the ends of the latter with fire-resistant material (for example, fire-resistant polyurethane foam PENOSIL Fire Rated)

This will protect the wooden structure from fire in case a short circuit occurs.

Manufacturers offer various membrane films that protect materials from high humidity. Experienced builders recommend purchasing vapor barrier upholstery with a reflective foil layer that does not allow heat to escape. The following types with a foil layer are distinguished:

- polypropylene;

- kraft paper;

- roofing felt;

- membrane;

- foil;

- coating

This film is installed with a large overlap (10-15 cm), and the joints are taped with foil tape for construction work.

In specialized departments of stores there is a wide selection of waterproofing products - foil-coated kraft paper, construction membrane and other products. Although you can save money and purchase regular plastic film or roofing felt.

To achieve the main goal - accumulation and “saving” of steam, you need to make 2 layers of PIP and 1 additional layer for thermal insulation. This measure will make the room warmer and more comfortable.

We invite you to familiarize yourself with the technology of insulating a house outside with polystyrene foam

Experts advise placing layers perpendicularly. This arrangement will increase the strength of the entire structure and help avoid severe deformation. If you use mineral wool and clay, the process will take place in several steps:

- take an unedged board (5 cm) and attach it to the bottom of the beams;

- to support the filing, we fix the flooring along all the bases;

- tongue and groove slats made of aspen are attached to them (taking into account the gap for ventilation);

- We lay vapor barrier material on the outside of the roof;

- spread mineral wool 15 cm wide over the laid mixture;

- then we lay polypropylene film;

- We place boards on top of the resulting structure; this is the future floor of the attic.

If everything is done correctly, the end result should be an excellent steam room. All the steam will remain inside for a long time, and the steam room will not cool down for a long time.

Where to order or buy

You can order bathhouse ceiling insulation from specialists. Employees of the enterprises, which are collected in a separate section of our website, perform insulation with high quality and in a short time.

In addition, it is possible to carry out thermal insulation work yourself. In this case, it is recommended to familiarize yourself with the list of insulation suppliers.

Share on social networks

In a village bathhouse there is no point in mixing sawdust with anything at all. Excess weight, extra labor costs, if you buy cement - extra material costs. An iron stove heats a small bathhouse in an hour, then everyone washes. and the bathhouse was not in demand for a week. It is much easier to simply sprinkle sawdust in a layer of 10-15 cm, and make a fence of boards around the “Sandwich” pipe and pour sand there. The only problem is that cats sleeping on the warm ceiling dig up sawdust. What do you think?

so it is, cheap and cheerful. But there are also disadvantages of sawdust: sawdust is fire hazardous, it will absorb steam, get wet, and then rot. It’s better to make a mixture of sawdust with free clay and then it will create a hydraulic lock. Well, cats won't dig

clay will be more “folk”, according to the primordial...

Features of ceiling insulation with sawdust

Insulation with sawdust allows you to get simply excellent results and thereby save on heating and the use of other, more expensive insulating materials. When arranging insulation, it is worth considering certain rules and requirements. To prevent insects and rodents from growing in the sawdust, and also to increase fire safety, lime must be present in the solution. To effectively protect sawdust from mold, you need to add copper sulfate to the mixture.

Before you start insulating the ceiling with sawdust, you need to cover the entire area of the ceiling with cardboard, and then distribute the composition and compact it

To insulate a house with sawdust, you need to perform a number of actions, in particular the following:

- Cardboard or parchment is spread over the entire area of the ceiling;

- The composition must be distributed evenly;

- The mixture must be compacted well.

When arranging the ceiling, the solution should be left for two weeks until completely dry.

Disadvantages of using clay

This old but reliable method of insulation does not have many disadvantages. There are only three main nuances:

- high labor costs;

- long drying period;

- the need to apply a thick layer of insulating mixture and plaster.

The clay insulation method, like many other options, is not without its drawbacks. However, compared to the final result, all these shortcomings are insignificant.

If you approach the process wisely, you can smooth out all the disadvantages:

- work not alone, but in a large group;

- plan construction work for the summer;

- Before starting work, take into account the area of the room after insulation (subtract 30 cm). Only after a thorough analysis of all the pros and cons can one begin to implement the planned plan for insulating the house.

What is the difficulty of insulating the floor in a bathhouse?

Very often, a bathhouse is a separate house in the country. It’s rare for anyone to maintain above-zero temperatures in winter. More often it is “heated” only for use and this is the difficulty. For insulation, you need a material that can withstand frost/defrost and is not afraid of moisture. After all, if we are talking about a Russian bath, and not a sauna, then the humidity in the steam room will be close to 90%.

Typically, a bathhouse and a change house often appear on the site first. And only then does the construction of the house begin

Another option to choose from is security. Baths are usually heated by wood stoves, and in most cases the buildings themselves are made of wood. The combination of open fire and wood is always dangerous. Therefore, it is advisable to insulate with non-flammable material. But there are no such things, and therefore they try to choose one that has a high ignition temperature, does not smoke when burning, and does not spread combustion.

How and with what to insulate the floor in a bathhouse. Choosing the best options

Three main functions of insulation, and the dangers of improper thermal insulation

First of all, it is necessary to establish the reasons why the air in the bathhouse can cool, there are only three of them:

- warm air can escape through cracks in the ceiling;

- if the ceiling and other objects in the bathhouse are cold, then the heated air will cool down in contact with them;

- heat can penetrate through single-layer barriers.

To ensure good thermal insulation, all three nuances must be taken into account. Therefore, there should be no gaps between the insulation boards.

Improper insulation of a bath can lead to some problems:

- Condensation will settle on the ceiling;

- the heat will not last long;

- To obtain the required temperature in the bathhouse, you will have to spend more heating resources.

Main characteristics of sawdust

There are several characteristics that help you compare different insulation materials and choose the one that best suits your specific situation.

These are the characteristics:

- cost (excluding delivery);

- thermal conductivity;

- vapor permeability;

- resistance to high humidity and condensation;

- life time.

Cost is one of the most important parameters, especially if you have to insulate a large area. After all, the cost of 1m2 of the cheapest modern material, even without taking into account delivery costs, exceeds 150 rubles.

Therefore, when insulating a large house, the cost of purchasing insulation alone amounts to hundreds of thousands of rubles. Sawdust is much cheaper.

You can read more about their costs here.

Thermal conductivity is another important parameter on which the thickness of the layer required to reduce heat loss to a given level depends.

In this parameter, sawdust is inferior to all modern insulation materials, but you can slightly increase the thickness of the layer and bring heat loss to a given level.

In terms of thermal conductivity, 10 cm of wood sawing waste corresponds to a layer of mineral wool 8–9 cm thick and a layer of polystyrene foam 7 cm thick.

Vapor permeability is the ability of a material to pass water vapor through itself. This characteristic is very important for materials that are used to reduce heat loss in breathable houses built from wood or hollow clay bricks.

In terms of this parameter, sawdust leaves any other materials far behind, because of all modern insulation materials, only mineral wool allows steam to pass through at least a little. The rest of the materials completely block this process, which is why the microclimate in the house changes not for the better.

Resistance to high humidity and condensation is important for any insulating material, because humidity is always present in the air, and condensation occurs when temperatures change.

Sawdust absorbs excess moisture, and after a while, when air humidity drops, it releases steam. Therefore, humidity cannot harm them, which cannot be said about mineral wool, which, even if it gets a little wet, sharply loses its thermal insulation properties.

The actual service life of a material can only be determined by its condition after some time.

Polystyrene foam, polystyrene and polyurethane foam rarely withstand 30 years, because they are destroyed by oxygen and ultraviolet radiation, mineral wool can withstand 50–70 years, and sawdust can easily withstand a service life of 150 years.

In Russia and other countries there are houses built in the early and mid-19th century and insulated with sawdust. Despite such a considerable age, the sawdust insulation is in excellent condition and does not require either repair or replacement.

All this allows us to draw an unambiguous conclusion - in terms of the totality of its characteristics, sawdust is in no way inferior to any modern insulating material, and when used correctly, it is noticeably superior to them.

Installation of insulation around the chimney

Separately, it is necessary to discuss the insulation of the space around the chimney pipe, because this is one of the fire hazardous places and it should be secured to the maximum. In the place where the pipe enters the ceiling, the temperature of the pipe itself and the space around it is very high, the wooden sheathing around the pipe can begin to smolder and ignite. Therefore, you should leave a space of at least 70 cm around the chimney and cover it from the side of the room with a sheet of stainless or galvanized steel 2.5 - 3 mm thick, through a gasket made of asbestos cement sheet 3-5 mm thick, with a hole larger than pipe diameter by a couple of centimeters.

The pipe itself in this place should be wrapped with a double layer of asbestos cement 5 mm thick. with an exit 15-20 cm above and below the ceiling. It is better to make a cement or clay screed on top around the pipe with a layer of 5-7 cm and only after that lay mineral wool or fill in expanded clay.

Methods of using sawdust

There are 4 methods for insulating with sawdust:

- backfill;

- fill;

- plastering;

- use of slabs.

To backfill, wood sawing waste is mixed with lime, which prevents the appearance of rot or mold even with increased humidity and protects the insulation from rodents and various beetles.

After 2-3 years, and sometimes earlier, you have to add additional sawdust, because the lower rows are caked and compacted.

To fill, wood sawing waste is mixed with various binders in different proportions.

Then the finished composition is poured into voids or cavities prepared for it, where it turns into a fairly strong and hard material with low thermal conductivity.

By changing the amount of sawdust and binder, the thermal conductivity and strength of the insulating material are regulated.

For plastering, the same compositions are used as for pouring, only more suitable proportions are selected. In addition, before plastering, the walls are lined with chain-link mesh or its plastic equivalent, this improves the adhesion of the insulating layer to the wall.

Insulating boards are made from the same compounds that are used for pouring and plastering, only by selecting the most suitable binder.

In addition, they can be laid in floor cavities formed by floor joists and the lining or ceiling of the lower floor.

The following are used as binders:

- cement;

- gypsum;

- clay;

- PVA.

Read more about these insulation methods, as well as about choosing the optimal binder and the correct proportions here.

Material selection and backfill options

- The sawdust material must be selected slightly damp or completely dry. The smell should be clean, without any admixture of aromas unusual for wood. Before use, the mixture must be treated with antiperones and antiseptics and dry again. When the mass dries, you can add 10% lime (fluff) and very little copper sulfate (borax), after which the composition is mixed as thoroughly as possible.

- There are several installation options:

- backfill in clean dry form;

- backfilling with sawdust mixed with cement (diluted with water);

- backfilling with sawdust mixed with clay or sand-clay mixture.

Dry backfill option

When filling only large sawdust, the problem arises of the impossibility of thorough compaction.

For this method, it is necessary to make two layers of filling. The first is coarse sawdust or shavings, the second is fine dust. The measure is indicated to get rid of dust in the house, which inevitably appears if only fine-chip waste is used.

When filling only large sawdust, the problem arises of the impossibility of thorough compaction, which is necessary to preserve heat in the house. Thus, large waste wood is poured into a layer of at least 10-15 cm, compacted and a layer of small sawdust of the same thickness is placed on top. The layers must be pressed and trampled.

Sawdust and cement

Mixing sawdust with dry cement

When implementing a thermal insulation layer from sawdust with cement, it is necessary to choose slightly damp shavings, the shelf life of which is at least 1 year. Make sure there are no pockets of mold, mildew or other bacteria. The mixture has a ratio: 20:3:2. In this case, the solution is added only in small portions to prevent drying out.

When mixing the dry ingredients, add water very carefully so that lumps of unmixed material do not appear.

When using sawdust with cement, sometimes it is necessary to prepare a sand substrate where backfilling/filling will be done. Otherwise, the insulation is filled in and compacted to a thickness of 5-10 cm. The main indicator of maturation is the elasticity of the base. The layer may crunch a little, but should not fall through.

Final processing plays an important role. For fearless operation, a structure made of boards is laid on the base; if the floor is not used (on the roof, attic), the insulation is not covered

Insulation with natural materials

This technology is more suitable for baths equipped with an attic. After installing the roof and the main floor made of boards or bars, the ceiling is insulated. But it is important to take into account that the lower plane of the ceiling - the ceiling of the room itself - should in no case be covered with synthetic decorative materials - plastic lining, foam ceiling panels, polyethylene film, etc.

If a ceiling is installed from wooden slats or boards, they cannot be painted or varnished. Many varnishes and paints are not designed for high temperature and humidity. As they decompose, they release harmful compounds of polyesters and resins, which are not only allergenic, but also carcinogenic, not to mention the possibility of skin rashes and irritations.

Fastening slats in the attic

After correctly installing the ceiling, we go up to the attic and nail thin slats across the boards at a distance of a meter from each other. They will serve as the basis for attaching the ceiling vapor barrier. For vapor barrier, it is best to use rolled materials - roofing felt, glassine. It is not recommended to use polyethylene film.

It is necessary to lay the vapor barrier material in such a way that the strips overlap each other by 5 centimeters. Then we fix the roofing felt or other material, using a stapler to staple it to the slats. The base is ready. Subsequent thermal insulation material can be:

- clay;

- expanded clay;

- clay with sawdust;

- expanded clay concrete;

- foam concrete.

Insulation of the bathhouse ceiling with expanded clay and clay

The ceiling can be insulated with clay in several layers with an intermediate filling of expanded clay or sawdust. To do this, the clay is moistened to a semi-liquid state and mixed with chopped straw. The mass after mixing should be homogeneous (within acceptable limits) and have the consistency of soft plasticine or mortar for laying brick walls.

The mass is applied directly to the vapor barrier in a layer up to 5-8 cm thick and carefully smoothed. It is especially important to carefully seal the perimeter of the ceiling where it adjoins the walls. The load-bearing beams may protrude somewhat from the upper plane of the insulation. Drying of the clay mixture lasts 20 - 30 days at positive temperatures.

During this time, a network of cracks appears on the surface - this is an acceptable phenomenon. Therefore, we cover the insulation layer again with liquefied clay and after a few days fill it with expanded clay or sawdust. You can use wood chips. Expanded clay can be used to cover the floor without treating it with clay, but in this case the vapor barrier layer needs to be made more powerful - from a double layer of roofing material or glassine.

For this work you need to stock up on the necessary amount of material -

- mineral wool based on basalt or silicon;

- expanded polystyrene, preferably modified;

- foam chips.

The vapor barrier is installed in the same way as in the previous version. Mineral wool rolls are rolled out end to end along their length and pressed tightly against the underlying layer. Then the second layer is laid across the first and also carefully leveled. This is necessary to ensure that the joints overlap and do not serve as temperature bridges. The mineral wool can be covered with expanded clay or sawdust on top - this will enhance the heat-insulating effect.

Expanded polystyrene

Expanded polystyrene is also laid in two layers, perpendicular to each other. The joints can be treated with penoizol or covered with sawdust, but it is better with foam chips. It is unlikely that you will be able to correctly fill penoizol with your own hands - a special installation is needed here. By properly insulating the ceiling, you will get comfortable conditions in the bathhouse for a healthy pastime.

Mineral wool is one of the most popular insulation materials, but it can absorb moisture

In many ways, the quality of thermal insulation in a bathhouse depends on the choice of material. Such a room can be insulated using both expensive inventions of the construction industry and “penny” folk remedies.

What kind of insulation can be used for the ceiling in a bathhouse:

- Mineral wool (or basalt insulation) is not a new material for insulating the ceiling in a bathhouse, but it is very effective. This type of wool has a porous structure, due to which the air contained between its tangled fibers helps maintain a high temperature in the room. When wet, this material loses its thermal insulation properties.

- Super-light polypropylene foam is an insulation material designed specifically for baths and saunas. On one side it has a heat-reflecting layer of foil. Thanks to this addition, the heating time of a bathhouse decorated with such a heat insulator is reduced several times.

- Expanded clay is also used to insulate baths. However, it increases the mass of the bath structure, so it is used only for large structures. It, like mineral wool, has the property of absorbing moisture. The ceiling finished with this material must be additionally waterproofed.

- Growing aerated concrete is a fairly new insulation material that has a lot of positive properties. It is very simple to insulate the ceiling in a bathhouse with this material.

- Penoizol is a budget-friendly type of ceiling insulation in a bathhouse. It is sprayed from a special device and gradually increases in size. The advantage of such a heat insulator is additional sound insulation characteristics and fire safety.

- Ecowool is insulation made from recycled paper and disinfectants. It is environmentally friendly and fireproof. Unfortunately, without special equipment it will not be possible to insulate a bathhouse with such material.

- Sawdust, clay, cement are popular insulation materials. Their cost is relatively low, therefore in villages they are most often used for thermal insulation of the ceiling in a bathhouse.

The number of insulation materials for baths is quite large. The range is constantly updated, because the construction industry does not stand still and invents more and more new options.

All the insulation materials we have given have their advantages and disadvantages, so which one is better to use for a bathhouse cannot be said for sure. It all depends on the preferences and financial capabilities of the owner of the building.

The old-fashioned method has been proven over the years. This composition has excellent thermal insulation properties.

It can be used in several ways:

- Preparation of a liquid solution. Take 2 buckets of clay and the same amount of sawdust, add water and mix the solution until it becomes thick sour cream. This mixture is poured onto the insulating material in a layer of up to 10-15 cm, dried for 1 month, forming a monolithic mixture that is fireproof. Possible slight leakage through the ceiling.

- The preparation of the mixture is the same, but it dries somewhere on a flat surface, then it is cut into briquettes, which are used to insulate the ceiling.

- A 5-7 cm layer of sawdust is poured onto the insulating material, and a similar layer of clay is placed on top.

One of the most common types of thermal insulation today:

- When laying sheets of mineral wool, it is necessary already at the stage of installation of ceiling beams. The distance between them should be equal to the width of the insulation layers to make it easier to lay them.

- It is important to seal the joints of the isolon well so that the mineral wool does not spill onto the ceiling, in which case it will fall on those steaming.

- It is better to choose insulation with impregnation that prevents it from crumbling.

- It is advisable to cover the top layer of mineral wool with a layer of waterproofing.

- Insulation with expanded clay. When using this insulation, it is important to consider that it absorbs moisture well, so it is important to make the ceiling very durable and able to withstand heavy weight. It is better to cover the top with a layer of waterproofing.

- Insulation with sawdust and cement. Take 5 buckets of sawdust, half a bucket of cement, half a bucket of lime, 2 tablespoons of copper sulfate as a fire retardant. Cement, sawdust, and lime are mixed in a container or concrete mixer. Vitriol is diluted in a bucket of water and added to the mixture. Then add water until the consistency of thick porridge is obtained. This mixture is evenly applied to the covered isolon.

- Insulation with leaves and clay. In the fall, foliage is collected, applied in a layer of more than 25 cm, and 5 cm of clay is placed on top. After a few months, the layer will be about 10 cm.

- The application of isolon as a waterproofing material is end-to-end, which allows the insulation to flow through the ceiling.

- Insulation with sawdust and clay or sawdust and cement with a large addition of water will flood the entire ceiling and the insulation will take even longer to dry.

- Izolon as a waterproofing material must be overlapped by 15-20 cm onto the frame.

- Damp foliage is used as insulation; it will rot or rot.

- Many people do not use top waterproofing.

Features of ceiling insulation with sawdust

Insulation with sawdust allows you to get simply excellent results and thereby save on heating and the use of other, more expensive insulating materials. When arranging insulation, it is worth considering certain rules and requirements. To prevent insects and rodents from growing in the sawdust, and also to increase fire safety, lime must be present in the solution. To effectively protect sawdust from mold, you need to add copper sulfate to the mixture.

Before you start insulating the ceiling with sawdust, you need to cover the entire area of the ceiling with cardboard, and then distribute the composition and compact it

To insulate a house with sawdust, you need to perform a number of actions, in particular the following:

- Cardboard or parchment is spread over the entire area of the ceiling;

- The composition must be distributed evenly;

- The mixture must be compacted well.

When arranging the ceiling, the solution should be left for two weeks until completely dry.

Expert advice

We went through popular YouTube channels, where they talk about baths authoritatively, knowledgeably, by people whose opinions we ourselves listen to. But the only problem is that they talk about a lot of things, but for some reason the problem of insulating ceilings, as well as the choice of materials, does not attract everyone’s attention.

Therefore, don’t blame me, the example of expert advice on ceiling insulation will be the video below, made - we simply couldn’t find anything more significant.

But what’s interesting is that you won’t hear standard descriptions in it. On the contrary, the authors of the video turn to the experience of previous generations and offer the most budget-friendly, simplest option for organizing both the ceiling itself and its insulation - this is a completely simple floor ceiling, insulated... with sawdust and clay. It couldn't be simpler.

You don’t even need to bother with the lining - you can make the flooring boards into a finished ceiling if you plan and sand them first.

https://youtube.com/watch?v=xCCC_y1f810

Of course, any opinion will be controversial, and you have the right to question it or not consider it an expert.

***

Now that it is already clear why a ceiling without insulation is a waste of heat, all that remains is to wish every owner that in any weather his bathhouse will warm up properly and keep warm for the second day.

Wall insulation

Throughout the evolution of our housing, the inevitable use of clay has always been visible. Currently, there are also several options for its use for wall insulation. These include:

- the use of adobe, in the form of dried building blocks consisting of clay with filler;

- during frame construction, when a cavity is made in advance, subsequently filled with clay with a binding material;

- due to the application of clay with filler to the inner surface of the wall.

When using it in its natural state, it is imperative to use a binding element in the form of fine straw or sawdust, which helps maintain the integrity of the structure when completely dry.

The advantages of this method of insulation

It is no coincidence that the use of clay is so popular. This method of insulation has a number of advantages compared to other methods:

- proven and reliable technology: it has been developed over the centuries, it has long proven its effectiveness;

- environmental friendliness: the material is completely safe for the health of people, animals, and the environment;

- this method of insulation does not significantly load the floors and foundation;

- all work can be done with your own hands, even without much experience in construction;

- the material does not attract rodents and insects;

- fire safety: clay does not burn, so it can be safely used for insulation near pipes, stoves and other heating devices;

- cheap: you can even dig up the clay yourself, i.e. for free.

Article on the topic: What types of stone fences are there?