Having a portable stove on hand in an unfinished home or garage is a big deal. You can finish the work put off since the fall without haste. True, such a stove is very expensive, and it weighs almost a hundred kilograms, so how mobile is it? But even in such situations, there is a way out - to make a stove yourself, for example, from old gas cylinders. Moreover, such creativity will cost much less than buying a cast iron potbelly stove, because all the work can be done independently, and the materials can be collected at any metal collection point for almost nothing.

Making a heating unit with your own hands from a cylinder

A thrifty owner carefully insulates his home, trying to reduce heating costs. In addition, there are a number of objects that need to be heated periodically: workshops, garages, outbuildings. It is necessary to regularly heat greenhouses or winter gardens.

Therefore, home craftsmen are constantly developing and implementing additional heating units of various designs. The most popular are products made from gas cylinders. The reason for this is the convenient shape and almost ideal proportions and characteristics of the material.

The efficiency of cylinder stoves reaches 85–90%, which is a very high figure in comparison with homemade stoves of other forms. The rounded shape is ideal for intensive pyrolysis of fuel and allows you to arrange openings for smoke exit and oxygen supply to the combustion zone at the lowest cost.

A simple and effective gas cylinder stove will last a long time

Operating principle of a potbelly stove

A potbelly stove is a primitive version of a metal wood-burning stove. This device works extremely simply: firewood is placed in the firebox, it burns, the stove body heats up and gives off heat to the surrounding air. Smoke gases are removed through the chimney, and the ash is poured through the grate into the ash pan, which should be cleaned periodically.

One of the main advantages of a potbelly stove is its simplicity of design. There are no strict dimensions here, the main thing is that the body can withstand heat and the chimney works properly. An experienced craftsman will make such a stove in just a couple of hours. And you can burn almost any dry wood in it: logs and sawdust. On our website there is an article with a detailed description of the process of making a potbelly stove with your own hands.

A potbelly stove is also heated with other flammable materials: diesel fuel, coal, peat, household waste, etc. If desired, you can cook quite successfully on such a stove. This point should be considered before the construction begins in order to create a smooth cooking surface.

A potbelly stove is a combustion chamber made of thick metal with a loading door, a chimney, a grate and an ash pit. You can use an old gas cylinder as a housing

But one should also take into account the disadvantages of such a heating solution. For starters, there is a high risk of burns and fires.

For the potbelly stove you need to choose a special place, decorated with fire-resistant materials. It is advisable for it to stand to the side, where no one will accidentally touch the body and get burned.

If desired, the upper part of a vertical potbelly stove from an old gas cylinder can be turned into a modest-sized hob

Such a metal structure weighs a lot, so we are not talking about any mobility of the device. It will be difficult to move a potbelly stove to heat different rooms.

Such stoves are usually used to heat utility rooms where there is no electricity or where it is supplied intermittently: garage, barn, workshop, etc.

From two gas cylinders connected perpendicularly, you can make an improved version of the potbelly stove, which allows you to retain more heat and get high efficiency when burning fuel

Another problem is low efficiency, since part of the thermal energy during the combustion of wood literally flies out into the chimney. There are various ways to retain heat and modify your stove slightly to make it work more efficiently.

Finally, you need to take care of good ventilation of the room in which the potbelly stove is installed, since such a device burns a large amount of oxygen during operation.

So, a potbelly stove consists of a metal body, the role of which is usually “invited” to be an old gas cylinder. It is necessary to make two doors in the case: large and small. The first serves to load fuel, the second is needed as a blower, through which air enters from the combustion chamber to ensure the combustion process and draft.

A drawing of a stove-stove from a gas cylinder allows you to make a device with specific parameters and calculated power, but such accuracy is not required

Below, at some distance from the bottom of the structure, a grate should be welded. It can be made from thick wire or simply take a sheet of thick metal and cut long slits in it. The distance between the grate rods should be such that the combustion material does not spill down into the ash pan.

If the potbelly stove will be heated only with wood, the gaps of the grate are made larger, but when it is intended to use wood chips, the grate should be made more frequent.

A curved metal chimney installed on a potbelly stove made from a gas cylinder allows you to retain more heat in the room and increase the efficiency of the structure

The ash box can be welded from sheet metal or take a ready-made metal container of a suitable size and resistant to strong heat. Some people prefer to do without an ash pan altogether, simply scooping out the ash from the lower section as needed, although this is not very convenient. As a rule, the chimney for a potbelly stove is oriented upward to provide the necessary draft.

The standard design of a gas cylinder stove can be modified to increase productivity by turning a solid fuel heater into a heater or hob:

Image gallery

Photo from

Fixed to body

Attaching heating pipes to the cylinder

Air heating unit

Devices for heating food

What is a cylinder stove?

A classic representative of heating units from an old cylinder is the well-known “potbelly stove”. It received this name for its extraordinary gluttony, consuming large amounts of fuel. But its main advantage is fast ignition and heating. This is especially important in extreme situations, when for some reason the operation of the main heating stops.

In the design of such a furnace, the cylinders can be located in both vertical and horizontal positions. Heat transfer occurs through the surface of the furnace and can be significantly increased by welding metal ribs onto the surface. In addition, you can utilize the heat of flue gases by passing them through a pipe embedded in a container of water. Water heated in this way is used in a heating circuit or used in the household through an indirect heating boiler.

Pyrolysis furnaces occupy a special place in cylinder heating devices. Pyrolysis is the thermal decomposition of fuel that occurs with minimal access to oxygen. At temperatures above 300 degrees, the fuel in the furnace does not simply burn through the oxidation process, but decomposes into gas fractions, which give higher temperatures when ignited.

Photo gallery: types of stoves with a cylinder body

What cylinders can be used

Not every gas cylinder is suitable for making a furnace body. For example, it is not recommended to use cylinders made of composite materials. Despite its strength, the composite does not tolerate high temperatures.

A 5-liter container cannot serve as a furnace body due to its small size, but it is successfully used to make containers for liquid fuel.

You can use cylinders with a volume of 12 and 27 liters. They make excellent thermal units with a capacity of 2–3 kilowatts and 5–7 kilowatts, respectively.

Most often, stove bodies are made from cylinders with a capacity of 50 liters. Its dimensions - diameter 30 centimeters and height 85 - are optimal for installing a heating unit. A stove of this volume is capable of efficiently heating a small country house.

A 50-liter propane cylinder is best suited for the body of a homemade stove

Oxygen cylinders for furnaces are rarely used. The size ratio is not entirely convenient for the installation of a firebox, and the significant height makes such a unit unstable.

Preparatory activities

If you think through everything and prepare it in advance, then during the work you will be able to avoid mistakes and reduce time costs. First of all, you will need to remove the remaining gas from the cylinder, collect the necessary tools and purchase the missing materials. A detailed drawing or sketch of the heating device will also help in the work.

What kind of cylinder is needed and how to prepare it for work

First of all, we note that only all-metal cylinders for household propane-butane are suitable for making a potbelly stove, including those used to equip LPG in trucks or cars. The best preparation can be considered a 50-liter vessel, which can be found in most private households. Its height of 850 mm and diameter of 300 mm is enough to burn all types of fuel, from firewood or sawdust to used motor oil.

A good potbelly stove can be built from a 27-liter propane cylinder if you use a horizontal design of the unit and retrofit it with an ash chamber. Its small size allows this unit to be used as a mobile structure.

Since even an empty cylinder may contain gas residues, condensate or its vapor, it can be dangerous to carry out any work with it without careful preparation of the container - any spark can lead to an explosion.

The water will displace the remaining gas from the cylinder, after which you can begin plumbing work without fear

To completely remove propane or its derivatives, use a proven method:

- Open the valve and release the remaining gas from the cylinder.

- Turn the container upside down and pour out the condensate.

- Using a gas wrench or an adjustable wrench, remove the valve.

- Place the vessel vertically and use a hose to completely fill it with water. The liquid will completely displace the remaining gas and make the preparation for the potbelly stove safe.

- After the water has been drained, you can carry out any plumbing work with the cylinder - cutting, drilling, cooking, etc.

Since both gas and condensate are explosive substances, and in addition, have a strong, unpleasant odor, work must be carried out in the open air, away from open flame sources.

The valve from the cylinder can be unscrewed using an adjustable wrench

What you need to avoid being distracted by small things

Before getting started, you need to prepare the following tools:

- welding inverter or transformer designed for currents up to 200 A;

- a manual grinder, or, as it is called in our country, an angle grinder, designed for the use of discs with a diameter of up to 180 mm;

- stripping and cutting discs for metal work;

- grinder attachment for cleaning metal from rust;

- electrodes with a diameter of 3–4 mm;

- welder's hammer;

- drill with a set of drills for steel;

- chisel;

- hammer;

- pliers;

- tape measure, metal ruler and square;

- marker and core.

In addition to one or two gas cylinders, to build a potbelly stove you will need:

A potbelly stove made from a cylinder can be equipped with factory cast iron doors

- sheet steel more than 3 mm thick;

- chimney pipe with a diameter of 100 mm;

- chimney elbow 90° or 2x45°;

- cast iron doors;

- grate bars or steel reinforcement with a diameter of 20 mm to replace them;

- hinges for hanging the door;

- metal corners with a shelf measuring at least 30 mm.

If you are a supporter of aesthetics in any of its manifestations, then, in addition to everything else, prepare a solvent, primer and paint. A painted potbelly stove will look much better, and the final finishing will give the unit a complete look. Of course, these materials must be designed for use in high temperature environments.

Which design to choose for your project

Despite all the variety of stoves that can be built from a regular gas cylinder, existing designs can be reduced to three main types:

- horizontal;

- vertical;

- combined.

A horizontal potbelly stove is easier to manufacture and, according to the owners, has greater heat transfer (which, in principle, is not far from the truth, given the slightly enlarged fuel chamber). At the same time, it occupies a large area, which in some cases is unacceptable. Horizontal units are good where there is room to turn around - in spacious workshops, warehouses, greenhouses, etc.

The horizontal position of the cylinder is more advantageous from the point of view of thermophysics

The vertical heating device takes up much less space and has an ideal configuration for installation in a corner. For installation in garages and small rooms, home craftsmen choose this particular design, although it is more difficult to manufacture. The difficulties arise from the fact that to install the grate you have to weld in a limited space, and this is not very convenient. At the same time, there is a method when, to install the grate, the cylinder is cut into two parts, and then welded again.

Vertical stove - one of the most compact heating devices

Combined potbelly stoves are made from two or more cylinders, one of which acts as a firebox, and the other as a heat exchanger. In fact, such a heating device is the same horizontal structure, but since its chambers are made of separate vessels, we still classify such structures as a separate subspecies. Combined-type stoves are the most economical and thermally efficient heating devices, but they cannot be called ideal, given their large dimensions and increased labor costs.

The combined heating device has increased efficiency

Below we have presented drawings and diagrams that can help you in your work or in designing your own structure.

Drawings and diagrams of potbelly stoves that can be built from gas containers

Drawing of a horizontal unit

Scheme of a vertical potbelly stove Drawing of a vertical potbelly stove made of yuallon Drawing of a long-burning potbelly stove

Types of long-burning stoves from a gas cylinder

There are many options for making stoves from cylinders. Each home master makes his own changes to them, according to his capabilities and understanding of the process. At the same time, long-burning pyrolysis furnaces are the most popular. In such designs, the combustion time of the combustion material varies from 12 hours to a day or more, which can significantly reduce fuel consumption.

Furnaces with conical fuel stacking

A popular type of pyrolysis furnace is a design with conical fuel stacking. In such a furnace, a pin is installed along the axis of the firebox from the grate. When loading, a wooden or tin cone is placed on it with the base up. The firebox is filled from above with sawdust, shavings or wood chips. In this case, the combustion material must be compacted well so that the filling is as dense as possible.

When fuel is loaded, the cone must be pulled out and the lid closed. The fuel is ignited through a ash pit with a small amount of wood chips or a tablet of dry fuel. As soon as the fuel burns well, the ash door must be closed, limiting the flow of air into the firebox. Then the fuel simply smolders, but this is enough to reach the pyrolysis temperature. Smoke is discharged through a pipe in the upper part of the housing. With this design, “samovar” water heating tanks are also used for a radiator heating system or heating water in an indirect heating boiler. It is convenient to use a gas or oxygen cylinder as a heating container, passing the chimney pipe along the axis of the vessel. A fitting for hot water is welded in the upper part, and for return flow in the lower part. Circulation occurs naturally without the use of a pump, which makes the heating system energy independent.

Manufacturing procedure

The orientation of the housing is chosen depending on the location and purpose of use. The horizontally positioned design is more convenient for cooking or bathing. The vertical version is often used for heating; They place it in garages: it takes up little space, and the traction in it is stronger.

Potbelly stove made from two cylinders in the garage Source ad-cd.net

Installation of a horizontal stove

The stove-stove is assembled in the following sequence:

- A square hole is marked and cut at the end to install the loading door (sometimes the end is cut off entirely).

- At the opposite end, according to the markings, a round hole is cut out for the chimney pipe.

- A hole for the grate is marked and cut out at the bottom. A box for collecting ash is welded under it (it is made of sheet metal).

- The ash chamber simultaneously plays the role of a blower, so it is supplemented with a door for adjusting the draft. To make the door, a fragment cut from the body is suitable, but you can supply a purchased part. The finished door makes the task easier, as it is equipped with a frame and a latch.

- To make a grate, thick reinforcing (knitting) wire is suitable; a lattice of the required size is cooked from it.

- For safe operation, reliable support is needed. Legs from a corner or runners from a profile are suitable as a stand. The supports are fixed to the body using spot welding; as a result, they must support the weight of the structure along with the loaded fuel.

Grate option Source ytimg.com

- A pipe - an adapter - is welded to the rear round hole, through which the chimney pipe is connected. The pipe needs a thick wall, otherwise it will quickly burn out under the influence of hot combustion products.

Slow burning pyrolysis furnace “Bubafonya”

It is impossible to describe or simply list all the designs of stoves that can be made from cylinders, but it is advisable to consider in detail the “bubafonya” design. This model can be made at home with your own hands.

Safety

Before describing the design of the furnace and its manufacturing technology, let us pay attention to safety issues. We will talk about preparing the cylinder itself for processing. Despite its dense structure, the inner surface of the metal is riddled with a network of microscopic cracks. During long-term operation of the container for its intended purpose, a considerable amount of gas condensate and its sediment accumulates inside these defects. Such a substance may be explosive and is in no way beneficial to health. Before you start working with the cylinder, you need to fill it with water and let it sit for 2-3 days. It is better to perform the operation away from home. When the liquid is drained, the reasons for this recommendation will become clear - it has an extremely unpleasant and strong odor.

Video: how to safely disassemble a gas cylinder

Tools and materials for making the Bubafonya stove

To make such a heating unit with your own hands, you will need:

Table: required materials and tools

| Name | Purpose | Notes |

| Cylinder for furnace body | Manufacturing of the main product | boo |

| Steel rod with a diameter of 10 mm | Making handles for the oven lid and body | From waste |

| Angles 45x45, any profile, pipe cuttings | For support legs | From waste |

| Bulgarian | Cutting blank parts, cutting the cylinder during the manufacture of the body | |

| Steel sheet 6–10 millimeters thick | Making a pancake | |

| Steel strip 40x4 millimeters | Manufacturing of support ribs | |

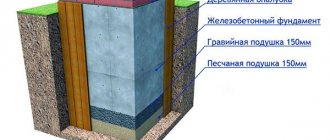

| Cement, sand, gravel and fireclay bricks | Making the furnace support base | |

| Reinforcing bars | Foundation reinforcement | |

| Trowel, shovel, container for mixing the solution | Pouring the foundation | |

| Welding machine for working with ferrous metals and electrodes for it | Making welded joints when assembling the furnace | Possible to rent |

| Electric drill no less than 0.7 kW, set of metal drills | Drilling holes | |

| Measuring tool | Taking measurements and marking | |

| Locksmith's corner | Positioning of parts during assembly, quality control | |

| Kerner | Hole marking | |

| Files flat and semicircular | Removing sharp edges and burrs, adjusting dimensions | |

| Marker black | Marking production | |

| Individual protection means | Goggles, welder's mask, face shield, mittens, gloves, special shoes, rags. |

The basic principle of the work performed

A do-it-yourself long-burning potbelly stove, like all wood-burning devices, consists of elements such as

1. The blower is a special channel, which is usually located at the very bottom of the furnace body. It is through this channel that air is usually supplied, which is the main catalyst for fuel combustion. This element is usually equipped with a door, which is used to effectively regulate the intensity of the combustion process. It simply closes or completely opens the channel from time to time. At the same time, the internal space of such a blower can be used as a special container designed to collect ash.

2. Firebox, that is, the combustion chamber of the fuel used, located strictly above the ash pit. This element is part of the channel through which air is supplied. It is separated by special rods, which are known as grates. The firebox must have its own separate door, which is required for loading fuel.

The ignition process, as a rule, is carried out strictly with the door of the combustion part open and with the door of the existing blower completely closed. All unburned parts of the fuel usually fall through the grate into the mounted ash pit. They can also fly out through a special exhaust channel.

3. The chimney is an exhaust duct used to remove combustion products from the stove. A view, that is, a special wedge-shaped shutter, is mounted in the body of the chimney. It was originally intended to completely close the entire exhaust duct. Using it, you can seriously slow down the overall process of efficient fuel combustion, while simultaneously increasing efficiency parameters.

Do-it-yourself stoves made from a gas cylinder usually involve placing two structural elements in a metal container body: a firebox and a high-quality ash pan. The chimney of this stove can be mounted separately.

- Such a potbelly stove works based on the following principles:

- The blower supplies air to the combustion part;

- The firebox usually burns coal or wood;

- A part of the stove, such as the chimney, removes gas and all unburned elements, that is, soot;

- The combustion control process is carried out by means of a throttle valve. It, in turn, is inserted into a short fitting and a special wedge-shaped view, pre-installed into the body of the chimney;

- Fuel is loaded into a special door cut into the body of the cylinder.

In fact, everything is relatively simple and clear. All that remains is to figure out how to correctly place the combustion part and the blower in the cylinder. It is important to understand how to connect a special chimney duct to it. All this can be found out by studying the information below.

Preparing for assembly, choosing an installation location

Before starting work on assembling the stove, it is necessary to prepare the installation site. After pouring the foundation, it will take time for the concrete to harden. During this period, you can slowly make the stove itself. The foundation can be used no earlier than 7 days after pouring. On top of the concrete base you need to lay a platform of refractory bricks.

A high-quality foundation is necessary for safe operation of the furnace.

When choosing a place to install the stove, you need to consider the following circumstances:

- the distance to the nearest walls made of flammable material should be more than one meter; if there is no such place, the walls must be additionally protected from heating with an asbestos sheet 8–10 millimeters thick; install a sheet of galvanized metal 0.5–0.7 millimeters thick on top of it;

- the chimney in the vertical part should not fall on the supporting beam;

- if an external chimney with an outlet through the wall is used, the length of the horizontal part should not be more than one meter; otherwise, you need to make a chimney with a slope of 45 degrees.

It is better to prepare parts and assemble the stove indoors, for example, in a garage. This will save your neighbors from unnecessary noise when working with an angle grinder and from the sparkle of the electric welding arc. The room must be equipped with exhaust ventilation. If welding is carried out outdoors, the work area must be protected with protective screens.

Will a small bottle suffice?

You can also work with a small balloon. It is made according to the same plan as a horizontal stove.

- But in this version, instead of drilled holes in the bottom of the stove, a cast iron grate is installed. A window of the required size was cut out for it.

Installation of a cast iron grate

- The blower in combination with the grate is welded as follows.

Ash pan made from a piece of channel

- Next, the legs are welded onto the ash pan box, the structure is turned over and the chimney pipe is installed on top and secured by welding.

- After completing work on the potbelly stove, it is installed in a permanent place and the chimney is taken out into the street.

Furnace modernization

Improving the operating parameters of the furnace is associated with an increase in its heat transfer. For this purpose, additional heat exchange surfaces are used on the furnace body. Such parts can be made from various metal profiles, including strips, angles, and profile pipes. The choice of material depends on what is available from leftovers.

Additional heat exchangers made of metal profiles increase the efficiency of the device

Additional heating surfaces can be installed not only on the outer surface, but also inside the firebox, which allows you to intensively heat the air in the room. A negative result of such a solution will be oxygen burnout at high temperatures.

Scheme and principle of operation of a potbelly stove

The history of these heating units goes back to the beginning of the last century, when they were used to heat rooms in houses and even apartments. This popularity is explained by the primitiveness of the stove design and ease of manufacture. But this same simplicity negatively affects the efficiency of its operation, because the efficiency of a traditional potbelly stove hardly exceeded 45%. Therefore, today it is used mainly for periodic heating of cottages and garages.

Initially, the heater was a metal body with a door at one end for storing firewood and an ash pan, and a chimney pipe was welded to the back. There was no grate, the fuel burned directly on the bottom (hearth). At the same time, the lion's share of the heat left the room through the chimney, since the hot combustion products entered there directly from the firebox. To understand the structure and operating principle of such a potbelly stove, it is worth studying the following diagram:

As you can see, hot flue gases containing a large amount of heat immediately leave the body of the furnace and are not used to heat the room. Later, the design was modified by unknown craftsmen in order to take away this heat, as a result of which the following types of wood-burning potbelly stoves appeared:

- stove with grate and smoke circuits;

- long-burning heater, where the process of burning wood occurs from top to bottom.

Note. To additionally extract heat from the chimney pipe, they began to install a samovar-type water heat exchanger on it, which will be discussed below.

The two-pass wood stove, shown below, has a grate and 2 baffles that force the flue gases to make a tortuous path inside the body before venting out. Thanks to this, the potbelly stove becomes more economical, since combustion products have time to exchange heat with the surrounding air through the metal walls of the unit.

There is also a variant of a round stove with one smoke circuit, where pyrolysis gases are burned. This potbelly stove is designed for burning sawdust and small wood waste. Here there is a double-walled design and a lower location of the chimney pipe, since gases must travel from the firebox from top to bottom in order to give off heat. The operating principle of such a homemade potbelly stove is shown in the diagram:

Another design, where solid fuel is burned from top to bottom, is not so economical, but it works much longer from one fill. The firewood here is set on fire and burns from above, pressed down by a weight with a pipe through which air enters. How such a long-burning potbelly stove functions is shown in the diagram:

For reference. People call this unit nothing more than the “Bubafonya” oven.

Features of operation of a pyrolysis furnace

The main difference between pyrolysis furnaces is the ability to use a wide variety of fuels. In solid fuel stoves, it is possible to burn not only traditional flammable substances, but also rubber, plastic and other materials that are strictly not recommended for burning conventional stoves.

This feature is associated with complete decomposition of the fuel and secondary combustion of the resulting gases in a separate chamber. After this, only carbon dioxide and water vapor remain in the smoke emissions. No harmful emissions into the atmosphere occur during pyrolysis.

But when using such fuel at the ignition stage, a persistent smell of burnt rubber remains in the room. Therefore, such heating units must be installed outside residential premises.

What and how to make doors from

Doors for potbelly stoves can be purchased cast. You will need a small height for the ash pan and a larger one for storing fuel. There are ready-made blocks - a flow door with a blower in one design. In this case, a frame made from corners welded to size is welded into a hole cut to size, and the casting is already bolted to it. To prevent air from blowing in from the cracks, a small edge is welded around the perimeter of the cutout under the door - a 1-2 cm strip of metal.

How to attach a cast iron stove door to a gas cylinder

You can not buy doors, but use a cut piece of a balloon wall. Then you will need some kind of hinges or replacement parts. It’s clear with the hinges: mark the places, weld them. There is an interesting version of homemade loops: several links of a thick chain.

The hinges on the door can be made from several links of steel chain

A latch will need to be welded to such a door.

Advantages and disadvantages

The positive aspects of homemade stoves include:

- excellent thermal conductivity (provided by the thick metal walls of the cylinder);

- convenient dimensions (can be made to fit your garage);

- ease of manufacture and maintenance;

- availability of consumables and fuel.

Among the few disadvantages, one can highlight only the ability to use a limited number of types of fuel (wood, coal, fuel briquettes), and with a vertical design, there is also the need to adjust the size of the logs to the length of the firebox.

Calculation of parameters: drawings and recommendations

You should start with the selection of source material. A 50-liter gas cylinder is ideal.

Its dimensions: 300 mm in diameter, 850 mm in height with a 4 mm metal wall.

These cylinders are commonly used in a variety of applications, from stove fuel to industrial applications.

Main parameters and features of stove manufacturing:

- the chimney is usually made of a pipe with a cross-section of 100–125 mm with a wall of 3-4 mm;

- place it vertically, perhaps with a slight deviation, 25-350;

- the firebox and ash pan are equipped with doors, which must be locked to improve heat transfer during fuel combustion and for fire safety purposes; in addition, the doors are used to regulate the air supply;

- it is important that the firebox must have sufficient depth for firewood of a convenient size;

- grates are needed for storing fuel and separating ash and coals during the combustion process;

- It is better to weld them from the most durable and heat-resistant material, for example from reinforcing bars with a thickness of 12-15 mm;

- their length must correspond to the inner diameter of the cylinder body; this grid usually has a mesh or a gap with a pitch of 10–15 mm;

- In order for your wood-burning “potbelly stove” to heat and fire properly, it is built according to the principle of a conventional wood-burning stove.

What do you need to prepare?

From the tools you need to collect:

- welding machine (200A);

- grinder – “grinder”, preferably with discs with a diameter of at least 180 mm;

- electrodes;

- circles for grinding and cutting metal;

- hammer cleaning slag from welding;

- a brush with metal bristles;

- folding meter, tape measure, chalk or marker for marking;

- drill and drill bits of the required diameters;

- chisel, regular hammer and pliers.

From materials, in addition to one or two gas cylinders, you must purchase:

- a sheet of metal, at least three millimeters thick - it is useful for constructing a hob and ash pan;

- ready-made cast iron doors, or you can also make them yourself from a metal sheet or a piece of metal cut from a cylinder;

- chimney pipe;

- corner or thick reinforcement - they will be needed for the manufacture of legs and grate. The latter can be purchased ready-made (from cast iron) or constructed using holes drilled in the bottom of the cylinder.

It should be noted here that both a standard gas cylinder and a small cylinder are suitable for the manufacture of such a stove.

Chimney cross-section size

The minimum permissible cross-section of the chimney is determined by the amount of energy released per hour of operation of the stove, which is determined by the ratio S = 1.75E (kW/hour). Here E = mq, where m is the mass of fuel in the load, q is the specific energy of the fuel burning over an hour, table value. The necessary information is given in the table.

Table: data for calculating the cross-section of the chimney

Type of fuel Specific gravity (kg/dm.kv) Energy intensity (kW/hour)

Aspen logs 0.144 2.83

Coniferous shavings and sawdust 0.138 3.21

Alder briquettes 0.286 3.49

Coal 0.402 4.85

Peat 0.341 2.37

Having made the necessary calculations, we obtain the minimum required chimney diameter for the Bubafonya stove of 150 millimeters.

Air intake pipe size

Having determined the size of the chimney, it is easy to calculate the cross-section of the air intake from the ratio d = 4S/P (pi).