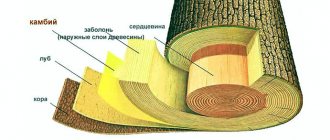

The ends are the most vulnerable areas of the logs, since the wood fibers remain completely open and are more exposed to the negative effects of weather factors than other areas. The processes of moistening and rapid evaporation of moisture lead to the formation of cracks at the ends, as a result the logs can crack, which has a very bad effect on the strength of the wooden structure. Treating the ends of rounded log logs with special antiseptic agents will help prevent the development of negative processes. If protective treatment is carried out in a timely manner, the wood dries evenly, which has a positive effect on the appearance of the logs and the log house as a whole.

Why process the ends of logs?

The need to treat the ends becomes obvious if you look at an untreated log that has lain on the street for several years, the ends of which have lost their natural color and darkened, become covered with cracks, and fungus and mold have appeared on them.

This happens because the open ends actively absorb moisture, which then quickly evaporates, and the loose wood structure becomes a refuge for microorganisms and insects.

Moisture evaporates through the end and side surfaces of logs at different rates. Evaporation of moisture through the ends occurs much faster, which leads to the formation of cracks and deformation of the crowns.

Painting the ends of the log house promotes uniform drying of the logs, since the rate of evaporation through the painted surface slows down, and accordingly, the process of cracking stops.

In what order to install a log bathhouse

It's no secret that the first crown of the house

or any other building - the most responsible. Since the dimensions of the lumber were known to me in advance, I precisely adjusted the layout of the future bathhouse and the size of the foundation to their length. Having accurately marked the first crown, it was enough in the future to use only a plumb line and a level so that the walls and corners of the bathhouse were vertical.

Log bathhouse. First crown

Before laying the first crown on the surface of the bathhouse foundation, I made waterproofing from two layers of RKP-350 roofing material.

Log bathhouse

, thanks to horizontal insulation, will not be exposed to ground moisture, which can rise through the foundation concrete due to capillary pores.

After the first crown, the rest are arranged. The entire frame made of timber

must be mounted along the crowns so that the lumber in the corners and other junctions is tied to each other.

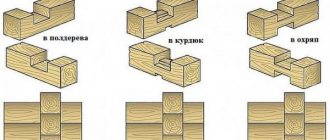

How to connect beams in corners

To connect the beams in the corners, I decided to use the simplest method, but quite sufficient for strength and heat protection - in a dressing with a root tenon (sometimes it is called a “warm corner”). It’s easier than not to tie the lumber together at all, installing them end-to-end, but then you would have to use staples to tie them together, and the corners of the bathhouse would be blown out.

Log bathhouse. Warm corner

All other methods that were in demand in the past - in a paw, in half a tree, in a cup, I immediately “rejected” as unreasonably complex. With modern means and methods for sealing joints, you can easily avoid unnecessary labor costs.

In order not to mark the configuration of the cutouts in the lumber for each corner separately, I simply made two cardboard templates, according to which I marked the ends. After this, making one or two cuts with a chainsaw and removing excess wood with a hammer and a wide chisel is a matter of a couple of minutes. The direction of the spike on each row must be changed. That is, if in an even row the tenon is on the right and the groove is on the left, in the odd row there should be a groove on the right and a tenon on the left. This bandage firmly holds the crowns together in height, preventing the frame from falling apart.

How to join a beam to a long wall

In some cases, it is necessary to make a T-shaped connection of the timber. This need arises when connecting an internal wall to an external one. I got three such connections for each crown.

It is better to make a T-shaped junction using a method that carpenters call a “dovetail” (in some sources this method is called a “frying pan connection”).

Log bathhouse. Dovetail connection

To do this, the end of the adjacent beam is cut out in a shape reminiscent of this very tail, and a corresponding notch is made in the long beam. After installing the unit, the connection must be wedged. For this, wedges made of dense, dry wood are used.

This type of connection provides sufficient strength and is completely airtight, since there are no through vertical joints.

How to connect crowns to tie a bathhouse frame

The connection of the crowns with each other must be carried out in order to ensure the strength of the structure of the bathhouse frame vertically. In other words, this is necessary so that the crowns do not move relative to each other. Previously, this operation was performed on wooden dowels - rods of round or square cross-section. They were driven into pre-drilled holes, connecting two or three adjacent crowns.

Not wanting to waste time preparing these dowels and drilling large diameter holes, I simply used 200 mm long nails. The nails are hammered very quickly, and if you deepen the head 3-5 cm into the upper beam, the nail will securely connect the two crowns, preventing them from moving.

To finish the nail and immerse it completely into the drilled hole, you need to use a hammer. If you don’t have it on hand, you can use an old, worn-out drill bit from a rotary hammer with a diameter of 10 mm.

Requirements for protective equipment

The first processing of the ends must be carried out immediately after the construction of the log house.

But since in the first years after construction there is an active process of shrinkage of the log house, it is necessary to treat the ends with a product that does not interfere with the natural shrinkage processes occurring in the wood. An antiseptic for the ends of a log house must have the following characteristics:

- do not interfere with the evaporation of moisture from the logs through the ends along the longitudinal fibers;

- do not suppress the processes of moisture removal through transverse fibers;

- do not interfere with the removal of moisture from the surface.

- protect wood from exposure to ultraviolet radiation;

- prevent rotting processes.

Preparatory stage: surface grinding

Before treating wooden walls with protective compounds, as noted earlier, they are sanded. This is done in order to remove the worn, mechanically damaged top layer.

The abrasive blade of the tool cuts off several millimeters of the wood layer

This is a mandatory procedure, as a result of which it is possible to cut off the porous layer of wood saturated with moisture. If it is not removed, it will prevent the penetration of protective compounds into the wood. And the air that is in the pores will not allow you to evenly cover the wood with varnish or paint - bubbles will appear on its surface.

Sanding of logs is carried out in stages:

- First, the surface is cleaned of large loose particles and bark, if any remains, using a disk brush with metal bristles.

- Then the areas near the junction of the two crowns are polished. This part of the work has to be done manually, since the joint is difficult to access. You can use the tool at low speeds and a sandpaper attachment.

- At the final stage, the front surface of the log is polished. The tool should operate at medium speed. The diameter of the abrasive disc should not exceed 15 cm. It is necessary to carefully process the surface of the wood, cutting off a layer of no more than 2 mm.

Sanding is a dusty process, so work must be done using personal protective equipment

How to treat the ends of logs?

The traditional end treatment is lime.

It is still often used for these purposes today. Lime is a natural antiseptic that protects wood from rotting and UV rays. However, the period of action of this product is very short, since the first rain will completely wash away the lime, and the ends will be left without protection. Knowing this, many owners of wooden houses use PVA glue or acrylic varnish to process the ends. But the effectiveness of these products is also questionable, since they form a film on the surface that prevents the evaporation of moisture and interferes with the full air exchange of the wood.

How to paint the ends of rounded logs to ensure their effective protection? Currently, Russian and foreign manufacturers produce a lot of impregnations for processing ends. Among domestic antiseptics, three products are recognized as the best:

- Senezh Tor.

- Neomid Thor Plus.

- Biotor.

Senezh Tor

The product has good penetrating ability.

The antiseptic is absorbed into the wood to a depth of several centimeters, forming a protective layer on the surface that allows air to pass through and repels water. The coating helps remove excess moisture from the wood, prevents the development of putrefactive processes, and reduces the depth and number of end cracks. The antiseptic does not lose its protective properties for several years. The product does not contain solvents and does not emit odor, tolerates frost well and has fire retardant properties. For ease of application and control of treated areas, the antiseptic slightly changes the color of the wood.

Neomid Thor Plus

The product protects the ends from biological damage by microorganisms and insects, prevents the formation of fungus and mold and prevents rotting.

The antiseptic creates an elastic protective film on the ends of the logs that does not allow moisture to pass through, which prevents the accumulation of excess moisture in the wood fibers. At the same time, the coating is vapor permeable, so it does not interfere with the air exchange processes occurring in the wood.

Painting the ends of logs with this product does not in any way affect the aesthetic characteristics of the log house, since the antiseptic preserves the natural color and texture of the wood.

Biotor

It has similar characteristics as the products listed above. Impregnation protects the ends of logs and beams, creating a waterproof transparent coating on the surface that prevents rotting and cracking of the ends, and also reduces existing cracks. The elastic film also helps reduce the linear deformation of wood that occurs during shrinkage.

Choice of paint and varnish

See also

Smart siding: review, reviews, installation technology

Antiseptic and fire protection treatment of the outside of a log bathhouse is important. But it is equally important to then coat the wood with paint or varnish. And at least 2 layers.

A bathhouse is not quite the same as painting imitation timber, since the material, as well as the operating conditions, are somewhat different.

When thinking about how to paint a log bathhouse on the outside, you usually choose among the following options:

- Oil paints

. The most affordable. But they are not environmentally friendly. Plus the service life is insignificant. That’s why I don’t recommend taking it; - Alkyd varnishes and paints

. One of the best options for baths, as well as exterior wood finishing. There are no toxins or solvents in the composition. Durable, durable, vapor permeable. They also have a wide palette of shades. Color fading does not occur over time; - Scuba diving

. They contain acrylates, resins and dispersions. Eco-friendly and beautiful in appearance. But they are inferior in durability; - Oil waxes and clear varnishes

. The main advantage is the ability to preserve the original appearance of the material. But you can’t count on a high level of protection; - Acrylic paints.

Perhaps the best paint option for wood, which is ahead of even alkyd analogues. They are offered in a large assortment, are environmentally friendly, odorless, do not cause allergies and fit perfectly on a wooden surface. The disadvantage is the high price.

And then decide for yourself how to paint the outside of the timber bathhouse.

I don’t think it’s worth mentioning how to paint a bathhouse.

Processing technology

To provide a wooden house or bathhouse with good and durable protection, it is necessary to adhere to a certain order of work.

Before treating the ends with an antiseptic, it is necessary to perform a number of mandatory operations. The work is performed in the following sequence:

- Trimming of a log house. This operation involves cutting off the protruding parts of the logs. During the construction of a house from otsb, the size of the logs is not regulated. After construction, the length of the logs in the cuts is rarely the same, and the ends, as a rule, are also not perfectly even. The formation of a neat and even vertical plane is done after construction. The protruding ends are cut off with an electric or chainsaw.

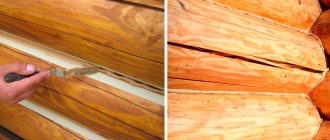

- Next, the ends of the frame are polished. Using grinding, the surface is prepared for antiseptic treatment. After sanding, the absorbency of the wood increases, the ends will absorb the antiseptic better and more deeply, which will ultimately increase the period of action of the protective treatment.

At the first stage, rough surface treatment is performed using a grinder with coarse abrasive. Then the ends are sanded with a finer sanding attachment. Processing must be carried out until a layer of undamaged and clean wood appears.

Grinding the ends of a log frame made of rounded logs can only be done in dry weather. You can only process completely dried logs, the humidity of which does not exceed 20%. When sanding wet wood, fluff is formed, which prevents the surface from being smooth and even.

- Protective treatment of ends with antiseptic. The ends are treated with a wide brush at least three times. Impregnation is applied in a generous layer. After the first layer has completely dried (about a day), apply the second, and then after 24 hours the third layer.

- Sealant treatment. This operation is performed after antiseptic treatment to create a durable moisture-repellent coating on the ends that prevents excessive moisture in the wood. For these purposes, it is recommended to use special acrylic sealants.

How to apply Torvens oil correctly

Before applying, the oil must be carefully applied with a brush for 3-5 minutes. This will give it a uniform consistency. Then you need to do the following:

- Apply the composition evenly with a soft-bristled paint brush. In this case, the ambient temperature should be from +5 ° C to +35 ° C, the weather and the tree itself should be dry.

- Leave the first layer to dry for 8 hours.

- Apply the next layer 16-24 hours after the first has dried.

Torvens end oil for initial application gives a consumption of 1 liter per 14 m2. During application of the second layer, the consumption will be 1 liter per 8 m2.

End processing after shrinkage

After the initial shrinkage of the log house, approximately 12 months after construction, the ends are painted with a product that creates a durable protective film on the surface. This can be either drying oil or paint containing oil or wax.

Antiseptic treatment is necessary in any case, even if in the future it is planned to finish the ends of the log house with siding, clapboard or other decorative building materials.

will process the ends of the log house at a high professional level. We have been specializing in finishing wooden houses and baths for more than ten years, so we guarantee excellent quality of processing. All work will be completed exactly on time specified in the contract.

To discuss all working conditions in more detail, contact us using the coordinates in the “Contacts” section.

Calculate the cost of painting and insulating your home right now

Select types of work:

Select materials:

Choice of antiseptic

As you understand, treating the outside of a log bathhouse necessarily involves the use of antiseptics.

But the treatment of a log house, like a bathhouse, involves the use of certain antiseptics. Therefore, you first need to study the range and understand what impregnation for the outside of a bath will be effective.

- Easily washable compounds are not suitable for external use. They can be used in the rest room, as well as in the dressing room. But they are not used for steam rooms and exterior decoration. This is largely due to the presence of metal salts, which wash out such an antiseptic from the wood;

- Only hard-to-wash antiseptics are suitable for exterior finishing. They contain natural as well as synthetic oils;

- Steam rooms use fast-acting substances. They have a high level of antifungal protection. Plus they can withstand high temperatures.

Antiseptic treatment of a log house can be performed using 2 types of products:

- Colored

. They are able to paint wood in the chosen color and shade. Easy to apply. There are no significant disadvantages; - Colorless

. They are much harder to apply. But a significant advantage lies in the ability to preserve the original appearance of the wood.

If you are treating a log house or a log bathhouse, but you do not want the structure to darken over time, remember one nuance. Every 1.5-2 hours you need to change the brush with which antiseptics are applied. But it is best to use spray bottles. Leave the brushes for applying products to hard-to-reach areas.

Selection of the best antiseptic composition

Any antiseptic is a substance that prevents the development of microorganisms and fungi. It prevents the formation of mold, which can cause blue spots to appear on the surface of the wood.

In addition, such treatment protects the tree from the effects of all kinds of wood-eating insects: wood-boring beetles can render any structure unusable if care is not taken to protect it in time. Coating a log house with an antiseptic increases the durability of logs and beams, so its use in the future will save on repairs.

Which antiseptic to choose for a log house? There are dozens of options available today: special protective equipment is offered by both domestic and foreign companies; the variety of brands does not allow you to quickly decide on the right product. There are several rules that will allow you to make the right choice:

One of the best solutions is proven products from well-known companies. If you choose a well-known brand, you can be sure that the products will be effective.

Today, Neomid 200 is in demand; products from foreign manufacturers can be called Tikkurila or the Teknos brand. Many builders trust Finnish manufacturers, since the culture of working with wood in this country has always been at its best.

- A good antiseptic for a log bathhouse cannot be cheap. It is not recommended to choose protective equipment on construction markets or purchase them secondhand. In a reliable store, there is less risk of encountering a fake, which may turn out to be not only useless, but also toxic.

- The label must indicate that the product protects against all biological threats: fungus, mold, rot, insects, etc. The product must be stored correctly.

- For outdoor work, it is recommended to choose antiseptics that are difficult to wash out - they retain their properties longer, but even in this case, the impregnation will need periodic updating. Any product is gradually washed away under the influence of street moisture, so wood definitely needs an additional external coating.