If you decide to build the log house yourself, you will need to decide how you will connect the logs or beams at the corners. You will also need to understand how, if necessary, to join two logs or beams in length and insert a partition.

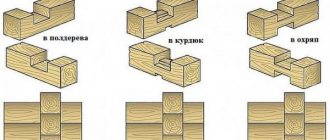

Regardless of what the frame is made of, there are two types of corner joints:

- with a remainder (or release) - this is when there is still some piece of log or timber behind the junction;

- or without any remainder.

When cutting with residue, there is a fairly large waste of material. Each remainder is at least 20-25 cm. These “tails” in one crown take 160-200 cm. The consumption is quite considerable. But on the other hand, such a cutting is called a “warm corner”, precisely because with normal caulking they do not dry out.

The corner in the log house can be with or without remainder

Cutting a log house without residue is more economical in terms of material consumption during the construction stage, but in this option the corner is the most freezing place. Also, with this method of connecting logs and beams in the corner, even small errors greatly affect the quality. Therefore, increased demands are placed on the quality of cutting bowls.

There is a big difference in the technology of constructing a log house from logs and timber. The logs have a round shape and without processing it is impossible to join them tightly. Therefore, a recess is made in the lower or upper crown - a groove, into/on which the next log is laid. This increases the surface of their contact. It is the width of the groove that is the actual thickness of the log wall. How warm the wall will be depends on the shape of the groove and the accuracy of its execution.

With timber everything is different. Since the planed one has almost the same dimensions, and the profiled and glued ones have no “almost”, and their edges are flat, no adjustment or groove is needed. Therefore, the entire assembly of a log house from timber consists of forming joints in the corners. Inter-crown insulation (jute, tow, moss) successfully copes with blocking small inconsistencies. As a result, a log house is built many times faster.

Connecting logs in corners with remainder

First, let's talk about log houses. Recently, they have become popular again, especially in suburban construction: they look attractive and are also natural. Moreover, even despite a significant overconsumption of material, the corners are made with a remainder. These methods of joining logs are traditional. They came to us from our great-grandfathers, this is how they built their houses.

Log house in a bowl

As has already been said, a longitudinal recess is made in each log - a groove. In the corners they are trimmed more, according to the shape of the log lying across. This notch is round in shape, which is why it is called a bowl, and the method of cutting a corner is called a bowl. The second name is “in the oblo”.

Marking the upper and lower bowl

Depending on the location of the bowl, there are upper and lower bowls. The upper bowl is so called because the log rests on top of the crown, clasping the lower one. This connection is also called “clap”. Remember: the bowl is upper, despite the fact that it is formed at the bottom of the log.

The work is carried out in several stages. The log is first placed in the log house and leveled. Then they outline the contours of the groove and the bowl, place it on a flat surface and process it there - cutting the bowls. When the excavation is ready, the log is raised again and placed in place, trying it on. If necessary, they are adjusted (removed again, trimmed where necessary) and only then laid on a compactor (tow, jute, moss). All these movements are compensated by the fact that with this method of cutting, sediment simply flows down the side surfaces of the wall, and they, as a rule, are well protected by several layers of impregnations and paints.

Types of bowls for joining logs in corners

The lower bowl can be molded directly in the log house: all manipulations can be done on the laid crown. When the walls are already raised high, it is very inconvenient to do this if you lack dexterity, so you still have to drag the logs up/down. Perhaps this is why this method is less popular.

It is easier to make a frame into a bowl: it allows you to correct almost all mistakes. In addition, despite all the apparent complexity, it is this type of joining of logs that is easier for beginners to do. All others require more carpentry skill.

How to make a joint from a log frame into the lower bowl is shown in the video below. The explanation is detailed, showing techniques for working with an ax and the full procedure. First you just need to talk about the tool that is used to draw the log. This is a carpenter's trait or scriber.

The device is very similar to a school compass. There is also a sharp stop on one side and a pencil on the other. Just like in a compass, the required distance is fixed with a screw. Having placed the ends at the required distance, the sharp part is guided along the log for which the bowl needs to be cut. Using a pencil, respectively, according to the one in which the groove and bowl will be cut. This produces markings, which are then drawn with a marker. It will become clearer when you see the process of marking the bowl in the video.

Actually, now a video about how to connect logs into the lower bowl. The first part deals with molding the longitudinal groove, the second directly deals with cutting the bowl.

Connection in okhryap

This type of connection consists of two semicircular bowls. In order for a corner folded using this method to be warm, considerable experience is required: even minor errors in the width of the groove or the thickness of the lintel will cause drafts.

Log in okhryap

Kinds

A warm corner improves the external and internal appearance of the building, since its walls are free of irregularities and unnecessary protrusions. To make a high-quality warm corner, it is necessary to consider different methods of cutting joints, which have their own characteristics, however, they have the same fastening mechanism.

Styling with remainder

Such connections are called “in oblo”. It has two main advantages - a high level of sealing, as well as joint strength without fixation. This locking design system provides different types of joints.

- The one-sided key groove is a transverse notch in each bar, and its width corresponds to the same parameter of the bar. It is located at the top and is most often applied to profiled wood, as it fits perfectly into its structure. The grooves are made straight and square. In some cases, it is allowed to secure the connection using dowels.

- More complex is the two-way connection. For this, the timber is sawed from the top and bottom sides to 1/4 of the thickness. Double fixation makes the structure more durable, which completely eliminates displacement. An indispensable requirement is a smooth wood structure with no defects in the form of cracks and knots.

- The four-way connection is the most reliable in terms of sealing, but it has a more complex preparation of the beams, so it is used quite rarely.

Joints without residue

Cost-effectiveness is the main advantage of this technology, while the end parts of the timber do not protrude from the walls. However, there are also disadvantages of such a connection - it is less durable than with other joining methods.

There are several options for obtaining even corners of a log house.

- Half-wood is a joining in which the beams from one and the other wall are cut down to 50% of their thickness, after which these cuts must be fixed with dowels, because such a connection is quite weak. In this case, caulking is applied later. In the paw - this is a similar method, which is distinguished by more complex work with the preparation of the material, due to which the quality of the connection is higher and more durable.

- Connection using dowels, which are made only from hard and durable wood. They perform the task of inserting in the grooves. In fact, they are used to fasten the beams together at the side and end. This joining promotes a tight fit and prevents any displacement. These spare parts can have any shape - oblique, longitudinal and transverse. Dovetail dowels are especially relevant. Unfortunately, it is difficult to make them yourself, because this requires a special machine.

- The simplest is considered to be a warm butt corner, and there is no need to saw the timber. The ends of the material are fixed in a checkerboard pattern using squares, staples, clamps or metal plates with nails. Bonding occurs along the length. If damp building materials are used, it is extremely difficult to avoid deformation, therefore, as a rule, careful insulation of the gaps is required in the future. You can do the work yourself, but it is better to use dry wood.

- The most common fastening is in the root tenon. When all the necessary cuts are precisely calculated, and there can be quite a lot of them, since up to 5 grooves and tenons are used, then this design is the most reliable and stable. Simultaneously with the connection, linen or jute insulation is placed in the grooves. This prevents blowing and no additional protection is required.

Direct joining is often carried out in the main tenon or involves connecting the longitudinal beam end-to-end using dowels. The oblique lock, in general, is rarely used, since it is unprofitable in all respects.

Longitudinal fastening is carried out using tongues, usually birch, and high demands are placed on them - defects such as delamination and knots are simply unacceptable, moreover, the wood fibers in these hardware should only be located parallel to the axis. Qualified craftsmen, of course, can carry out such work, but does this make sense when there are simpler and better types of warm corners?

Cutting logs with corners without residue

As we said earlier, the corners are colder without any residue, but they allow you to significantly save on building materials.

Angle "to the paw"

Among the joints of logs in the corners, the “paw” method is popular. It is easy to implement, and at the same time provides high strength and reliability of the connection. Also, the presence of inclined cuts makes it possible to achieve high tightness. The method has been tested for a long time, even GOST standards have been developed: size tables for each log diameter (see photo).

Table of foot joint sizes for different log diameters

All dimensions are plotted relative to the found middle of the log and a vertical line drawn from it (it is drawn using a plumb line).

Connecting logs without leaving any residue. Angle to paw

The order of work is as follows:

- Find the length of the cut part (called the block). It must be no less than the diameter of the largest log available (in the figure it is marked L). We set this value aside from the edge of the log (let it be 250 mm), draw vertical lines in these places. They will be the boundaries of the idiot.

- Let the diameter of the processed log be 200 mm. From the middle line, 1/2 of the value of A is set aside. D for a 200 mm log is 141 mm. We divide this value in half and put it on both sides of the center. We draw vertical lines.

- We trim (cut with a chain saw). As a result, you should get the same picture as in figure a).

- We take the appropriate dimensions from the table and mark them on the block.

- We trim off the excess (cut it off). The result should be a figure like in Figure b).

This is what the angle from the logs into the paw looks like (dovetail due to the fact that the connection is in the form of a trapezoid)

All logs are processed in this way one by one. As you can see, the dimensions depend on the diameters of the logs. In order not to have to worry about drawing every time, they make templates from thin plywood according to the diameters of the logs that are available (they label them). Then, having found the middle and made a block, they apply and trace a suitable template. With this order of work, there is less chance of making mistakes, and chopping bowls takes less time.

Adviсe

A log house is the most common option for constructing such a building. The assembly process itself takes a little time, especially if all the preparatory work was carried out efficiently.

Although it is possible to build such a house yourself, it is better to consult with an experienced craftsman before starting work. It is necessary to take into account every little detail, because the strength and safety of the new building may depend on it.

Of course, reviews about this cutting method are contradictory. But it is supported not only by its obvious, well-known advantages, but also by the fact that this method is still the most common, despite certain difficulties and disadvantages inherent in it.

A reasonable approach to business, strict adherence to all the necessary rules will help you successfully complete this work and get a warm, cozy, durable and safe log house.

See below for information on how to cut into a paw.

Tags: beam, paw, template

« Previous entry

Joining the timber with the remainder

The easiest way to join timber in the corners of a log house is “into the floor of the tree”. A rectangular groove is cut, the dimensions of which depend on the thickness of the timber and are: The depth of the notch is half the thickness of the timber. That’s why it’s called “half a tree”.

Connecting the timber in the corners with the remainder - in half a tree, in a fat tail, in an okhryap

The “tail tail” method is distinguished by the presence of an additional tenon, which provides a stronger and more reliable connection, but requires more carpentry skill. More difficult is connecting the timber into an okhryap. Here you cannot make a mistake when calculating the width of the jumper, but it is much easier to implement than on a log: the geometry here is standard and you can use a template, which significantly speeds up the work, and then an error can only occur when cutting.

Bottom line

Taking into account modern requirements for the thermal insulation properties and reliability of wooden houses, a corner connection using the “warm corner” technology is more advantageous than a “bowl” one. This method of assembling log houses allows you to achieve high strength, as well as savings on heating during the operation of permanent housing. As for the complexity of execution, today this pushes few people towards simpler solutions. Moreover, for many companies, the cost of assembling a wooden house does not depend on the chosen corner connection.

Connecting timber in a corner without leaving a trace

There are several types of connection. Traditionally, “half-tree” and “paw” are used for bathhouses and houses. They differ only in shape. Half a tree has smooth, parallel edges. It's easy to implement. When joining the timber “into the paw”, the shape of the tenons is made trapezoidal. It is a little more difficult to perform, but there is less chance of through holes occurring.

Joining the beam in the corner without leaving a trace: half a tree and a paw

There are several other types of butt joints for timber. They are not very reliable and do not provide proper tightness, although they are economical in terms of material consumption. They are rarely used for residential buildings, mainly for the construction of outbuildings.

A simple butt connection occurs with alternation. This makes the angle stronger. For reinforcement, you can use steel plates or knock down the beam with long nails at an angle.

Butt joint of timber

There are also methods for butt assembly with dowels of different shapes.

Another method of construction: using frame-timber technology. Then, in the corners and at the joints of the timber along the length, a vertical stand is placed with grooves formed in the required planes. At the ends of the beam, a spike is formed into the appropriate shape. When laying, you have to “put on” each element from above.

The advantage is that you can mold all the studs according to a single template, and then simply assemble everything like a construction set (not forgetting to lay inter-crown insulation). The connection turns out to be airtight and quite reliable, moreover, the joint itself is not visible and the appearance is very attractive.

Connecting timber using panel technology: quickly, warmly and reliably

How to connect beads lengthwise

The easiest way is half a tree. Its configuration and shape are similar to those made when connecting a corner. But the disadvantage of this splicing method is that when longitudinal forces arise, which can occur during drying or movement of the soil, such a connection is easily broken. A continuous gap is formed.

Long beam connection

The oblique rim lock has the same disadvantage: it is easy to disengage. If you need reliable joining of timber, use a straight rim lock. As you can see, due to the protrusion, pressed by the crowns located on top and the weight of the roof, it will resist the forces of longitudinal tension (and compression too). It is more difficult to implement, but much more reliable.

Construction of a log house

Scope of work:

- Construction of the foundation. The log house is lightweight, so there is no need for massive foundation structures. Most often, columnar or shallow-depth tapes are used. Waterproofing of surfaces in contact with the ground, if necessary, installation of insulation. Backfilling with drainage soils.

- The supporting lower crown is laid on a horizontal waterproofing made of two layers of waterproofing. The first two elements are laid strictly parallel, the next 2 logs are laid perpendicularly on top of them. The resulting rectangle is carefully leveled using a laser level.

- Installation of the following links with a tight fit of the paw connection. Tow is used during assembly.

- After assembly is completed, longitudinal and corner seams are sealed. The wood is treated with fire retardant and antiseptic preparations.

- Finally, the corners are insulated from the inside with modern heat insulators.

After completion of the assembly, the frame is kept for a year, protected from precipitation, after which the cracks are re-caulked and further work on the roof installation and finishing work is carried out.

- Wall kit