Wooden floors on joists are one of the oldest methods of flooring and the only one used in the northern regions of our country. Modern materials have only improved ancient technologies, due to which the scope of applications has significantly expanded and performance indicators have improved. Before proceeding directly to the consideration of various options, you should familiarize yourself a little with the engineering requirements for calculations.

Installation of wooden floors on joists

Reasons for the popularity of log structures

Technical characteristics of logs and requirements for their installation

Logs are distinguished from beams by their smaller size and mobility. If beams cannot be moved after installation, and repairs are very long and labor-intensive, then logs are a mobile architectural element. They are much easier to install and, if necessary, repairs are carried out faster.

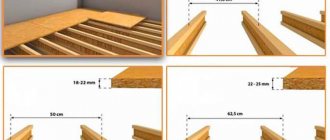

Distance between joists

Optimal section proportions

Before you start building a floor, you need to study the requirements of regulatory documents for the size of the joists and the distance between them, taking into account the thickness of the floorboards.

Table of lag sections at a pitch of 70 cm

| Distance between joist supports | Linear dimensions of logs |

| 200 cm | 110×660 mm |

| 300 cm | 150×80 mm |

| 400 cm | 180×100 mm |

| 500 cm | 200×150 mm |

| 600 cm | 220×180 mm |

Table of distance between joists depending on the thickness of the board

| Thickness of pine floorboard, mm | Distance between adjacent joists, cm |

| 20 | 30 |

| 25 | 40 |

| 30 | 50 |

| 35 | 60 |

| 40 | 70 |

| 45 | 80 |

In order to learn how to independently make calculations based on tables, it will be useful to consider a simple example. Initial data: the length of the room is 10 m, take a floorboard 30 mm thick.

floorboard

Lags

Batten

Calculation method

According to the table, with such a thickness of the board, the distance between the logs is 50 cm; with a room length of 10 m, 20 logs will be needed. The distance between the logs and the walls cannot exceed 30 cm. This means that we will have to increase their number by one piece, the distance between the others will decrease to 45 centimeters.

Important note. During calculations, all roundings should be done only downwards, thus creating an additional margin of safety.

There is no need to calculate dimensions and distances accurate to the millimeter; no one takes such measurements. By the way, during construction, the vast majority of architectural elements and structures are measured in centimeters, the greatest accuracy is half a centimeter. Millimeters are almost never used during measurements.

Floor joists

A wooden beam of rectangular cross-section can be used as a log

Stage 1 – select the material

A durable, reliable floor covering, which during operation will not require significant funds for repairs and will last for many years, depends on the initially correctly selected material.

Grooved board (DP)

Parameters of tongue and groove boards

Tongue-and-groove floor beam (BP)

How to choose quality lumber

When producing tongue and groove from high-quality edged boards, the requirements of GOST standards are taken into account, which state that:

- When the board width is from 6 to 14 cm, it has a holistic structure; products with a larger width are produced glued.

- The board to be varnished must have a roughness of 120 microns, the products to be painted have a roughness of 200 microns. For the back side of the lumber, the roughness is 500 microns.

- If lumber is to be packaged in film, its moisture content should be 8%, in other cases – 12%.

DP made of pine

Profile of tongue and groove board

The advantage of wide boards made by gluing is their high strength and resistance to warping. In addition, it is more convenient to use.

As for the type of wood, budget varieties include lumber from pine and spruce, while larch and cedar are valuable species with a higher cost. Their advantage is that the structure of the wood contains a natural antiseptic and is therefore more resistant to negative influences.

Larch board

Note! Wood species that are not acceptable for making flooring material are linden and poplar. Materials made from alder and aspen (BP-27 and DP-27) have limitations - they can only be used for residential premises. It is also worth considering that aspen and alder are not used for the manufacture of DP-35.

Solid oak board

The tongue-and-groove board is equipped on the back side with one wide or several narrow cuts, which provide air circulation and compensate for the internal tension of the tree.

Several undercuts on the back provide natural ventilation

What to consider when choosing

Recommendations for choosing floor boards are as follows:

- A visual inspection is aimed at identifying defects (cracks, splits, stains). If at least one such drawback is detected, you should refuse to purchase these boards.

- Wood moisture content should not exceed 10%.

- It is necessary to pay attention to the geometric parameters of the board, check the tightness of the lock joint - there should be no cracks or gaps.

- A clean floor is usually installed from a board whose thickness does not exceed 2.2 cm, but in some cases, when there is a significant load on the floor, the material can be thicker.

- The optimal board length is two meters or more. Taking less is not recommended.

- The wood must be well-dried - when laying wet material on the floor, the boards will deform.

- Experts recommend purchasing material 15% more than the calculated quantity.

- The boards purchased must belong to the same batch so that they have the same pattern and color.

- It is also important that the shade of wood for the floor matches the color scheme of the interior.

- An important nuance is to unpack the products before storing them. If this is done in advance, the boards may become deformed.

Board grade AB

Video - Which type of wood to choose

Floor subfloor options

These types of floors can be installed on a wooden or concrete base or on the ground. Each option has its own technological features, which must be kept in mind during work. As for the specific purpose of the premises, taking this parameter into account, the base of the floor and its operational characteristics are selected. The technology of the device itself remains almost unchanged. There are, of course, options for warm and cold floors, but these features also have a common construction algorithm.

Installation of a wooden floor on joists on wooden bases

Such floors can be made in both wooden and brick buildings and can have several varieties. The features of flooring need to be considered at the building design stage. Not only the purpose of each room and its size are taken into account, but also the climatic zone of residence, microclimate requirements and the financial capabilities of the developer. Below are step-by-step recommendations for constructing this type of flooring.

Laying a wooden floor on joists in a wooden house

Wooden floor - photo

Depending on specific conditions, the algorithm can be slightly modified, but all main construction operations must be completed. The base can be moisture-resistant OSB boards or sheets of plywood. The design of the floor coverings provides for the possibility of laying insulation; the use of rolled and pressed glass wool or polystyrene foam is allowed. If there are insulation materials, then you should definitely install hydro- and vapor barriers.

roll waterproofing

Step 1. Take the dimensions of the room and calculate the number of joists, taking into account the above recommendations. Prepare materials and tools, make markings. Do the work slowly; mistakes made at this stage have extremely negative consequences. Eliminating them will take a lot of time.

Step 2 . Start installing the logs from the outer wall ones. If the room has subfloors, then the logs can be fixed directly to them. To make work easier, it is better to use metal squares with perforations; such elements significantly speed up work and increase the stability of the joists. Using the mark on the wall, taking into account the thickness of the floorboards, align one end of the joist and fix its position.

Installation of floor joists

Practical advice. When installing the outer joists, do not fix them immediately; first, you should only tighten the screws. This will allow you to make final fine adjustments.

Do the same actions at the second end of the log, constantly monitor its level position. Once the lag lays down normally, you can firmly fasten the ends and begin installing intermediate fasteners. The distance between them depends on the thickness of the boards that are used for the logs; it is approximately 70 centimeters.

Step 3. You need to stretch the ropes between the outermost logs; align all the remaining logs along this line. Constantly check with a level; installation accuracy should be ±1–2 mm. There is no point anymore, it takes a lot of extra time. A small difference in height will be removed during finishing of the front surface of the floorboards.

Step 4. If the floors are warm, then you need to lay thermal insulation between the joists; waterproofing and vapor barrier are used to prevent moisture from entering. The distances between the logs must be adjusted taking into account the length and width of the insulation. This can be either mineral wool or polystyrene foam, or bulk types of insulation. If all the preparatory work has been completed, you can begin laying the floorboards.

Laying thermal insulation between joists

Thermal insulation of the floor with mineral wool

There are options for installing joists on floor beams. These are so-called ventilated floors and are most often used for non-residential premises. There is no need to be particularly precise; size alignment is done using lags. The logs are attached to the beams with nails or self-tapping screws from the side. The algorithm of work is the same. First, the extreme ones are placed, a rope is pulled between them and all the others are fixed along it.

Laying lags on the beams of the lower frame

Ventilation is carried out through special vents in the foundations; the distance between the ground and the floor must be at least fifty centimeters. Otherwise, the air exchange rate does not meet the required indicators, and this causes damage to wooden structures.

Do-it-yourself concrete screed installation technology

Let's start the analysis with the simplest type of tie - tied, but in addition, this instruction will show steps for installing other types of tie.

Preparing the surface for pouring screed

Let's assume that floor slabs or pre-filled subfloors on the ground are used as the base, on which the concrete screed will be installed. For a bonded base, it is important to ensure good adhesion, that is, a good bond between the base and the poured layer. To do this, the floor surface is primed. In addition to adhesion, the primer will bind all the dust on the surface of the concrete.

The next step is to fill all the cracks and defects in the rough coating with cement mortar, so as not to leave any places for leaks in the future mixture. After repair and priming of the surface, an edge damper tape is glued around the perimeter of the room. The tape serves to compensate for the thermal expansion of concrete. Without the use of damping material between the screed and the wall, cracks are likely to appear on the surface of the screed.

Waterproofing the floor under the screed

Waterproofing the floor surface, as mentioned above, is used only for floating screeds or for screeds on a separating layer. There are two types of waterproofing of cement bases - coating and roll. When using coating waterproofing, its installation is carried out after priming and drying the surface, before installing the edge tape. This is done in order to apply a layer of waterproofing with an overlap of at least 10 cm on the walls.

As a roll waterproofing, as a rule, polyethylene greenhouse film is used, the strips of which are laid overlapping each other by 10-15 cm, as well as overlapping by 10 cm on the walls.

The joints of the waterproofing are glued with mounting double-sided tape or glue. Waterproofing the floor under the screed is mandatory for wet areas - the kitchen, bathroom and toilet, as well as rooms located on the ground floor, to prevent moisture from entering them from the basement.

Insulation of concrete floor screed

Like waterproofing, thermal insulation of the screed is not carried out for the simplest connected screed. The use of insulation is justified if a heated floor system is installed in the floor. In this case, the insulation layer will create a protective screen that prevents heat from escaping downwards. Otherwise, the heat from the underfloor heating pipes will heat not only the air in the room, but also the floor slabs, creating an excessive consumption of thermal energy.

The use of a layer of insulation is also justified to create sound insulation, which is important for the upper floors of private homes, or for apartments in apartment buildings.

For insulation, as a rule, dense sheets of expanded polystyrene or expanded clay are used. The latter has lower sound and heat insulation parameters, but is durable. If the screed is installed on the floor slabs above the basement floor, then the insulation can be laid as desired. If you do not plan to use a heated floor, then the cost of insulation will be recouped in the future by savings on heating.

Floor screed reinforcement

Reinforcement of a cement floor screed is most often carried out when installing a floating screed with heated floor pipes located inside it.

The modern market offers a new material for reinforcement - synthetic fiber. Adding it when mixing into the solution can significantly increase the mechanical properties of the screed, thanks to the creation of strong local bonds. However, this method of reinforcement is more suitable for monolithic screeds without the use of underfloor heating systems. For bases with heated floors, it will be more reliable to use traditional reinforcement methods.

For reinforcement, a special steel mesh is used or it is made from welded reinforcement, creating a mesh with a cell size of 50 to 100 mm. As a rule, ready-made mesh is not expensive, so making a reinforcement frame manually does not make sense.

The most important point when reinforcing a cement screed is the location of the reinforcement. Many people make the mistake at this stage of simply laying the reinforcement on the floor. With this arrangement, the fittings will not work. In order for the steel mesh to function as reinforcement, it must be located in the thickness of the concrete. To do this, you need to use special spacers that allow you to raise the reinforcement frame a couple of centimeters above the ground.

After installing the reinforcement frame, the heated floor system is laid out over it. Reinforcing mesh cells are convenient to use for fastening water pipes. It is important to remember even at the design stage that the use of a heated floor inside the screed increases its thickness, so the height of the room can be significantly reduced.

Installation of beacons for floor screed

To ensure that the surface of the concrete screed is smooth and its installation is easy and quick, a system of beacons is installed, the upper surface of which determines the surface of the future screed. Beacons are installed by level, dividing the room into several zones. Thus, they serve as guides for leveling the cement mortar as a rule.

The distance between the beacon profiles is not regulated and is selected based on the length of the rule with a small margin in order to carry out alternating translational movements to the sides. However, the distance between the wall and the first beacon should be no more than 20-30 cm, because Due to the inconvenience of leveling the mixture in such areas, significant unevenness and subsidence can form there.

Before installing the guides, it is necessary to determine the zero level of the screed, that is, the upper level of the beacon profiles along which the alignment will be carried out. This can be done in many ways, both ancient and modern. Let's consider one of the most modern and simplest methods available to almost everyone - determining the zero level using a laser level.

To begin with, the laser level is turned on and installed in the center of the room at an arbitrary height. Let's call the line that the laser casts on the wall the base line. Before determining the zero level, it is necessary to determine the highest point on the surface of the base. To do this, you need a regular tape measure, which measures the distance from the base line to the floor at several points in the room near the wall. In the place where the value is minimal, the height will be greatest.

At the highest point of the room, a segment is laid down from the base line minus the thickness of the future screed. For example, if a regular screed without insulation, 5 cm thick, is assumed, and the base line is marked at a height of 30 cm, then the segment is set aside at 25 cm. This will be the zero level of the future screed.

The same distance from the base line is laid out along the entire perimeter of the room, and then the points are connected into one line, forming the level of the future subfloor.

Next, they begin to install beacons. To determine the required zero level in the center of the room, the easiest way is to use lacing, which is attached to the wall at the places where the zero level is applied and is pulled in several places perpendicular to the direction of the beacons.

Regardless of the type of future screed, it is easiest to install beacons using a quick-drying solution. To do this, the mixture is applied in several places in small piles along the entire length of the beacon profile, which is recessed into these piles until it touches the previously tensioned lacing.

When installing a tied screed without using waterproofing, self-tapping screws with special beacon profile clamps can be used to install beacons. To do this, self-tapping screws are mounted directly into the floor slabs at a distance of 70-80 cm from each other, and the height of the lighthouse is leveled by unscrewing or tightening the self-tapping screw.

Before pouring the screed, you must wait until the solution in which the beacons are embedded has completely dried. Otherwise, when working as a rule, the horizontal level of their installation may be violated, which will lead to unevenness in the finished screed. When installing beacons on self-tapping screws, you can fill them immediately.

Preparation of cement mortar for pouring screed

Preparing the solution is one of the most important stages, because the strength and integrity of the future coating will depend on its quality. According to current building codes, the mortar for pouring screed must have a grade of at least M-150. For this, either a home-made solution, mixed directly on site, or a ready-made solution, delivered to the site with a mixer from the nearest concrete plant, is suitable.

When mixing the solution yourself, you can use ready-made purchased mixtures, available in a large variety on the market, or use the classic combination of cement, sand and water. To make your own cement-sand mortar, the ratio of these components should be 1:3 (1 part cement and 3 parts sand). The choice of sand must be approached with special attention. As a rule, preference is given to fine quarry sand, sifted through a sieve and cleared of impurities in the form of stones and clay. This sand binds best to cement and gives the best mortar consistency.

In both the first and second cases, it is important to choose the right amount of water for mixing. If there is excess moisture, the screed will shrink too much, and the strength properties of the cement will also be lost. On the contrary, if there is a lack of moisture, the solution will certainly crack, compromising the integrity of the screed. The ideal consistency of the solution should resemble thick sour cream.

Installation of floors on wooden joists on concrete

Such floors are considered more complex, labor-intensive and expensive; all wooden structures must be reliably protected from direct contact with concrete. Otherwise, the structures will quickly become unusable and will have to be replaced prematurely. There is a chemical way to protect lags from rotting processes using various impregnations. They are quite effective and actually prevent the process of wood deterioration. But unfortunately, impregnated wooden structures can no longer be considered environmentally friendly, and it is for this indicator that most developers install natural wooden floors.

If the logs are laid over the entire area on concrete, then waterproofing is required between them.

Waterproofing is laid between the floor joists and the concrete base

But they can also be secured using metal squares, which allows you to create a gap between the base and the joist. It must be borne in mind that in this case the load-bearing characteristics of the floor are somewhat reduced.

Attaching joists to the floor with corners

Fasteners for joists

- Make an exact marking of the position of the joists on the concrete screed, mark the line with a rope with blue.

- Using a drill and a Pobedit drill, drill holes for the angles; the distance between them is selected depending on the size of the lag.

Fixing corners

- Align the two opposite ends of the lags according to the marks and level, attach them to the squares. Check the position with a level.

- Fix the remaining angles to the joists under the level.

In the photo there are fixed logs

This fixation method has its advantages. Firstly, direct contact of wooden structures with concrete ones is completely excluded. Secondly, logs can also be installed on a black screed. Using corners, you can eliminate irregularities of several centimeters; there is no need to make a finishing screed. This saves a lot of time and money.

Adjustable supports for floor joists

Boards or sheet materials are laid on top of the logs

The second method of laying on a concrete screed is to lay the logs directly on it; a material based on modified bitumen is used for insulation.

Laying logs on the ground

The method is used for outbuildings, bathhouses, gazebos, verandas, etc. The wood must be treated with antiseptics. It is better to have a columnar foundation; if you want to make a more durable strip foundation, then it is necessary to provide vents for natural ventilation in advance.

Floor on joists on the ground

How is this floor made?

Step 1. Remove the topsoil. You can use it to fill the beds or level the area in front of the house.

Removing a layer of soil

Step 2 . Mark the columns. The distance between them is selected taking into account the load and size of the logs. The posts can be made of concrete, block or prefabricated. The dimensions of the supports are approximately 40x40 cm, the burial depth is within 30 cm. A layer of sand ≈ 10 cm thick should be poured onto the bottom and compacted.

Step 3. Fill the supports with concrete. To prepare concrete, you should use two parts crushed stone and three parts sand for one part of cement. Water is added as needed. There is no need to make formwork in the ground; formwork from boards or OSB scraps is installed above the ground level. During the manufacture of formwork, you need to use a level; all edges must be strictly vertical.

Wooden floor base

Ready-made concrete pillars

Practical advice. It is much easier to make columns from ready-made blocks. Horizontal alignment must be done along the rope. After the outer ones are aligned with the hydraulic level, a rope is pulled between them. Deviations should not exceed ± 1 cm. This variation is eliminated during installation of the log.

Installation of blocks under logs

Laying columns under plank floor joists, diagram

Step 4. Start fixing the lags; you should also start work from the outermost ones. For precise horizontal alignment, you can use shims. It is not advisable to take wedges made of wood; over time, they will dry out and wobble will appear: the floor will begin to creak unpleasantly when walking. Between wooden structures and concrete surfaces, it is imperative to place two layers of roofing material for reliable waterproofing.

Joists laid on supports

Step 5. After the outermost logs are laid, a rope is stretched between them and all the remaining ones are laid under it. The logs are fixed with metal squares on dowels and screws. To increase stability, it is recommended to install them on both sides. Floor boards can be laid directly on the joists or a subfloor can be laid first. The final choice depends on the characteristics of the operation and purpose of the room.

Wooden floor on joists

Joists laid on blocks and waterproofing

Methods for fastening tongue-and-groove boards

As already mentioned, it is best to make a wooden floor in an apartment from tongue-and-groove boards. It is made from dry calibrated boards, which is why the price is higher. It can be attached in two ways: in a tenon and in a groove. The tenon is considered more reliable, because it turns out that 2/3 of the thickness of the board is “grabbed.” While when fastening a tongue-and-groove board into a groove, it holds only 1/3 or less - depending on the shape of the tongue.

How to lay a wooden floor with your own hands: choose the type of fastening of the tongue-and-groove board

One more thing. Either in a tenon or in a groove, the screws are placed at a small distance from the edge. To avoid peeling/cracking of the wood, pre-drill holes. Yes, it takes a long time, but a cracked tenon/groove is almost a guarantee of a squeak. The fixation is far from being the same, the board begins to “walk”, hence the creaking.

Professional advice on choosing lags

Coniferous wood should be used for logs.

Larch logs

If possible, materials should be impregnated with antiseptics. These are very effective means for protecting wood not only from fungi, but also from many pests.

wood antiseptic

Antiseptic for wood

Antiseptic

Always select joists with a safety margin, especially in cases where the installation method involves bending loads. It must be remembered that correcting mistakes made during the construction of flooring always costs much more than carrying out the work with high-quality materials and in compliance with recommended technologies.

Logs from boards

Choose your joist boards carefully. They must be absolutely healthy without signs of rot. The presence of through cracks and rotten knots is completely prohibited. If there are large healthy through knots, then you need to install the joists in such a way that there is a stop under them.

When attaching the logs, do not allow the possibility of wobbling.

Fix the joists firmly

Most loose joists cause very unpleasant squeaks in the flooring while walking. To eliminate such phenomena, you will have to remove floor coverings; this is time-consuming and expensive; it is not always possible to keep the dismantled materials in a condition suitable for reuse.