Wet grass underfoot, foggy windows, droplets on the walls of a damp basement - all this is the result of condensation of water vapor from the atmospheric air. Everyone has encountered this, but not everyone was interested in how to determine the dew point. Most often, this task has to be solved by architects, builders and designers, and people far from this area are hardly familiar with this concept.

How to determine dew point

The nature of the appearance of dew

Water condensation on various surfaces occurs as follows. Atmospheric air is always saturated with water vapor to one degree or another. Water changes from a gaseous state to a liquid state when its temperature decreases. This occurs when atmospheric air comes into contact with colder surfaces and subsequent heat loss. The result is the appearance of water droplets.

Morning dew is easily explained by the laws of physics

The temperature at which water vapor from the air passes into a liquid state is called dew point .

The higher the content of water vapor in the air (or other mixture of gases), the higher the condensation temperature of water, or dew point. So, with a relative air humidity of 100%, the dew point exactly coincides with its temperature. And vice versa: the lower the relative air humidity, the lower the dew point. This means that for condensation to fall out, you will have to cool the air more.

Studying the dew point in construction

Regulations

The need to calculate the dew point is regulated by building codes and regulations. SP 23-101-2004 “Design of thermal protection of buildings”, as well as SNiP 23-02 “Thermal protection of buildings”. Insufficient insulation moves the dew point closer to the room.

Since the temperature in the area of window units or doors is lower than the overall calculated dew point, condensation in these segments is inevitable during the cold season. Determining the dew point is important for deciding which side to carry out insulation work on and what thickness it is more appropriate to purchase insulation.

Table . Dependence of wall material thickness on thermal conductivity

| Wall material | Coeff. heat-conducting I , W/(m* o C ) | Required thickness in meters |

| Expanded polystyrene | 0,039 | 0,12 |

| Mineral wool | 0,041 | 0,13 |

| Reinforced concrete | 1,7 | 5,33 |

| Solid silicate brick masonry | 0,76 | 2,38 |

| Perforated brickwork | 0,5 | 1,57 |

| Glued laminated timber | 0,16 | 0,5 |

| Expanded clay concrete | 0,47 | 1,48 |

| Gas silicate | 0,15 | 0,47 |

| Foam concrete | 0,3 | 0,94 |

| Cinder concrete | 0,6 | 1,88 |

Minimizing heat loss and maintaining a comfortable microclimate are the top priorities when designing and insulating buildings. Compliance with building rules and regulations, as well as sanitary and hygienic standards, will allow you to competently prepare engineering documentation and calculate the volume of required building materials.

Scope of the concept

This term is widely used in industrial and civil construction. The need to determine this value arises when insulating the walls of a room. If you neglect to calculate this indicator, problems will appear after insulation work. One option is damage to the wall finish due to settling moisture. If the finish is tolerant of water, but drops of condensation will fall on the walls, there is nothing good about it either. A humid environment promotes the development of pathogenic microorganisms and mold.

In aviation, dew point is also calculated. During the flight, condensation occurs on some parts of the aircraft. In this case, the condensate freezes and parts of the aircraft become icy.

Ignoring the dew point can lead to a plane crash.

This value is also used in forestry. Forest fire protection specialists use the dew point to calculate the fire hazard class, which characterizes the possibility of forest fires. Based on this, protective measures are designed.

Dew point is used in calculations for planning fire prevention measures

In agriculture, knowing the dew point, the probability of damage to crops by non-infectious diseases (damage caused by weather conditions) is determined. At the same time, one of the tasks of breeding is to develop varieties of cultivated plants capable of condensing moisture from the air on their vegetative organs. This will allow successful farming in conditions of low rainfall.

Dew point placement

Comfortable values for a person

For most people, conditions with a point value in the range of +10…+15℃ are optimal. If the indicator increases, then the person feels discomfort. When the point value is less than +10℃, the environment becomes dry, and from +15℃ humidity begins to be felt. If the indicator is above +20℃, it becomes stuffy. People with heart and respiratory problems are more susceptible to environmental parameters than others.

The dew point temperature determines the comfort level of living in the house

How to calculate dew point

According to the mathematical formula

Carrying out calculations manually using a formula is a fairly accurate method. However, to use the formula, you must first determine several other indicators. The formula looks like this:

Formula for calculating dew point

As can be seen from the figure, a and b are constant quantities. T – air temperature. Rh – relative air humidity. This calculation method will give results with an error of 0.5ºС.

Using an online calculator

Since manual calculation using a formula is not suitable for everyone (due to insufficient knowledge in mathematics or lack of time), online calculators are publicly available on the Internet that calculate the dew point based on the entered information. Using them is absolutely simple: you just need to enter the initial data (ambient air temperature and relative humidity). The result of the calculations will appear on the screen.

Calculator programs

Not everyone can relate the dew point indicator and the expected consequences of improper insulation. This requires specific knowledge in physics and construction. Therefore, in addition to conventional calculators that calculate this value, programs with advanced capabilities have been created. They are also freely available and can be used online.

Such programs take into account many parameters when calculating:

- The locality in which the building was built (is under construction). Statistics of average monthly temperatures, relative humidity, and pressure in this region immediately appear.

- Type of room. Obviously, the air humidity in the bathroom will be higher than in the room, and this in turn affects the type of permissible insulation.

- Construction type. Here you can choose from a wall, ceiling, attic floor and other positions.

- Layers of construction. Here it is taken into account what is located behind the insulated wall - another room or street.

- Floor or wall material.

- Temperature and relative humidity of indoor and outdoor air.

After filling in all the required fields, the program will create a dew point graph.

Dew point determination table

If you need to quickly obtain the dew point value, tables are used. The table data is very inaccurate and gives approximate results. But they are easy and quick to use: you just need to find the desired cell at the intersection of the column and row with the desired temperature and relative humidity.

Table 1. Determination of dew point by two indicators.

Determination of dew point by two indicators

Special tools

In meteorology, special tools have been invented to determine the dew point. However, even to calculate using a mathematical formula or any other method described above, you need your own tools.

Temperature is measured with a thermometer, humidity with a hygrometer. For convenience, in this case, a tool capable of measuring both temperature and air humidity is suitable - a digital thermohygrometer.

This instrument combines the functions of a thermometer and a hygrometer.

In addition, there are devices that combine several functions: measuring temperature, humidity, calculating dew point and storing information.

In most cases, working with such a device looks like this.

- Turn on the device. Pay attention to the battery charge.

This is what one of the popular devices looks like - Place the tip of the sensor at a right angle to the surface under study.

The correct position of the device will ensure accurate measurements - To hold the measurement data, press the Hold button in the menu. This way you can view the results in a comfortable position of the device.

Recording does not mean saving - To save the data, click the Save button.

The ability to save eliminates the need to write data in a notepad - If you need to transfer information to a computer, connect the device to the network via USB.

Connecting a dew point meter to a computer is no more difficult than a mobile phone - Copy the data to your computer.

Computer – reliable data storage

Working with devices for measuring dew point is simple even for a person without special training. The interface is intuitive, and if you have any questions, please refer to the instructions.

What material is used for finishing floors?

As we have already found out, external thermal insulation allows you to achieve a better effect compared to internal one. In addition, such insulation protects the building from negative environmental changes and mechanical damage, which makes it durable. However, in order to reliably insulate walls, it is necessary to choose the right insulation material.

Despite the fact that there are different air temperatures outside and inside the house, the same insulation options are used in both cases. However, the following requirements apply to materials for external insulation:

- resistance to shrinkage and damage;

- durability;

- resistance to sunlight;

- ease of installation.

Examples of insulation of concrete and brick walls

For buildings made of wood, the ability of the material to transmit steam is of great importance, because such floors must “breathe”. According to the rules, it is assumed that the insulation will be used for a long time, and replacing it every few years will be impractical. Therefore, it is important to choose the right façade layer.

Table No. 1. Types of insulation for walls

| Title, illustration | Characteristic |

| Mineral wool is made from the finest fibers, which are obtained after glass is melted. According to the location of these fibers, the structure of the material differs (layered, corrugated), it has different thicknesses. Moreover, each subtype of mineral wool is characterized by individual characteristics: 1. Glass wool. Due to the content of limestone and various chemical components, the material is resistant to high temperatures (up to 480 degrees). 2. Stone wool. It is made from fibers of various rocks, therefore it has a high density, which is why it can withstand heating up to 580 degrees. 3. Slag wool. Produced from waste from the metallurgical industry. It is heat resistant up to 280 degrees and is also waterproof. This material can be found on sale in both slabs and rolls with various coatings (paper, foil, aluminum). The positive qualities of this material include: 1. It has a structure with small fibers, which promotes normal air circulation and the passage of steam. Therefore, practically no condensation forms on the surface. 2. The mineral base makes the material resistant to fire, which is also additional protection. 3. The material has better resistance to humidity. Therefore, the risk of dampness entering the room is reduced. 4. Mineral wool allows you to achieve sound insulation of the room. 5. Various microorganisms and insects do not settle in this synthetic material. Among the disadvantages, it is noted that mineral wool shrinks over time and becomes deformed with constant contact with moisture. In addition, it is problematic to install, due to the fact that glass particles get on the skin and cause irritation. |

| Insulation based on this material allows you to achieve optimal thermal insulation due to its characteristic cellular structure. The slabs practically do not absorb moisture, which means they are suitable for finishing any objects. Some advantages of expanded polystyrene should be noted: 1. The slabs have minimal weight, which greatly facilitates the installation process, so even an inexperienced craftsman can handle this process. In addition, such a layer does not overload the floors. 2. This synthetic material does not develop mold because it is not exposed to microorganisms. 3. If the installation rules are followed, the service life of the material is about fifty years. 4. This material is resistant to aggressive alkali and other chemicals. 5. During the installation process, workers do not have to use special protective equipment for their hands and face, as when working with mineral wool. Among the disadvantages of the material, it should be noted: 1. Expanded polystyrene does not allow steam to pass through, which means it cannot be used if there is a timber structure. 2. The material is destroyed when exposed to certain oily substances and ultraviolet rays. 3. The material is inferior in noise insulation properties to previous insulation materials. 4. When heated, it releases toxins that are hazardous to health, and in the event of a fire, their quantity increases significantly. |

| Otherwise, cellulose insulation is also commonly called ecowool; it is made from paper industry waste. It turns out that 85% of the composition is cellulose fibers, and the remaining 15% are antiseptic components. This material is placed in all empty holes, resulting in durable insulation. It can be mounted either dry or with the addition of glue. With dry installation, craftsmen quickly cope with the process, and then proceed to other finishing work. However, such insulation will not be entirely reliable, therefore, by adding glue, the resistance of the insulation to any aggressive influence increases. This means that the second option will be preferable due to its high performance. The main advantages of the material: - safety from an environmental point of view; — excellent thermal insulation and noise insulation; — fire resistance; - budget cost. Among the negative aspects, the possibility of shrinkage during long-term use should be noted. |

Prices for mineral wool

Minvata

Video - Calculation of insulation thickness

The importance of determining dew point

If you do not take into account the position of the dew point in the wall, a series of negative events will follow.

The insulation material quickly becomes unusable, and the service life of the wall material itself is reduced. Due to regular wetting, the finish will not hold up: the wallpaper gradually peels off, the plaster crumbles, and the paint peels off. Due to excess humidity in the room, mold, mildew and other pathogenic microorganisms develop in a short period of time on walls, ventilation systems, ceilings and other surfaces.

Ignoring the physical nature of condensation can lead to unsanitary conditions in the room

Some facts

The issue of the position of the critical point in the wall is removed if you cover it from the inside with a vapor barrier material. Some types of finishes, such as vinyl wallpaper, have these properties. No steam enters the structure, and it will be dry regardless of the temperature distribution. The exception is the case when the wall freezes through and the critical point is on the inner surface.

Covering enclosing elements with vapor barriers is practiced in Western European countries. But this solution has a drawback: to remove excess moisture, you have to increase the air exchange rate, i.e. ventilation performance. This entails an increase in heat loss and, as a consequence, heating costs. A house with “breathing”, i.e. vapor-permeable walls are cheaper.

How does dew behave on uninsulated walls?

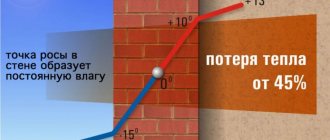

With uninsulated walls, there are several variations in the behavior of the dew point. In some situations, it is located in the inner space of the wall - closer to the street or closer to the room. In the second case, with a strong decrease in temperature, the place of steam condensation will shift to the inner surface of the wall. Then drops of condensation will certainly form on its surface.

Uninsulated walls often get wet

In some cases (cold building frame material), the dew point can be located indoors all year round, that is, on the inner surface of the wall. Then it is necessary to make applied calculations and take care of the insulation of the wall, taking into account the climatic characteristics of the locality in which the building is located.

In general, the location of the dew point in a ceiling or wall is interconnected with a number of physical factors:

- humidity of outdoor air and indoor air;

- outdoor and indoor air temperatures;

- thickness of the ceiling or wall.

Experts' opinion

Experts believe that the best thermal insulation option is mineral wool. If installed correctly, the material will not cause harm and will last a long time. The main thing is to avoid high humidity. To do this, the cotton wool is additionally covered with a film that limits the access of moisture.

Another option is to install breathable materials on both sides of the insulation that will release liquid to the outside. It is recommended to lay polystyrene foam or expanded polystyrene in combination with materials that do not allow water vapor to pass through and prevent moisture condensation.

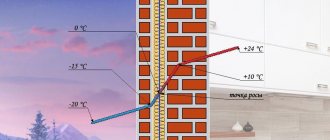

Dew point in externally insulated walls

With the correct selection of material and correctly calculated thickness of the insulating layer, the dew point will always be in the insulation and will never move towards the inner surface. The walls are dry all year round. Only the insulation is damaged by weather conditions; the wear of the walls slows down.

External insulation is the surest protection against condensation in the apartment

If the thickness of the insulation is less than required, or the thermal conductivity of the material has not been taken into account, the dew point will behave in the same way as in an uninsulated wall, that is, moisture will continue to accumulate in the room if it accumulated before insulation. If this happens, there is only one way out - to increase the thickness of the insulating material. This can be done by adding another layer of thermal insulation or replacing the old material with a new one of suitable thickness.

If the insulating layer is excessively thick, the dew point will not go beyond its limits throughout the year. This will not entail any negative consequences: the wall will be dry all year round. However, calculations are made in order to avoid unreasonable financial expenses. After all, if you can escape moisture and retain heat with less insulation, then why spend more?

Should I insulate the walls inside or outside?

Possible consequences

Improper installation of thermal insulation can lead to unpleasant consequences. The material is applied only to the facade, since additional insulation from the inside is considered impractical for the following reasons:

- Living space is decreasing.

- The wall freezes because the heat from the room does not reach the ceiling. As a result, condensation penetrates inside the thermal insulation. The wall is wet and subject to corrosion.

Poor installation results in wall destruction. If the surface under the insulation is uneven and old, it will have to be reapplied, after making repairs. If the insulation on the outside is not additionally covered, then in one season it will become wet, become unusable and begin to move away from the walls. The thermal layer must be protected from the external environment.

Video: Removing the dew point from the wall

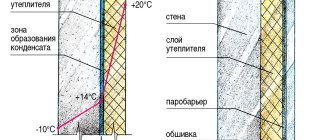

Dew point in internally insulated walls

Insulating walls only from the inside inevitably leads to a shift in the dew point towards the room. This happens because the thermal insulation material retains heat in the room, thereby making the wall colder. And, as you know, the colder the surface, the more likely it is that air moisture will condense on it.

If at normal temperatures for a given region the dew point is located close to the inner surface of the wall and does not cause any inconvenience, then on particularly cold days it can move into the room, that is, onto the inner surface of the wall. Then the wall will get wet under the insulation.

If moisture constantly accumulates on an uninsulated wall, then after work on the internal insulation of the room, the wall will continue to get wet under the insulation throughout the cold season. This will lead to gradual deterioration of all layers of building materials located on the inside of the wall, including the finishing.

Internal insulation does not protect against getting wet

In some cases, after internal insulation of a normal wall, the dew point changes location to the insulation. Then, throughout the winter, not only the wall will be wet, but also the thermal insulation material itself.

One way or another, in order to avoid damage to the finish and internal insulation layers, you need to remember one simple rule: insulation of the inner surface of the wall is carried out only after its external insulation.

Factors influencing heat loss

Thermal processes correlate well with electrical processes: temperature difference acts as voltage, heat flow can be thought of as current - there is no need to create a special term for resistance. The concept of least resistance, called thermal bridges in heating engineering, is also completely correct.

If you consider any material in cross section, it is quite easy to determine the path of heat flow at both the micro and macro levels. As the first model, we will take a concrete wall in which, due to technological necessity, the through fastenings are made with steel rods of arbitrary cross-section. Steel conducts heat slightly better than concrete, so three main heat flows can be distinguished

- From steel bars to concrete

- Through the thickness of concrete

- Through the steel bars

Heat loss through thermal bridges in concrete

The most interesting model is the final heat flow. Because the steel core heats up faster, the temperature difference between the two materials will occur closer to the outside of the wall. Thus, the steel not only “pumps” heat out itself, but also increases the thermal conductivity of the adjacent concrete masses.

Thermal processes in porous media proceed according to a similar pattern. Almost all building materials consist of an extensive network of solid materials, between which there is a space filled with air. Therefore, a solid, dense material is the main conductor of heat, but due to its complex structure, the path along which heat moves is larger than its cross-sectional area. Therefore, the second factor determining thermal resistance is the heterogeneity of each layer and the entire building envelope.

Reducing heat loss and shifting the dew point in the thermal insulation of external walls

About the dew point in plastic windows

When it comes to the dew point in double-glazed windows, many people imagine some specific mysterious place. In reality, the dew point cannot be seen, as we have already found out. Let us repeat: dew point refers to the temperature at which, when cooled, the vapor in the air becomes saturated and condenses. There are special tables that allow you to calculate the dew point at relative humidity and a specific temperature. One such table is shown below.

Dew point at relative humidity

On a note! Let’s say the air humidity is 50% and the temperature is +21 degrees. Under such circumstances, the dew point will be +10.2. What does it mean? If the temperature of any surface in the apartment drops to +10.2 degrees, then condensation will begin to appear on it (the surface). As a rule, the coldest surfaces in the apartment are plastic windows, and therefore it is on them that in most cases excess moisture falls.

People often experience condensation on double-glazed windows. Based on everything said above, we can conclude that condensation can be dealt with in two ways - by increasing the temperature of the glass and reducing the humidity in the apartment. Thus, comfortable humidity can be achieved by ensuring normal air exchange. All excess moisture comes from washing, boiling pots, etc. – should leave the room and not accumulate in it. First of all, the apartment should be regularly ventilated. The frequency of ventilation is determined individually, but we recommend doing this for at least 10 minutes twice a day. Don’t forget about special supply ventilation valves.

Useful tips

Ventilation must be ensured in such a way that the relative humidity in the home does not exceed normal values (40%-60%). This requires an air flow from outside. In houses and apartments with natural ventilation, it should enter through the cracks in the windows.

But when you replace windows with sealed vinyl windows, there is no air flow. Ventilation does not work, even if the exhaust ducts are equipped with fans. This problem can be solved by installing window or wall valves.

Also make sure there is a gap under the inner door.