Home > For buyers > Useful articles > Sauna stoves > 6 unique features of EasyStim sauna stoves

What do you need for a good bath? Fire, water and hot stones! It is these three components that create a real “bath miracle”. And the right stove made of high-quality materials and with a well-thought-out design will help to combine them into one whole!

The ratio of temperature and humidity in a steam room can be different, so there are several options for dry-air and wet baths. The EasySteam stoves we offer from the Anapa, Sochi and Gelendzhik series are able to accurately recreate the atmosphere of a traditional Russian bath, and models from the Yalta series have two modes available - a wet bath with a low temperature and a hot dry-air sauna.

EasySteam stoves are produced by a Russian company founded in 2005. The experience and skill accumulated over this time allow the company to continuously improve stoves, combining the best achievements with useful innovations in each model.

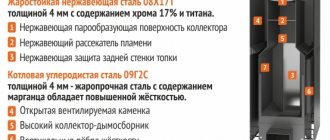

Heat resistant stainless steel

For the manufacture of EasySteam sauna heaters, thick sheet stainless steel AISI 430 is used. Due to its low carbon content and fairly high chromium content, it is ductile and has corrosion resistance not only in natural conditions, but also at temperatures from 500 to 800°C.

AISI 430 steel is also characterized by:

- low coefficient of thermal expansion, thanks to which products made from it are not afraid of temperature changes;

- low thermal inertia, which allows you to warm up the stove in a short time with moderate fuel consumption.

Closed heater with thermal valve

In EasySteam stoves, the heater is located directly above the firebox, so the maximum amount of heat is transferred to the stones. It has a complex geometric shape with a semicircular bottom, which ensures uniform load distribution. The weight of the loaded stones depends on the model of the sauna stove.

The Yalta series stoves also have an external open heater - a layer of stones laid behind an openwork steel casing around the firebox and inner heater.

All models of EasySteam stoves are equipped with a thermostatic valve. By opening or closing it, you can speed up the transfer of heat to the steam room or increase the heating of the stones.

Analysis of bath units of the Sochi series

Sauna stoves of the Sochi series are designed to work in steam Russian baths. They are produced with a closed heater, separated from the environment by a simple housing. You can cover the heater during the assembly and installation process with a stationary sheet of metal or brickwork. If desired, you can make an imitation of bath stones laid openly directly on top of the top panel. However, such masonry cannot perform the function of generating steam; its destiny is decoration.

Description and technical features

Units for Russian steam rooms from the EasySteam company are made of heat-resistant materials. The body and structural elements of sauna stoves are extremely resistant to intense exposure to high temperatures, alternating with the supply of cold water. The production uses steel alloys with a chromium content of 17% or more, which guarantees high strength. The smallest wall thickness of the metal elements is made of stainless steel AISI 430 4 mm, and the heater is made of alloy steel AISI 439 6 mm. Also, at the customer’s request, it is possible to install Wolfshoher Tonwerke (made in Germany) heat-insulating material (fireclay slabs) in the combustion chamber. The manufacturing technology is dominated by stamping, rolling, and bending technologies, thanks to which the number of welds weakening the structure is reduced to a minimum.

Convection channels (2) are formed between the body (1) and the internal components of the stove, increasing heat transfer. They are located along the back and side walls of the oven. The chimney is surrounded by a bent-stamped tank of a heater (3) - one of the main working parts of Russian bath units. Water is supplied to the heater through a pipe designed to release steam (7).

In addition to the convection channels, the task of fully heating the heater is solved by the labyrinth chimney (6), which runs along the central axis of the tank. According to this original solution of the designers, the masonry is heated both from the outside and from the inside. To prevent direct flame from entering the chimney, the lower entrance to it is equipped with a divider (5), due to which only combustion products enter the chimney channel.

The formation of finely dispersed steam is carried out by a steam generator (8), which is a complex system of vertically and horizontally installed tubes. Horizontal elements are perforated along the entire length for uniform steam release. A dispenser (9) with a check valve is attached to the top of the steam generator, preventing the movement of vapor in the opposite direction. Before starting the fire, the dosing device is checked for functionality. You just need to unscrew it and shake it. If the valve inside moves freely in both directions and rattles when it touches the edge, you can start heating the sauna stove.

The structure of the firebox differs little from the usual folk standards. At the bottom, as usual, there is a grate (11), which is necessary to create traction. There is an ash pan (15) to remove combustion products. A useful innovation is the presence of protective screens (4) on the inner surface of the combustion space. They optimize the transfer of thermal energy to the bottom of the heater and protect the walls of the firebox from overheating.

The facade of the stove (14) is equipped with a combustion door for storing fuel, equipped with large heat-resistant glass. A fuel channel (13) is separated from it, making it possible to load firewood from the room adjacent to the steam room.

Focusing on taste preferences and financial capabilities, the future owner selects the lining for the stove and stones to put in the heater tank.

Foundation for a solid sauna stove

The weight of the Sochi stove, which inspires sincere confidence, almost in an ultimatum form dictates the need to build a foundation. The physical weight of the unit with stones alone reaches 200-260 kg, depending on the model. The weight of the stone or brick casing should be added to it. And it, for example, from a coil is 240 kg. Such a colossus, especially with a stone cladding, cannot simply be installed on the floor. The foundation for its installation must be solid, sufficiently powerful, reinforced concrete.

When choosing a place to build a foundation, the following rules must be observed:

- Only this can be installed on the base under the sauna stove. It is impossible to combine the foundation of the building itself and the stove itself due to the difference in load. The soil and the foundation structure itself under the unit and under the walls of the bathhouse sags by different amounts. It is permissible to place a stove and a separate chimney system on the same foundation.

- The distance between the foundation for the stove and the foundation of the building should be 30-50 cm to ensure that both structures move independently from each other during settlement.

- Dimensions of the foundation in plan, i.e. its width and length are determined based on the actual dimensions of the unit, taking into account the thickness of the cladding. If the flooring will rest on the stove foundation, then the size of the foundation should be increased by 10 cm around the perimeter. However, it is better to install separate supports under the flooring.

The depth of the foundation is determined by the depth of seasonal freezing in a particular region. The underground structure should be deepened below the readings determined by the meteorological service by 220 mm. For example, when installing a bathhouse in the Moscow region on loamy or clayey soil, the foundation pit for the stove must be dug to a depth of 1320 mm, because the depth of seasonal freezing there, verified by many years of observations, is 1100 mm.

It is completely in vain that the depth of seasonal freezing in private construction is sometimes not given due attention. But it affects specifically light private buildings, and not heavy high-rise buildings. Rocks containing groundwater tend to expand when frozen because... the volume of ice is significantly greater than the volume of unfrozen water. Following changes in volume, the foundations of low-rise buildings move, rising in winter and returning to their previous positions when thawing.

Ground seasonal movements are not uniform due to the chaotic location of water in the rock. As a result of uneven movement, cracks appear in reinforced concrete foundations, followed by destruction. Prefabricated foundations made of blocks or bricks behave much worse. In the best case, uneven settlement will be indicated by a distortion of the furnace resting on the foundation, in the worst case – depressurization of the chimney exhaust system with all the ensuing catastrophic consequences.

Protective screen for wood stove

The screen of sauna stoves of the Sochi series from EasySteam is made of heat-resistant solid brick, soapstone slabs and a coil. When using hollow ceramic bricks, all technological voids of each element are filled with dry sand in order to increase the heating of the stove lining.

A stone or brick screen built around a sauna stove performs several undeniably significant functions, these are:

- Preservation of the heat released during the heating process, so there is no need to constantly add firewood.

- Protection of steamers from burns and direct radiation.

- Formation of additional convection channels that provide microclimate regulation in the steam room.

In addition, the presence of a screen ensures complete drying of the room and increases the prestige of the interior.

Organizing a protective screen is a delicate matter, requiring strict adherence to a number of important rules:

- The screen walls must be interconnected and form a single casing.

- The laying is done on a pre-prepared base that has had time to harden.

- Either a refractory oven mixture or a clay solution is used as a binding solution. The use of cement and adhesive compositions is unacceptable, because when heated they release toxins and are destroyed.

- The chimney is constructed using a metal insert. The best option is a chimney built separately from the stove.

- The screen is laid in a quarter of a brick for chopped wooden bathhouses. A half-brick screen is used to equip bath structures without massive wooden elements that need careful drying.

- The minimum height of the screen is 30-50 cm greater than the height of the stove.

- The distance between the stiffening ribs of the unit and the inner wall of the screen should be no more than 3 cm. If the convection channels formed as a result are larger, the bath will take longer and heat up worse.

- Convection screen doors should be installed at the shortest distance from the floor. The doors will ensure that cold air is drawn in from the bottom surface of the bath, heated and released in a heated state. This eliminates the problem of cold floors.

- The recommended height of the front wall of the screen is equal to the distance between the floor and ceiling in the steam room.

The technology for organizing a screen made of stone slabs is no different from the method for constructing a brick analogue. There is a difference in its construction for specific models. However, the manufacturing company provides its products with detailed instructions with a clear description of the specifics of the process.

Water heating system

The system designed for heating water is a circuit with two functional components, these are:

- Heat exchanger attached to the side wall of the unit. In fact, this is an ordinary rectangular container, the internal volume of which is 8 liters. At the top and bottom of the heat exchanger there are two fittings for connecting the pipeline from the storage tank.

- A remote tank equipped with fittings for connecting the pipeline, a tap for drawing heated water and a fitting for discharging excess steam. The tank is filled through a neck equipped with a sealed lid. Buyers choose the configuration and volume of the storage tank in accordance with their own needs.

The circuit operates on the principle of a miniature hot water supply system.

Preparing the unit for operation

Wood-burning stoves are allowed to be installed in a room with properly functioning ventilation. In the steam room, it is recommended to organize a supply and exhaust system that guarantees complete removal of combustion products. The presence of a ventilation window is a prerequisite for the natural removal of carbon dioxide. Place it in the corner of the steam room farthest from the stove at the maximum possible height. Supply ventilation should ensure the supply of fresh air from the street. Its channel is connected to the gap between the stove body and the protective screen to optimize traction.

Before installing the unit on the foundation in the steam room, you need to carry out the first firebox outside so that the remaining industrial contaminants and dust burn out. The duration of the first fire is 4-5 hours. During the installation process, you should scrupulously follow the requirements and recommendations of the manufacturer indicated in the instructions. Before starting up the sauna unit, a thorough check of the organization of all components and testing for functionality is carried out.

The stones are placed through the neck of the heater, located on the top panel of the stove. For the laying, natural stones with excellent heat capacity are used that can withstand the onslaught of high temperatures. The lower part of the heater tank from the bottom to the steam generator is filled with large stones, the upper part with their counterparts of the middle fraction, and the voids between them with small ones. Going overboard with the weight of the bookmark is extremely undesirable. Just like forming a monolith out of stones without air channels to provide ventilation.

Tubular steam generator

"Enjoy Your Bath!" - Everyone has heard this wish at least once. But is the steam in a bathhouse always really light? And what does this depend on?

Light steam does not burn the body or make breathing difficult, but pleasantly warms and gives a feeling of comfort. But such steam can be obtained only in one case - by supplying water to hot, rather than slightly heated, stones.

Such conditions can be ensured either by a large mass of stones, which needs to be heated for a very long time, or by a special design of the sauna heater. EasySteam engineers took the second path, placing a tubular steam generator in the closed heater of their furnaces. Water enters it through a dispenser with a check valve, is heated in the pipes and distributed in the lower layer of stones. It is here that a high temperature is constantly maintained, due to which finely dispersed light steam is formed.

In commercial versions of EasySteam sauna stoves (with high power and increased weight of stones), a two-level steam generator is used. It provides a sufficient volume of high-quality steam for a spacious steam room.

EasyStim family of wood stoves

The first line of bath units with the Izistim trademark was introduced in 2007. Wood-burning stoves produced by Kostroma residents for Russian baths have confidently supplanted the products of foreign manufacturers in the domestic market. There was literally nothing secret about their legitimate success. Just pure calculation coupled with a thorough knowledge of Slavic bath traditions. It is doubtful that a stove that ideally matches the spirit of a Russian steam room could be made by Finns or Germans.

In addition to the indisputable Slavic origin, the list of priorities of Kostroma bath stoves includes:

- Long-term operational life due to a thoroughly thought-out design and the use of heat-resistant materials.

- High performance combined with relative compact size.

- One hundred percent safety with unconditional compliance with the rules of use.

- The presence of a stone or brick casing that provides heat shielding and maintains the temperature characteristic of Russian steam rooms.

- A clearly calculated location of the heater and steam generator, allowing you to obtain steam of impeccable quality.

- An extensive panoramic screen that creates a special sauna atmosphere with the illusion of an open fire.

- Possibility of connecting hot water supply systems adjacent to the steam room to the unit.

Designers and technologists from Kostroma paid due attention to the wide range of requests from domestic bath attendants, and the implementers of their brilliant ideas paid attention to details. Thanks to this, consumers were presented with a number of structurally similar units, but differing in power, i.e. If possible, process steam rooms of different sizes.

The products were divided into series, each of which was endowed with the name of a popular Russian resort:

- “Anapa” is a stove designed for small private baths with a steam room volume from 8 m³ to 16 m³.

- “Sochi” is a larger oven than the previous representative. It is designed to process steam rooms with a volume of 12 m³ to 22 m³.

- “Gelendzhik” is a solid sauna stove that evenly supplies light steam to rooms from 20 m³ to 35 m³.

The list of resort towns was interrupted by a professional category unit called “Cherepovets Domna”. It is intended for the arrangement of bath complexes with steam rooms with a volume of up to 44 m³. True, the resort theme was subsequently supported by two modifications for the sauna, called “Yalta”.

Structurally, all stoves of the original production are practically the same. Only in the Anapa subgroup there is a small model B9 without a side outlet for irrigating the stone backfill with water. The “Yalta” series, equipped with two heaters, has a unique structure. A closed internal heater surrounds the smoke channel and is surrounded by an open tank with ventilated masonry. This design provides radiation shielding without the use of expensive external cladding. In addition to the obvious economic benefits, Yalta has another significant advantage: it can be used not only as a supplier of dry steam to a sauna, but also as a typical stove for a Russian bath. Which is very attractive for those who like to periodically change their vaping mode.

Despite all the advantages of versatility and economy, the Slavic soul found wood-burning structures with closed heaters, already proven in practice, to be closer and warmer. Sincere reviews from happy owners of EasySteam sauna stoves confirm that the Sochi series turned out to be the most popular and in demand. It is worth understanding the technical characteristics of a worthy representative of bath units.

Multilayer welding seam

Why was this particular method chosen to connect the parts? In multilayer welding, relatively low current values are used, and the steel at the weld site melts slightly. Therefore, the chemical composition of the metal in the weld zone remains almost unchanged and there is no need to worry about accelerated corrosion of the metal in this area, which is inevitable during conventional welding.

In addition, with the implementation of each subsequent layer, heat treatment of the previous one occurs. As a result, the weld and heat-affected zone acquire a fine-grained structure, increased toughness, ductility and the ability to withstand temperature deformation.

Protective cover for heat retention

Facing sauna stoves with natural stone slabs is not only very beautiful, but also has a beneficial effect on the microclimate in the steam room. The fact is that direct contact of air with hot metal promotes the burnout of oxygen, and hard thermal radiation from it is not beneficial for the body. Stone, unlike steel, accumulates a lot of heat and releases it slowly. Therefore, the radiation from the stone is perceived as soft and similar to the sun, and the desired air temperature in the steam room is maintained for a long time.

Polished stone slabs made of coils, soapstone or pyroxenite with a thickness of 40 mm are used for cladding EasySteam stoves.

EasySteam

Since ancient times in Rus', bathing procedures were not only an opportunity to cleanse one’s body, but also a whole ritual: birch brooms, fragrant steam, the smell of heated resin in the steam room - our distant ancestors looked forward to all this as a holiday. And today the trend has not gone away - the bathhouse today is not only a good tradition, but also a way to relax and unwind, but also a fashion trend that has not lost its popularity for many years.

For connoisseurs of a real Russian bath, the Russian brand EasySteam offers a line of high-quality sauna stoves made of stainless steel in a casing made of natural stone, soapstone and coil. Stainless steel combustion chambers, designed taking into account the temperature range in Russia, will perfectly heat steam rooms from 8 to 50 m³ in just one and a half to two hours, putting the stove in Russian bath mode.

Russian-made EasySteam steel stoves can rightfully be called unparalleled: possessing the highest quality, operational durability and safety, they firmly occupy their niche in the market of sauna stoves and related equipment.

Sauna stove - the head of everything

To arrange a bathhouse, the first thing you need to carefully choose, after weighing all the pros and cons, is the sauna stove, because that’s where it all begins. The EasySteam brand offers you four model ranges of stoves: Yalta, presented in four modifications, as well as Anapa, Sochi and Gelendzhik, each of which has 2-3 modifications of the combustion chamber and more than 10 cladding options.

|

|

Hot water system

The manufacturer offers two options for additional equipment for heating water:

- pipe tanks with a capacity of 48 and 64 liters, made of stainless steel. To heat water, they use the energy of flue gases, and at the same time soften the infrared radiation coming from the pipe;

- rectangular wall tanks with powder-polymer coating with a volume of 50, 80 and 100 liters.

Our services

Our company has extensive experience in installing sauna stoves, as well as a staff of specialists who will install the equipment in compliance with all norms and regulations. And that's not all - we offer our clients!

- Izistim stoves in our online store

- Finishing a bathhouse, steam room