Why is it important to follow installation technology?

Stone stoves are able to accumulate thermal energy and gradually release it into the steam room atmosphere. Proper installation of the heater is the key to quick and high-quality heating.

A conventional stove for a Russian bath assumes uniform and gradual heating. The heating process is a lengthy operation. Active vaporization begins only after the fuel burns out. Proper installation can significantly reduce the time it takes to get the steam room into working condition.

In addition, properly laid material will retain heat and release it slowly. Therefore, you will have to put a new portion of firewood into the firebox much less often.

How to calculate the amount of stone

The “Weight of stones to be laid” parameter is contained in the instructions for each stove. But these are average indicators, and adjustments need to be made based on density

This parameter depends on the breed.

Approximate indicators are as follows:

| Breed | Density, g/cm3 |

| Chromite | 4,5-4,8 |

| Jade | 3,25-3,36 |

| Gabbro-diabase | 3,07 |

| Quartzite | 2,6 |

| Jasper | 2,65 |

| Quartz | 2,6-2,65 |

| Dunit | 3,28 |

You can put almost 2 times more material into the heater than is recommended by the stove manufacturers. But if its body is made of stainless steel, overload is contraindicated. This metal has excellent heat resistance, but becomes ductile at high temperatures. In combination with significant overload, this can lead to deformation of the firebox.

From a structural and aesthetic point of view, the stove should be filled with a slight heap or level with the top of the stone basket.

If you select a medium-density stone, when calculating the mass, follow the manufacturer’s recommendations. By purchasing dense breeds, the weight can be increased by 20 kg.

Advice! If a homemade stove is installed in the steam room, to calculate the quantity you need to take an average of 30 kg of stones per 1 m3 of steam room. For dense breeds, the weight can be increased by 5 - 7 kg.

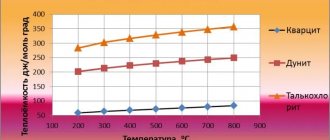

About the salt bath

In this section, the main criterion for checking the good quality of a stone of a certain breed is the ratio of its thermal conductivity to heat capacity, multiplied by the density of the stone; Let's call it conditionally bath quality. Optimal moisture absorption is taken to 0.8% by weight. With this approach, heater stones of different types form quite natural groups and inventions immediately catch the eye. Stones that fit into the group also turn out to correspond to authoritative recommendations.

Soapstone chlorite

Soapstone (steatite, wen stone)

It is also soapstone carbonate, soapstone magnesite, steatite, wen, soapstone, firestone, stove stone, potting stone - that’s how many synonyms there are! And all thanks to truly remarkable properties. In geology and mineralogy, the name steatite is used for this mineral, because its composition is not constant. The physical and mechanical parameters of soapstone chlorite are as follows:

- Melting point 1630-1640 degrees Celsius.

- Color – without foreign impurities from light to dark gray, see fig. on right.

- Mass heat capacity 0.98 kJ per kg per degree Kelvin (K).

- Thermal conductivity 6 W/(m per K).

- TCR 0.001%/ K.

- Hardness 1-5.5 on the Mohs scale.

- Density 2.75 g/cu. cm.

Bath quality is 16.835, this is a record value. Porosity, moisture absorption, vapor release and surface strength depend on the Mohs strength of the sample, which varies over a very wide range: 1 – scratched by a fingernail; 5.5 is the hardness of glass. Soapstone chlorite is generally harder the darker it is. Light soapstone in an open heater can generate dust.

Soapstone in a sauna stove heats up for a moderately long time, but produces long-lasting soft steam. Light or vigorous - at your discretion; “burn” the stove as you wish, soapstone is heat-resistant. Traditional Finnish stones for sauna stoves are soapstone. For a Russian bath, a dark one in a combined heater is suitable, because The hardest soapstone has a moisture absorption of more than 2%.

Soapchlorite is organophilic, i.e. absorbs grease vapors and other organic matter from the air. This, on the one hand, is good - the air is purified; on the other hand, soapstone chlorite lives in a bathhouse for no more than 3-4 years, and then quite expensive stones need to be replaced. By the way, the fact that soapstone is mined only in Finland is commercially oriented misinformation. There are more than 20 industrial deposits of steatite in the world, and Ural soapstone is no worse than Finnish one.

Colored soapstone must be taken selectively. All warm shades are definitely rejected due to iron impurities (see also below). Greenish steatite may also contain iron and/or heavy metal compounds, which can only be determined by laboratory analysis. Slightly bluish soapstone is certainly suitable for bathing.

The stone blows

This mineral belongs to the group of peridotites containing 44% olivine and little silicon oxide SiO2. That is, the likelihood of particularly harmful silicate dust appearing in the bath air is minimal - dunite contains up to 90% olivine. The greenish tint of dunite (see figure on the right) is due to compounds of chromium and copper, which are harmless in the bath. Dunite parameters:

- Density 3.28.

- Thermal conductivity approx. 2.3.

- Heat capacity approx. 1.2.

Bath quality – 9.05. Moisture absorption is close to optimal, about 0.8%, not organophilic. Quite expensive, but also durable: with regular, simple care it can last in a bathhouse for more than 10 years due to its low porosity. Surface strength and resistance to thermal shock are high, does not generate dust. Dunite stones are most suitable for a Russian sauna stove, because...

Water is not allowed into the heater in the bathhouse. They give you steam in the bathhouse. To add steam, you can add or add water to the heater. Serve water carefully, not in a thick stream from the ladle. Steam from the water supply is formed and disperses throughout the steam room gradually. They push on, immediately throwing everything out of the ladle: the push from the wave of steam is physically felt by the body.

Basalt

The cheapest bath stone and very durable due to high surface strength, low TCR and low abrasion. The basalt loading of the heater can withstand over 1000 sauna cycles using hot steam before it needs to be replaced (about 40 years, if you steam weekly). However, you need to take basalt for a bath very carefully, because... its porosity coefficient ranges from 0.6-19, and moisture absorption, respectively. 0.15-10%.

Olivine basalt is suitable for a sauna heater - dark, heavy, with fine-grained fractures, on the left in Fig. Greenish basalt with a slightly conchoidal fracture (in the center) should be tested for suitability in a similar manner to self-assembled pebbles (see below). Gray porous basalt (on the right in the figure) is absolutely unsuitable for a bath.

Types of basalt

The heat capacity and density of basalt are quite high, 0.84 and 2.52-2.97, respectively. The thermal conductivity of basalt strongly depends on the olivine content in it, but the bath quality is barely 6.5-7 at best. Basalt breathes very slowly and produces harsh steam. Therefore, among inexpensive bath stones in the steam room of a bathhouse, especially a Russian one, its intrusive relatives - gabbro and diabase - are more used.

It is best to look for stones for bathing in nature in dry, elevated places; from there the so-called field or tilled boulders. The best are moraine boulders and pebbles, left behind by a once retreating glacier and carried by flows of meltwater from it far to the south. Moraine stones are rounded and most often have a slightly flattened shape, which is ideal for laying in a heater, see below.

The suitability of river and sea pebbles for a bath depends on their origin. Pebbles that were not washed out of glacial deposits, but piled with water in historical times, may not withstand the tests of suitability for a bathhouse. Therefore, from natural deposits, pebbles for testing should be immediately taken gray, well rounded, without pores, chips and foreign inclusions.

A scattering of river pebbles

Testing natural pebbles for suitability for a sauna stove is carried out in 4 stages. First, carefully, with pressure, wash all the stones with a stiff hair brush in 2-3 changes of clean water without soap or any other detergents. This is necessary to remove loose particles of weathering crust (erosion). From the washed stones, we select 2-6 of the most unsightly ones, as many will fall on the bottom of an enamel pan, bucket or boiling water (also enameled).

Now heat the water in the indicated container to a rapid boil and let it boil for 10-15 minutes so that the dissolved gases come out of the water. We extinguish the fire or remove the vessel with water from it and let the boil calm down. Drop the stones into the resulting boiling water. If bubbles appear from any of them or dregs immediately begin to disperse, the entire batch is rejected: the source of the placer is a vein of unusable stone.

The next step is to cover the dish with a lid and let the water with the stones cool to room temperature. We take out the stones, cover the dishes again and let the water settle until completely transparent. We look at the sediment: if it is different shades of gray, everything is fine, the stones passed this test. Slightly, a little, bluish - even better, the stones contain useful trace elements.

The last test is well known: fill an iron barrel halfway with water. Half so that the cloud of hot steam and, possibly, fragments of stones would go up and not hit to the sides. Now we heat the stones, one by one, in the furnace firebox until red hot and throw them into the barrel. Those that remain intact are suitable for the stove.

Scheme of the stove in the bathhouse.

- Polished stones. They have a rounded surface that provides excellent air circulation. The disadvantage of this solution is the rather long heating time.

- Chip stones have a wide heating surface and can release heat in larger portions.

Choosing the shape and size of stones

Placing stones in the sauna stove of the correct size and shape is the key to good and light steam. The shape affects the amount of water retained.

The ideal would be to choose a tumbled or chipped form:

Chip stones are large in area, the downside is strength, frequent cracks and breakages.

Tumbled - the most durable. During the process, fragile samples are eliminated. The area of such stones is not inferior to crushed cobblestones, the downside is their high cost.

Advice! Do not buy smooth, polished cobblestones. They retain moisture very poorly.

Where to get

River stones for a steam room

We already talked about this in the article about how to choose bath stones. However, we can repeat ourselves. There are two main sources: nature and the store. Those who have some experience in identifying unsuitable sedimentary rocks can collect the “harvest” in a field, forest or on the bank of a mountain river. Local residents can tell you where to find suitable stones for a sauna stove, and at the same time show you what they look like.

If you do not have such experience, and the locals themselves buy in the store, then all that remains is to follow their example. In order to prevent dishonest sellers from deceiving you, read the article we have already mentioned or (if you have already figured out what to choose) an article about a specific breed - we usually provide information on methods for checking quality and authenticity. Here are some rocks you can read about here:

- Quartz and crimson quartzite

- Jade

- Porphyrite

- Soapstone chlorite

- Dunit

- Gabbro-diabase

- Nephritis

In addition, there is an article about which stones are better for baths and saunas.

Is it possible to mix different breeds?

The purpose of mixing different types of stone is to save money. Filling a large oven with expensive rocks is quite expensive. Therefore, the volume is diluted with minerals of lower cost.

You can stack the stones mixed or in layers. Rocks that heat up faster are laid down. Other varieties are placed on top.

From an aesthetic point of view, beautiful stones are placed along the edge so that they are visible and pleasing to the eye. Nondescript varieties are hidden inside.

Preparing stone for laying

Before laying, the stones must be pre-washed. The process takes several hours.

First, place all the stones in a container of clean water and leave for an hour and a half. No need to add detergents.

- After the allotted time has passed, check the stones: they should become slippery. This is necessary so that dirt can be removed from them more easily and quickly.

- After that, take a brush and carefully work them on all sides. It is advisable to use a brush with thick and stiff bristles, which can completely remove dirt.

- Then rinse the material with clean water and wait until it dries naturally.

- After the first heating, carefully inspect the stones. If they are washed well, the natural color will remain unchanged. If plaque appears on the surface, this will be a signal that the washing procedure must be repeated.

Laying methods

There are 2 installation methods: open and closed. The quality of the resulting steam depends on the choice. The choice of one or the other depends on the type of oven and other circumstances.

But there are general rules:

- Large stones are laid down to form a base for small ones. The lower part of the heater is located closer to the firebox, and the temperature there is higher, and larger stones require more heat. If you place them on top, they will take a very long time to heat up. This will increase the preparation time for the bath and, accordingly, fuel consumption will increase.

- Leave space between the surfaces of the stones. There is a misconception that when laying open, it is not necessary to follow this rule, since this does not at all affect the heating process of the stones. There is logic in this, but there are other factors to consider. For example, when heated, stones will expand - depending on the rock, some more, others less. If there is not enough space between them, this will lead to the stones quickly cracking, and if the structure of the heater is not strong enough, it may become deformed and even collapse.

There are many nuances of installation, so when starting to solve the problem yourself, you need to carefully study all aspects of the topic.

Open backfill

It is used in baths that are heated “on white”, as well as in steam rooms with electric stoves.

With this method, exhaust gases do not pass through the stones, and heating occurs from the walls of the furnace.

The advantage of open backfill is that soot and soot do not settle on the stones and do not get into the steam.

- The disadvantage of this method is the slow heating of the heater. More firewood will be needed to achieve the desired temperature.

Important! In an open oven, you should not stack stones because the top stones will not heat up enough. It is correct to limit the height to the side of the heater.

Closed styling

In this method, the stones are placed above the firebox. The base is a cast iron grate or a slotted brick vault. The bottom layer heats up to 1000 degrees, so you need to choose the stone wisely. The breed must be resistant to such temperature effects.

The quality of the stone in a closed system is critical. Even minor defects during heating will separate from the main body, crumble and can clog the furnace roofs. This will result in the heater not heating up.

When laying closed, it is important not only to lay the stones correctly, but also to regularly check their condition and replace damaged elements.

Advice from professionals

Avid steamers know a lot about the bathing process. They use a variety of brooms, experiment with steam supply, and practice several long passes. As for the selection of stones, here, too, professional bathhouse attendants have their own tricks:

- Disinfection of stones can be carried out with an ordinary strong salt solution in proportions of 1:3. The minerals are soaked in a bucket for a day, after which they are washed and placed in the oven.

- To speed up the heating process and retain heat, stones are mixed with cast iron ingots. Even the next morning you can wash yourself comfortably in such a bathhouse.

- To saturate steam with healing components, it is better to use herbal decoctions rather than oils and aromatic balms. They are capable of leaving soot on stones that is difficult to clean. Oils and balms can be used as flavoring agents in the form of open vessels placed on the shelves of the steam room.

- You need to splash water on the heater without fanaticism. It is enough to water the stones with a special device. The steam from such an amount of water is no less, but the benefits for preserving the stones in proper form are greater. In addition, a metal sauna stove operates longer without stress on the material of the body and grill.

Compliance with all the rules and advice will help a newcomer to the bath business to fall in love with the process of the most accessible method of healing in Russian.

Having your own sauna is not only about having a pleasant time with friends and relatives. This is responsibility for your own health. The choice of stones for the stove is an important point in the complex of measures for preparing the steam room. Follow the points in this article to ensure that your bath procedures become regular, useful and enjoyable.

Sources

- https://BlogoBane.ru/kamni-dlya-bani/

- https://v-banyu.ru/kak-ukladyvat-kamni-v-bannuyu-pech.html

- https://FB.ru/article/450813/kak-ulojit-kamni-v-bannuyu-pech-vyibor-poryadok-ukladki-ocherednost

- https://DimDom.ru/kamni-dlya-bani-kakie-luchshe-vybrat.html

- https://gadgetok.ru/top-luchshih-kamnej-dlya-bani.html

- https://www.teplodar.ru/help/articles/detail/kamni-dlya-bannoy-pechi/

- https://parilochka.com/pechi-dlya-bani/kamni/ukladka.html

[collapse]

Bookmark order

You have selected the largest specimens and are going to put them on the bottom. Their shape is arbitrary, often elongated to one side.

When installing, observe the following recommendations:

- Do not place oblong stones flat. It’s better to place them end-to-end, with the narrower side down. The rule is due to the greater speed of thermal energy propagation along the layers, and not across them. Another reason for this choice is the need for free passage of hot air between the stones. End masonry increases the number of gaps between specimens.

- In the bottom row you need to place rocks that will not quickly collapse from high temperatures. For example, it is a pity to put jadeite near the fire, because the stone is expensive, and such an arrangement will quickly crumble. For the bottom row, dunite, peridotite, and porphyrite are more suitable. These breeds are more adapted to high temperatures.

- After placing the first row, proceed to the second. Here, stones should also not be placed tightly. This is necessary for air circulation. Also, the distance between the stones is necessary to prevent destruction of the stove. The material expands when heated, and dense packing increases compression.

Boned or chipped?

The embanked stone is processed (boned) and has a smooth surface. Such stones look beautiful in a heater, but are always more expensive than crushed stones.

There is an opinion that when embanked, the stone receives microcracks on the surface and therefore will last less than the chipped one.

If you want exactly banked stones, then we can recommend filling the main part of the heater with crushed stones, and laying beautiful banked stones on the very top. When the stone becomes unusable, you will only update the top row.

Another feature of bunded stone: it has a smooth surface. When water hits a stone, it immediately bounces off and may not have time to warm up further, and if the stone is cold, then it simply flows down without stopping on the stones.

When using crushed stones, the situation is better: the surface is rough, and water will stay on it longer. If the stove has cooled down a little, then when heated, the moisture will evaporate, and when it gets on the hot stones, the water will spend a little longer on them than on the banked stones and will produce more finely dispersed (light) steam.

You don’t have to take the stones so seriously; these questions usually bother people who are passionate about bathing, like us)

But still, it’s better not to skimp on stone, because it’s from the stone that we get steam, and not from the hot metal of the furnace.

Features of installation in an electric oven

An electric sauna heater is a container containing heating elements (an electric heating device in the form of a metal tube). They are placed at a certain distance from each other, which makes it possible to lay stones between individual elements.

The most important difference in filling such a furnace is the size of the fraction. You need to take relatively small stones - about 4-7 cm on the larger side. They need to be placed so that there is a small space between the elements, and a small gap between them and the electric heaters.

Expert opinion

Lovkachev Boris Petrovich

Bath master who knows everything about steaming

Do not apply much force when distributing the material. Heating elements are prohibited from bending, distorting, or changing the space between them.

The stones should rest on each other and not on the heating elements. If the heating elements are laid too tightly, they will not be able to provide the required amount of heat, so they will leave the passport mode: the heating time of the bath will become longer. Constantly overheating parts will fail before their average service life.

The final layer of stones should completely cover the heating elements that cannot reach the side of the electric heater. There should be 7-8 cm from the heating elements to the top edge of the filler.

Attention! It is prohibited to turn on the electric heater without stones! The heating elements must be held with your hand during installation.

In general, the bookmark order does not differ from the requirements described above:

- The filler is weighed and compared with what the manufacturer recommends in the data sheet. Overloading and underloading should not be allowed.

- The stones are sorted into batches of the same size.

- The largest ones are placed down.

Link to article

The stove is often called the heart of any sauna. The designs of these stoves are very different: wood-burning, gas or electric, factory-made or home-made, expensive or budget. The bathhouse owner has a truly wide range of options. Sometimes it can be difficult to sort through this variety and make the right choice. In this article, we are going to bring some clarity and make it easier to solve the problem of choice by studying the main parameters of popular sauna stoves.

TRADITIONS FOR THOUSANDS OF YEARS

For many millennia, the best stove for a bath has been considered to be one that is heated with wood and creates heat with red-hot stones. That is why such stoves are called heaters. The choice of sauna stoves is now incredibly wide, but wood stoves are not losing their positions, and the number of supporters of the classic heating method is growing. Those who like to have a good steam bath are attracted by the pleasant smell of heated wood, the crackling of logs and the mesmerizing play of flames. There is a special charm in a wood-burning sauna stove that cannot be forgotten and makes you want to enter this blessed steam room again to deeply inhale the light healing heat.

SELECTING THE POWER OF THE SOAKER

Sauna stoves differ in thermal power, which is correlated with the volume of the room. The calculation is simple: approximately one kilowatt of heat per 1 cubic meter of steam room. First, let's calculate the volume of a paired room by measuring its length, width and height. For example, with a length of 2 meters, a width of 1.5 meters and a height of 2.2 meters, the volume will be 6.6 cubic meters. If there are uninsulated areas in the form of brickwork, windows, tiled cladding and a glass entrance door, we increase this number by 1.5. We get 9.9 cubic meters. It would seem that a furnace with a thermal power of 10 kilowatts is quite suitable. But it would be reasonable to purchase a stove with some reserve, 12–14 kilowatts, but a power of 8 kilowatts will clearly not be enough.

EXPERT ADVICE

Bathhouse owners often make the mistake of purchasing a stove with a large power reserve, believing that it will warm up the steam room faster. At first this will happen, but then the stove needs to be switched to the minimum fire mode. The air in the steam room will indeed already be hot, but the stones will not be warmed up enough, this takes time. By splashing water on unheated stones, you will not get the light steam that all sauna lovers desire. The other extreme would be a mistake - using a low-power oven. As a result, you will warm up the room sufficiently, but the stove in this mode will work, as they say, “wear and tear”, and is unlikely to last long.

STARTING THE OVEN FROM THE BATHROOM

The remote version of the stove is attractive because the installation of firewood and cleaning of the firebox occurs from another room. The design of the fuel channel in such furnaces is elongated. So much so that it passes through the partition separating the steam room from another room, dressing room or rest room. Here you can make a compact firewood rack without cluttering up the space near the heater. The wall around the passage of the elongated combustion channel can be lined with brick and insulation, covered with metal sheets and beautifully decorated. In some models, such fireboxes are equipped with a fairly spacious frame with heat-resistant glass, and a quite attractive fireplace portal with decorative design is formed in the recreation room. You can enjoy watching the flame work in the stove and control the combustion mode. Many sauna lovers prefer these types of heater models.

STEEL BODY OF SOAKER

A simple version of the sauna stove uses heat-resistant sheet iron 4–6 mm thick. Such ovens are compact and relatively inexpensive. The housing becomes very hot when burning, and there is a chance of accidentally getting burned. But there are models with a two-layer body, in the form of a kind of thermos, where the surface heats up uncritically. Circulation channels help heat the air quickly and evenly. More expensive models are even finished with ceramic tiles on the outside. Such finishing does not affect the quality of the stove at all, but you have to pay extra for an attractive appearance. Stoves made of chromium-containing steel that do not burn off oxygen in the room are considered quite durable. Various models of stoves from Finnish companies Helo, Kastor and Harvia are very popular in Russia. But, according to our bathhouse lovers, domestic stoves under the brands Vulcan, Sukhovey, Sudarushka, Termofor and Ermak are no worse than imported options at a very affordable price.

HOW MANY STONES DO YOU NEED?

The quality of the heat and its duration depend on the number of stones in the sauna stove. There are furnaces where stones are placed inside the structure and heated with an open flame without becoming covered with soot. Then you need a little of them, but the air in the steam room may be too dry. A softer option is to place stones on a metal surface and around a hot steel pipe. Here they can be stacked in larger volumes, creating a long-lasting heat accumulator. But an excessive volume of stones will reduce the possibility of obtaining high-quality steam. In a Russian steam bath, it is customary to warm up the air to 40–50 degrees at the bottom of the steam room, with a gradual increase to 80–85 degrees right at the ceiling. In dry saunas, lovers of contrasting sensations sometimes raise the temperature to 120 degrees, if health allows.

EXPERT ADVICE

For normal thermal conditions, you need to maintain the proportions between the volume of the steam room and the mass of the stones in the ratio of 4–5 kg per 1 m³ of steam room. The round shape for such stones is considered the best, since the circulation of heated air improves. The optimal size of stones is between 60–70 mm. But you need to pay attention to their quality. Small cracks in hot stone can lead to rapid destruction and even cause injury if a sudden rupture occurs. Large gray river pebbles, gneisses, quartzites and gabbro-diabase can withstand high heat well. Soapstone, popularly called soapstone, retains heat for a surprisingly long time, and semi-precious jadeite is valued for its healing properties and beautiful appearance.

THE BETTER THE ELECTRIC OVEN

A compact electric heater in a steam room takes up less usable space, unlike a solid fuel design. The ability to control the temperature using automation is also convenient. Such stoves do not need a chimney, and the room will always be clean, without ash and smoke. The service life of an electric stove is much longer than wood-burning heaters, and its location has no special restrictions. Safety is considered an important advantage: sensitive automation and a protective shutdown system provide the necessary cyclic operation, minimizing the likelihood of critical overheating. Many models are equipped with temperature sensors and remote control panels. This allows you to speed up the heating of the steam room with soft and uniform heat. Of course, such stoves require three stable phases of power supply and preparedness for fairly high heating costs.

EXPERT ADVICE

When choosing an electric oven, pay attention to electric temperature heaters. Tubular heating elements heat up red-hot, but last less than tape heating elements, which do not burn up the oxygen in the room. Many models are equipped with combination heaters to speed up the process. The external design of electric heaters is varied and performs practical functions: it increases protection from contrasting infrared radiation, neutralizes temperature changes and creates a comfortable thermal background in the steam room.

WE FIRE THE OVEN WITHOUT SOOT

When purchasing a wood-burning sauna stove, you need to take care of the right firewood. Refrain from heating the heater with scraps of chipboard, plywood or painted boards with polymer residues - this can hopelessly ruin the aroma of the steam room. The combustion of coniferous wood in the chimney quickly deposits soot, which will have to be constantly removed. The best firewood is considered to be birch, alder and especially aspen, which do not produce soot and even clean the chimney of traces of sedimentary soot. Remember that the firewood must be dry and fresh. Then the steam in your sauna will be light and fragrant.

Possible installation errors

Violation of stone laying technology is a risk of improper air circulation and, as a result, poor heating of the room. You can also experience accelerated destruction of the material, and sometimes damage to the firebox itself.

Common mistakes of inexperienced bathhouse owners:

- Incorrect quantity selected . Insufficient number of elements will not produce enough steam. If there is more material than recommended, it will not be able to warm up well.

- Incorrectly selected breed and fraction size . Steam formation depends on the properties of the components, and the circulation of gases in the space between the stones depends on the size.

Care of the heater

To continuously enjoy your stay in the steam room, you should periodically sort through, wash, clean and replace cracked stones. Assessing the steam quality helps determine the need for overhaul.

If it becomes hard or the heater begins to heat up poorly and cools down quickly, then it is time to replace or rebuild the material.

As a result of prolonged use, stones begin to fade, crack and lose their abilities. It’s not for nothing that kiln masters sometimes call burnt out stones “dead”.

Please note! The smaller the stone, the more often it needs to be sorted and replaced earlier.

Furnace Maintenance

During the maintenance procedure, you can leave intact stones. They are cleaned and washed in cold water. This needs to be done if the oven begins to heat up poorly and does not hold heat. Most often you have to change the backfill completely. After a certain period of use, the stones burn out and are called “dead”. The breed loses its ability to accumulate heat. The smaller the stones, the sooner they will need to be replaced.

FAQ

Is it necessary to fill all the small cavities inside the Kutkin stove with small pebbles, in which there is a gap of 3 cm between the casing and the body? Or does it only need to be filled in the central part?

The gap is a structural element that ensures proper heat transfer. There is no need to fill it with small stones.

I put the purchased porphyrite in the stove, but for some reason it cracks when fired. Isn't this dangerous?

Porphyrite may crack slightly during the first or second heating - this is normal. But if the crackling sound is heard constantly, the stones should be reconsidered and, if necessary, replaced. Perhaps you received heterogeneous specimens with foreign impurities.

I installed a convection oven in the bathhouse and laid it with stone according to all the rules. But the stones do not heat well, although the temperature in the steam room is high. What's the matter?

Economical convection ovens are much more often used in saunas rather than Russian baths. They were purposefully created in order to reduce the amount of fuel and time to heat the room. That is why short heating leads to maximum heating of the room, and the stones do not have time to warm up. No matter how you arrange them, they will produce weak steam. For a Russian bath you will have to change the stove or install a steam generator.