As a good rule, the beginning of each construction should be the calculation of funds, which act as a measure of the capabilities of the future developer. Everyone wants to live in mansions, but some have lush and tall ones, while others have simple ones: an upper room and a vestibule. The same is true with baths. You should always consider upcoming expenses. This will shorten the construction time and increase confidence in its completion. Nevertheless, developers often begin construction under the Napoleonic motto “The main thing is to start the battle, and then we will see,” which is where long-term construction projects appear.

How much will it cost to build a bathhouse from a log house - approximate estimate and tips

- Bathhouse project

- Bathhouse foundation

- Log house

- Bathhouse roof

- Finishing, communications

- What else can you save on:

Ordering the design and construction of a bathhouse from a specialized organization is quite expensive. Even with the most conservative estimates, it will cost at least 320,000 rubles. If you perform all the technological operations yourself, it will be much cheaper. What should be taken into account, how you can reasonably save money on the construction of a bathhouse - the reader will learn about all this from this article.

On a note! You will have to do accurate calculations of approximate costs yourself. Any structure is characterized by its own characteristics - architectural design, dimensions, materials used, their cross-section, degree of processing, “filling” and decoration of the premises. Factors such as soil characteristics, climate characteristics and a number of others are also taken into account. Therefore, below are only general (least expensive) examples of how much it costs to build a good log bathhouse, and practical recommendations.

Bathhouse project

If you do not build a whole bathhouse complex on the territory (a two-story building with guest rooms, a billiard room, a garage, and so on), then to accept the procedures it is quite enough to build a bathhouse from a log frame with dimensions ranging from 3 x 4 to 5 x 6 (m). For an individual plot this is a completely acceptable option.

Article on the topic: What does it mean to brew in a water bath

If you decide to buy a ready-made turnkey bathhouse project, then it is much cheaper to go with the standard version. Any specialized company has enough of them, as they say, for every taste. You just need to visit several different offices (and in any locality many organizations provide such services), choose the best ones, compare prices and purchase.

Ordering according to your own drawings (individual project) is always more expensive. If we consider that the design cost is approximately 35% of the total construction costs, then the savings on the finished development are quite significant.

A small bathhouse that does not have any structural difficulties can be built without a professional project. On our website in the “Do it yourself bathhouse” section there are many different recommendations for self-construction. For a person with an education, it will not be difficult to understand all the nuances. You just need to spend time, and you can do without the services of professionals. A bathhouse is not such a “strategic” object where special knowledge is needed.

Bathhouse foundation

In the private sector, it is generally customary to focus on tape. For a 3 x 4 log house you will need:

- Concrete mortar – 7.5; sand – 1.5 (m3).

- The rod is about 178 m.

Plus, insulation and waterproofing. The total cost of constructing a shallow belt will be approximately 50,000 - 60,000 rubles.

Recommendation - for a bathhouse, a columnar or pile type foundation is sufficient. On average, savings are 1.5 times.

Preparations with natural humidity are much cheaper. It seems to be the best option. But if you take into account all the nuances of drying wood yourself, then this is not the best solution.

- First, you will need storage space.

- Secondly, you will have to take many additional measures - organize shelter for stacks, correctly arrange workpieces in them, ensure high-quality ventilation, and so on.

- Thirdly, this will take quite a lot of time.

- Fourthly, practice shows that independent organization of wood drying does not provide the same quality of material as the production cycle.

A finished log house can be purchased for about 55,000. Its equipment will cost the same - installing windows, doors, and roofing. Total about 110,000 rubles. If you install it yourself, you can safely reduce the cost by 30 - 35%.

It is advisable to purchase already dried wood. There are savings here in the long term, since although such samples are more expensive, their shelf life is much longer. Consequently, you will not have to frequently deal with caulking, replacing rotten products and other types of repairs.

Article on the topic: What kind of paint are used to paint fences in Moscow?

For the lower crown it is better to buy larch. For walls, you can choose cheaper wood - spruce or pine.

Bathhouse roof

For a bathhouse, a lean-to structure is sufficient. In this case, you will not have to install a rafter system and spend money on materials. As a covering - metal profiles, slate, welded products. They are inexpensive, and taking into account the dimensions of the roof, such a roof will not require serious financial costs. The construction of the bathhouse roof is described in detail here.

Finishing, communications

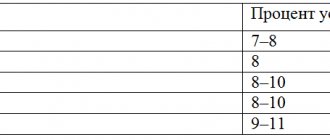

The data is approximate, in rubles.

- Stove, chimney system - about 23,000.

- Insulation - within 4,000 - 5,000.

- Floors – 14.

- Caulk – 15.

- Internal equipment: benches, shelves, cabinets, etc. – 5,000 – 8,000.

- Cladding with clapboard – 15,000.

- Consumables – 10,000.

- Organization of connection to the power supply line, water supply - up to 14,000.

Conclusion - when independently constructing a small bathhouse (3 x 4), you can focus on the amount of 225,000 - 235,000 rubles. This will be enough if you do not engage in expensive finishing and limit yourself to the necessary minimum for adopting procedures.

Why don't construction sites give the final price?

But we don’t want long-term construction, we choose a different path - a prudent one and want to know how much it costs to build a bathhouse before its construction begins. But how accurate can the calculations be? Most manufacturers of frame or log houses and bathhouses name only approximate amounts, knowledge of which gives developers absolutely nothing. This is not their fault, the whole point is that the price of a turnkey bathhouse depends on a number of factors, which cannot be calculated by looking at a simple layout; this requires a detailed design and a construction estimate.

And, as a rule, no one gives them out just like that. Normal working projects, those where you can get a specification for any screw securing the hooks in the dressing room, are drawn up for each object individually, after concluding a contract, discussing the wishes of the customer and making a certain amount of advance payment.

The only way to find out the cost of a particular object is to find a completed project, that is, a ready-made bathhouse that has been put into operation. In this case, you can get very close to some kind of cost certainty. Although you can purchase a standard bathhouse project, of which there are plenty on the Internet, be guided by an amount in the region of 10-50 thousand, depending on the quality and prevalence of the project. However, do not expect specifications for internal equipment, furniture, etc. from such a standard project. In most cases, sections with electrical, heating and sewerage are missing.

Selection of construction project

Calculating the cost of building a bathhouse begins with choosing its design. In this case, the project is selected taking into account both the purely aesthetic side of the issue and the technical one. As for the architectural form, these are construction options in Finnish, classical and modern styles. They differ in architectural elements and, accordingly, in cost.

As for technical issues, this is the material used for construction. Today, baths are built from the following materials:

- timber and logs;

- brick;

- gas and foam concrete blocks.

Calculation of materials for the construction of a bathhouse made of timber shows that the construction of a wooden bathhouse will cost the least. Thus, the average cost of building a bathhouse measuring 6x6 m will be 150–170 thousand rubles. At the same time, it is quite possible to build bathhouses from timber yourself, saving on the labor costs of professional builders.

As for the most expensive bathhouse, it is a brick bathhouse, since the cost of bricks is high.

However, this construction option has an undoubted advantage - the absolute non-flammability of such a structure. In addition, brick is not afraid of high humidity, as it perfectly resists rotting.

Article on the topic: Is it possible to coat the log house of a bathhouse with mining?

An excellent intermediate option is to construct the described building from foam blocks. The fact is that foam blocks are light in weight, which makes it possible to build with them even on soft soils. Moreover, these blocks do not burn, are not susceptible to damage by microorganisms, and are easy to process. At the same time, they absorb moisture very well, which will require additional costs for waterproofing.

Estimate for building a bathhouse - how to do it right

Construction of the simplest bathhouse requires at least an approximate estimate

Do you have an irresistible desire to build your own sauna? Then don’t delay for too long and start drawing up an estimate. The estimate for the construction of a bathhouse, be it Turkish, Finnish or originally Russian, requires a serious approach.

I recommend immediately contacting a well-known company in your region that has an understanding of construction technology and all the specifics of this issue.

As they say, any construction requires both moral and material costs from you. The estimate itself will help you in the early stages to sort out all possible issues that may arise during the construction of a bathhouse, thereby clearly indicating the price range. You will also be able to avoid unnecessary costs in the future, because all points are agreed upon in advance. A huge amount of materials about the work, too, a lot of proposals. Drawing up an estimate will solve all problems, all you have to do is review and pay.

When you come to a company and they offer you this service, you should already have a clear idea of what kind of bathhouse you want, from what materials approximately. This is very important, as this will simplify the work of the staff in drawing up an estimate, where all your wishes will certainly be taken into account. You can indicate, for example, to the company’s personnel that you want to build a bathhouse, all trimmed with clapboard, in which there will be a heater with an electric heater - this is the so-called Finnish sauna.

Or very high-quality baths are made from a log frame, which is pre-impregnated with an antiseptic and fire-fighting solution, as well as caulked with tow. There are a lot of options, the choice is entirely yours! The sauna is an elixir of good mood and good health!

Share with friends:

pifagor-design.ru

Estimate

Bathhouse construction estimate

To make it easier to calculate your upcoming income, you should make an approximate list of work. It will look something like this:

- Creating a project. At the same time, you cannot do without an architect who will make all the drawings in accordance with the requirements. For example, a typical construction project from 6.5 m*6.5 m timber in a private company can cost approximately $250 or 8,000 rubles.

- Foundation. Prices for the necessary materials depend on where they are purchased.

- Walls and roof. Here you will need to purchase roofing covering.

- Shelves.

- Communications.

- Bake.

- Laying insulation.

- Finishing work.

- Consumables.

- Additional expenses.

The last article may be the largest, since it depends on the individual requirements of the customer. For example, if you take the standard option, then this will be a minor expense, but if you want a jacuzzi, you will have to spend money. This column should also include the purchase of equipment and tools.

Calculation technology

The estimate can be calculated either independently or ordered from a construction organization. At the same time, when doing independent calculations, you must have at least a little experience in carrying out construction work. In the case where there is no such experience, it is recommended to consult with an experienced builder who will tell you all the intricacies of drawing up an estimate.

In addition, on many construction sites there is a calculator for calculating the construction of a bathhouse. This is a special program with which you can easily calculate the costs that you can spend on construction work. To do this, you will need to enter in the appropriate form the figures for the volume of building material you need, its type and other data. At the end, you will be able to get ready-made figures that you can rely on during the preparation stage of construction work.

Calculation of blocks for the construction of a bathhouse using formulas, as well as a calculator for this, are usually posted on their Internet resources by various construction companies and sellers of building materials. As a result, you can not only calculate the cost of the building material you need, but also order it immediately. As a result, you don’t even have to come to the supplier’s office, since you can make the payment online, and the products you purchased will be delivered directly to the construction site.

What will be the cost of an affordable frame bath?

If you are primarily interested in the price and speed of construction with appropriate quality, then you still need to choose a bathhouse made using frame technology . When ordering a building of this design from a specialized company, the nodal system allows you to install a bathhouse on the site in just 1-3 days.

Turnkey frame bathhouse 2 meters by 4 meters without external processing of wooden structures

At the production site, wall panels are pre-fabricated and delivered ready-made for subsequent assembly on site. Such a bathhouse does not require an expensive foundation; it is installed on concrete blocks measuring 20x20x40.

Article on the topic: When perennial flowers are planted along a low fence

Under good weather conditions, assembly on site actually takes place within one to three days. The advantage is that such a bath does not require shrinkage, so it can be used immediately after installation.

Turnkey frame bathhouse 2 meters by 4 meters with external finishing

In order to get a little bearing on the price, let’s take, as an example, a frame bathhouse with the following characteristics (photos and diagrams are given above!):

- Size: 2 m by 4 m (terrace not provided);

- Insulation: 50mm thick stone wool (all walls and ceiling) with a wind-moisture-proof membrane;

- Interior and exterior finishing: lining;

- Roofing: galvanized corrugated sheeting,

- Doors: 2 pcs. (wood), plus an attic hatch;

- Windows: 2 pcs. (deaf);

- Floor: board 40x150, unrebated;

- Foundation: block, 9 blocks (blocks 20x20x40);

- Rafter system: timber 50x100 and 50x50mm;

- Lathing: board 25x150;

- Shelves in the steam room.

The cost of a bathhouse of this design, almost turnkey (including delivery of materials and installation) is 110-130 thousand rubles .

It would not be amiss to give another approximate calculation of the cost (price) of materials for the independent construction of a frame-type bathhouse.

What does the estimate consist of?

The estimate is a list of costs necessary to carry out the work, including the cost of design documentation, permits, construction materials, auxiliary and related materials, the cost of purchasing or renting power tools, own labor costs, wages of hired workers, the use of special equipment, expenses for fuel and electricity, costs for landscaping and finishing work.

Before you start building a bathhouse with your own hands, you need to take into account everything down to the smallest detail. Think over its future location, taking into account the features of the terrain and the general concept of designing a suburban area. At the same time, we must not forget about the need to connect all utilities, such as electricity, water supply, sewerage. Take into account the possibility of a truck with materials and construction equipment arriving to perform excavation work.

Calculation of costs for building a bathhouse

Advice! It is better to buy building materials at wholesale construction stores or online building materials stores, because they usually have a more interesting price for the buyer than in retail stores.

Cost systematization

All stages of construction represent a fairly large amount of work, so your table can ultimately reach quite a large size and become unreadable. For ease of use and normal perception, it is recommended to divide it into several logically complete sections.

For example, an estimate for a bathhouse made of 6x9 laminated timber will be more understandable, which will allow you to avoid errors in its calculation if it is made up of the following parts:

- Cost of design and permitting documentation.

- The cost of planning and excavation work, digging a pit, laying a foundation,

- An estimate for a bathhouse made of timber, which will include all costs for materials and work on arranging the floor, erecting walls, installing interior partitions, and ceilings.

- List of costs for work and materials for arranging roof structures and performing roofing work.

- A separate item should be the costs of laying utilities (water supply, sewerage) and connecting the bathhouse to the electrical network of the garden plot.

- An estimate for the interior finishing of the bathhouse, which will include the costs of general finishing work. In addition to these, you can also include the costs of internal thermal insulation of the room, installation of windows, entrance and interior doors, plumbing and electrical appliances. In the same section, you can reflect the costs of purchasing and installing equipment intended for the steam room and washing room, as well as the rest room (shelves, sun loungers, stove).

- In the final section, you will need to indicate the costs of landscaping and landscaping the area around the bathhouse (equipping platforms and paths, laying out flower beds, installing benches). This section may also include an estimate for finishing the outside of the bathhouse, since it mainly involves painting work and installation of decorative elements.

All work, the implementation of which has a purely aesthetic and decorative function, is deliberately included in the final section of the estimate. If you miscalculate your budget allocated for construction, the bathhouse will be able to fully function without performing the work from the last section.

In conclusion, it should be recalled once again that when calculating the final cost of a material, you need to take into account not only its market price, but also the costs of loading and unloading, as well as transportation costs for its delivery to the construction site. Advice! When drawing up an estimate, it is recommended to set aside a certain amount of money, for example, 10-20% of the total project cost, for unforeseen expenses. This money will be very useful in case of any emergency situation.

And if it does not arise, they will delight you even more with their presence

Advice! When drawing up an estimate, it is recommended to set aside a certain amount of money, for example, 10-20% of the total project cost, for unforeseen expenses. This money will be very useful in the event of any emergency situation. And if it does not arise, they will delight you even more with their presence.

Start of construction

The photo shows the first crowns.

Depending on the project and appearance of the future structure, construction is carried out in one of two ways:

- with the remainder - if no exterior finishing is planned;

- without any residue - with (or without) finishing of the façade of the bathhouse.

The first crown: how to properly and thoroughly install a log house

Particular attention should be paid to the installation of the first crown - it must be accurately leveled, since this parameter will subsequently affect the entire structure, its geometry, and, consequently, reliability and durability.

For this purpose, it is necessary to lay slats with a thickness of no more than 15 mm around the perimeter of the foundation and at a distance of about 30 cm between them. For better waterproofing, as well as to avoid heat losses, the connection between the foundation and the first crown can be treated with polyurethane foam.

Article on the topic: At what distance from the fence can you build a house in Belarus

Inter-crown insulation

In the future, between the remaining crowns, various materials are used as thermal insulation: natural, mineral and synthetic. Jute insulation for timber is especially popular.

And the most inexpensive options include tow and moss, but using them, after construction is completed, it will be necessary to carry out caulking work.

Floor finishing

Depending on the purpose of the room, the design of the covering varies. The boards are mounted on previously installed logs.

For rooms where there is contact with water, poured floors are made. To do this, a small gap is maintained between the boards - 3-4 mm. To prevent moisture from escaping into the soil, a tray with a drain is constructed. Wastewater is sent to a septic tank or sewer.

Floors of non-leakage construction require insulation. For a strip foundation, a membrane or film waterproofing layer is laid and filled with expanded clay up to the joists. A hydraulic barrier is installed between the boards and expanded clay. The free space is filled with insulation (mineral wool) and lined with boards.

For columnar and pile foundations, it is necessary to first hem the support beams and then lay insulating materials.

Step-by-step instructions for DIY construction

In order for construction to proceed correctly, it is worth following the technology step by step:

- Foundation. It is recommended to use a strip foundation to reduce the load on the foam blocks. Formwork is made using boards, and for beacons I use nylon cord. A protective waterproofing layer must be installed at the foundation. Roofing felt or a layer of bitumen mastic is well suited for this.

- Construction of walls . For construction, blocks with strength D600-D800 are used, the first 2 rows are laid on a cement-sand mortar, then an adhesive composition can be used.

Experts say that the first 2 rows need to be reinforced, but some builders talk about reinforcing every 4-5 rows of bathhouse masonry. Openings for windows and doors also need reinforcement. A metal mesh with small cells is suitable for this. The foundation is reinforced with rods.

- Masonry . The blocks are laid only on the edge, while the vertical level is checked with a plumb line.

The photo shows step-by-step construction of a bathhouse:

The thickness of the joining seam should not exceed 5 mm. If the seams are too thick, this will contribute to the formation of cold bridges.

Interior finishing work

The walls are covered with certain types of wood. Due to high temperature and humidity, chipboard and linoleum cannot be used. Natural wood - alder, larch, cedar, linden - is suitable for cladding. They retain heat indoors.

Wooden lining is considered the best option for finishing the room. It is mounted on the sheathing to prevent contact with the insulation and waterproofing.

Wood paneling is also used for the ceiling

In the steam room it is important to create the effect of a thermos. And this is achievable with proper installation of the insulating layer

It is attached to the underside of the floor beams and secured with a rough layer of filing. The foil insulation is mounted below and pressed with rolling slats - the basis for fixing the lining.

The stove is the basis for the bath. For small rooms, simple devices that you can make with your own hands or replace with an electric furnace will suffice. The second option is preferable due to minimal air pollution and high safety, but it costs additional and considerable costs.

Important! To avoid fire, the place for the heating elements is lined with non-combustible materials. Distance to wooden parts – from 20 cm

Floors

For floor joists it is better to use 100*150 mm timber. You will need 8 pieces of it. * 636 = 5088 rub. The subfloor will require 26 inch boards with a width of 150 mm. ( 4,136 ). If the floors in the entire bathhouse are wooden, then 26 pieces of floorboards will also be required. *590 = 15340 rub. The floor insulation should be good and amount to 150 mm. It will take 27 packs of insulation *430 rubles = 11610 rubles. Total by gender: 36,174 rubles.

Bathhouses 4x6 made of timber / Construction of turnkey houses and bathhouses from logs and timber

Rational designs for bathhouses made of 4x6 timber are of interest to clients, since this size turns out to be ideal for use by a large company. Timber baths decorate the site, making it more lived-in and respectable.

Description of sauna houses made of timber

The selected bathhouse made of 4 by 6 timber may be similar to dozens of similar ones, but it may also stand out with its original layout. Unique is the ability to adapt a specific project to the needs of the customer, his desires and conditions.

Timber baths are reliable buildings that can be used for many decades.

A standard sauna house of this size made of timber is divided into three rooms approximately equal in area: a dressing room, a washing room and a steam room. A common option is to reduce the size of the steam room and washing room in favor of turning the dressing room into a full-fledged relaxation room. This is clearly visible in the project for a bathhouse made of timber with an attic: in addition to a spacious recreation room, the building also has an attractive attic room that can be used as a living space.

An equally worthy option is a 6x4 bathhouse made of timber with a porch, which has a convenient and original layout. The common wall of the dressing room and steam room guarantees comfortable temperatures throughout the entire bath.

Video of a built 4 by 6 bathhouse made of timber with an attic

Features of the construction of sauna houses made of timber

A bathhouse is built from 4 x 6 timber on a turnkey basis according to standards and recommendations that guarantee an ideal result. In their work, specialists use only high-quality timber of their own making, which is a guarantee of the reliability and strength of the material. With high-quality processing and careful treatment during the construction process, the Kirov winter forest will repay its owners with the warmth of the walls and the attractive aroma of the forest.

Work with construction is carried out according to the following scheme:

- Preliminary telephone approval.

- The manager will visit the site to sign the contract and clarify details.

- The actual construction work. They start with a foundation (filled strip - reliable and durable), then the walls are made of timber, the roof is mounted and covered with the selected material, the interior decoration of the room is carried out, windows and doors made of wood are installed.

- Acceptance of the finished building by future owners, during which minor inaccuracies can be identified and corrected, as well as the building can be supplemented with details: a porch, a canopy and other small details.

Timber baths with an area of 24 sq.m are an ideal solution from all points of view. A timber structure is reliable, unpretentious and attractive, and a competent approach to the construction of a sauna house will guarantee its durability.

Catalog of projects - log baths

Catalog of projects - saunas made of timber 150x150

masterdachi.ru

How to build a foundation for a bathhouse and its approximate price

Few doubt the importance of this stage for any construction. The most optimal foundations for such premises are two types :

As a budget option for a frame sauna, a slab foundation made from ordinary reinforced concrete slabs, perhaps even used ones, is quite suitable. Depending on the condition, the cost of one slab can range from 30 to 100 Euros .

videos on the Internet , you can see the process of making a strip foundation . It involves the use of such materials:

- crushed stone;

- sand;

- cement M500 or M400;

- fittings;

- waterproofing.

Approximate proportions for preparing concrete: 1 part cement, 3 sand and 3 crushed stone. As an alternative, it is possible to purchase a ready-made mortar with preliminary reinforcement. The cost of such a foundation for a 4x4 room will be equal to 60-80 thousand rubles .

A columnar foundation is economical and requires little labor; for stable soils this is an ideal option. The distance between the pillars should be within 1.5-2 meters. As a rule, a reinforced lintel is installed between the pillars - a grillage, but it is possible to use a metal channel or wooden beam. Thus, the price of such a foundation is 5-10% less than a strip foundation and it will be possible to build a bathhouse less expensive.

Items displayed in the estimate

It is always necessary to start drawing up an estimate by studying the design documentation.

In order to understand the principle of the formation of estimate documentation and see the example of an estimate proposed in the material, you need to understand exactly which points the document should be formed from. Remember, if you miss one of the construction stages and do not include it in the calculations, you can end up in an unpleasant situation, which is fraught with negative consequences for a half-built timber frame.

So, the estimate documentation for the construction of a house made of timber should include the following items:

- Costs for purchasing all wall material, including fittings, fasteners (pins), insulation, etc. It is worth remembering that depending on the type of timber (planed, profiled, glued) the amount may vary. And the cross-section of lumber plays an important role in obtaining the final amount.

- The cost of installing the foundation and floor inside the house. It is worth noting here that most often the installation of the base takes 30% of the total amount of construction financing. Although a lightweight type of foundation can be installed under a timber frame, which will somehow save money.

- Costs for finishing materials both outside the house (if it is needed for planed timber) and inside the cottage. This is why we will calculate the area of the walls of the building.

Costs for roofing, including both roofing material and timber for rafters

- Expenses for roof installation, including both roofing material and timber for rafters, sheathing, as well as insulation, waterproofing materials and all fasteners.

- It is also worth including in the estimate the financing of the work of professionals if construction is planned not with your own hands, but with the help of invited craftsmen.

Advantages and disadvantages

Before building a frame sauna, you need to familiarize yourself with all the advantages and disadvantages. It differs from others:

- Speed of construction. The construction period is 20-40 days, regardless of weather conditions.

- Lightness of construction. Does not place large loads on the foundation.

- Cost. The price per square meter is lower due to the raw materials used and low labor costs.

- Environmentally friendly. Harmless to health, maintains an optimal microclimate.

- Resistant to earth vibrations.

- Exploitation. The frame sauna at the dacha is immediately ready for use.

- Fuel economy. Firewood consumption is 2-3 times less than for a brick one.

- Thermal insulation. Retains heat and warms up almost instantly.

- Reliability. The service life varies from 10 to 20 years.

- Placement. The location may have a high level of groundwater.

- Architectural forms. It is possible to build attics and verandas.

In other words, a do-it-yourself frame bathhouse is cheap, quick and very easy to build. But for all its positive properties, the building shrinks after a couple of years. This will result in damage to the finish. The use of chamber-drying wood helps prevent the process. Another significant disadvantage is the cost of external and internal finishing materials and insulation. To keep the building warm all year round, you cannot skimp on thermal insulation. It also needs to be periodically treated with antiseptic and fire retardants.

Roof

| Name | Size | Qty | Unit price (RUB) | Sum |

| Edged board | 50x150x6000 | 1.44 m cube | 4900 | 7056 |

| Edged board | 25x150x6000 | 1.85 m cube | 4900 | 9065 |

| Edged board | 25x100x6000 | 0.3 m cube | 4900 | 1470 |

| timber | 40x50x3000 | 150 linear m (0.3) | 5300 | 1590 |

| Ruberoid | 10 rolls | 250 | 2500 | |

| Vapor barrier | 74 sq.m. | 1 roll | 1200 | 1200 |

| Insulation | 600x1000 | 9 m cube | 2500 | 22500 |

| Hardware (nails, screws) | 70,150,70 | 15 kg | 150 | 5250 |

| Rafter bolts | 18mm | 14 pcs | 50 | 700 |

| Rafter kit | 28pcs | 200 | 5600 | |

| Making a roof | 74 sq.m. | 900 | 66600 | |

| Total for section 3 | 123531 |

The roof is gable, with three gables. Veranda under a common roof on three pillars with jacks.

Do-it-yourself sauna - savings, pros, cons

Owners of suburban areas often consider self-construction an option to save money. There is no need to hire a team, or even contact a construction company, whose services are not cheap - from drawing up a building project to final finishing. The owner-developer only loses personal time, and money will be required to purchase materials.

This option looks attractive, but you should think carefully about it, because not everyone will be able to:

- make the calculations correctly, it’s not for nothing that companies use design documentation to build even a miniature bathhouse;

- It’s purely physically necessary to lay out the foundation, assemble the walls, install the rafters and roofing work, and then there’s also the finishing touches ahead along with the installation of the stove, windows and doors;

- choose materials yourself without falling for the bait of unscrupulous suppliers and sellers at construction bases.

To do the job you will need a tool that is unlikely to be lying around in someone’s closet. But if these difficulties do not scare you, be patient and move forward!

Building a 3x4 sauna with your own hands from timber is not as difficult as it seems, if you carefully think through everything and provide for it. If you doubt your ability to calculate correctly, purchase a ready-made standard project or order an individual one. The documentation will indicate the required dimensions and values. There is also the option of purchasing a ready-made house kit - this will reduce the number of expensive tools for the work and simplify assembly.

Among the advantages of self-construction are savings and full compliance with the result. The owner will carefully monitor compliance with the rules and requirements, while unscrupulous assemblers “from the outside” may “mess up” in an effort to simplify their work, or even purchase substandard materials and pocket the saved difference. The downside is that the developer does not have the extensive experience that professional carpenters have, so construction will be delayed.

Saving

The cost of timber or a finished house kit depends on various factors. This includes the type of wood, the degree of humidity, and the pricing policy of the manufacturer. Let's consider a cheap and common option - pine with natural humidity, average price on the market, cross-section - 150x150 (so that there is appropriate heat in the steam room even in winter).

The cost of a house kit is calculated in rubles per cubic meter. Under the conditions described above, the lower level is 9-12 thousand rubles/m. cube A bathhouse with dimensions of 3x4 meters will require about 5 cubic meters of timber (without internal partitions), the exact amount depends on the cross-section of the lumber. The total cost of the finished house kit will be 55-65 thousand rubles. But don’t be fooled, these are just walls. The foundation, roof, rafter system, and interior decoration still remain.

If you plan to do all these stages of construction yourself, there will be savings. But is it worth it? Preparing the foundation is not an easy task. Even a columnar foundation will require an investment of time and effort. The cost of installing the base is one third of the final cost of the bath. Roof – another 15% of the price of the finished building.

When the frame of the log house is ready, you will need to invest in finishing, interior and floor partitions, as well as doors and windows. Let’s not forget about the stove, because it also costs money. Total: the cost of construction will be 130-170 thousand rubles. Construction companies will charge more - from 200 thousand, the cost of work by coven workers will seem lower - from 150 thousand, but in this case additional operations will be required, the cost of which will be announced to you during the process. Private teams carry out such a scheme - they inform the potential client of a low price for construction, after which, already in the process of work, they talk about the need for additional thermal insulation, inserting casing boxes, and installing swarms. In this case, the customer has nowhere to go and continues to pay. It is not uncommon for such a cheap construction of a bathhouse or house to actually cost more than in large, reputable companies.

Is the result always true?

The final calculation and actual costs may vary, so it is always necessary to leave a small amount of NZ.

In any case, the price of building a bathhouse with your own hands is significantly lower than turnkey construction. You can purchase a ready-made log house kit; it costs a little more than the material, but it will be easier to assemble it yourself. In addition, you will not have to overpay for the plan, since the log house for assembly has already been cut according to the standard plan.

You must immediately enlist the support of friends and relatives, since it is difficult to lay any material alone. It is convenient to lay even brick or gas blocks alone only on the lower rows.

The help of relatives and friends, plus a little patience and effort will help to significantly reduce the price of a bathhouse. You can build one with little money on hand.