Why does condensation form in the dressing room? This question worries many. Any Russian bathhouse has a room called a dressing room. In it, as a rule, people relax after the steam room, store things, other various attributes and a small fuel reserve for the stove. However, very often the condensation that forms on the walls and ceiling in the dressing room becomes a huge problem, since it is not easy to get rid of it due to the fact that the dressing room directly communicates with the “wettest” rooms.

Building a bathhouse on your country property is one thing, but taking proper care of it is something completely different. The problem of high humidity with the formation of condensation, which settles on the surface of the walls and ceiling of the bathhouse, leads to the appearance of mold and mildew on them, and wet walls from excess moisture are susceptible to very rapid destruction of building structures and rotting of wooden parts.

It is rare that a stove is installed in the dressing room, which simultaneously performs the function of heating the room and providing natural ventilation through it. In all other options, to get rid of condensation in the dressing room, the most optimal and convenient methods of ventilating the bath should be provided.

Why does condensation occur in the dressing room and how to get rid of it?

Why does condensation form in the dressing room?

This question worries many. Any Russian bathhouse has a room called a dressing room. In it, as a rule, people relax after the steam room, store things, other various attributes and a small fuel reserve for the stove. However, very often the condensation that forms on the walls and ceiling in the dressing room becomes a huge problem, since it is not easy to get rid of it due to the fact that the dressing room directly communicates with the “wettest” rooms. Building a bathhouse on your country property is one thing, but proper care of it is something completely different. The problem of high humidity with the formation of condensation, which settles on the surface of the walls and ceiling of the bathhouse, leads to the appearance of mold and mildew on them, and wet walls from excess moisture are susceptible to very rapid destruction of building structures and rotting of wooden parts.

It is rare that a stove is installed in the dressing room, which simultaneously performs the function of heating the room and providing natural ventilation through it. In all other options, to get rid of condensation in the dressing room, the most optimal and convenient methods of ventilating the bath should be provided.

Why does condensation occur?

Condensation occurs for one reason - temperature difference. In the case of a bath, the difference between the microclimate of the dressing room and the temperature of the surface on which the drops appear is implied. Liquid often accumulates on the ceiling or in the corners of the walls. Condensation starts for three main reasons:

At first, barely noticeable drops seem harmless, but they cannot be ignored. If you ignore this process, the wood will begin to rot, fungus will spread, and the wooden beams will dry out.

In winter, the drops will freeze safely. Ultimately, the bathhouse will fall into disrepair due to the slow destruction of building materials. Therefore, it is important to fight the “enemy” in the early stages.

Why is there ventilation in a bathhouse?

In this case, the ventilation system in the bathhouse is very important. But let’s not expand too much, going into lengthy, uninteresting discussions, but instead let’s look at one specific example.

A person in a bathhouse is essentially in a room with just a huge amount of hot steam. And, of course, he inhales this steam. But people, as we know, breathe oxygen, exhaling the notorious carbon dioxide instead. And if the air exchange is insufficient, then the person steaming after a while will easily get burned.

For this reason, bath ventilation should be extremely effective and fully comply with all stated requirements (we’ll talk about them a little later). There are several types of ventilation systems, and all of them will be discussed in this article. And if you familiarize yourself with their features, you will be able to choose the most suitable option for yourself!

What it is

When burning any fuel - gas, coal, peat, coke and others, in addition to heat, steam is also released. As it rises, it cools upon contact with air of a lower temperature, and part of it turns into condensation in the smoke channel, that is, into moisture flowing down the walls. This is a natural, but negative and even dangerous physical phenomenon that can result in the most harmful consequences for the entire heating system (below, in a separate section, we will tell you exactly what they are).

Ways to get rid of condensation in the waiting room

There are different methods for getting rid of condensation in the dressing room. Among them, several can be noted that allow us to remove this negative factor.

- Ventilation. This method is the simplest and is used when it is not possible to use other methods. Ventilation allows you to remove some of the moist air from the room. This leads to a decrease in overall humidity and stops the formation of condensation. To ventilate the dressing room, just open the front door for a while. The walls and ceiling must be wiped free of moisture.

- Natural ventilation system. With this method, air ducts are installed in the room from below and above, which ensure natural air flow. For effective ventilation, the diameter of the air ducts must be at least 10 cm.

- Installation of forced ventilation systems. Even the smallest forced ventilation system will remove moist air from the room, thereby eliminating the main cause of condensation. In this case, small fans are installed in the air ducts, which ensure continuous movement of air flow. Fans are installed in the lower and upper air ducts.

- Thermal insulation. In this case, thermal insulation panels are installed in order to eliminate the cooling of the internal cladding panels of the walls and ceiling.

- Installation of an additional stove or fireplace. One of the most difficult and expensive ways to combat condensation. This provides additional heating of the room and walls, thereby eliminating the cause of condensation.

How to get rid of the condensation that has formed on the walls and ceiling in the dressing room in simple and effective ways? To answer this question, you can offer several options and actions that will help reduce the level of condensation in the bath:

- It is recommended to make round or rectangular holes for ventilation under the very ceiling, in the opposite walls in the dressing room. The holes must have rectangular sides or a diameter of at least 10 cm.

- Low-power electric fans of several W can be installed in the holes provided for ventilation. These fans will forcefully pull excess moist air outside.

- In winter, if necessary, the vent holes are covered with dense material - a cloth or a sponge while heating the bathhouse - so that the room does not cool down, and then after all water procedures are completed, the holes are opened again.

- The ceiling of the dressing room can also be dried by opening the doors from the heated steam room. Thus, the released warm air will move from one room to another and, of course, will rush upward. Naturally, it is recommended to carry out this activity after completing the main process of staying in the bathhouse.

- It is not recommended to paint the waiting room and steam room, varnish it, or dry some of the wooden products. If necessary, “windy” areas are treated with emery cloth.

- The wooden ceiling in the dressing room can be impregnated with antiseptic, antifungal and moisture-resistant compounds that will protect it from blackness, blueness and other unpleasant manifestations. You can apply impregnation to the ceiling using a roller or brush in several layers - for reliability.

- It is elementary and not superfluous, after you have steamed, to take an ordinary mop with a rag and wipe the ceiling in the dressing room from the drops of water that have formed on it - condensation.

- The reason for increased dampness in the dressing room may also be the presence of moisture under the floor, which drains during washing and accumulates there, and then evaporates through cracks in the floor and settles on the ceiling.

- Under the floor in the dressing room, it is recommended to install several sheets of galvanized iron with a slope in one direction so that water drains and does not accumulate in the underground.

Condensation in the bathhouse, get rid of it before the bathhouse rots!

Condensation on the ceilings of the bathhouse is formed due to temperature differences. If hot air enters a cool room, it turns into liquid and covers the surfaces of the steam room. Condensation becomes especially noticeable in winter - it forms if you flood the bathhouse after a week-long break.

As the stove heats up, hot air rises and remains on the ceiling. Therefore, in cold seasons, it is recommended to heat the bathhouse for at least four hours - so that the room is thoroughly warmed up and the condensation evaporates.

If the steam room is heated once every 7 days or less, then the procedure is as follows:

When pre-heating, condensation primarily forms in two places: the ceiling and the upper logs. In winter, it is important to warm up the bathhouse gradually, since large emissions of hot air are harmful to all structures. Therefore, when heating, firewood is added slowly and little by little.

If drying the steam room does not help to cope with condensation, then the problem should be looked for in the floor insulation. Often the insulation is not laid in a thick enough layer, which leads to a lack of tightness. For a bathhouse, the thickness of the insulation is at least 20 centimeters. The material used is basalt fiber or mineral wool.

A cold ceiling is also a consequence of ignoring the vapor barrier layer during construction. Normally, it is laid before placing the insulation. Over time, any insulation becomes saturated with moisture and ceases to cope with its tasks without a vapor barrier.

Slow heating is characteristic of expanded clay. In bathhouses where expanded clay was used as insulation, the ceilings are always cold for two reasons:

The constant formation of condensation accelerates the process of wood decay and destroys the structure.

If it forms in the rest room, then it is necessary to consider ventilation techniques. In summer, drying the room is easy - just open all the windows and doors and lift the floor boards.

In winter, it is recommended to dry the steam room both before bath procedures and after - the next day.

A well-thought-out artificial ventilation system will also help cope with condensation.

The point of such a system is to install fans that speed up the movement of air and prevent it from stagnating.

Source

Remedies

There are different methods for getting rid of condensation in the dressing room. Among them, several can be noted that allow us to remove this negative factor.

- Ventilation. This method is the simplest and is used when it is not possible to use other methods. Ventilation allows you to remove some of the moist air from the room. This leads to a decrease in overall humidity and stops the formation of condensation. To ventilate the dressing room, just open the front door for a while. The walls and ceiling must be wiped free of moisture.

- Natural ventilation system. With this method, air ducts are installed in the room from below and above, which ensure natural air flow. For effective ventilation, the diameter of the air ducts must be at least 10 cm.

- Installation of forced ventilation systems. Even the smallest forced ventilation system will remove moist air from the room, thereby eliminating the main cause of condensation. In this case, small fans are installed in the air ducts, which ensure continuous movement of air flow. Fans are installed in the lower and upper air ducts.

- Thermal insulation. In this case, thermal insulation panels are installed in order to eliminate the cooling of the internal cladding panels of the walls and ceiling.

- Installation of an additional stove or fireplace. One of the most difficult and expensive ways to combat condensation. This provides additional heating of the room and walls, thereby eliminating the cause of condensation.

How to deal with condensation?

To determine control methods, you need to understand what caused the condensation. Check the insulation first - this will involve covering the walls and ceiling. To stop the appearance of droplets, it is necessary to exclude all possible cold bridges. Bridges appear in cases where insulation of uneven thickness is installed - especially in the corners.

If this method fails, switch to ventilation. When the air exchange system does not work properly, moist air leaves the steam room slowly, and access to fresh air is difficult.

Dismantling the old heat-insulating layer and replacing the material with a new one will help correct the situation.

If you are not ready for such radical actions, then take care of natural ventilation - it will speed up air circulation.

To combat condensation, it is not necessary to dismantle the entire bathhouse down to the foundation.

For the lazy, there is a third way - an additional source of heat. An air conditioner, fan heater, or heater will serve as such a source.

The principle is this:

hot air rises, heats the ceiling and walls. As a result, the temperature in the bath comes to balance. However, such a move will not solve the problem - it will only correct its consequences.

Source

How to eliminate the causes of condensation in the dressing room?

One of the easiest ways to remove condensation is to coat surfaces exposed to hot steam with heat-insulating paint. When the bath warms up, the upper part of the walls and ceiling will heat up faster, which will significantly reduce the amount of moisture formed on them. It is also necessary to insulate the room from the outside, moving the dew point closer to the outer layer of load-bearing walls.

If you're willing to spend a one-time investment, you can purchase a dehumidifier that will do all the work for you. It will eliminate excess humidity, which causes condensation, which means that the windows will no longer sweat, the walls will not get wet, and the ceiling will not drip.

Upgrading the ventilation system will help get rid of condensation in the dressing room in winter. One of the easiest ways is to create ventilation holes in the ceiling - strictly opposite each other at opposite ends of the room. This way, excess steam and humidity will escape from the room, and you won’t have to worry about drafts.

Low-power fans can be installed in ready-made ventilation holes to help cope with dampness. Do not forget that during procedures in the steam room, all ventilation holes must be closed with thick fabric or special valves until the end of the session.

Many craftsmen advise installing vaults for water drainage. If you have a so-called leaky floor - gaps are left between the floorboards, then the vault is installed directly under the floor itself and should have a slope towards the drain hole.

In the case of floorboards tightly fitted to each other, the drain is installed in the lowest place. It is imperative to insulate the floor with waterproofing and periodically check its integrity. Craftsmen advise installing valves in the drain to prevent the appearance of an unpleasant odor.

Installing heating devices in the dressing room also helps reduce humidity and eliminate condensation factors. A stove or fireplace heated with wood or heated by electricity will dry the air from steam and prevent condensation from forming.

Don't forget about safety precautions. Any heating devices must be installed strictly according to the rules, because their presence increases the risk of fire. Do not leave stoves and fireplaces unattended, extinguish the coals before leaving and turn off the power from the mains.

For more information on installing heating devices and ventilation in the dressing room, see below.

What is condensate?

Condensation is the name given to moisture that settles on walls and ceilings due to temperature differences. Under the influence of heat from the stove, the water evaporates and is converted into steam, which, thanks to the circulation of air in the room, collects at the boundaries of the room. The walls, ceiling and windows are at the junction of two temperatures. On the one hand, this is the warmth of the interior, on the other, the cold from the street. The steam settles on the cooler surface, forming dampness.

A number of factors can influence the formation of moisture:

- Violations during thermal insulation work. A thermal insulator, for example, polystyrene foam, does not “breathe” simply because it does not allow steam to pass through it, which results in the formation of moisture. Sometimes the reason is the dew point, which is located not outside, but inside the room, causing the walls to become damp and wet. Recall that the dew point is the temperature at which steam turns into water.

- Violations during ventilation installation. The temperature in the steam room and dressing room varies significantly and when the doors are opened, steam settles in the room and flows down the walls.

- High humidity in the room. Water evaporates in the form of steam, collects near the walls and ceiling and forms condensation.

- High air temperature, especially in winter. The temperature in the bathhouse (dressing room) is always higher than the temperature outside, and in winter this value can be tens of degrees. Steam settles on a colder surface, windows sweat, and moisture collects on the walls and ceiling.

Why does condensation occur in the dressing room and how to get rid of it?

This is done with the help of “chairs” for sexual transfers. It is necessary to calculate so that the furnace vent is below the poured floor. Now you can start pouring, and you need to make sure that there is a slight slope in the direction of the drain pipe. Let's start installing the stove.

All that remains is to lay the floors. To do this, we insulate the concrete with any suitable material, and install logs on top. We lay boards on the joists, but with such a condition that there is a small gap between them, about 10-15mm. This is where the water will flow.

Now the final stage is lining the walls and ceiling with clapboard, but there is nothing complicated here.

By following these simple steps, you can ensure that condensation drains into the drain, and thereby get rid of its accumulation on the walls.

Bathhouse - Getting rid of condensation on the walls in the bathhouse

Many people love to wash in a Russian bath. Why not build it on your country plot? But it’s one thing to build it, and quite another to take care of it. Many bathhouse owners are faced with the problem of high humidity, which settles on the walls and ceiling and leads to wood rotting and the formation of mold and mildew on the walls. Condensation flows down the walls without drying completely, and this causes irreparable damage to building structures.

Why is condensation dangerous?

Dampness and high humidity, first of all, are a favorable environment for the development of various microorganisms, fungi, and mold. Wet walls and ceilings often lead to the formation of rot, which can cause the bathhouse to fall into disrepair. Just as mentioned above, all this can adversely affect human health.

Why does condensation form in the dressing room?

There are many reasons for the formation of condensation in a bathhouse, the main ones being:

- Insufficient ventilation of the room;

- Increased humidity in the space;

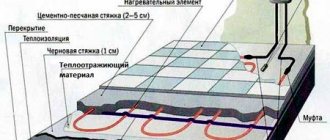

- Improper thermal insulation of walls, floors and ceilings, as well as windows and doors; Scheme of thermal insulation of walls in a bathhouse

The process of installing insulation on the floor

- Regularly high air temperatures, which especially affects the occurrence of condensation in winter;

- Incorrect and ill-conceived ventilation in the bathhouse.

Ventilation hole diagram

All these factors negatively affect the level of condensation, forming moisture on the walls, ceiling and floor, which can adversely affect the quality and strength of the materials from which the bath vaults are built.

Scheme of condensation formation in the dressing room

To avoid side effects from exposure to condensation on surfaces, you should know what to do to save the room. Special tools, equipment, or simply proper care of the bathhouse space will help with this.

The danger of condensation for a bath

Condensation is not just innocent moisture on surfaces. Due to this phenomenon, the following may occur:

- Rotting of materials;

- Fungus formation on different surfaces;

- Destruction of building materials from the inside and, as a result, the emergency condition of the bathhouse;

- Dryness of wooden beams, as well as loss of their quality and overall structure.

All these moments are extremely unpleasant for those who have erected a wonderful structure for a pleasant pastime in their private sector.

Scheme of insulation of various rooms in the bathhouse

However, there is no need to sound the alarm, if you think in detail about the methods of dealing with the “disease” of a room with high humidity, then everything will work out and you can forget about this problem forever.

How to get rid of humidity in a bathhouse and remove unpleasant odor

Everyone knows that a sauna is very good for health. In various types of baths and saunas (Finnish, Russian, Turkish, Roman, sports or other) a certain and individual level of humidity and temperature is maintained. In operating steam rooms, high humidity in the bathhouse is a necessity and the norm. However, steam and moisture have a destructive effect on the structure, interior coverings and wood trim if the bathhouse (sauna) room is improperly or insufficiently ventilated. When excess moisture is not removed from the room, from corners, places where there is little air movement, or it is noticeable that fungus and mold will soon appear on the walls - a clear sign of an unacceptable unhealthy microclimate in the bathhouse. And one more nuance: if the bathhouse is not used, its premises must be dry, otherwise you will not even notice how the premises have become a breeding ground for diseases and fungus.

Microclimate standards in the bathhouse

Different types of baths maintain different ratios of air temperature and humidity levels, and it is important to know these standards in order to constantly maintain climate indicators. The health effect, comfort and well-being of people in the bath depend on this. The beneficial effect of the bath is based on deep warming of the body and removal of toxins from the body. The presence of steam in the air improves its thermal conductivity and accelerates the warming of the skin and the body as a whole.

Microclimate standards for different types of baths

Russian bath - a steam bath with a humidity level of up to 60-65% and a temperature from 45 to 70 ° C, with a dressing room and a steam room. Hot Russian bath - the temperature in the steam room can rise to 90 ° C and above, and the humidity is maintained at a level of up to 35%. The Turkish bath or hammam is similar to Roman baths with ceramic finishing, has a soft microclimate, the highest steam content in the air - humidity up to 90-100% with temperatures up to 45 ° C.

Usually this is a complex of rooms with different temperatures. A Finnish bath is a sauna with high air heating (up to 100 °C and above) and not very high humidity - about 10%. Almost no steam in the air. It consists of a large dressing room for relaxation, a steam room and a shower. You can also name Japanese water baths, Roman baths - these are national baths and are rare in our country. There are also special sports saunas that maintain extreme humidity. They are intended for training athletes. The above indicators must be maintained regularly and are different for each type. You cannot get, for example, a Finnish sauna and not monitor the humidity level so that it reaches 40% - then it is no longer a Finnish sauna, but a place harmful to health. Many people wonder how to control the moisture content in the air? Maintaining the temperature is not a problem, but the humidity...

A special device has been created for this - an air dehumidifier with a built-in hygrometer, and only it can help regulate the moisture level. The hygrometer built into it will regularly measure moisture levels and signal the dehumidifier to either begin drying the air or stop working when the target is reached. The humidity level you need is set in the settings as optimal, and then the device independently controls the environment you need. This process will help you keep your bathhouse in proper condition. You just need to understand that the dehumidifier cannot be placed in the bathhouse itself, because the conditions are not at all intended for equipment! The dehumidifier is installed in the anteroom, near the exit from the steam room. You can read more about what a dehumidifier is in our article.

Ventilation system in the dressing room

The functioning of ventilation in the dressing room is ensured both by the flow of air through window and door openings, and through special vents made in the wood. Air flow is regulated by special sliding plugs.

The size of the vents is usually 15-20 centimeters. The lower vent is located approximately 50 centimeters from the floor and not far from the combustion chamber. The second vent should be on the opposite side, approximately 2 meters from the floor level.

Forced ventilation of the room can be created using a fan installed in the exhaust hole. This device will make the removal of moist air more intense.

How to make ventilation in the dressing room with your own hands?

A bathhouse, which is used only in the summer, can do without insulation.

Insulation, as well as ventilation in the dressing room and bathhouse, are, however, necessary if these rooms are used throughout the year. Ventilating the air will help avoid the consequences of high humidity (mold, mildew), which will make it possible to save the wood from rotting and extend the life of the bathhouse. The ventilation system also ensures quick heating of the steam room.

Arrangement of the waiting room

The room must be warm enough, so you will need to insulate surfaces, including walls, floors and ceilings. You also need to organize heating and a supply and exhaust ventilation system.

Floor in the waiting room

In order not to spoil the feeling after the bath, the floor in the dressing room should be insulated. Typically, sanded and treated wood is used as flooring material. Special wood treatment prevents the formation of fungus and mold that can appear in high humidity.

Thermal insulation of the floor is carried out as follows:

- We fill the logs with bars that will act as a frame for the rough flooring made from unedged boards.

- To protect the wood and insulating material from excessive moisture, we put a vapor barrier underneath.

- We place moisture-resistant insulation between the joists on the subfloor. For insulation, polystyrene foam, polyurethane foam or polystyrene foam boards are suitable.

- We lay a layer of waterproofing, and above that - floor boards or lining.

Note! It is not recommended to create concrete floors in the dressing room. However, you can use expanded clay concrete screed to further create a “warm” floor.

Waiting room ceiling

If you have an attic, it is recommended to choose a false ceiling. If small items, such as brooms and basins, will be stored there, then it is better to opt for a flat ceiling.

Ceiling insulation is carried out according to similar principles used for floor insulation. However, the choice of insulation here is more varied and allows for both cheap and expensive materials. Basalt wool is considered the best option, as it is characterized by high fire safety and moisture resistance.

The main purpose of ceiling insulation is to reduce heat loss, as heated air is directed upward. Based on this goal, we use foiled polyethylene to reflect heat, the seams of which are treated with reinforced tape. We attach polyethylene to wooden blocks to the ceiling. We cover the ceiling with 120 mm clapboard.

Waiting room walls

We carry out insulation of internal walls with our own hands as follows:

- We prepare the required number of identical wooden blocks (dimensions are determined based on the length or height of the wall, depending on the method of installing the lining).

- We fix the bars to the wall with self-tapping screws (every 50 centimeters).

- We attach the foil film to the bars and walls using a stapler.

- We install the lining.

We do insulation from the outside as follows:

- We use a wooden block sheathing along the height of the wall. We place boards below and above, to which we attach the bars with metal corners.

- We place mineral wool between the bars.

- We lay a vapor barrier and glue the joints with tape.

- We arrange another lathing on top for facing work.

Windows can be of any size. The best option is a double frame made of wood or double glazing.

Reasons for the formation of condensation in the dressing room

As a result of the difference between the temperatures in the dressing room and the steam room, condensation appears.

The following factors lead to the formation of condensation:

- the dressing room is too cold;

- the ventilation system is not equipped correctly;

- The outside temperature is too low.

Thus, to overcome the problem of condensation, it is necessary to provide high-quality heating and ventilation.

Ventilation system in the dressing room

The functioning of ventilation in the dressing room is ensured both by the flow of air through window and door openings, and through special vents made in the wood. Air flow is regulated by special sliding plugs.

The size of the vents is usually 15-20 centimeters. The lower vent is located approximately 50 centimeters from the floor and not far from the combustion chamber. The second vent should be on the opposite side, approximately 2 meters from the floor level.

Forced ventilation of the room can be created using a fan installed in the exhaust hole. This device will make the removal of moist air more intense.

Waiting room heating

The ideal scheme is if one of the walls of the brick oven opens into the dressing room. In this case, there is no need to create separate heating in the dressing room. However, a small heater will not be enough to heat all the rooms of the bathhouse. In such a situation, you can use any of the following types of heating:

- You can use pipes that are laid through the combustion chamber to the compartment with stones. The essence of the idea: hot steam air enters the dressing room after watering the stones with water, and the steam itself remains within the steam room.

- You can install a system of air channels passing through all rooms of the bathhouse and equipped with valves.

- If the area of the dressing room allows, you can install an additional stove.

Advice! To prevent wood rotting, it is recommended to dry the wood after each heavy moistening.

Thus, to avoid excessive humidification and condensation, only ventilation of the waiting room is not enough. A set of measures is needed that, in addition to ventilation, will ensure high-quality insulation of the room.

Source: https://klivent.biz/ventilyaciya/ventilyaciya-v-predbannike.html

How to eliminate the causes of condensation in the dressing room?

One of the easiest ways to remove condensation is to coat surfaces exposed to hot steam with heat-insulating paint. When the bath warms up, the upper part of the walls and ceiling will heat up faster, which will significantly reduce the amount of moisture formed on them. It is also necessary to insulate the room from the outside, moving the dew point closer to the outer layer of load-bearing walls.

If you're willing to spend a one-time investment, you can purchase a dehumidifier that will do all the work for you. It will eliminate excess humidity, which causes condensation, which means that the windows will no longer sweat, the walls will not get wet, and the ceiling will not drip.

Upgrading the ventilation system will help get rid of condensation in the dressing room in winter. One of the easiest ways is to create ventilation holes in the ceiling - strictly opposite each other at opposite ends of the room. This way, excess steam and humidity will escape from the room, and you won’t have to worry about drafts.

Low-power fans can be installed in ready-made ventilation holes to help cope with dampness. Do not forget that during procedures in the steam room, all ventilation holes must be closed with thick fabric or special valves until the end of the session.

Many craftsmen advise installing vaults for water drainage. If you have a so-called leaky floor - gaps are left between the floorboards, then the vault is installed directly under the floor itself and should have a slope towards the drain hole.

In the case of floorboards tightly fitted to each other, the drain is installed in the lowest place. It is imperative to insulate the floor with waterproofing and periodically check its integrity. Craftsmen advise installing valves in the drain to prevent the appearance of an unpleasant odor.

Installing heating devices in the dressing room also helps reduce humidity and eliminate condensation factors. A stove or fireplace heated with wood or heated by electricity will dry the air from steam and prevent condensation from forming.

Don't forget about safety precautions. Any heating devices must be installed strictly according to the rules, because their presence increases the risk of fire. Do not leave stoves and fireplaces unattended, extinguish the coals before leaving and turn off the power from the mains.

For more information on installing heating devices and ventilation in the dressing room, see below.

Causes

Many people have noticed that water droplets form on a glass jar that is sterilized over steam (the jar sweats). After heating the jar, droplets stop appearing. The same thing happens if you bring a cold metal spoon to the spout of a boiling kettle. After some time after heating the spoon, droplets will stop forming.

The main reason for the formation of condensation is the fact that heated water vapor, which falls on a colder surface or in a colder environment, begins to form water in the form of small drops.

It also rains for the same reason. Heated water vapor enters the upper (colder) layers of the atmosphere. In the same way, moisture appears on the walls and ceiling of the dressing room. At the same time, the walls and ceiling become wet and damp. The accumulated drops of water drip down onto the floor, making it wet.

There are several reasons for the appearance of condensation in the dressing room:

- High indoor humidity. Moist air collects in poorly ventilated areas, causing moisture and dampness.

- Warm moist air hitting the cold walls of the bathhouse.

- Lack of ventilation in the room or its insufficient functioning.

In addition, the reason for the appearance of condensation is the lack of necessary thermal insulation between the inner coating of the walls of the dressing room and the outer wall of the bathhouse . As a result, the coating is constantly cooled. All this leads to the constant presence of condensation. It deteriorates the properties of the material from which the building is constructed, reducing its durability. Drops of water falling on electrical wires can cause a short circuit.

One of the reasons for the formation of condensation may be the flow of water under the floor directly from the bathhouse itself. Therefore, it is necessary to make sure that there is no moisture entering through the subfloor. If there is a leak, everything must be done to eliminate it.

This unpleasant phenomenon may be accompanied by rotting of the materials from which the bathhouse is built. These are mainly wooden parts of the building. A large amount of fungus and mold may appear on the walls and ceiling, as well as under the cladding. Rust forms on metal surfaces.

Options for getting rid of condensation

Scheme of insulation of bathhouse walls from the outside Formation of condensation in the pipe

Today, every owner of a summer cottage with a bathhouse built on its territory can afford to choose the most appropriate way to combat condensation in the premises.

Ventilation

If it is not possible to use more modern methods, then you should at least let fresh air into the bathhouse space. This is one of the ways to get rid of condensation in the dressing room in winter.

It is clear that during your stay the windows and entrance doors will not be opened, because you can freeze and ruin the essence of the steam room.

Detailed diagram of the ventilation device in the bathhouse

Therefore, it is better to make the moment of relaxation habitual, and when everyone has left the bathhouse space, carry out the following procedures:

- Open the dressing room door.

- Wipe all surfaces thoroughly with a mop or cloth.

- Leave the door open until the moisture has completely left the room.

- Then you should again go over all surfaces with a dry cloth to eradicate sources of corrosion from the open spaces of the room.

Installation of fans

This is an ideal option that will help ventilate the space without unnecessary effort. Even the most primitive ventilation systems will help remove the moisture that has formed from the bathhouse, which will ensure normal air circulation in the room and get rid of condensation.

Ventilation hole in the dressing room

To ensure that the cost of financial resources does not exceed the norm, you can buy the most inexpensive ventilation systems. They will have to be changed periodically, but they will serve their time, performing their functionality efficiently.

Installation of a fan in a bathhouseDiagram of a forced ventilation device in a dressing room

It is worth remembering that when visiting the steam room, the ventilation holes should be covered with thick fabric or special valves. After the end of the session, be sure to open the ventilation units to remove excess moisture. Watch the video to learn where mold and mildew come from in a bathhouse.

Proper thermal insulation and design of water outflows

Sometimes eliminating condensation becomes possible after installing proper thermal insulation and vaults for water drainage. Often, condensation occurs when water flows beneath the surface of a structure.

Accumulating in the facade of the building, the liquid begins to evaporate, as a result of which moisture appears on the surfaces of the floor, ceiling, and walls. If the thermal insulation of walls, floors and ceilings is not done correctly, condensation may appear due to incorrect thermoregulation in the space. Drafts, blowing, cracks can negatively affect the overall atmosphere in the room. Therefore, it is worth periodically checking for damage to the insulation material. If defects are found, the thermal insulation system should be corrected or reconstructed.

Bake

If it is possible to install a stove or fireplace in the dressing room, then this solution will be ideal and the construction of the bathhouse will last for many years. A stove or fireplace heated with wood or electricity will help dry the air and eliminate factors that can cause increased condensation.

Drawing of a ventilation device using a sauna stove

It is worth remembering that if a stove is installed in the bathhouse, you should carefully ensure that safety precautions are observed at the proper level. After all, the presence of such devices increases the risk of ignition. Therefore, you should never forget to turn off the fireplace or put out the coals in the stove to avoid trouble.

Existing options for ventilation in the bathhouse

Condensation in the dressing room can play a cruel joke on private sector owners. Constant moisture on the walls, ceiling and floor can begin to destroy the structure of a wooden bathhouse from the inside, which entails enormous costs. Therefore, it is worth approaching the issue of caring for the bathhouse with full responsibility. If you properly get rid of condensation, then it cannot harm your favorite place for intimate conversations, health procedures and just a pleasant pastime.

What is condensate?

During the cold season, low outside temperatures help to cool external windows and walls, as well as lower the temperature of the heated air in the room itself. When this happens, moisture begins to condense in the air, which flows down the windows and begins to be absorbed into the cladding materials of the building. In the winter season, the situation worsens due to the fact that fresh air cannot replace humid air and therefore a process called condensation is repeated again and again. Very often, finding out the main cause of condensation can be very difficult, and sometimes completely impossible. The influence is exerted by many factors, including:

- air temperature;

- poor ventilation;

- thermal insulation;

- humidity.

Chemical elements that help get rid of condensation

Chemical industry products help protect cold water supply pipes from condensation: Stermizol, Corundum, Teplomet and others.

The use of these insulating mixtures involves the following steps:

- The pipe is cleaned of dirt and rust.

- Apply a layer of primer for better adhesion of the insulation to the surface and leave to dry.

- Using a roller, brush or spray, cover the surface with a protective mixture. The most effective is the application of 5 layers of insulation, and each layer must dry thoroughly before the next application. The optimal drying time for such mixtures is about 1 hour.

- A special fixer helps to extend the service life of a thermally insulated pipeline, which at the same time makes the pipes more attractive.

Which method to use to combat condensation on cold water supply pipes depends on the reasons for the formation of this phenomenon and the specific operating conditions

How to remove resin from the ceiling in a bathhouse

Resin is an integral part of coniferous wood. It is contained in capillary vessels called resin ducts. An increase in temperature usually causes the resin to protrude onto the surface of the wood product.

Resin leaks on coniferous wood

If you made a ceiling from coniferous wood, you will definitely encounter resin. It can concentrate around knots, “eyes,” or in so-called “resin pockets,” which are formed when the cambium of a living tree is damaged.

The best option is if you use coniferous wood, then only for the main boards and beams of the ceiling , and then sew everything up with foil, stuff the sheathing, and then install hardwood lining on top of it. In this case, nothing will leak out.

For those whose coniferous wood is not covered with anything, we can advise you to try the method we read on one forum: use a blowtorch to walk through the wood from which resin is flowing in order to burn out the resin and clog the channels. However, we have not tested it ourselves.

Periodic cleaning would be less drastic , but you will have to remove resin from the ceiling in a bathhouse many times. It can be removed either mechanically or by dissolution. (Or combining both.)

Dissolution is achieved with the following compositions:

- Mix pure acetone with water in the following proportion: 1 part acetone to 3 parts water;

- dissolve soda ash in water at a ratio of 5 grams of soda to 95 grams of water;

- a mixture of the described solutions.

Solutions should be heated or diluted with hot water. Then use a brush to apply and rub in the solution.

***

We ask our readers: write in the comments on this page what topics about the bathhouse interest you, but you did not find them on the pages of our website.

Insulation of the ceiling in a steam bath room

If the bathhouse has an attic or attic, the insulation process should proceed as follows: the board is coated with a 20 cm layer of clay. This material copes well with the task of retaining moisture. Wooden chips must be poured into the cracks between the boards. If they are not available, then you can use any other material that provides good thermal insulation. For example, you can backfill with expanded clay. But the thickness of the layer of this material must be at least 200 mm.

Insulating a bathhouse without an attic

First, the vapor barrier material is laid, then the insulation is attached, onto which the beam beam is sewn. Then the shelf boards are nailed.

When insulating the ceiling of a bathhouse, special attention must be paid to the junction of the pipe and the insulation. To ensure that fire safety standards are not violated, it is necessary to make an indent of 200 mm between the pipe and the heat-insulating material. This problem is easily solved by creating a box from rafter legs

It will be a barrier separating the pipe and the insulation. The space inside the box can be filled with fire-resistant insulation, for example, stone wool

This problem is easily solved by creating a box from rafter legs. It will be a barrier separating the pipe and the insulation. The space inside the box can be filled with fire-resistant insulation, such as stone wool.

It is optimal if the roof of the bathhouse is designed in such a way that there are no places through which warm air can escape from the room and cold air can enter from outside. Insulating the ceiling has another goal - to avoid the formation of condensation. Condensation is converted into moisture, which, in turn, is the main enemy for most building materials.

Please note that not all materials are suitable for ceiling insulation work. It is worth refusing to use materials such as chipboard, plywood, and fiberboard for thermal insulation. They can not only become deformed during operation, but also release substances harmful to human health when exposed to high temperatures.

Is condensation dependent on ventilation?

Condensation on the walls in the dressing room is a consequence of improper installation of ventilation. It is known that in the washing room and steam room the air temperature is much higher than in the dressing room. When people leave the steam room, all the steam goes into the room and settles on the walls, flowing down in streams. All this happens due to temperature changes. After a certain period of time, the bottom boards have to be replaced, as they begin to rot, become overgrown with fungus, and an unpleasant musty smell appears. It is necessary that the room has a window with a window, in addition to the main ventilation, this will make it easier to dry the walls and reduce condensation.