Most Finnish and Swedish saunas use heater stoves with fireboxes without tunnels, with firewood loaded directly from the steam room. This is due to traditions and the harsh climate, but more often – to the small size of the steam room of the bathhouse. For temperate and mild climates, a more rational solution would be a sauna stove with a firebox from the dressing room. And this is not a matter of fear of burning or causing a fire. Despite all the inconveniences associated with maintenance, a stove with a remote firebox provides a noticeably greater level of comfort than a classic heater - potbelly stove.

It’s easy to make a brick portal for an external firebox in a chopped bathhouse

Advantages of a design with an external firebox

A classic Russian bath involves the use of a real wood-burning stove, and not its imitation. And in order to create the necessary atmosphere in the steam room, a means of heating the room is installed directly in it. This is the only way to achieve the desired temperature for steaming the entire body.

It’s good when the stove is heated with selected wood. The room is saturated with an indescribable pleasant aroma. True, there is always a possibility that harmful gases generated during combustion will fill the steam room, despite the fact that the stove should work as an exhaust ventilation. And this happens anyway when the firebox door opens.

The second unpleasant moment is the garbage in the steam room, which cannot be avoided when bringing firewood into it. And manipulating the stove in a cramped room, when they are already taking thermal procedures and trying to relax, is completely inappropriate. Therefore, the option when the stove is heated from another room looks very attractive.

Firebox in the rest room Source cstor.nn2.ru

In addition, a stove in a bathhouse with a firebox in the dressing room has a lot of advantages:

- Not only the steam room is heated, but also the adjacent room.

- There is nothing stopping you from regularly adding firewood to the stove. This means crowded conditions and people in the steam room.

- It becomes possible to protect a hot oven with a safety screen. And this will avoid accidental burns.

- The steam room will be kept perfectly clean.

- In the room where the firebox is located, you can arrange a place for drying firewood. There are situations when such a problem is very relevant.

- The air in the steam room always remains clean and pleasant to breathe. After all, the steam in this case turns out to be light.

- The steam room will receive more usable space, since the space occupied by the open firebox door will be freed up.

- If desired, the firebox can be taken not only into the next room, but also outside.

The latter circumstance is especially relevant when you need to heat the bathhouse with coal instead of firewood. In this case, combustion products are more harmful and it is better that they do not even get into the dressing room. In addition, there is much more dirt from such fuel.

Taking the firebox outside Source oboiman.ru

The option has a significant disadvantage. In order to add fuel to the stove, you must interrupt the bathing procedures and leave the room. Therefore, this approach is justified in commercial organizations, when a special employee monitors the kindling. But since coal provides more heat than wood, some bathhouse owners deliberately accept certain inconveniences.

Having a certain skill, the stove in a bathhouse with a firebox from the dressing room is laid out independently from brick. This approach will support the traditional foundations of bath procedures, since the heater has always been considered an indispensable attribute of the Russian bath. But progress also brings its advantages, which are more practical.

For example, metal stoves heat up faster and therefore require less fuel. In addition, in steel structures, the outlet channel is already welded to the boiler and all that remains is to equip an opening in the wall for it. And some heavy cast iron stoves have a removable firebox. And this adds new possibilities when used.

Installation of a cast iron stove with a remote firebox Source oboiman.ru

Modern stoves are equipped with a firebox door with transparent protective glass. There are both disadvantages and advantages to this. Since such material does not heat up, in the closed position no heat enters the dressing room. To heat the room, you will either have to regularly open the door slightly or install an additional heater.

But if there are no problems with the temperature of the rest room, then such a design can serve as a fireplace. If you move chairs to the firebox, you can observe the fire through the transparent glass. This type of relaxation is especially pleasant after couples treatments.

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

Furnace firebox material

— this must be taken into account

Steel firebox

As a rule, furnaces are made of structural steel 3-4 mm thick, rarely thicker. Steel furnaces include heating furnaces, heating and cooking furnaces and long-burning furnaces. The peculiarity is that in such furnaces, for the most part, there is no lining. Everything is logical, the higher the combustion temperature (and the combustion temperature of stoves with lining, as previously written, can reach 500-600 degrees Celsius), the faster the firewood burns, which means it is not entirely suitable for stoves of this heating group.

The advantages of steel wood-burning stoves include, respectively, the duration of combustion. And the disadvantages are the service life of such stoves, which is the shortest in comparison with stoves made of other materials. Also, the disadvantages include the low quality of firewood combustion, which leads to greater condensation formation. These ovens therefore require more frequent cleaning than others.

Steel firebox with lining

The most common type of material is a steel firebox with an internal lining (insulation). Fireclay brick is most often used as a lining (although today it is a slightly outdated material that has obvious disadvantages: it is heavy, porous, and not durable.

More modern materials include vermiculite and cast fireclay (white, smooth, non-porous). Some manufacturers use their own unique lining material, for example: Acumotte, Termotec, Reallit, etc. Such materials are based on cast fireclay, to which various substances are added that increase the strength, self-cleaning and durability of the lining.

The advantages of steel stoves include the beauty of combustion (especially important for fireplace stoves!), and the best quality of combustion of the wood itself.

The disadvantages include the fact that sooner or later (every few years) the lining will still have to be changed, since it is a consumable material.

See how Acumotte material even withstands a blow from a poker!

Video testing of Acumotte lining in Kratki furnaces and fireboxes

Cast iron firebox

As we wrote earlier, cast iron stoves are produced without lining. The advantages of cast iron stoves include their durability and soft heat. The disadvantages of such stoves include their heavy weight and fragility due to temperature changes (if you splash cold water on a heated stove, the stove may crack).

Safety requirements

Installing a sauna stove with an external firebox requires the introduction of additional protective measures. But we also shouldn’t forget about the basic ways to comply with fire safety in order to protect people visiting the steam room from injury, and yourself from penalties from supervision. And the implementation of all the recommendations prescribed in the sixth chapter of SNiP number 41-01-2003 will help in this.

Installation of an iron stove with the firebox removed to the dressing room Source oboiman.ru

And in a few words, all the basic requirements boil down to the following:

- A reliable foundation is erected under the main structure of the furnace, which should be adjacent to the wall of the room where the firebox will be installed.

- The remote fuel duct made of iron should only pass through a stone wall. Therefore, if the latter is made of wood, it is necessary to equip a niche in it, which is lined with brick.

- The distance between the metal parts of the stove and the wooden wall must be at least 40 cm.

- This parameter can be reduced if the fuel channel is laid with a reliable insulator. For example, basalt wool or cement-fiber material. If the insulation thickness is at least 5 cm, then the distance can be reduced to 25 cm. When an even thicker gasket is used, then even to 12.5 cm.

- Before the firebox, a steel sheet with dimensions of at least 40x80 cm must be laid on the floor. It will not only prevent fire from coals falling out of the stove, but will also help in removing debris from the fuel.

Steel sheet in front of the firebox Source remontnik.ru

- The distance from the stove to the ceiling of the steam room must be at least 120 cm.

- The edge of the combustion door should be 125 centimeters from the nearest door.

- A homemade iron stove must be lined with bricks.

This last measure will help to avoid a fire in the room if, through negligence, wooden objects, of which there are plenty in the sauna room, interact with the stove body. Factory-made products are usually protected by double walls.

Door type

Pay attention to this factor, because... Ignoring this little thing can ruin a lot. In fact, everything is simple here...

With glass : with fireplace door or with small glass

The fireplace door, as you already understand, is the first sign of fireplace stoves. A small glass is intended only to control the amount of firewood in the firebox without opening the door.

Without glass - just “solid” stoves with a metal or cast iron door.

Construction of a brick kiln

Having the skill of bricklaying, you can install the stove in a bathhouse with a firebox from the dressing room yourself. To do this, you need to stock up on the necessary materials and tools. You will need clay, sand and fire bricks. You will also need grates and doors for the firebox. You can’t do without a steel corner.

The work cannot be completed without a construction trowel and levels of different lengths. And initially you need to decide on the layout of the furnace. If your work experience is minimal, then it is better to abandon sophisticated projects and stick to the simplest ones.

Laying a stove for a bath Source remontik.org

Foundation for a sauna stove

The installation of any stove begins with the foundation, and when the floor of a country house is concrete, this already solves one problem - there is no need to make a special foundation. Here you can only decorate the floor with ceramic decorative tiles for beauty and ease of cleaning. It was a completely different story when we built a wooden house.

Here you already need to take care of sufficient thermal insulation of the floor. Fire safety is also of paramount importance: metal sheets must occupy a space of at least 40 cm in front of the door. This is necessary in order to avoid coals falling out of the stove onto the wooden floor.

Is a foundation always needed for a stove?

If the stove-heater does not exceed 700-750 kg, there is no need for a foundation. Steel fireboxes supplied by online stores are still usually less than this weight. But if you love cast iron structures, you most likely cannot do without pouring concrete. Likewise, a foundation will be required if the firebox is surrounded by large brickwork. In any case, in controversial situations it is better not to neglect safety and carry out the appropriate work.

The procedure for carrying out work on the construction of the foundation

The stove foundation is an important element of the future bathhouse. The quality of work on its installation greatly influences the following parameters:

- stove safety;

- its service life;

- correct operation of all components of the heating device.

Let's look at the step-by-step procedure for constructing a stove bath foundation:

- At the location where the firebox is installed, a pit is prepared, the perimeter of which is 15-20 cm larger than that of the stove being installed, and the depth is 50 cm;

- After compaction, the bottom of the pit is sprinkled with a mixture of crushed stone and sand;

- Waterproofing is laid in the form of a polyethylene film;

- The road mesh reinforcing the foundation is attached to the reinforcement using wire or welding. The mesh frame has a perimeter 5-7 centimeters smaller than that of the oven being created;

- A concrete solution is prepared from a mixture of sand and cement in a ratio of 3:1, which is used to fill the foundation pit;

- The leveling is carried out using a vibrating screed, and then the result is checked using a level;

- When the solution has hardened, it is covered with two layers of roofing material;

- Using fireclay bricks, they form the basis for the future furnace.

Installation of a metal structure

Today, manufacturers produce a large number of designs of iron stoves for baths. And options with the removal of the firebox to an adjacent room are especially popular among buyers. In addition, the remote channel is often equipped with a door with panoramic glass. And this helps to monitor the kindling process without opening the stove.

The installation of a metal stove in a bathhouse takes place on a foundation located near the partition. In the latter, an opening is cut for the fuel channel. Before installation, all surfaces are carefully insulated to protect them from excessive heating.

For the same purposes, metal stoves are often lined with brick. But this measure is more common for home-made structures. Because factory-made ovens have very reliable protection and do not need additional protection. Therefore, their lining is purely decorative.

Top 10 rating according to KP

Editor's Choice

Professor Butakov Student (from 12.2 thousand rubles)

Professor Butakov Student.

Photo: yandex.market.ru A stove that is easy to use and easy to install. The chimney in most homes does not require any additional installations or holes. The model is very compact and heats the room well. The device heats up quickly. Such a stove would look great in any country house or country house. The burning time in smoldering mode reaches 7-8 hours. The flame level can be adjusted. The power is good - 9 kW. The heating device operates on wood.

Characteristics:

| Heated volume | 150 m³ |

| Power | 9 kW |

| Type | closed |

| Chimney | There is |

| Efficiency | 85% |

| Fuel | firewood |

| Outer shell material | steel |

| Door material | steel |

| Top panel material | steel |

| Chimney diameter | 12 cm |

| Chimney connection | rear |

| Dimensions (WxHxD) | 37x65x54.5 cm |

| Weight | 57 kg |

Advantages and disadvantages

Burning time, easy to use

Poor design of gate clamp

show more

Guca Arina Low (from 42 thousand rubles)

Guca Arina Low.

Photo: yandex.market.ru The option is not cheap, but it is of high quality. Here you will find powerful heating and good quality glass that does not let air through. To prevent it from becoming dirty, use dry firewood, such as birch or aspen. In general, this model has an excellent design, it will look good in the interior and will not take up much space. The body is made of cast iron, which is considered extremely reliable. Connection to the chimney is possible from the back and top, which is very convenient.

Characteristics:

| Heated volume | 210 m³ |

| Power | 10 kW |

| Type | closed |

| Chimney | There is |

| Efficiency | 84% |

| Fuel | firewood |

| Outer shell material | cast iron |

| Door material | glass |

| Top panel material | cast iron |

| Chimney diameter | 12 cm |

| Chimney connection | back and top |

| Dimensions (WxHxD) | 48×77.50×43.5 cm |

| Weight | 115 kg |

show more

Advantages and disadvantages

Design, fast heating

Over time, there may be problems with the reliability of the door

Harvia KIP60E (from 16.1 thousand rubles)

Harvia KIP60E.

Photo: yandex.market.ru A hanging stove that can operate from an electrical network and by heating stones. It is of good quality and heat, intended for “home” baths and saunas. The cable for the heater can be released at a height of 0.5 m. The heated volume is 8 cubic meters. The power of 6 kW and the capacity for 25 kg of stones will do everything to ensure that the room warms up quickly and evenly, and you can quickly warm up and relax. The materials in the model are said to be reliable, so it should last a long time.

Characteristics:

| Heated volume | 8 m³ |

| Power | 6 kW |

| Type | hanging stove |

| Network operation | Yes |

| Type | closed |

| Remote control | remote control |

| Dimensions (WxHxD) | 41x60x28 cm |

| Weight | 16 kg |

| Additional Information | maximum weight of stones 25 kg |

Advantages and disadvantages

Quality, functionality

Electricity consumption

show more

What other ovens are worth paying attention to?

THORMA Bozen (from 30.6 thousand rubles)

THORMA Bozen.

Photo: yandex.market.ru Compact model with an elegant design. Easy to install and configure. It is easy to wash and clean. It works on wood, the main thing is to choose dry ones and not exceeding a length of 35 cm. The flame level in the stove can be adjusted. According to user reviews, it lasts for a very long time. The clean glass system helps keep the door in good condition. There are several body colors to choose from, depending on your wishes.

Characteristics:

| Heated volume | 124 m³ |

| Power | 5 kW |

| Type | closed |

| Chimney | There is |

| Efficiency | 72% |

| Fuel | firewood |

| Outer shell material | steel |

| Door material | glass |

| Chimney diameter | 12 cm |

| Chimney connection | rear |

| Maximum length of firewood | 35 cm |

| Dimensions (WxHxD) | 32.60×90.60×34.50 cm |

| Weight | 60 kg |

| Additional Information | color: black, white, beige, burgundy |

Advantages and disadvantages

Functionality, build quality

No instructions in Russian

show more

NMK Sibir BV-180 (from 17.4 thousand rubles)

NMK Sibir BV-180.

Photo: yandex.market.ru A floor-standing stove designed to warm the air. The metal and reliable structure consists of eleven interconnected round pipes that provide natural convection. Thanks to this, the air is quickly heated and distributed smoothly throughout the entire volume of the room. The stove can heat houses, workshops, greenhouses, garages and more. The declared power of the furnace is 7 kW. The stove operates on wood and stove gases, which remain after they smolder.

Characteristics:

| Type | floor oven |

| Heated volume | 180 m³ |

| Power | 7 kW |

| Type | closed |

| Chimney | There is |

| Efficiency | 85% |

| Fuel | combined |

| Secondary combustion | There is |

| Firebox volume | 42 l |

| Outer shell material | steel |

| Firebox material | steel |

| Chimney diameter | 11.5 cm |

| Chimney connection | rear |

| Dimensions (WxHxD) | 45x68x88 cm |

| Weight | 82 kg |

| Additional Information | wood, wood waste, cardboard, briquettes |

Advantages and disadvantages

Heats up quickly, long burning function

Inconvenient to clean

show more

TMF Indigirka-2 (57 thousand rubles)

TMF Indigirka-2.

Photo: yandex.market.ru This product is not cheap, but its quality is good. The stove is wall-mounted. The characteristics are powerful. So, the heated volume is 50 cubic meters. Power is 4 kW, which is not a low figure. Almost any firewood will be suitable as fuel. The connection to the chimney here is from the top, the maximum length is no more than three meters. There is a cooktop which is a great bonus. The model is made of steel and is distinguished by enviable reliability.

Characteristics:

| Heated volume | 50 m³ |

| Power | 4 kW |

| Type | closed |

| Chimney | There is |

| Efficiency | 85% |

| Fuel | firewood |

| Outer shell material | steel |

| Door material | glass |

| Top panel material | steel |

| Chimney diameter | 8 cm |

| Chimney connection | top |

| Dimensions (WxHxD) | 44×65.50×43 cm |

| Weight | 37 kg |

| Additional Information | minimum chimney height 3 m |

Advantages and disadvantages

Quality, compactness

Price

show more

Convection Varna 100H (from 8900 rubles)

Convection Varna 100H.

Photo: yandex.market.ru This is a more budget option. The heating stove can operate in rooms with a volume of up to one hundred cubic meters. We are talking about both residential buildings and production workshops. There is a flame adjustment and a long burning system, which is very convenient. The device weighs relatively little, which is also very convenient. The increased cooking surface area of the oven allows you to place quite large containers on it.

Characteristics:

| Heated volume | 100 m³ |

| Type | closed |

| Chimney | There is |

| Fuel | firewood |

| Outer shell material | steel |

| Door material | steel |

| Dimensions (WxHxD) | 53x57x52.60 cm |

| Weight | 36 kg |

Advantages and disadvantages

Price, quickly warms up the room

Not equipped with gate

show more

This is interesting

The best wall-mounted split systems for a country house

Vesuvius Mini (from 3600 rubles)

Vesuvius Mini.

Photo: yandex.market.ru Compared to its competitors, this is a fairly cheap floor-standing stove. It looks simple, but, according to users, it holds heat well and warms up very quickly. The model is distinguished by a very reliable metal that will last for several years. The device runs on wood. There is a convenient chimney here. Buyers note that such a stove will be suitable in a private home, but it will perform even better in a garage. And if you wish, you can even cook barbecue in such a stove.

Characteristics:

| Type | floor oven |

| Type | closed |

| Chimney | There is |

| Firebox wall thickness | 0.5 cm |

| Outer shell material | steel |

| Door material | steel |

| Firebox material | steel |

| Chimney diameter | 11.5 cm |

| Chimney connection | top |

| Dimensions (WxHxD) | 30x45x50 cm |

| Weight | 20 kg |

Advantages and disadvantages

Price, reliability

Wall thickness

show more

TMF Fire-battery 7 (from 13 thousand rubles)

TMF Fire-battery 7. Photo: yandex.market.ru

High-quality wall-mounted stove with outlet through the wall. It has a solid heated volume of 150 cubic meters. The power is also good - 10 kW. The firebox volume is almost 50 liters, which many will also like. The stove in the houses is working. This model is suitable for owners of country houses. When fully loaded, it can provide up to 10 hours of heating, while the air in the room warms up very quickly. The price of the device is also not the highest on the market.

Characteristics:

| Heated volume | 150 m³ |

| Power | 10 kW |

| Type | closed |

| Chimney | There is |

| Fuel | firewood |

| Firebox volume | 47 l |

| Door material | glass |

| Chimney diameter | 12 cm |

| Chimney connection | back and top |

| Dimensions (WxHxD) | 37x76x68 cm |

| Weight | 52 kg |

| Additional Information | slot convector; minimum chimney height 5 m |

Advantages and disadvantages

Easy to kindle, compact

When overheating there is a smell from the steel

show more

Breneran AOT-06/00 (from 11.1 thousand rubles)

Breneran AOT-06/00.

Photo: yandex.market.ru A stove designed for heating air in different types of rooms. It is an all-welded steel structure coated with heat-resistant paint. It is possible that during the first heating there will even be a characteristic smell, but do not rush to give up, this will not happen in the future. The device consists of two combustion chambers - the lower one, where gasification occurs, and the upper one, where gases are burned. The front pipes also have afterburner injectors. The stove type is floor-standing, so first select a place for it.

Characteristics:

| Type | floor oven |

| Heated volume | 100 m³ |

| Power | 6 kW |

| Type | closed |

| Chimney | There is |

| Fuel | firewood |

| Firebox volume | 40 l |

| Chimney diameter | 12 cm |

| Chimney connection | rear |

| Dimensions (WxHxD) | 43.50×63.20×60.80 cm |

| Weight | 55 kg |

Advantages and disadvantages

Easy to heat, high efficiency

No ash pan

show more

This is interesting

The best heaters for your home

Video description

The video will show what a stove looks like in a bathhouse with a firebox in the dressing room, metal, lined with brick:

Exiting the firebox through a stone wall

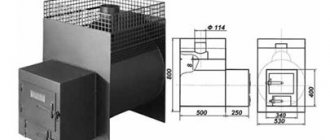

A window is cut out in a concrete or brick partition. Its location is precisely measured using the dimensions of the oven. Since the designs of stoves with remote fireboxes are varied, the height of the window can vary from 40 to 60 cm. And the width can be from 25 to 50 cm.

But to the exact dimensions of the external firebox you should always add 20 mm in each direction. This must be done because metal expands when heated. And all gaps are sealed with elastic, heat-resistant material. The most commonly used is asbestos cord.

In addition, it is necessary to install a metal fence. All free space between the fuel channel and the facing material is sewn with a steel sheet. Since most often all surfaces in the bathhouse are covered with clapboard, the distance from the wood to the firebox should be at least 25 cm. Taking into account that a fairly thick insulator is used.

Lining the stove with bricks step by step

- We make markings on the floor, taking into account a distance of 3-4 cm from the firebox.

- It is necessary to lay waterproofing around its perimeter to help the floor dry.

- After thoroughly mixing the concrete solution, spread it around the perimeter.

- We lay the bottom row of bricks on it. Next, taking into account all the features of the brickwork construction, the walls of the furnace are erected. Sealing of joints is carried out using a solution that has not yet hardened.

The stove is ready for use after all layers of masonry have completely dried.

Video description

For information on how to install an iron stove in a bathhouse with a firebox from the dressing room, watch this video:

Firebox outlet through a wooden wall

If the partition is wooden, then you can’t get away with a window. It will be necessary to create a full opening to the floor, which is then covered with bricks. And already in the masonry a window for the fuel channel is equipped.

To find the height and width of the opening, you need to mark exactly where on the wall the door to the firebox will be located. Having transferred its contours to the surface of the partition, you need to add 25 cm up and to each side. And already using these marks to cut out the opening.

When creating a window for the fuel channel, which is required by installing an iron stove in a bathhouse, you must follow the recommendations described above.

What to do when the wall thickness is significant

It happens that the stove design has a very short fuel channel. And if the wall thickness is significant, then the door does not extend beyond its surface. In this case, it is necessary to cut an opening in the wall and lay a stone niche made of decorative bricks in it.

And for reliability, a flat jumper is installed above the masonry. A metal sheet with a thickness of 8 to 10 mm is selected for it. As in previous cases, you must remember to seal all gaps with asbestos materials.

Power of wood stoves for home

- choose the type - decide on the power

Power is a parameter that must be indicated in the technical data sheet for the stove and is measured in kilowatts. Many manufacturers claim that 1 kW heats 10 sq.m. premises. It would seem that everything is simple - you multiply the power of the stove by 10 and get the area of the room that this stove is intended to heat.

But wait, because the height of the ceilings in different houses is different, and it turns out that for the same area there can be completely different volumes of the room. Taking this into account, our company’s specialists recommend sticking not to the area, but to the volume of the room. Therefore, you need to proceed from the calculation that 1 kW will heat 20 cubic meters. Therefore, we multiply the power of the stove by 20, we get the volume of the room in cubic meters that such a stove can heat. To calculate your room volume, just multiply the height by the width by the length of the space. On our website, all models of home stoves already indicate what volume they are suitable for:

Koksharov Sergey Manager of the store on the street. Narodnaya, 87

Don't ignore the following two rules:

- The stove only heats the room where it is located. Heat, of course, can flow into adjacent rooms, but only through open doors or specially installed ventilation grilles in the walls.

- You should not choose a stove based on power. Take with a reserve of at least 30% of the original volume of the room. Do not forget that there are many factors that additionally influence the rate of heat loss from the room: the number of windows, the quality of the house’s thermal insulation, etc.

Briefly about the main thing

Exiting the furnace firebox to the dressing room is largely considered a practical solution. In this case, two rooms are heated at once. Therefore, the rest after taking paired procedures is more comfortable. It is also easier to maintain the required temperature in the steam room and restore order. Because there is much more freedom of movement in the waiting room.

The most difficult thing to implement is the classic version of a brick stove, since its construction requires some experience. But if you follow all the recommendations of experts, you can build a fully functional stove. And also take care of the fire safety of the premises.

It is much easier to use a ready-made factory-made oven. It is more reliable and even compact. Its installation in a steam room is not difficult. The only problem will be arranging a niche for the fuel channel. But following the instructions of specialists, covering the opening with bricks and insulating it will not be difficult even for a beginner in this matter.

Ratings 0

Presence or absence of a long-burning system

So that you don’t get confused, let’s immediately define this: there are long-burning stoves (we wrote about them above), and there are those with a long-burning function.

Almost every modern stove has a long-burning function. Its principle is that we cover the supply of combustion air to the maximum (we remember from school that the combustion catalyst is oxygen - the less of it, the longer and less intense the combustion). Considering that the task of the stove is to generate heat, all modern stoves are equipped with this function (only “stove stoves” lack it).