The stove in the bathhouse is the basis of everything. The entire functionality of the bathhouse depends on the quality of the stove. Many options for stoves have been developed; the choice of one type or another is most often determined by the financial capabilities of the owner and his ideas about the effectiveness of this type of stove. However, there are general requirements for the arrangement of sauna stoves, in terms of fire safety, ease of use and operational requirements. One of these issues is the proper installation of the stove and, in particular, the availability of a foundation for the stove.

Opinions differ on this issue, there are arguments for and against. Let's try to figure it out in more detail.

Choosing a location for the oven

The most correct decision would be the initial design of the bathhouse, taking into account all the rooms and the location of the stove. If it is possible to heat all other rooms from another source, it is placed in a steam room. If not, consider the option of installing a stove in a bathhouse with a firebox from the dressing room so that it heats both it and the washing compartment. To do this, an opening is provided in the partition between these compartments, which is subsequently lined around the firebox with fireproof materials.

Project of a bathhouse with a steam room and shower Source sk-ac.ru

Both options have their positive and negative sides:

- Installation in a steam room allows you to control the operation of the stove without interrupting bath procedures. But the firebox and the space in front of it take up extra space; with this placement, the oxygen in the room burns faster, which requires the installation of a ventilation system. And most importantly, you have to organize autonomous heating of the dressing room, locker room, bathroom and other rooms of the bathhouse, or conduct it from home.

- The second option is much more effective and economical, since installing a stove in a bathhouse with a firebox in the dressing room is not much more difficult, but there are more advantages. The steam room maintains a normal microclimate and frees up useful space; all rooms are heated from one stove. But the bathing procedures have to be interrupted in order to add firewood to the firebox.

However, convenience is not the only and not the most important criterion for choosing a suitable location for a heating unit. The issue of fire safety is much more pressing.

Correct corner placement scheme Source banyabest.ru

First of all, you need to decide how and where to bring the chimney through the roof. It is best if it is connected to the stove in a straight line, without unnecessary bends or turns.

When placing it in a corner or against one wall, you need to follow the rules for installing a stove in a bathhouse with a firebox from a dressing room in a wooden log house. The distance from the metal body to walls made of flammable materials must be at least 50 cm on any side. It can be reduced by insulating the walls with fireproof shields. This can be sheets of mineralite, asbestos cardboard or basalt cardboard, as well as facing with ceramic tiles or a screen made of red ceramic brick.

Insulating walls with mineralite slabs before installing a stove Source bg.aviarydecor.com

A distance of at least 120 cm should be maintained from the firebox door to the front door. And in front of the firebox, be sure to lay a metal sheet or cover the floor with tiles.

It is easier to provide for all these points at the design stage. If this has not been done, the task will become more complicated, and there will be fewer options for convenient placement of the stove.

At what stage is it being built?

It is advisable to lay matching types of foundations simultaneously; with this approach, the structures do not move during excavation work and all stages require a minimum of time. For bored supports, this requirement is mandatory; driving piles using vibration equipment negatively affects the characteristics of the main foundation of the bathhouse. The same applies to grounds of other types.

An exception can be made only for screw piles mounted even inside finished buildings. The latter option is considered optimal when reconstructing a bathhouse or the need to move a heavy cast-iron stove.

Base structure

Before installing the stove in the bathhouse, you need to decide whether to make a solid concrete base for it. This depends on several factors: on the condition of the existing floor, on the material from which it is made, on whether the stove will be covered with brick:

- If the subfloor is a monolithic concrete slab, no additional work on the foundation will be required. Unless you will need to raise the platform under the heating device to the level of the finished floor, laying it out of brick.

- If the floor is a flooring made of strong boards on powerful joists, it will be necessary to make a simple calculation to find out whether it will support the weight of the structure.

If the condition of the plank floor is in doubt, you need to open the flooring, inspect and, if necessary, strengthen the joists Source yandex.uz

- An old plank covering, especially one with visible signs of drying out or rotting, cannot be used as a base for a stove under any circumstances.

Calculating the weight of the furnace to select a base

Standard flooring made of magpie boards on joists laid in increments of up to 1 meter will withstand a load of up to 700 kg. Therefore, if you want to do without a concrete foundation, before installing the stove in the bathhouse, you need to make sure that its weight does not exceed the specified value.

As a rule, metal structures are much lighter, but not only their weight is taken into account, but also the entire accompanying load. Namely:

- the weight of a full tank of hot water (the weight of the tank itself and the water it contains are added up);

- weight of the heater with stones;

The mass of factory products is indicated in the passport. In the case of homemade structures, you will have to determine it yourself Source rabotayout.ru

- chimney weight;

- the weight of the brick cladding, if it is planned.

In the case of cladding, the dimensions of the furnace will also be required in order to calculate the required amount of brick for constructing a heat shield.

It is not difficult. Having decided in advance how to install a sauna stove: with a firebox from a dressing room or from a steam room, in a corner or in the middle of a wall, you can also decide on the shape of the screen and the number of walls in it. There can be from 2 to 4. To the external dimensions of the stove, add 5-10 cm in each direction to create an air gap between the brick and the metal body, and the perimeter of the cladding is obtained. Since masonry is usually carried out in half a brick, the quantity required for one row is calculated by dividing the perimeter by the length of the brick (25 cm).

Then calculate the number of rows of masonry to the required height, dividing it by 7 cm (6.5 cm - brick height + 0.5 cm - joint thickness).

The amount of brick is calculated based on the length and height of the cladding walls Source sl.aviarydecor.com

See also: Catalog of house projects with a fireplace or stove

The results obtained are multiplied and the amount of brick required for masonry is obtained. The weight of one brick is about 4 kg. We multiply the amount of brick by its weight, add the weight of the mortar and get the total weight of the cladding.

Advice! For a safety margin, it is advisable to increase the result by 15-20%.

All that remains is to add the weight of the stove, tank, heater, chimney and heat shield together. If the total weight does not exceed 700 kg, an additional base need not be made. If it is higher, you will have to build a foundation for the stove in the bathhouse: how to properly make such a foundation yourself will be described below.

Preparing the wooden base

No matter how durable a wooden floor may seem, it is recommended to open it and inspect it for rot on the joists and boards from the inside. And replace all elements with defects, having previously treated them with antiseptic impregnation.

Before installing the stove, the floor area allocated for its installation is finished with heat-resistant materials. It is lined with porcelain stoneware or artificial stone, or covered with sheet fire-resistant material and a sheet of iron screwed on top.

Preparatory work

Before starting work, you need to determine the characteristics of the soil: strength, freezing depth, heaving, etc. The depth of construction of the structure will depend on this.

In sandy or dry soil, it should sink approximately 80 cm. In heaving soil, concrete must be placed at a depth greater than the freezing depth, which can reach 120 - 150 cm. If you plan to build a brick heater, then this rule should never be neglected.

Next you need to dig a pit. Its dimensions on each side should be larger than the foundation itself. This is necessary so that after pouring the concrete and dismantling the formwork, the voids between the concrete and the walls of the pit are filled with sand or gravel.

In the future, this filling will soften the impact of moving layers of soil on the walls of the structure.

Video description

One of the options for how to install a stove in a bathhouse on a wooden floor, how to finish the floor and walls, is shown in the video:

Such protection should be larger than the dimensions of the heating unit by 5-10 cm at the back and sides and protrude beyond the firebox by 40-50 cm to prevent accidental fire from coals falling out of it.

Making a concrete foundation

If calculations have shown that you need a foundation for an iron stove in a bathhouse, how to do this work yourself? This depends on whether there is already a floor at the installation site or its arrangement has not yet begun. In the first case, the flooring will have to be disassembled and re-installed after pouring the foundation. It may be necessary to rearrange the joists or lay additional ones around the perimeter of the concrete base.

It is necessary to lay logs under the ends of the flooring boards around the stove. Source pechkur.ru

- The dimensions of the foundation in plan should be 10-15 cm larger than the dimensions of the stove. And if it is covered with a brick screen, then it will protrude beyond the masonry by the same distance.

- After marking, soil is selected inside it to a depth of about half a meter, making the walls vertical. At the same time, make sure that the pit does not adjoin closely to the foundation of the bathhouse: there should be a minimum distance of 5 cm between them.

- Therefore, if the stove is located near a wall or in a corner, fifty-fifty boards are laid between the main and stove foundations to ensure the necessary clearance and independent settlement. If not left in place, uneven settlement may cause the base under the stove to crack or become deformed.

- Crushed stone or a sand-gravel mixture is poured into the bottom of the mini-pit, making a cushion 20-25 cm high.

Pit for pouring the foundation Source homerenovates.com

See also: Catalog of companies that specialize in the installation of stoves and fireplaces

- Next, the formwork is lowered into the pit, the walls of which should be of such a height as to slightly not reach the level of the finished floor. And concrete is poured into the formwork, which is prepared from 1 part cement and 3 parts sand and filler (crushed stone).

- If the base is made for a heavy structure, it needs to be reinforced, since installing the stove correctly in the bathhouse is not enough - it needs to be prevented from “moving” over time due to a weak foundation.

- The base is left to dry for at least 2-3 weeks, periodically spraying the surface with water.

- The final stage is waterproofing the surface with roofing felt and laying bricks on it. Using brickwork, the base is raised to the required height and leveled in a horizontal plane.

Ready base Source oteplicax.ru

Slab foundation on a columnar support for a sauna stove

It is used on heavily heaving and clayey soils or in cases of significant soil freezing depth.

You can also build on dry soils to save building materials. Follow the following operating procedure:

- Remove the soil inside the marking by 150 mm.

- In the corners, drill cylindrical holes with a diameter of 20 cm (4 pcs.), the depth of which is 30-50 cm below the freezing level. The wells should not extend beyond the markings.

- Pour crushed stone into the wells in a layer of 10 cm and compact it.

- Install roofing material rolled into a cylinder into the holes, which will serve as formwork and waterproofing of the pillars.

- Make a frame for the wells and pit from a rod, install them in their regular places. For the frame, reinforcement or wire with a diameter of 8 mm is suitable.

- Prepare a concrete solution (see proportions above) and fill the pit. First, fill the wells with concrete and compact it with a vibrator, then the foundation pit. Fill everything without interruptions so that the pillars and slab form a monolith.

- After the concrete has hardened, about a month later, waterproof the foundation in any way. To achieve durable concrete, moisten it daily.

Preparing for installation

There is no need to rush to install the new unit in place. Before placing the stove in the bathhouse, you need to heat it well in the open air by loading the heater. This is done for two reasons.

Firstly, the paint that covers the metal body finally sets only at high temperatures. At the same time, it partially burns out and releases an unpleasant odor.

Secondly, bath stones often contain sulfides, which decompose at high temperatures into sulfur oxides. In turn, when combined with water they turn into acids. Sulfuric acid fumes don't just smell bad - they are very dangerous to health. But sulfides burn out quite easily, so it is advisable to heat the stove outside until the smell of sulfur completely disappears.

This is what a stone with sulfide inclusions looks like Source parilochka.com

Helpful information. Stones on which inclusions of sulfides occupy no more than 5% of the total surface area are considered safe. They burn out completely in 1-2 firings.

If the task is how to install a stove in a bathhouse with a firebox from a dressing room with your own hands, then if there is a partition between it and the steam compartment, part of it will have to be cut out. If there is no partition, it is better to immediately build it from a non-combustible material, for example, red brick. Or lay out the masonry to the desired height and continue with timber.

The dimensions of the opening in the combustible partition under the firebox are also not taken “from the ceiling”, but are determined depending on the power of the heating unit. With factory-made stoves, everything is simple: these parameters are indicated in the product passport. You can’t reduce them, but you can’t increase them as much as you like.

It is difficult to determine the power of a homemade stove. In such cases, the opening is made in such a way that there remains 25-35 cm from the firebox to the wooden wall, provided that it is protected along the contour with heat-insulating material: a strip of asbestos cardboard, basalt wool, etc. If such protection is not provided, this distance is increased to 40-50 cm.

An opening cut into the partition for an external firebox Source vsaunu777.ru

Final finishing

After installing the stove, you can begin its final finishing. This stage in construction is not entirely necessary, but it will significantly improve the appearance of the entire structure. Various materials are used to finish the furnace. The most popular method is: plastering, tiling, brick, stone.

Plastering the stove reduces the risk of fire in the bathhouse.

To summarize, it is worth noting that building a brick sauna stove with your own hands is the most crucial moment in the construction of a sauna. If you approach this process with full responsibility and care, then your time in the steam room will be as comfortable, enjoyable and healthy as possible.

Video description

The video presented here shows a competent and accurate solution to this problem:

Advice. In order not to doubt the performance characteristics and safety of the heat insulator, buy material designed for temperatures up to 800-1000 degrees.

Also, when installing the stove, you should think about the convenience of opening the firebox door. It is advisable that it opens in the other direction from the place where the firewood is stored, otherwise it will interfere with kindling, and the next time it is stacked it can cause a burn from accidentally touching the hot metal. Therefore, if possible, the door should be moved to the convenient side.

Selection and installation of a chimney

It is impossible to solve the problem of how to properly install a stove in a bathhouse without knowing the requirements for installing a chimney. But first you need to decide on its type. Chimneys are made of brick, steel, ceramic and in the form of a double pipe made of galvanized or stainless steel with a thermal insulation gasket - the so-called sandwiches.

The first option in the case of a metal stove can be immediately dismissed as too heavy and requiring the construction of a powerful foundation on which the brick structure will rest. This is very difficult and expensive, as it will require considerable expenses for materials and the services of specialists, who are also difficult to find in our time.

Brick chimney Source interistroy.ru

The remaining types are quite acceptable, and each of them has its own advantages:

- Thick-walled steel pipe is the most budget option. But when flue gases pass through it, it becomes very hot, which increases the risk of fire. However, this problem can be solved by organizing the correct penetration through the floors and roof.

- Ceramic chimneys can be considered the ideal solution: they are the most durable, as they do not corrode and withstand high temperatures without collapsing or deforming. But they are rarely used due to their very high cost and heavy weight.

Elements of a ceramic chimney Source gromasstroy.by

- Sandwich pipes are the best option in terms of price and performance characteristics. They are much lighter and cheaper than ceramic ones, and their outer surface does not heat up as much as single steel pipes do.

Most factory stoves are produced for such chimneys or even complete with them. However, the durability and performance characteristics of sandwich pipes largely depend on the quality of their assembly and the type of filler. If condensation forms in the internal space, the wet thermal insulation will cease to perform its functions. The same thing happens with mineral wool, which is not designed for heating above 800 degrees - it burns out, crumbles down, leaving the internal cavity of the chimney half empty, and therefore unable to prevent heating of the outer wall.

In addition, the sandwich pipe cannot be placed directly on the outlet pipe of the furnace. A single-wall pipe must first depart from it, which is connected to a double-wall pipe with a special adapter.

The sandwich pipe device allows you to assemble a chimney from several elements without welding Source vopros-remonta-info.ru

To insulate the stove foundation or not

There may be several situations here, and in one case insulation is desirable, in another it is quite possible to do without it.

If the foundation of the building is insulated, but the floors are not. A common situation in baths. The heat that leaves the oven will heat the floor. More firewood will be required, but the comfort of staying in the bathhouse will increase. Here it is at your discretion. You can do insulation, or you can not.

Mineral wool insulation is most often used

The foundation is without insulation, but the floors are made with insulation. In this case, insulation of the furnace foundation is necessary: you will warm the ground and thaw the foundation of the house. This is not only unnecessary, but also harmful: every thawing of the foundation brings closer the time when it begins to collapse. Not to mention that it will take a lot of time and wood to burn the firebox, and the floors will still remain cold. Insulating the foundation in this situation will also protect the stove from freezing. It may not protect you completely, but it will freeze less and warm up faster.

So with this option, you include a layer of insulation in the foundation pie. Then divide the concrete layer into two parts and place a heat-insulating layer in the middle. This can be basalt cardboard, hard mineral wool mats, high-density extruded polystyrene foam (not polystyrene foam, it cannot withstand loads). The layer of concrete laid on top must be reinforced. Lay a 10-12 mm ribbed rod lengthwise and crosswise in increments of 20 cm. At the joints, tighten with plastic clamps, or tie with a wire, just as you tie reinforcement for a foundation.

Both the floor and the foundation of the bathhouse are insulated. You can do without insulation. But to reduce wood consumption, you can save heat. If there is no insulation at all, it is probably better to put in a heat insulator. Although, the stove still warms the floor. In general, in this case, it’s up to you to decide.

Electric oven installation

It is much easier to solve the problem of how to properly install a stove in a bathhouse powered from the mains. The placement of such a unit is simplified due to its more modest dimensions and the absence of connection to the chimney, which is not necessary.

But in this case, other requirements arise, primarily related to electrical safety.

The main advantage of an electric furnace is independent installation Source usproekt.ru

When installing an electric furnace, it must be grounded. If this is difficult to implement, then grounding is used by connecting the ground wire of the unit to the neutral terminals on the distribution panel. Also, to avoid short circuits during power surges, a residual current device (RCD) is installed.

Certain requirements are also imposed on the wiring: its cross-section must correspond to the power consumption and voltage in the network. And the shell material must be heat-resistant.

Requirements

According to building and fire safety standards, stove bases:

They are laid with a distance from other structures of 5 cm and above.

Connection with the main foundation (namely, anchoring with rods) is permissible and in some cases necessary only for shallow strip foundations.Massive strips or slabs (including those supported on piles) are erected separately, without a rigid connection with other structures.

- They have dimensions and depth that are justified by calculation.

- Combine stability, strength and resistance to temperature changes. A properly laid foundation can withstand direct contact with the hot stove body and all loads without displacement relative to other bathhouse structures.

The required reliability is achieved through the use of durable and non-flammable materials: metal, concrete, rubble, crushed stone bedding.

Important! Savings on the foundation for massive furnace structures are not allowed.

Setting up a chimney

You need to understand how to build a chimney so that carbon monoxide does not enter the steam room.

The furnace pipeline gets very hot and can cause a fire, so the place is prepared especially carefully:

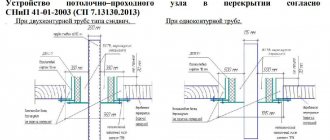

- make markings in the ceiling and cut a window measuring at least 50x50 cm;

- install a passage unit with mineralite into it with a hole equal to the diameter of the pipe + 3-5 mm;

- secure the polyurethane foam with special fasteners and attach it to the ceiling;

- insert a pipe into the protective box and cover it with kaolin wool to a depth of 5-7 cm, no more, so as not to create the opposite effect of overheating;

- After completing the work, use a stainless steel protective screen to increase fire safety, as well as for decorative purposes.

Advice: no matter how well the installation is done, you need to know how to properly ventilate the bathhouse, otherwise the balance of air exchange will be disrupted.

Below is a link to a video where you can learn more about this system:

Mounting tank assembly

This mandatory element can be attached as follows:

- fixed on the side wall of the stove;

- placed on top of a single-wall chimney;

- at the end, the heat exchanger is connected to the tank for uniform circulation of liquid.

You can study the issue in more detail and visually examine the process in the video:

Classification of foundation structures

The classification of furnace foundations is based on various characteristics: base material, design and laying depth. The table below shows the division of bases into separate varieties according to various criteria.

| Division of foundation into types according to characteristics | ||

| material | bookmark depth | designs |

| brick, rubble, reinforced concrete | non-recessed and recessed | strip, columnar, slab, pile |

- if the mass of the furnace exceeds two tons;

- when it is necessary to carry out construction work on soil made of porous clay or loess.

Monolithic reinforced concrete slab

In the second case, if you erect a strip or slab type support that is not connected to the main structure, you will need to bury it below the soil freezing mark. In this case, the average depth is about 1 m. This necessity is caused by the fact that loess becomes liquid under the influence of water, and wet porous clay expands greatly when freezing.

Shallow foundations are used for the construction of structures weighing up to 2 tons. They are often tied with anchors to the entire structure underneath the structure. On stable, hard, non-heaving soils, such foundations are best used. In this case, the maximum laying depth is up to 0.7 m.

Tape base is a popular, common support structure option. I make it unburdened or buried depending on the geological conditions of the site.

The foundation slab is poured completely under the entire furnace. If the soil is mobile, then the best option is to create a reinforced concrete monolithic support structure. Such a base will move with the soil. On stable soils, a prefabricated (from individual slabs) type of slab base is suitable.

The columnar base has become widespread on loamy, clayey soils and some other types. A strip or slab grillage must be made on top of the supports.

Using a pile foundation to build a bathhouse has a number of advantages:

- minimum degree of shrinkage;

- good load-bearing performance;

- resistance to compressive influences;

- virtual absence of earthworks;

- high installation speed.

Piles can last more than 50 years. During installation, it is necessary to monitor the vertical level to avoid distortions of the supports.

Among the materials, concrete is popular, which is poured into a frame made of reinforcement. This option is characterized by high strength and excellent load-bearing capabilities. It is designed for heavy structures.

Bricks are laid only under relatively light, small-sized stoves. The construction of a foundation from this material occurs faster and is characterized by lower labor costs than when pouring concrete.