What metal is best to make a sauna stove from?

Homemade sauna stoves cost on average 3-5 times cheaper than factory products. The savings will be even greater if you do the welding yourself. When making it yourself, you will need to decide on the following:

- What metal to make a sauna stove from?

What metal thickness will be optimal?

- What type of electrodes should be used to ensure maximum weld strength.

The speed of heating of the steam room, the duration and intensity of operation of a self-made stove depend on the answer to all these questions.

Types of stoves by shape

Do-it-yourself metal sauna stoves can be in the following shape:

- curly;

- rectangular;

- horizontal;

- cylindrical.

Rectangular installations are considered the most popular because their corner zones do not heat up to very high temperatures. The shape of the device is directly related to the uniform heating of both the installation itself and the room. Cylindrical and round shaped units have the lowest degree of heat transfer, so fairly thick iron is used for their production. Rectangular structures are distinguished by enviable stability, but have cold corners.

Which brand of steel is best for a sauna stove?

The heating temperature of the flue gases inside the furnace reaches 450-550°C. When heated at such intensity, deformation of the metal is observed.

Direct exposure to fire causes the steel to burn through. Of course, you can simply use metal with a thickness of 10 mm or more, but then you will have to heat the steam room for a long time and spend a large amount of fuel to warm it up. Due to the use of thick-walled steel sheets, a durable furnace will become economically unprofitable.

The task facing the master is to make the structure strong enough to prevent deformation, burnout and at the same time have good thermal conductivity. In the factory, for the manufacture of sauna stoves, metal with a high degree of heat resistance is used.

Alloy steel differs from structural steel in the following characteristics:

Resistance to moisture – alloy steel used in the manufacture of sauna stoves, stainless steel. There is no tendency to corrosion even with intense heating. Domestic brand of heat-resistant high-alloy stainless steel 08Х17Т. Some sources indicate almost complete identity of the characteristics of heat-resistant steels of this type. Structural iron is not corrosion resistant, which must be taken into account when calculating the thickness of the furnace walls.

Operating time – the service life of furnaces made of structural steel is 3-4 years. AISI 430 becomes unusable in 5-8 years.

Possibility of repair work - grades of heat-resistant steel for the manufacture of wood-burning sauna stoves, AISI 430 and 08Х17Т, have a low carbon content, which makes welding work possible. Structural iron contains sulfur and phosphorus compounds, which make it brittle and brittle.

Heat resistance – grades of heat-resistant steel for bath ovens, AISI 430 and 08Х17Т, can withstand heating up to 850°C without changing the structure of the metal and its crystal lattice. When the temperature rises to 600 °C, the tensile strength remains around 145 MPa. Scale formation occurs only when heated to 8500°C. The metal in a sauna stove with intensive combustion heats up to a temperature of 450-550°C. The structural material has lower heat resistance parameters.

Chrome-containing heat-resistant steel is expensive, and not all components experience the same thermal and corrosion load. For this reason, the design of a sauna stove is made of several metals:

- Firebox - AISI 430 or an analogue 08Х17Т is used for the combustion chamber. For independent production, steel 10 GOST 1050-88 is used.

How to make a sauna stove

As already mentioned, the main task of this type of heating device is to quickly “catch up” to the required temperature and be able to maintain it. There is a simple solution - install a fan that will blow on the walls of the furnace, accelerating heating.

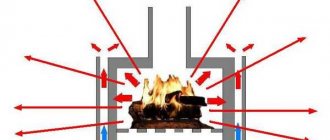

The convector casing performs approximately the same function. This is the casing around the oven body. There remains a gap of 1.5-2 cm between it and the wall of the firebox. Air is sucked into this gap from below. It passes along the walls, heats up, and at the same time cools the walls. Then it rises upward, spreading heat throughout the steam room.

Working principle of the convection casing

If the furnace body is made of thick metal, then the casing can be made of thin metal. It rarely heats up to high temperatures, and burnout does not threaten it. If in a sauna stove the heater is located at the top, above the firebox, as in the photo, then holes can be made in the body to ventilate the heater. Then part of the air that rises along the walls will enter the heater, blow on the stones and heat up even more. This type of heater is called ventilated. It is good for dry air saunas.

Drawings and diagrams

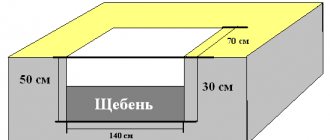

The design of sauna stoves is simpler. You need a normal size firebox that can accommodate large logs. In the upper part, above the top of the firebox, the sides of the heater are welded, the volume of which is usually 20-25 liters. There may be variations in width/height/depth, but there are no special tricks.

Diagrams of metal sauna stoves

Installing a tank to heat water in a sauna steam room is not the best idea. You won't be able to control the humidity, and at high temperatures it's easy to get burned. However, there are several options for installing tanks in the photo above.

Another type of heater is inside the firebox. If desired, you can put a lid on it and this oven can be used in two modes - with the lid open for dry vaping, and with the lid open to produce more steam.

Heater inside the body

Optimal metal thickness for a bathhouse stove

When determining the thickness of the metal, two main characteristics are taken into account that affect the operating parameters of the sauna stove:

- Burnout of steel - if you use a thin-walled sheet of ordinary metal for the firebox, after literally six months of fire the firebox will have to be repaired. Regular steel 4 mm thick will provide quick heating of the steam room, but will not last long. For this reason, manufacturers make the combustion chamber from AISI 430, a heat-resistant chromium stainless steel with a thickness of 4-6 mm.

The minimum thickness of steel in the combustion chamber is 4 mm, permissible only if AISI 430 and 08Х17Т are used. In other cases, a metal thickness of at least 6 mm is needed. Most craftsmen recommend using 8 mm thick structural steel when making a stove yourself.

What electrodes should be used to cook a sauna stove?

To weld the furnace, you will need electrodes selected depending on the steel used in production. Stainless steel is welded using argon arc welding. Suitable electrodes are TsL 11 and D4.

After welding work, it is necessary to remove scale and etching. This way you can avoid corrosion at the weld.

Electrodes for welding sauna stoves made of structural steel NIAT-5, EA-112/15, EA-981/15 and EA-981/15. The thickness is selected depending on the density of the metal and its heating temperature.

Making a sauna stove with your own hands is not difficult if you have special skills and the right choice of components and consumables.

Source of the article: https://avtonomnoeteplo.ru/pechi-kaminy/417-iz-kakogo-metalla-varit-bannuyu-pech.html

Electric sauna stoves

If you are ready to sacrifice the traditional components of bath procedures: the smell of burning wood, natural warmth, but at the same time make a choice in the direction of functionality and comfort, then your choice is an electric sauna stove. From this point of view, an electric stove for a bath is an ideal option: it does not require periodic addition of firewood, does not smoke, and due to its lightness and small size, it can fit into the interior of a steam room of even the smallest area.

Let's move straight to the advantages of electric ovens:

- Compactness. Yes, electric sauna stoves are the smallest of all listed. This is due to the lack of a firebox.

- Durability and reliability.

- The steam room heats up quickly and evenly.

- No chimney installation required.

- compactness;

- reliability and durability;

- quick heating of the steam room in a short time;

- uniform heating;

- affordable price;

- no need to build and clean a chimney, install gas pipes, etc.

- high level of fire safety.

Of course, electric sauna stoves also have disadvantages:

The main disadvantage, which outweighs all the advantages, is the type of fuel itself. If there are power outages in your area, then you will not be able to take a steam bath in your bathhouse. Of course, you can buy a generator, but this is not very convenient.

The second disadvantage is that the heating elements, which ensure heating of the stones in the furnace, are not the most reliable part of it. The heating element may overheat or water may get on it, which will cause it, and therefore the entire stove, to fail.

Advantages and disadvantages

A stainless steel stove is relevant in a miniature steam room . The cost of such a product is quite high.

However, excellent quality and long service life undoubtedly compensate for the high price. The main thing is not to make a mistake in choosing the manufacturer and model.

The advantages of a stainless steel stove include the following characteristics.

- Long service life. The physical properties of stainless steel help it maintain its original appearance for many years. As a rule, a conventional stove can last no more than 5 years, while stainless steel products have a service life of more than 15 years.

- Easy to install. The device is sold assembled and ready for installation. The stainless steel oven is equipped with detailed instructions. All that remains is to allocate a place for its installation.

- Increased heating rate. It is no secret that such steel has excellent thermal conductivity. The oven instantly heats up and “gives off” heat.

- Miniature dimensions. The product is light in weight and will easily fit in a small steamy room. The stove is easily transportable and does not require an additional foundation.

- Safety. When using a stainless steel stove, a minimal amount of oxygen is burned (it’s easier to breathe in a steam room).

However, the product still has shortcomings For example, there is a high probability of fire in wooden structures located near the stove. Thus, such devices are installed at a considerable distance from the casing of the steam room. The product also cools down instantly. Thus, a constant supply of fuel for the furnace is necessary. Another important point is that the welds of stainless steel structures are its weak point. When there is a temperature difference, there is a high probability of depressurization of the seams. Thus, experts advise using gradual heating.

Functional features of cast iron stoves

- The difficulty of repairing a cast iron stove. Parts for restoring the product can only be ordered from the manufacturer, since the main method of manufacturing cast iron elements is casting.

- Cast iron is a heavier material than steel. Stoves are heavy (200 kg or more). Not only is such a stove difficult to transport to its destination, but its installation will also require appropriate efforts and conditions.

- To install the equipment, it is possible to manufacture a special base for the furnace.

- The parts of a cast iron stove are connected using tongue and groove type locks. For some products, modern special sealants are used that can withstand high temperatures well.

However, cast iron stoves have been very popular for many years. Not only simple products were cast from cast iron, but also antique, real objects of art. Of course, casting was complicated: a drawing and model were created, according to which the necessary parts were made.

Types of materials

To create a stove for a “Russian bath”, a special alloy (corrosion-resistant) is used. It contains alloying components. The main element is chromium.

Steel also contains nickel, titanium, cobalt, manganese and molybdenum. When purchasing materials for making a stainless steel stove, the buyer should pay attention to the chromium content (at least 13%).

As for other alloying materials, their functionality consists of the following characteristics.

- Nickel gives the product elasticity and increases resistance to stress.

- Cobalt is “responsible” for high heat resistance.

- Silicon, which is part of the steel used to make the furnace, increases the scale content of the alloy. This property is especially important for sauna stoves.

- Manganese is responsible for the elasticity of steel, which helps it avoid damage due to temperature changes.

- Titanium increases strength and corrosion resistance.

Maintainability

As for maintainability, it is better to repair a stove made of steel. Repairs are made using conventional welding. However, a seam made by an unprofessional welder will most likely not bring the desired benefit, but rather the opposite. Loss of the firebox geometry will lead to the need to completely replace the sauna stove. Repairing a cast iron stove by welding will not work at all.

Cast iron is generally difficult to repair. However, if the cast iron stove initially has a prefabricated structure, then the part in need of repair can simply be replaced with a new one, if this is provided by the manufacturer.

Another advantage of cast iron is its resistance to corrosion. He is practically not exposed to it. An oxide film simply forms on the surface of cast iron, protecting it from the spread of corrosion. Destruction does not go deep into the metal. This wonderful effect is also known as passivation. Steel can also resist corrosion, but thanks to alloying. The final price of the furnace directly depends on the number of alloying elements in the composition.

Popular models

Connoisseurs of Russian baths prefer to purchase the following models.

- "Tunguska". An economical option with excellent characteristics. The design is lightweight and known for its affordable cost.

- "Angara" . The stove is in many ways similar to the Tunguska. Both options are in the same price range. "Angara" heats up quickly and is lightweight.

- "Ermak". An original stove, which has the ability to install additional accessories. The cost of this product is higher than “Tunguska” and “Ankara”.

- "Rus" . This device is made of durable stainless steel and is famous for its original design.

- "Feginger Classics". The stove is equipped with various operating modes. Firewood is burned using “top burning”.

- "Kuban". High quality device made of stainless steel. The oven is designed for 20 cubic meters and can accommodate up to 50 kg of stones. The liquid gets inside using a dispenser.

- "Kutkin" . A universal option with a closed heater and optimal infrared radiation. The stove is designed for Turkish and Russian baths.

- "Teklar Hangar" . A modern oven made of heat-resistant stainless steel. Relevant for Russian baths. Allows you to obtain a comfortable microclimate in the steam room.

- "Easy Steam Gelendzhik". Expensive, high-quality option with a stylish design. The main advantages are long service life and high power. The stove can be decorated with red brick.

Basic requirements for metal furnaces

Modern designs of metal sauna stoves are subject to high technical and operational requirements, which include the following:

- Wide functionality. Possibility to select different temperature modes to quickly heat the air and maintain an optimal microclimate in the premises.

- High efficiency. Efficient use of fuel material with the possibility of long-term heat accumulation. At the same time, increasing the volume of the firebox ensures complete combustion of fuel and increases efficiency.

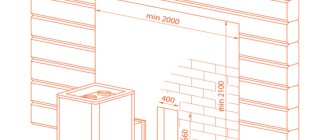

- Ergonomics. Iron heaters should remain compact to occupy a small area of the room. In small steam rooms, it is more rational to install a vertical type of structure with a firebox located in the technical room.

- Fire safety. Heating equipment must be safe for visitors and the premises. To avoid burns and injuries, the body of the device is covered with a metal convection casing, and the surfaces near the oven are lined with heat-resistant material.

- Equipment. More advanced models of devices can be equipped with water heaters that provide hot water supply in the bathhouse.

- Aesthetics. Metal heaters can have various designs with forged and glass decorative elements.

Simple heater for a summer house

Such a heating metal stove is well suited for quickly providing heat to a small bathhouse or even a sauna.

The main advantages are that it is mobile and easy to manufacture.

Preparing for vaping takes 1.5 hours, the walls heat up quickly. One caveat - you need to attach 2 chimneys to the stove. The first will participate in heating the room itself, the second will remove carbon monoxide.

What does the oven consist of:

- Steel - iron sheets of at least 3 mm.

- It is better to make the firebox from thicker steel -6 mm.

- The kit also includes latches and a metal grill.

This structure can be assembled using a welding machine. Such sets are purchased in a disassembled state, the instructions are already included. Designing a metal stove will not be difficult, as it will fully comply with fire safety rules.

Differences in heat resistance and heat resistance of metal

The ability of alloys to remain resistant to gas corrosion for a long time when exposed to high temperatures is a characteristic of heat resistance.

This is nichrome, silchrome, steel marked 36Х18Н25С2 or 15Х6СУ.

Heat-resistant materials are able to withstand increased temperature overloads during heating and friction without significant deformation of structures and materials.

The level of these materials is assessed according to 2 criteria:

Which steel is better to choose?

For different options for using and installing the furnace during production, you will need to use different types of steel, including heat-resistant steel. We will analyze the main places for possible installation of the furnace and the optimal choice of steel for its production.

For sauna stove

For home

The structure is exposed to long-term thermal loads, so it is important that the parts are made of good material. You can use steel for a sauna stove for a home potbelly stove, but it is better to prepare blanks from alloys with a chromium content of 12% or more.

The famous stoves of Professor Butakov from and are made from such a sheet. They will last much longer than homemade ones made from scrap materials. We should not forget the thickness of the walls of such furnaces. Made of alloy steel with a high level of resistance to deformation during prolonged heating, the furnaces can be made of sheet steel 4-5 mm thick.

If the stove is installed in a small country house and you plan to use it only in the fall or early spring during rare visits to the site, you can make a homemade stove from a pipe or gas cylinders with a convection system. This design is cheap and can heat the house for a long time.

For garage

For a garage, using expensive heat-resistant or heat-resistant steel is an unaffordable luxury. This stove is used for a short time and not very often. Therefore, by making a stove from rims or sheet metal, 3-4 mm thick , you can easily solve the issue of heating a garage space.